Vertical cutting off machine for fine dried noodles

A technology of cutting machine and noodles, applied in the field of mechanical equipment, to achieve the effect of easy adjustment of cutting length, improved mechanization, and precise operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

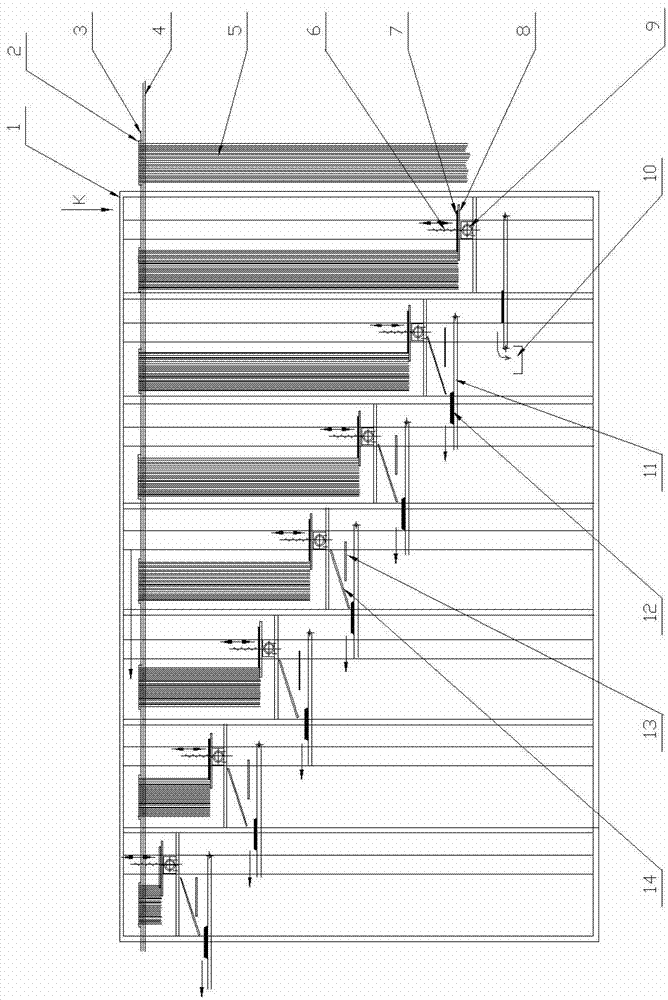

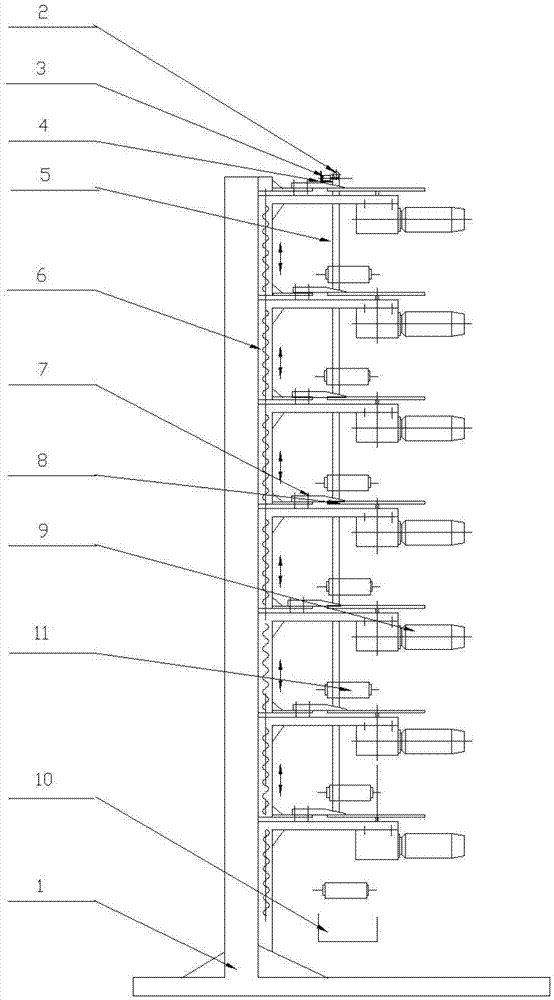

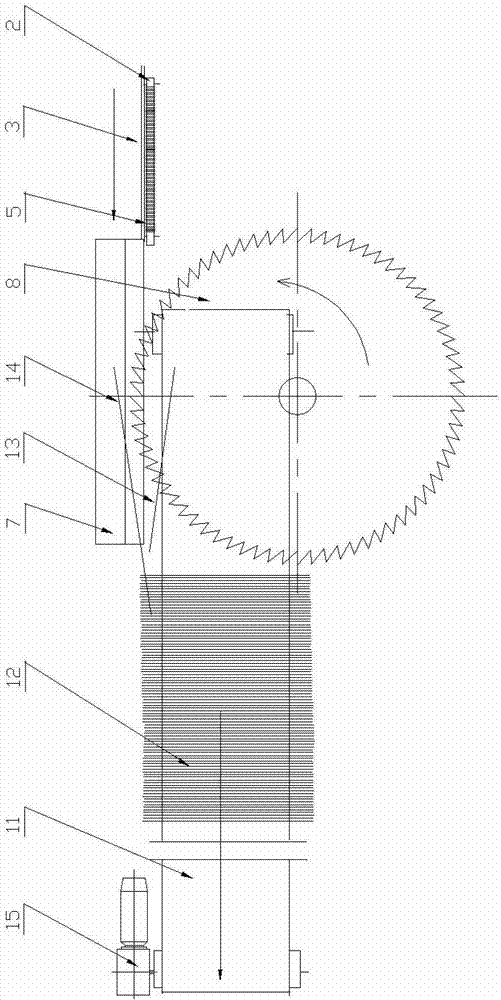

[0021] Embodiments of the vertical noodle cutting machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like Figure 1 to Figure 3 Shown, a kind of vermicelli vertical cutting machine embodiment that the present invention provides, when for the production requirement that a bar vermicelli is cut into six sections, the vermicelli vertical cutting machine of the present invention is to be installed with seven on the frame-shaped frame 1. The group includes a noodle cutting device composed of a fixed knife 7, a rotary cutter 8 and a rotary cutter drive mechanism 9, and each set of fixed knife 7 cooperates with a rotary cutter 8 whose rotation speed is 30 revolutions per minute to form a pair of noodle cutters, seven groups The noodle cutting device is horizontally installed on the longitudinal frame of the frame 1, and is perpendicular to the longitudinal frame of the frame 1. Each group of noodle cutting devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com