Multi-element low-alloying treatment method for high-strength gray cast iron

A processing method and high-strength technology, applied in the field of casting, can solve the problem of inability to ensure that the material of cast iron and casting quality are stable and meet the requirements, there is no high-strength gray cast iron alloy element matching method and melting batching technology, and the accuracy, speed and low cost cannot be guaranteed. Cost cast iron alloying treatment and other issues to achieve the effect of ensuring the material and internal quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] S1 production technical conditions

[0038] S1.1 Production of castings and technical requirements

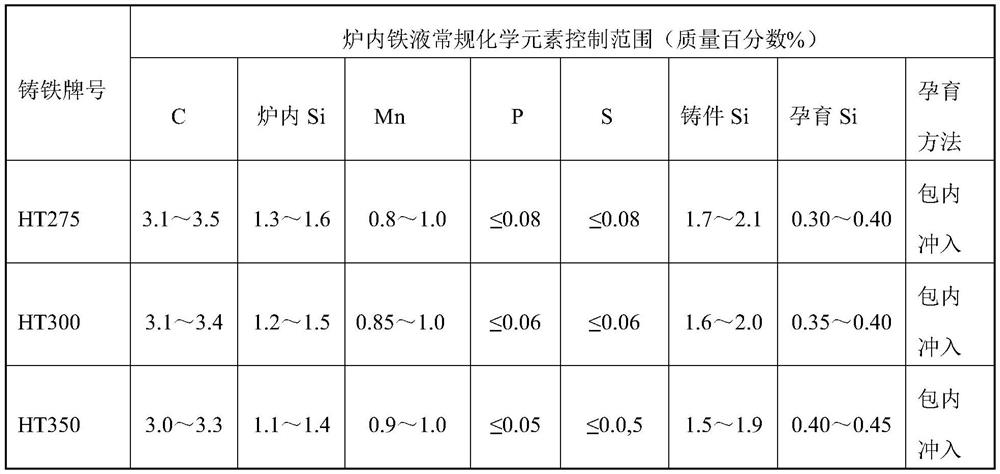

[0039] The production of castings takes the No. 3 transmission case of high-strength gray iron castings on diesel engines as an example. The casting material of the No. 3 transmission box is HT350, which belongs to the thin-walled high-strength gray iron casting of the box shell, the main wall thickness is about 10-15mm, the rough shape of the casting is about 700X500X170mm, and the casting weight is about 60Kg. The requirements for the mechanical properties of the castings are: the tensile strength of the single casting sample shall not be lower than 350Mpa, and the hardness shall be 210-240HB. Castings are not allowed to have casting defects that affect the strength and appearance quality of castings.

[0040] S1.2 Selected raw materials and smelting equipment

[0041] The smelting equipment for the production of high-strength gray iron castings for No. 3 transmissi...

Embodiment 2

[0077] S1 production technical conditions

[0078] S1.1 Production of castings and technical requirements

[0079] The production of castings takes the No. 2 transmission connecting plate of high-strength gray iron castings on diesel engines as an example. The casting material of the No. 2 transmission connecting disc is HT275, which belongs to the thick-walled high-strength gray iron casting of the wheel disc. The main wall thickness is about 50-55mm. The rough shape of the casting is about Φ180X60mm, and the casting weight is about 13Kg. The mechanical performance requirements of castings are: the tensile strength is not less than 275Mpa, and the hardness requirements are 230-250HB. Castings are not allowed to have casting defects that affect the strength and appearance quality of castings.

[0080] S1.2 Selected raw materials and smelting equipment

[0081] The smelting equipment for the production of high-strength gray iron castings for the No. 2 transmission connection...

Embodiment 3

[0109] S1 production technical conditions

[0110] S1.1 Production of castings and technical requirements

[0111] The production of castings takes the No. 5 cylinder liner of high-strength gray iron castings on diesel engines as an example. The casting material of the No. 5 cylinder liner is alloy gray cast iron, which is equivalent to HT300. It belongs to the thin-walled high-strength gray iron casting of the sleeve type. The main wall thickness is about 15-20mm. 15Kg. The mechanical performance requirements of castings are: the tensile strength of the main body is not less than 280Mpa, and the hardness of the main body is required to be 250-280HB. Castings are not allowed to have casting defects that affect the strength and appearance quality of castings.

[0112] S1.2 Selected raw materials and smelting equipment

[0113] The smelting equipment for the production of high-strength gray iron castings for No. 5 cylinder liners uses a 1.5t intermediate frequency electric fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com