A kind of glass fiber production method based on lanthanide rare earth material

A glass fiber and lanthanide rare earth technology, which is applied in the field of glass fiber production based on lanthanide rare earth materials, can solve the mechanical properties and forming properties of difficult glass fibers, cannot improve the performance of glass fibers, and the coating wetting effect is average, etc. It can improve the melting performance, promote the formation of the glass system network structure, and improve the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

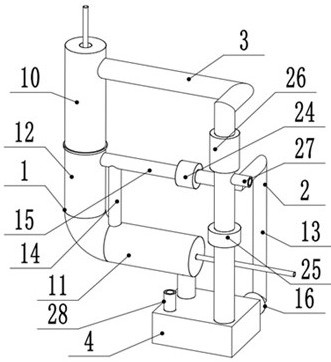

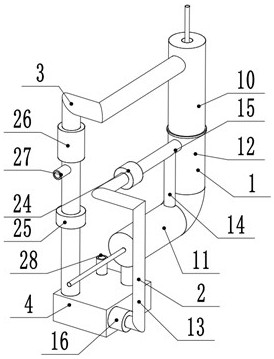

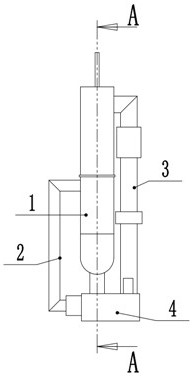

Image

Examples

Embodiment 1

[0042] S1, stirring silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide and lanthanide rare earth materials evenly;

[0043] S2, adding the mixture in step S1 into a melting furnace for heating, and drawing after heating to obtain glass fibers;

[0044] S3, pickling the glass fiber prepared in step S2;

[0045] S4. Washing the glass fibers pickled in step S3 with water, and the washing is completed when the pH value of the cleaning water is greater than 5;

[0046] S5, performing heat setting treatment on the glass fibers washed in step S4;

[0047] S6. The glass fibers obtained in step S5 are glued and dried through a sizing and drying device to obtain reinforced glass fibers with a coating.

[0048] In the described step S1, the weight component ratio of each raw material is SiO 2 56%, Al 2 o 3 17%, CaO9%, MgO8%, lanthanide rare earth materials 0.1%.

[0049] The lanthanide rare earth material in S1 is a lanthanide metal oxide.

[0050] In the step S1, the...

Embodiment 2

[0056] S1, stirring silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide and lanthanide rare earth materials evenly;

[0057] S2, adding the mixture in step S1 into a melting furnace for heating, and drawing after heating to obtain glass fibers;

[0058] S3, pickling the glass fiber prepared in step S2;

[0059] S4. Washing the glass fibers pickled in step S3 with water, and the washing is completed when the pH value of the cleaning water is greater than 5;

[0060] S5, performing heat setting treatment on the glass fibers washed in step S4;

[0061] S6. The glass fibers obtained in step S5 are glued and dried through a sizing and drying device to obtain reinforced glass fibers with a coating.

[0062] In the described step S1, the weight component ratio of each raw material is SiO 2 63%, Al 2 o 3 24%, CaO17%, MgO13%, lanthanide rare earth materials 2%.

[0063] The lanthanide rare earth material in S1 is a lanthanide metal oxide.

[0064] In the step S1, the...

Embodiment 3

[0070] S1, stirring silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide and lanthanide rare earth materials evenly;

[0071] S2, adding the mixture in step S1 into a melting furnace for heating, and drawing after heating to obtain glass fibers;

[0072] S3, pickling the glass fiber prepared in step S2;

[0073] S4. Washing the glass fibers pickled in step S3 with water, and the washing is completed when the pH value of the cleaning water is greater than 5;

[0074] S5, performing heat setting treatment on the glass fibers washed in step S4;

[0075] S6. The glass fibers obtained in step S5 are glued and dried through a sizing and drying device to obtain reinforced glass fibers with a coating.

[0076] In the described step S1, the weight component ratio of each raw material is SiO 2 60%, Al 2 o 3 19%, CaO10%, MgO10%, lanthanide rare earth materials 1%.

[0077] The lanthanide rare earth material in S1 is a lanthanide metal oxide.

[0078] In the step S1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com