A kind of high strength and high modulus glass fiber composition

A glass fiber, high modulus technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low glass melting quality, high phase line temperature, fast crystallization rate, etc., to improve mechanical properties, high mechanical properties, Improve the effect of alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

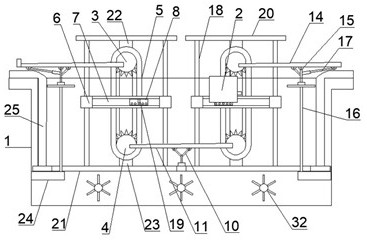

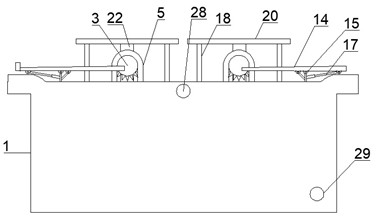

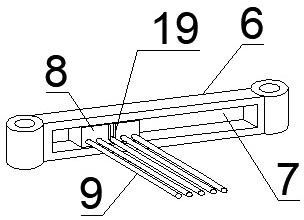

Image

Examples

Embodiment 1

[0038] A kind of high-strength high-modulus glass fiber composition that this embodiment relates to, each raw material weight component is: SiO 2 for 55 parts, Al 2 o 3 for 18 parts, Fe 2 o 3 0.1 parts for CaO, 10 parts for MgO, 10 parts for TiO 2 0.02 parts, K 2 O is 0.2 parts, Na 2 O is 0.5 part, P 2 o 5 0.3 parts, MnO 0.006 parts, BaO 0.005 parts, SrO 0.005 parts, ZrO 2 0.8 parts for BeO, 0.1 parts for CeO 2 is 0.005 parts.

[0039] The production process of the high-strength and high-modulus glass fiber composition described in this embodiment comprises the following steps:

[0040] (1) Pretreatment: Weigh each raw material by weight component, remove CeO 2 The other raw materials are mixed evenly and put into the glass fiber drawing furnace for melting treatment. The melting time is 20-25min, and the melting temperature is 1000-1200℃;

[0041] (2) Preparation of glass fiber precursor: add CeO to the glass fiber drawing furnace 2 , melting and drawing to obtai...

Embodiment 2

[0057] A kind of high-strength high-modulus glass fiber composition that this embodiment relates to, each raw material weight component is: SiO 2 for 50 parts, Al 2 o 3 for 15 parts, Fe 2 o 3 0.05 parts, 8 parts for CaO, 8 parts for MgO, 8 parts for TiO 2 is 0.01 parts, K 2 O is 0.1 parts, Na 2 O is 0.3 part, P 2 o 5 0.1 part, MnO 0.002 part, BaO 0.001 part, SrO 0.001 part, ZrO 2 0.1 parts for BeO, 0.05 parts for CeO 2 Be 0.001 part; Its preparation method is identical with embodiment 1.

[0058] The elastic modulus of the glass fiber prepared in this embodiment reaches 94Gpa, and the tensile strength reaches 2800Mpa.

Embodiment 3

[0060] A kind of high-strength high-modulus glass fiber composition that this embodiment relates to, each raw material weight component is: SiO 2 for 65 parts, Al 2 o 3 for 22 parts, Fe 2 o 3 0.3 parts, CaO 15 parts, MgO 15 parts, TiO 2 0.03 parts, K 2 O is 0.3 parts, Na 2 O is 0.9 parts, P 2 o 50.5 parts, MnO 0.01 parts, BaO 0.01 parts, SrO 0.01 parts, ZrO 2 1.5 parts for BeO, 0.3 parts for CeO 2 It is 0.01 part; Its preparation method is identical with embodiment 1.

[0061] The elastic modulus of the glass fiber prepared in this embodiment reaches 95Gpa, and the tensile strength reaches 2800Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com