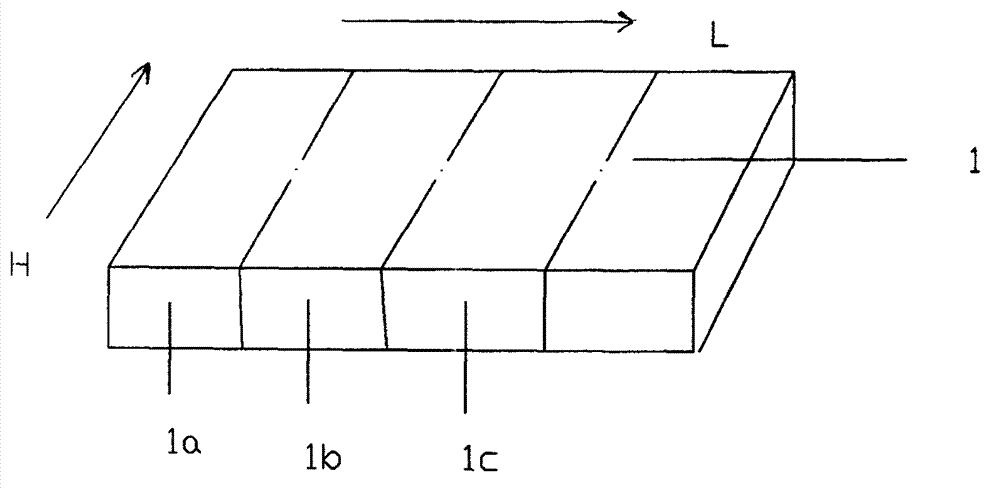

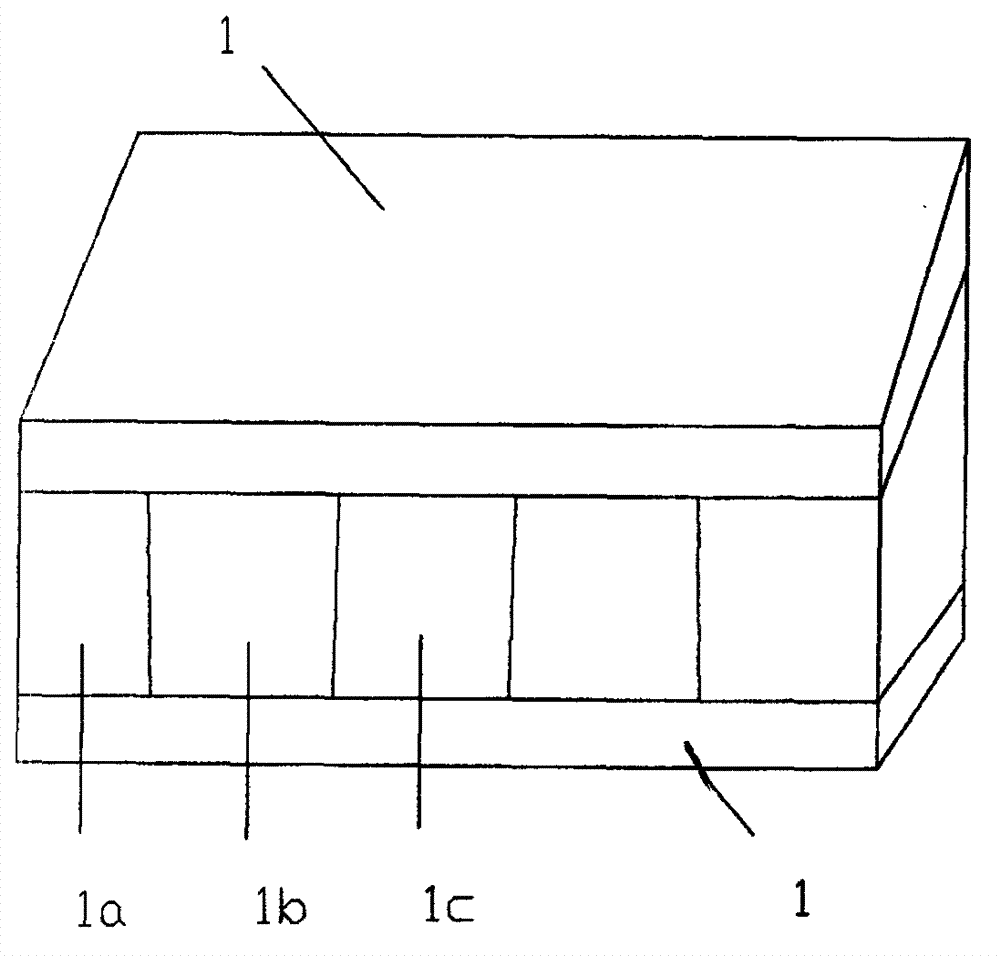

Fiber cotton cushion and preparation process thereof

A preparation process and fiber technology, which is applied in the field of fiber cotton pad and its preparation, can solve the problems of easy layer separation and falling off, difficult separation and falling off, limited thickness, etc., and achieve the goals of reducing layer falling off, wide selection of raw materials, and improving elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Before introducing the present invention, we should first understand the production technology of fiber cotton hot-melt cotton process. This process utilizes the fiber cortex of low-melting point composite short fiber to have low-temperature melting performance, and melts at a low temperature of 110-180 degrees (some products are melted at 100 or Fibers that can be melted and bonded under dry heat conditions of 120 degrees Celsius, while the melting point of ordinary polyester staple fibers is above 255 degrees), the melted peripheral part is like glue, bonded with other fibers, and has the function of an adhesive. There are many types of low-melting fiber, including LMF (4080 low-melting fiber), low-melting polyolefin thermal bonding fiber, low-melting fiber produced by polyester composite spinning, low-melting polyester, polypropylene, and polyamide thermal bonding. Melt glue, random copolymerized modified polyester with low melting point, etc. Two or more specially p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com