Preparation method of multi-stage pore-size distribution material

A technology of pore size distribution and chemical molecules, applied in the direction of single-component polyester artificial filaments, fiber chemical characteristics, fiber types, etc., can solve the problems of material limitations, complex synthesis steps of porous materials, etc., and achieve simple preparation methods and improved fluidity. Through performance, the effect of high surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a multi-level pore size distribution material, specifically:

[0029] (1) Preparation of coarse functionalized fibers and fine functionalized fibers:

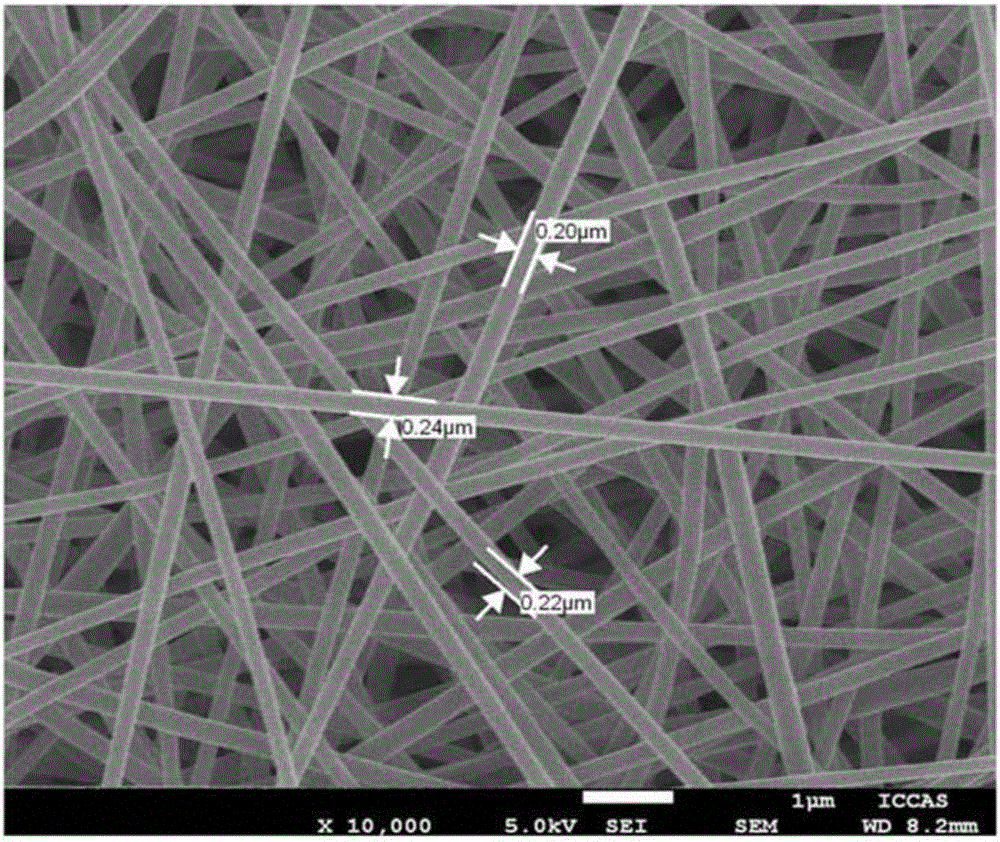

[0030] 1) Preparation of fine functionalized fibers: the fine functionalized fibers in this example are chitosan nanofibers, and the preparation process is to dissolve chitosan in a mixed solvent of hexafluoroisopropanol and acetic acid to obtain a mass concentration of 7% spinning solution, the spinning solution is prepared by electrospinning to obtain chitosan nanofibers with a diameter of 300nm; the mixed solvent of hexafluoroisopropanol and acetic acid is to mix hexafluoroisopropanol with Acetic acid is prepared by mixing according to a mass ratio of 3:2; the preparation conditions of the electrospinning method are: a voltage of 15kV, a control receiving distance of 15cm; fine functionalized fibers with a diameter of 150nm-750nm, with polymer fibers toughness;

[0031] 2) Preparation of coars...

Embodiment 2

[0035] A method for preparing a multi-level pore size distribution material, specifically:

[0036] (1) Preparation of coarse functionalized fibers and fine functionalized fibers:

[0037] 1) Preparation of coarse functionalized fibers: the coarse functionalized fibers in this example are short glass fibers, and the preparation process is to prepare short glass fibers with a diameter distribution of 100um by pool kiln drawing; the short glass fibers are inorganic fibers The material has good rigidity;

[0038]2) Preparation of fine functionalized fibers: the fine functionalized fibers in this example are polyacrylic acid fibers, and the preparation process is to prepare polyacrylic acid fibers with a diameter of 400nm-550nm by dry spinning; the polyacrylic acid fibers are high Molecular materials, when the diameter is 400nm-550nm, it has good toughness; combined with the toughness of fine functional fibers and the rigidity of inorganic fiber materials (glass short fibers), th...

Embodiment 3

[0043] A method for preparing a multi-level pore size distribution material, specifically:

[0044] (1) Preparation of coarse functionalized fibers and fine functionalized fibers:

[0045] 1) Preparation of coarse functionalized fibers: the coarse functionalized fibers in this example are silver fibers, and the preparation process is to prepare silver fibers with a diameter distribution of 20um-40um by template method;

[0046] 2) Preparation of fine functionalized fibers: the fine functionalized fibers in this example are polylactic acid fibers, and the preparation process adopts electrospinning process to prepare polylactic acid nanofibers with a diameter of 300nm-350nm;

[0047] (2) Homogenization treatment: According to the mass ratio of the silver fiber and the polylactic acid fiber being 1:150, weigh the silver fiber and the polylactic acid fiber prepared in step (1), and put them into the opening Mixing and opening treatment is carried out in the machine to obtain homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com