A kind of hydrophilic modified network cross-linked porous film and its preparation method

A technology of network cross-linking and hydrophilic modification, applied in the field of water treatment, can solve the problems of decreased flux, difficult process control, low efficiency, etc., and achieves the effects of good hydrophilicity and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

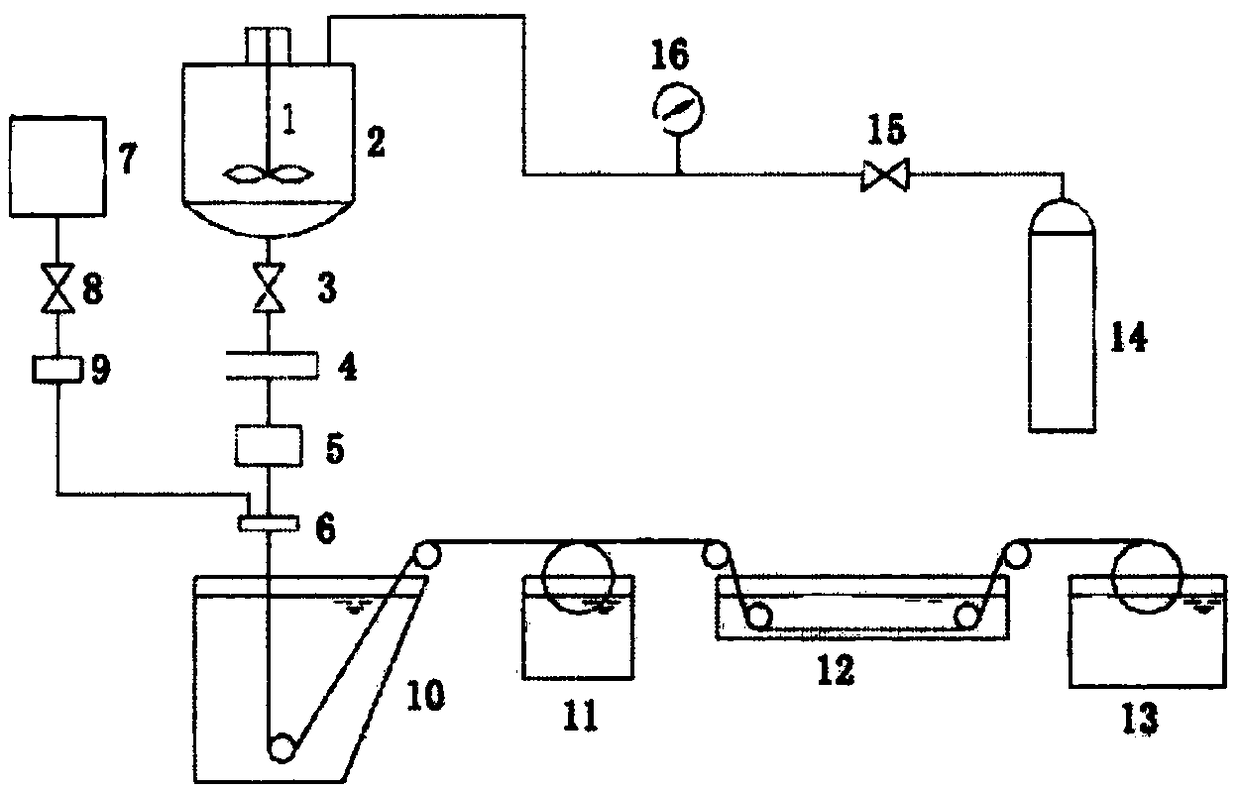

Image

Examples

Embodiment 1

[0073] Example 1: Preparation of hydrophilic modified network cross-linked porous membrane

[0074] The implementation steps of this embodiment are as follows:

[0075] A. Preparation of casting solution

[0076] Mix 5 parts by weight of polyvinylidene fluoride resin, 22 parts by weight of PVPk15 additive and 68 parts by weight of dimethylacetamide solvent to obtain the casting solution;

[0077] B. Add network crosslinking

[0078] According to 1.6% of the weight of the casting solution, add the cross-linked sulfonated polysulfone network cross-linked product to the casting solution obtained in step A, stir and mix, and carry out vacuum under the conditions of temperature 100°C and pressure 0.01MPa defoaming, followed by conventional non-solvent gel membrane forming method to obtain the porous membrane of the hydrophilic modified network cross-linked product.

Embodiment 2

[0079] Example 2: Preparation of hydrophilic modified network cross-linked porous membrane

[0080] The implementation steps of this embodiment are as follows:

[0081] A. Preparation of casting solution

[0082] 24 parts by weight of polyethylene resin, 28 parts by weight of PVPk17 additive and 50 parts by weight of dimethylformamide solvent are uniformly mixed to obtain the casting solution;

[0083] B. Add network crosslinking

[0084] According to 7.8% of the weight of the casting solution, add the cross-linked sulfonated polyethersulfone network cross-linked product to the casting solution obtained in step A, stir and mix, and carry out under the conditions of temperature 30°C and pressure 0.08MPa Vacuum defoaming, followed by conventional non-solvent gel film-forming method to form a film to obtain the porous film of the hydrophilic modified network cross-linked product.

Embodiment 3

[0085] Example 3: Preparation of hydrophilic modified network cross-linked porous membrane

[0086] The implementation steps of this embodiment are as follows:

[0087] A. Preparation of casting solution

[0088] 0.1 parts by weight of polypropylene resin, 10 parts by weight of PVPk30 additive and 56 parts by weight of methylpyrrolidone solvent were uniformly mixed to obtain the casting solution;

[0089] B. Add network crosslinking

[0090] Add the cross-linked sulfonated polyether ether sulfone network cross-linked product to the casting solution obtained in step A according to 0.1% of the weight of the casting solution, stir and mix well, under the conditions of temperature 130°C and pressure 0.10MPa Vacuum defoaming is carried out, and then a conventional non-solvent gel film-forming method is used to form a film to obtain the porous film of the hydrophilic modified network cross-linked product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com