Three-layer composite micropore diaphragm and preparation method therefor

A technology of microporous diaphragm and layer compounding, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of a large amount of waste liquid, waste gas, complex production process, poor mechanical properties, etc., achieve good high temperature resistance, simplify Effect of production equipment and process, high membrane rupture temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

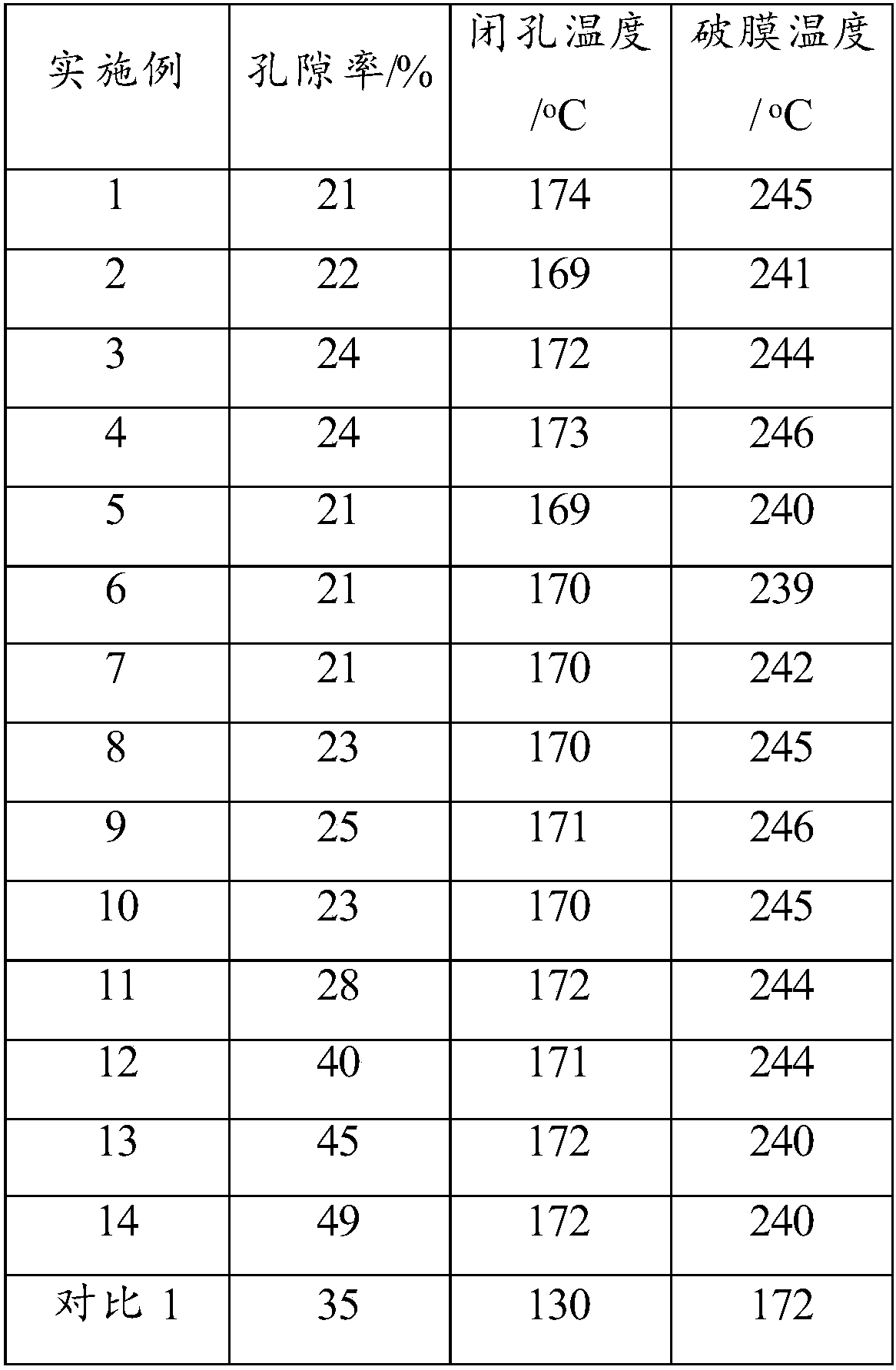

Embodiment 1

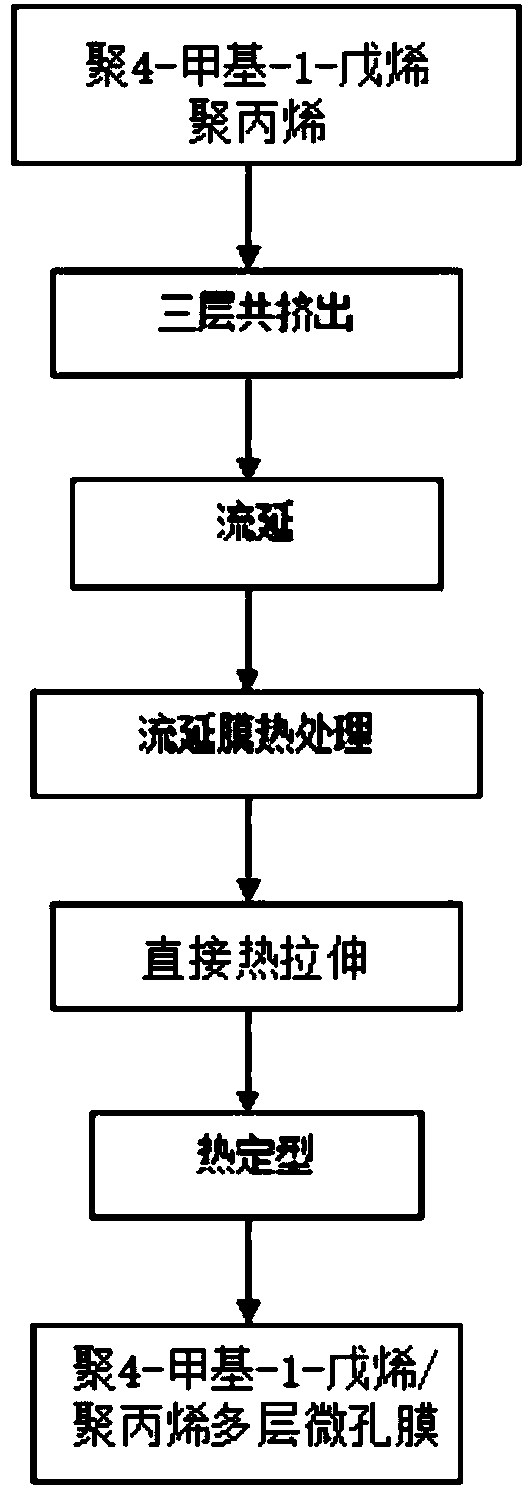

[0037] Add poly-4-methyl-1-pentene with a melt index of 6g / 10min and polypropylene with a melt index of 1g / 10min into different extruders, co-extrude through a multi-layer die, and cast to obtain a three-layer poly-4 - Methyl-1-pentene / polypropylene initial cast film. The temperature of the multi-layer die is 290°C, the casting temperature is 80°C, and the thickness of the casting film is 25um. Heat treatment at 145°C for 0.3h. Direct thermal stretching at 110°C, stretching rate 5mm / min, stretching ratio 100%, heat setting temperature 125°C, heat setting time 25min, to obtain three layers of poly-4-methyl-1-pentene / polypropylene micropores membrane.

[0038] The specific preparation flow chart is as figure 1 shown.

Embodiment 2

[0040] Add poly-4-methyl-1-pentene with a melt index of 32g / 10min and polypropylene with a melt index of 6g / 10min into different extruders, co-extrude through a multi-layer die, and cast to obtain a three-layer poly-4 - Methyl-1-pentene / polypropylene initial cast film. The temperature of the multi-layer die is 250°C, the casting temperature is 80°C, and the thickness of the casting film is 25um. Heat treatment at 145°C for 0.3h. Direct thermal stretching at 110°C with a stretching rate of 5 mm / min. The stretch ratio is 100%, the heat setting temperature is 125° C., and the heat setting time is 25 minutes to obtain a three-layer poly-4-methyl-1-pentene / polypropylene microporous membrane.

Embodiment 3

[0042]Add poly-4-methyl-1-pentene with a melt index of 18g / 10min and polypropylene with a melt index of 2.7g / 10min into different extruders, co-extrude through a multi-layer die, and cast to obtain a three-layer polystyrene. 4-Methyl-1-pentene / polypropylene initial cast film. The temperature of the multilayer die is 275°C, the casting temperature is 80°C, and the thickness of the casting film is 25um. Heat treatment at 145°C for 0.3h. Direct thermal stretching at 110°C, stretching rate 5mm / min, stretching ratio 100%, heat setting temperature 125°C, heat setting time 25min, to obtain three layers of poly-4-methyl-1-pentene / polypropylene micropores membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com