Double-wheel milling diaphragm wall structure and construction process thereof

A construction technique and anti-seepage wall technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as the soil layer is prone to collapse, and achieve the effects of reducing shedding, improving quality, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

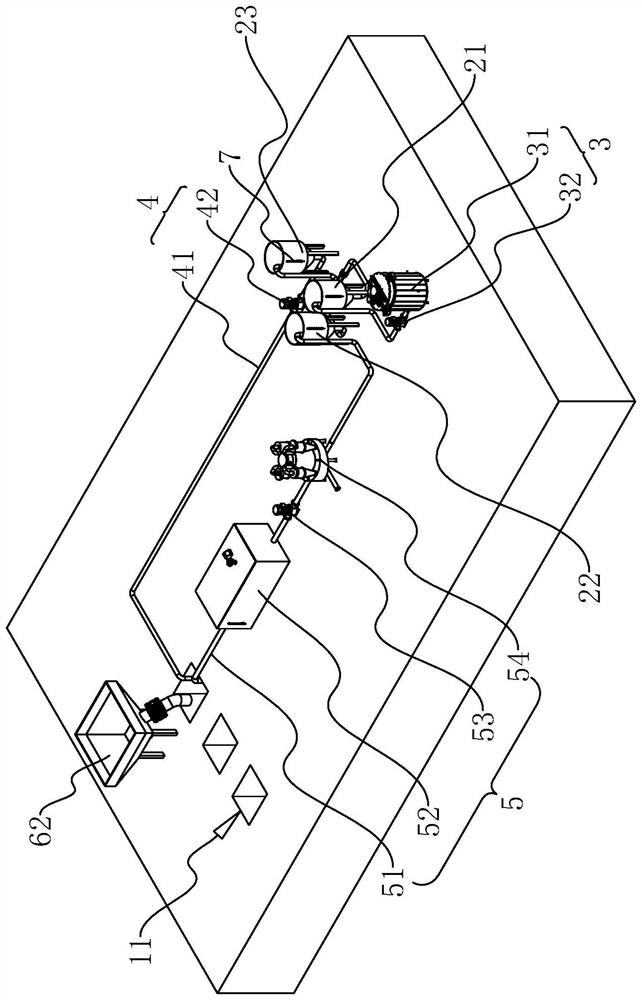

[0045] The following is attached Figure 1-7 The application is described in further detail.

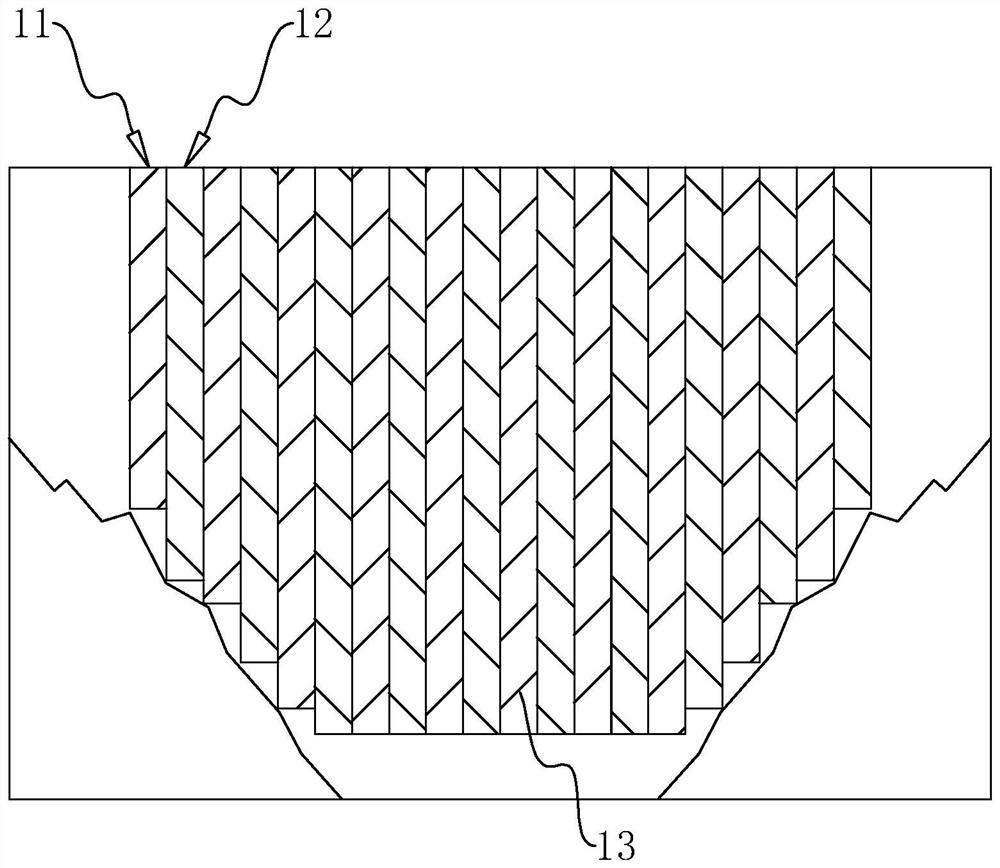

[0046] The embodiment of the present application discloses a double-wheel milling anti-seepage wall structure. refer to figure 1 The double-wheel milling cut-off wall structure includes a plurality of first slots 11 and second slots 12 vertically set on the ground, the plurality of first slots 11 and the plurality of second slots 12 communicate with each other and Arranged alternately along the horizontal direction, the first slots 11 and the second slots 12 are filled with concrete layers 13 .

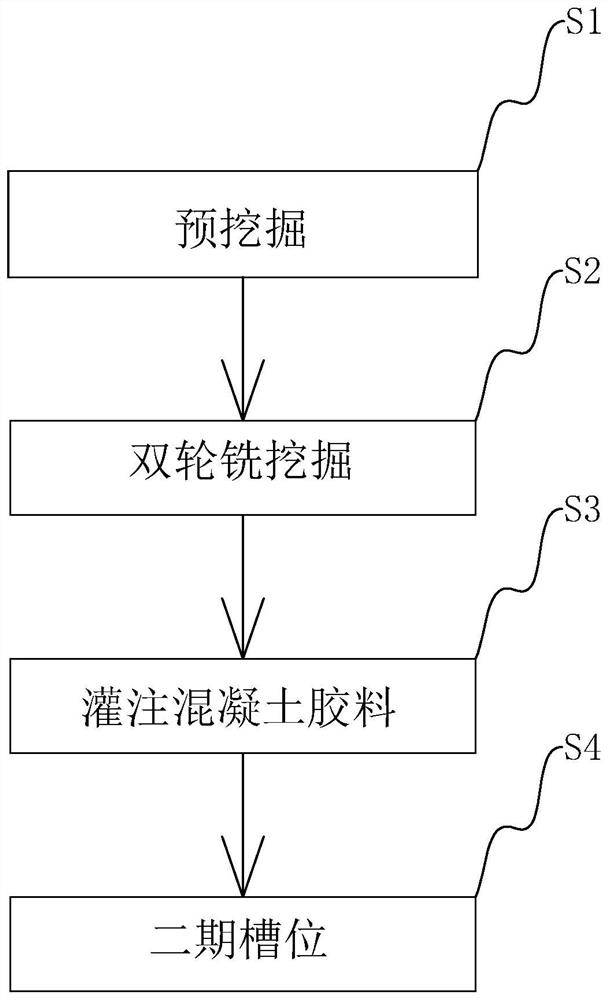

[0047] refer to figure 2 , the embodiment of the present application also discloses a construction process of a double-wheel milling cut-off wall structure, which is used to manufacture the above-mentioned double-wheel milling cut-off wall structure, including the following steps:

[0048] S1. Pre-excavation: first use the grab machine to open multiple first-stage slots arranged at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com