Safety control system and control method for liquid level of large low-temperature liquid storage tank

A technology of cryogenic liquid and safety control, applied in LNG) storage tanks, large cryogenic liquids (such as ethylene field, to avoid safety problems)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

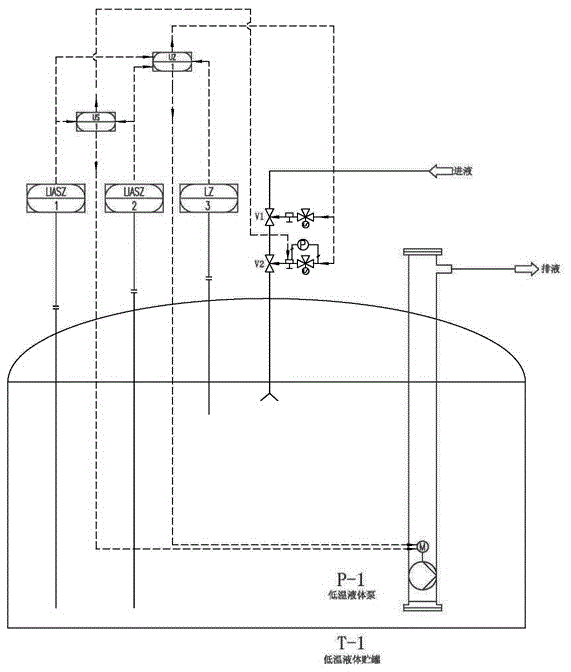

[0023] Example: figure 1 As shown, the liquid level safety control system of the large cryogenic liquid storage tank according to the present invention mainly includes five parts, and its composition and functions are respectively:

[0024] 1) The liquid level gauges LIASZ-1, LIASZ-2, and LZ-3 are installed in the storage tank respectively, and the obtained liquid level signal is connected with the control system DCS and the emergency stop system ESD, and is mainly used for liquid level measurement. Three liquid level gauges with different working principles use a servo level gauge, a radar level gauge, and a magnetostrictive level gauge, among which the servo level gauge and radar level gauge can be adjusted from 0% to 100%. The liquid level is continuously detected. The magnetostrictive liquid level gauge extends downward from the nozzle of the top to below the maximum liquid level. It can only detect 95% to 100% of the liquid level of the storage tank and is only used for j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com