Cleaning machine

A cleaning machine and cleaning rack technology, applied in the field of cleaning machines, can solve the problems of inconvenient operation, many impurities in cleaning liquid, and reduced work efficiency, and achieve the effects of simple and convenient operation, ensuring accurate limit, and preventing materials from flying out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

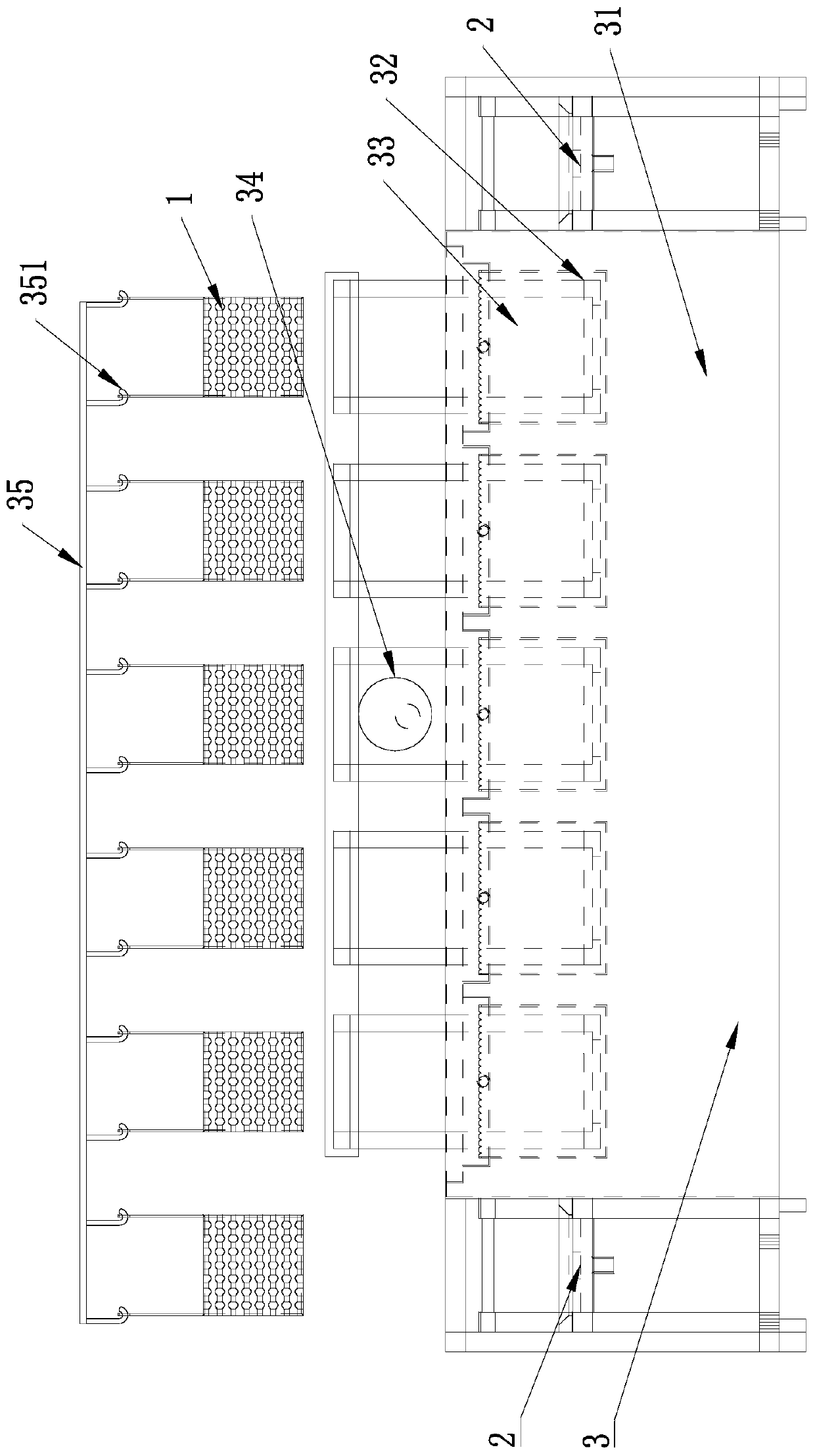

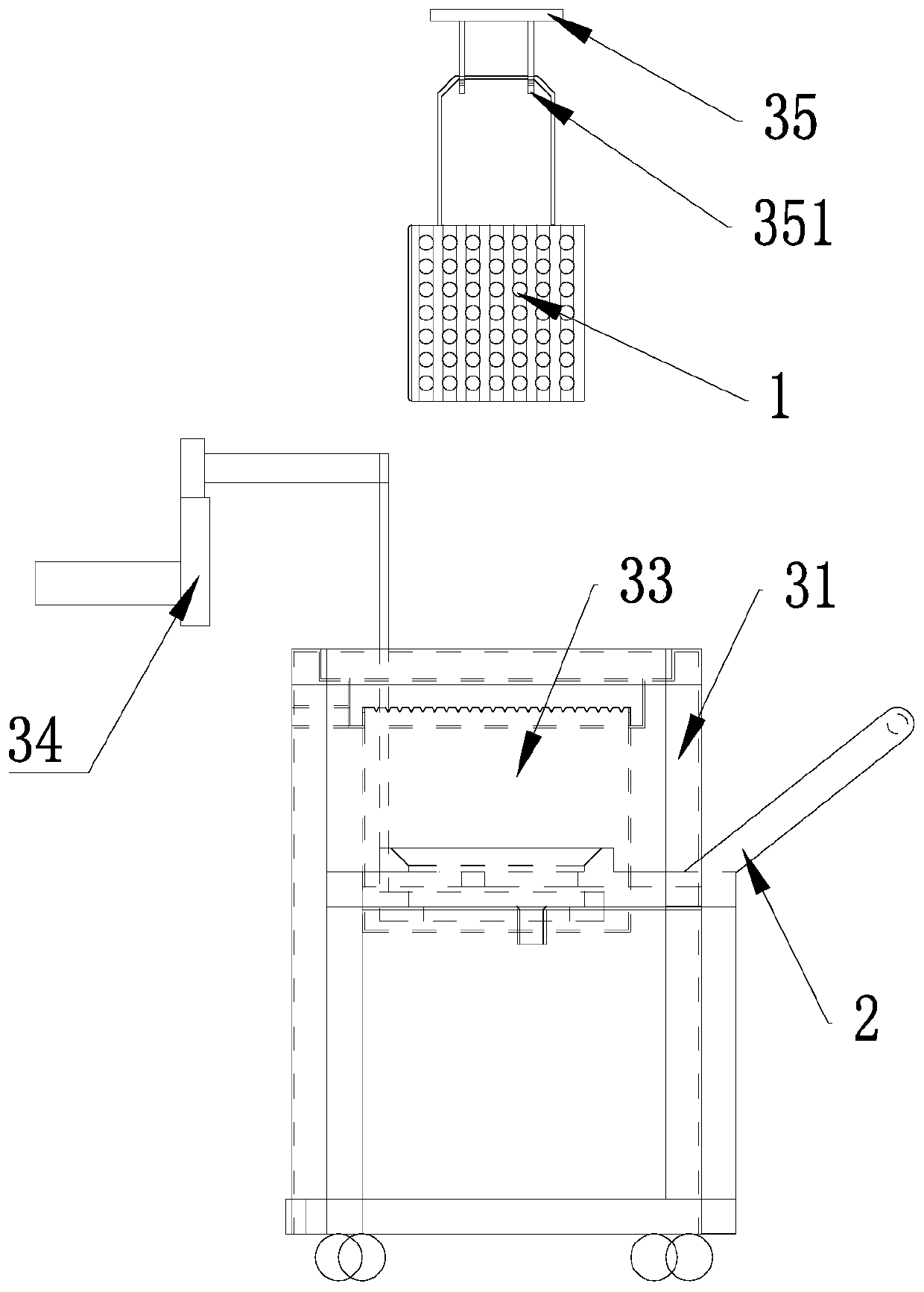

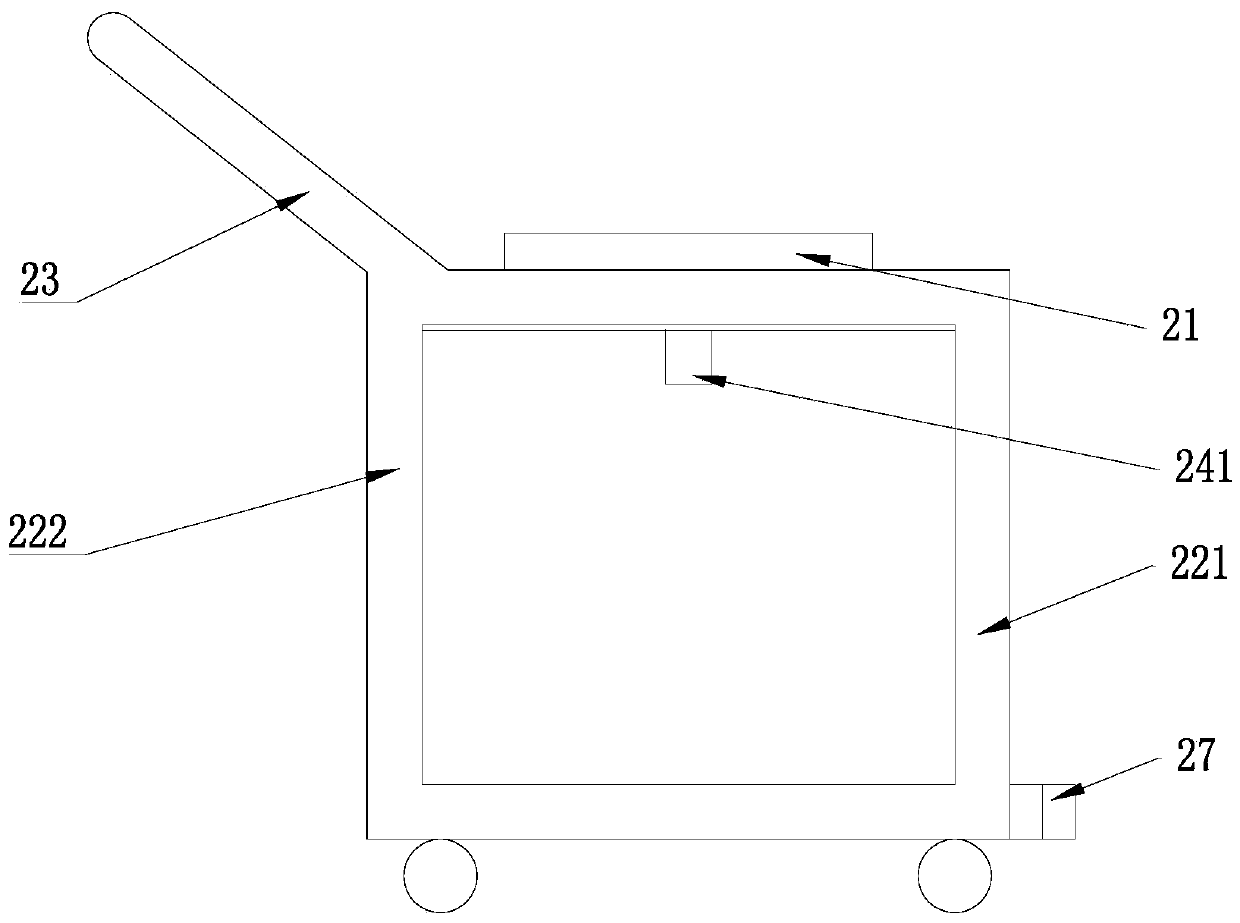

[0029] Such as Figure 1-7 As shown, the present embodiment relates to a washing machine, including a material rack 1, a material transport trolley 2, a cleaning transmission device 3 and a dehydration device 4, and the cleaning transmission device 3 includes a cleaning rack 31, and both ends of the cleaning rack 31 are provided with an accommodating trough, the material transport trolley 2 is placed in the holding tank, the material transport trolley 2 is provided with a limit tray 21 for placing the material rack, the cleaning rack 31 is provided with a plurality of cleaning tanks 32, and each cleaning tank 32 is provided with a The overflow tank 33 , the top edge of the overflow tank 33 is zigzag, and the dehydration device 4 is provided with a plurality of fixing grooves 41 for clamping the material rack 1 .

[0030] Such as Figure 3-5 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com