Metal foam composite material and preparation method thereof

A composite material and metal foam technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor strength of metal-based composite foam materials and limit the application of metal-based composite foam materials, and achieve Achieve high-value conversion, light weight and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

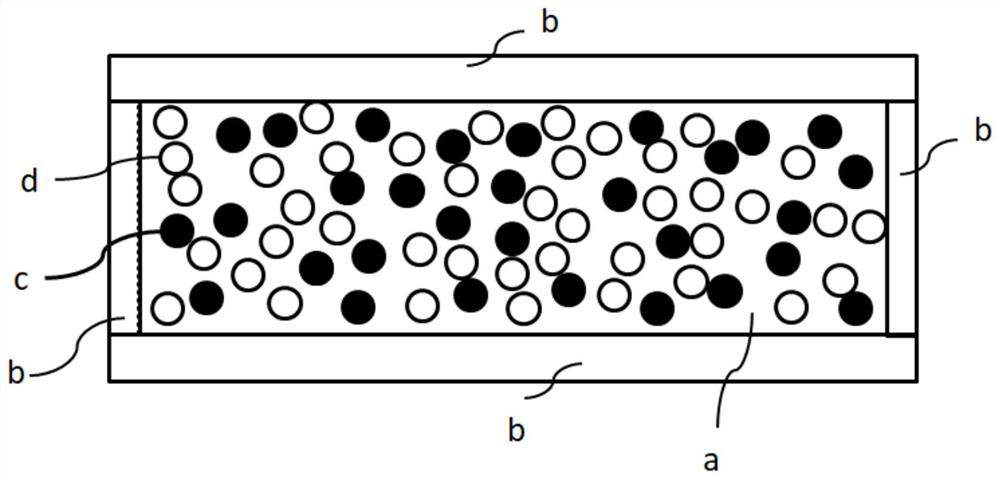

[0059] Another aspect of the present invention also provides a kind of preparation method of above-mentioned metal foam composite material, comprising:

[0060] 1) Lay the first layer of metal plate, mixed layer and second layer of metal plate sequentially in the mold from bottom to top and then seal the mold;

[0061] 2) Heat the mold to 400-900°C, pressurize to 5-30MPa, keep it for 45-120min, and cool to obtain metal foam composite material;

[0062] Wherein, the density of the first metal plate and the second metal plate is not less than 90%, and the mixed layer includes metal powder and hollow inorganic material, wherein the hollow inorganic material is selected from fly ash, Al 2 o 3 At least one of hollow ceramic balls or hollow silicon carbide.

[0063] The first layer of metal plate and the second layer of metal plate in the mold in step 1) go through step 2) to generate the metal layer of the metal foam composite material, and the mixed layer generates the inner cor...

Embodiment 1

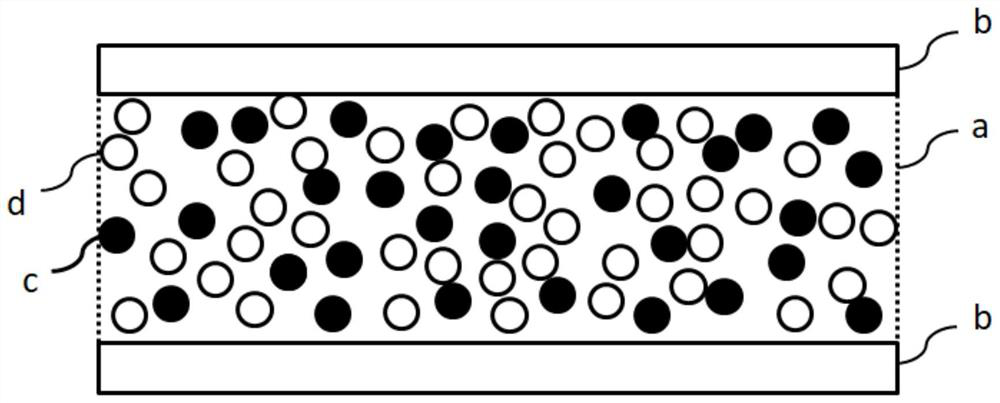

[0082] The structure of the metal foam composite material in this embodiment can refer to figure 1 , its preparation method comprises the following steps:

[0083] 1) Mix AZ91D magnesium alloy powder and fly ash particles and add 20mL of alcohol to obtain a mixture, wherein the volume of fly ash particles accounts for 60% of the total volume of AZ91D magnesium alloy powder and fly ash particles;

[0084]2) A circular AZ91D magnesium alloy plate with a diameter of 30mm and a thickness of 0.5mm is laid from bottom to top in the mold, and a mixed layer with a thickness of 20mm formed by the above mixture on the magnesium alloy plate has a diameter of 30mm and a thickness of 0.5mm AZ91D magnesium alloy plate, and then seal the mold;

[0085] 3) Place the mold in the hot-press sintering furnace, vacuumize the hot-press sintering furnace and raise the temperature of the hot-press sintering furnace to 300°C at a rate of 10°C / min and keep it warm for 60min, then stop the vacuuming an...

Embodiment 2

[0088] The structure and preparation method of the metal foam composite material in this example are basically the same as in Example 1, the only difference is that the diameter of the AZ91D magnesium alloy plate used in step 2) of the preparation method of this example is 30mm and the thickness is 0.8mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com