Method for in-situ construction of metal organic framework nanoparticles on surface of titanate

A metal-organic framework, nanoparticle technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve sensitization reactions, the corrosion resistance of metal biomaterials is not ideal, and it cannot actively induce new Bone and other problems to achieve the effect of improving surface bioactivity, optimizing loading capacity, improving surface hydrophobicity and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

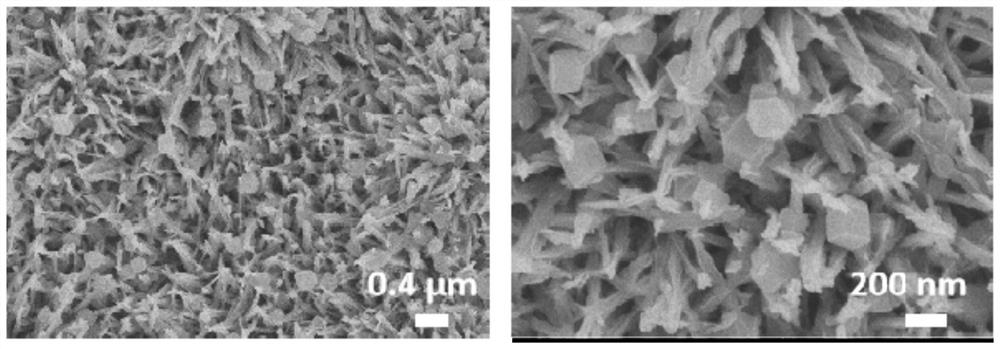

[0039] (1) Preparation of nano titanate structure by alkali heat treatment

[0040] The substrate used this time is Ti-6Al-4V titanium alloy. A Ti-6Al-4V titanium alloy substrate with a size of 15mm×15mm×0.5mm was prepared. Put the titanium alloy matrix into a polytetrafluoroethylene dish with a capacity of 30ml, and use a mixed acid diluted 15 times (the volume ratio is HF:HNO 3 : deionized water = 3:2:10) Soak the titanium alloy for 2 minutes, then rinse it with deionized water, then place it in deionized water, and perform ultrasonic cleaning for 5 minutes to remove impurities and oil stains on the titanium alloy substrate. After the ultrasound is completed, dry the cleaned titanium alloy substrate with a hair dryer, and put it into a Teflon liner with a capacity of 100ml. According to the size of the titanium alloy substrate and Teflon, there is no stacking in each Teflon liner. Insert 7 cleaned titanium alloy substrates, mark the front and back sides, and face up.

[0...

Embodiment 2

[0047] (1) titanate is prepared with embodiment 1;

[0048] (2) During the cation exchange process, the ion exchange time was changed to 1 h by titanate immersion, and other parameters and steps were the same as in Example 1;

[0049] (3) In-situ growth of ZIF-8 nanoparticles between titanate layers is the same as in Example 1.

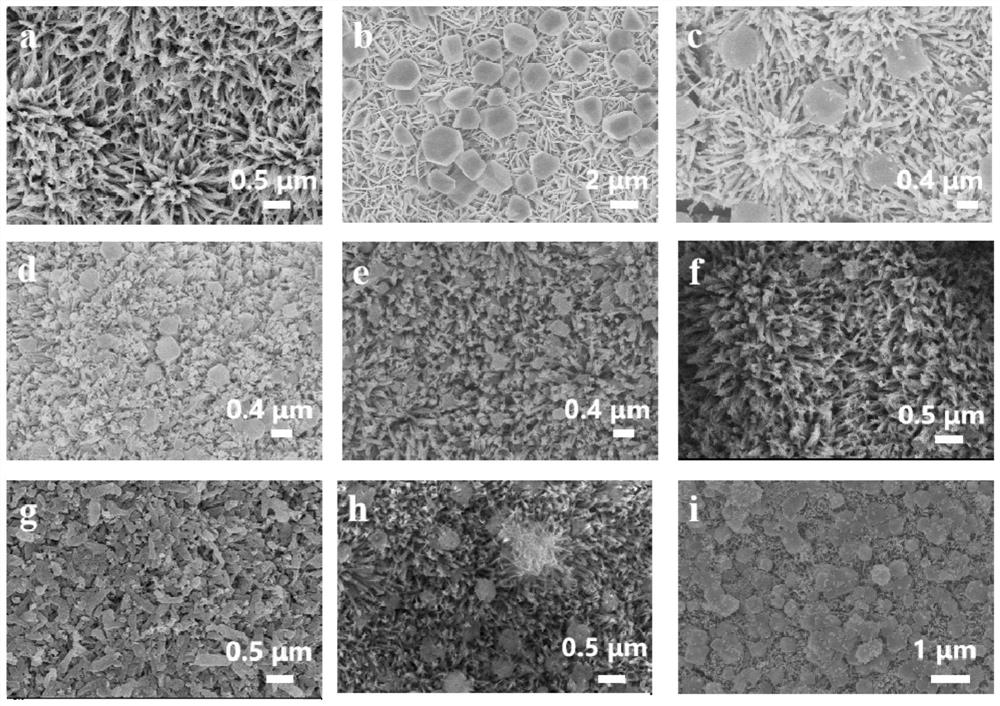

[0050] The result is as figure 2 As shown in c, ZIF-8 particles grown in situ can still be prepared by changing the cation exchange time.

Embodiment 3

[0052] (1) titanate is prepared with embodiment 1;

[0053] (2) in the cation exchange process, the concentration of zinc nitrate hexahydrate becomes 0.1M by 0.5M, and other parameters and steps are with embodiment 1;

[0054] (3) In-situ growth of ZIF-8 nanoparticles between titanate layers is the same as in Example 1.

[0055] The result is as figure 2 As shown in d, ZIF-8 particles grown in situ can still be prepared by reducing the concentration of the cation exchange solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com