High-strength absorbable active composite material and preparation method thereof

A technology of composite materials and polymers, applied in medical science, surgery, etc., can solve the problems of brittle limitation, poor mechanical strength of polylactic acid, and reduced material strength, and achieve the effect of improving surface properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

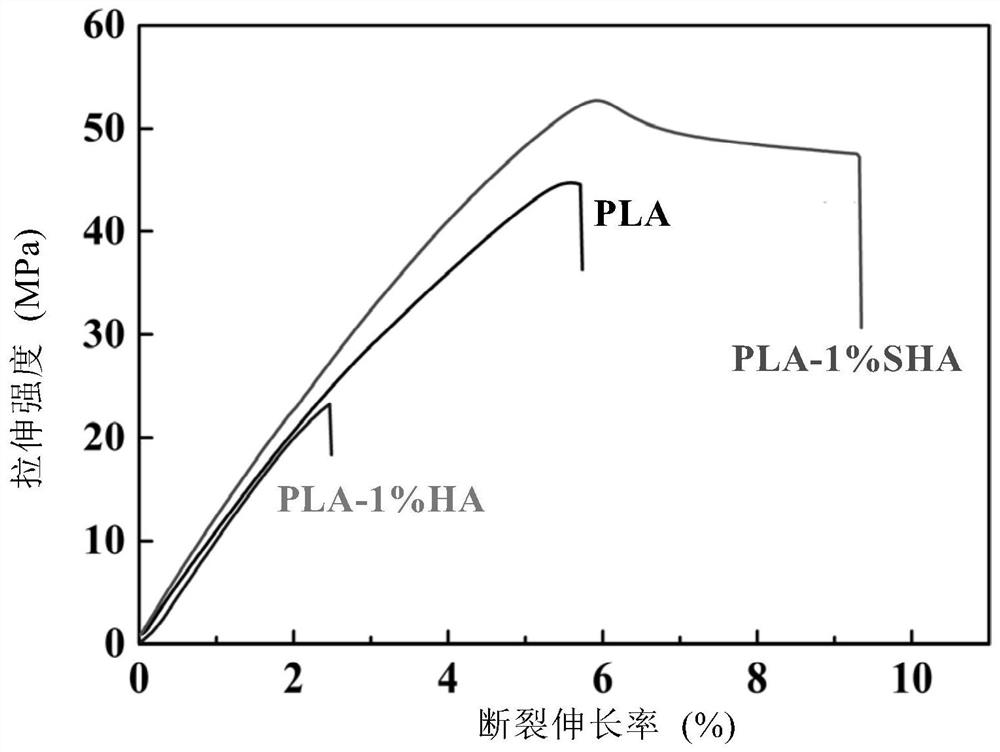

[0039] Synthesis of degradable polymer polylactic acid (PLA)-1% modified nano-hydroxyapatite (SHA) nanocomposites

[0040] Nano-hydroxyapatite particles with an aspect ratio of 5.5 were prepared by chemical precipitation method:

[0041] Prepare Ca(NO 3 ) 2 4H 2 O aqueous solution and (NH 4 ) 2 HPO 4 aqueous solution, the Ca / P molar ratio is controlled to be 1.67; then the Ca(NO 3 ) 2 4H 2 O aqueous solution was added (NH 4 ) 2 HPO 4 Solution, control the pH value of the reaction within the range of 10-12, control the reaction temperature to 100°C, stop the reaction after 2 hours of reaction, vacuum filter the reaction solution, and wash the filter cake alternately with deionized water and ethanol After suction filtration for 3-4 times, the filter cake was freeze-dried for 24 hours to obtain nano-hydroxyapatite particles (HA).

[0042] SHA nanoparticles were prepared by modifying hydroxyapatite with silane coupling agent 3-aminopropyltriethoxysilane (APTES):

[00...

Embodiment 2

[0047] Preparation of Synthetic Degradable Polymer Polylactic Acid (PLA)-1% Nano-Hydroxyapatite (HA) Nanocomposite

[0048] Nano-hydroxyapatite (HA) particles with an aspect ratio of 5.5 were prepared by chemical precipitation method:

[0049] Prepare Ca(NO 3 ) 2 4H 2 O aqueous solution and (NH 4 ) 2 HPO 4 aqueous solution, the Ca / P molar ratio is controlled to be 1.67; then the Ca(NO 3 ) 2 4H 2 O aqueous solution was added (NH 4 ) 2 HPO 4 Solution, control the pH value of the reaction in the range of 10-12, control the reaction temperature to 100°C, stop the reaction after 2 hours of reaction, vacuum filter the reaction solution, and wash the filter cake alternately with deionized water and ethanol After suction filtration for 3-4 times, the filter cake was freeze-dried for 24 hours to obtain nano-hydroxyapatite particles (HA).

[0050] The lactide monomer that takes 50g is in there-necked flask, adds 0.325wt% stannous octoate (Sn(Oct) 2 ) catalyst and unmodified...

Embodiment 3

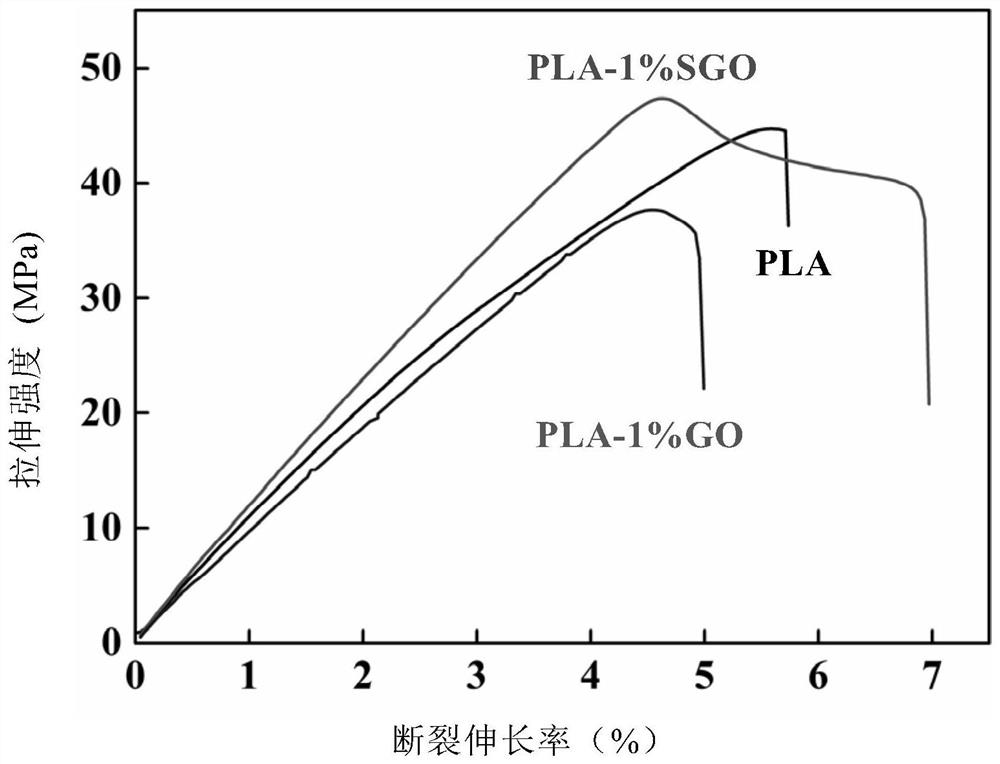

[0058] Preparation of Synthetic Degradable Polymer Polylactic Acid-1% Modified Graphene Oxide (SGO) Composite

[0059] Graphene oxide (GO) was prepared by the Hummer method:

[0060] First mix 5g graphite with 2g NaNO 3 Disperse in 120mL concentrated H 2 Stir in an ice bath after SO, add 20g KMnO4 after 60min and wait for 60min to react, then transfer to a warm water bath at 30°C and continue to react for 30min, then slowly add 250mL deionized water, and keep the reaction temperature at 90°C, add an appropriate amount of h 2 o 2 Until no bubbles are generated, filter while hot, wash with deionized water and 5% hydrochloric acid several times until neutral, and dry in a vacuum oven at 60°C after centrifugation to obtain graphite oxide.

[0061] SGO nanospheres were prepared by modifying graphene oxide with silane coupling agent (APTES):

[0062] Weigh 400 mg of graphene oxide and disperse it into 200 mL of anhydrous toluene, stir at 600 rpm for 2 h, then add 800 μL of APTE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com