Green and environment-friendly catalyst for automobile exhaust treatment and preparation method of catalyst

A green environmental protection, automobile exhaust technology, applied in catalyst activation/preparation, physical/chemical process catalyst, gas treatment, etc., can solve the problems of high price, limited application, etc., and achieve the effect of high speed, long service life and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

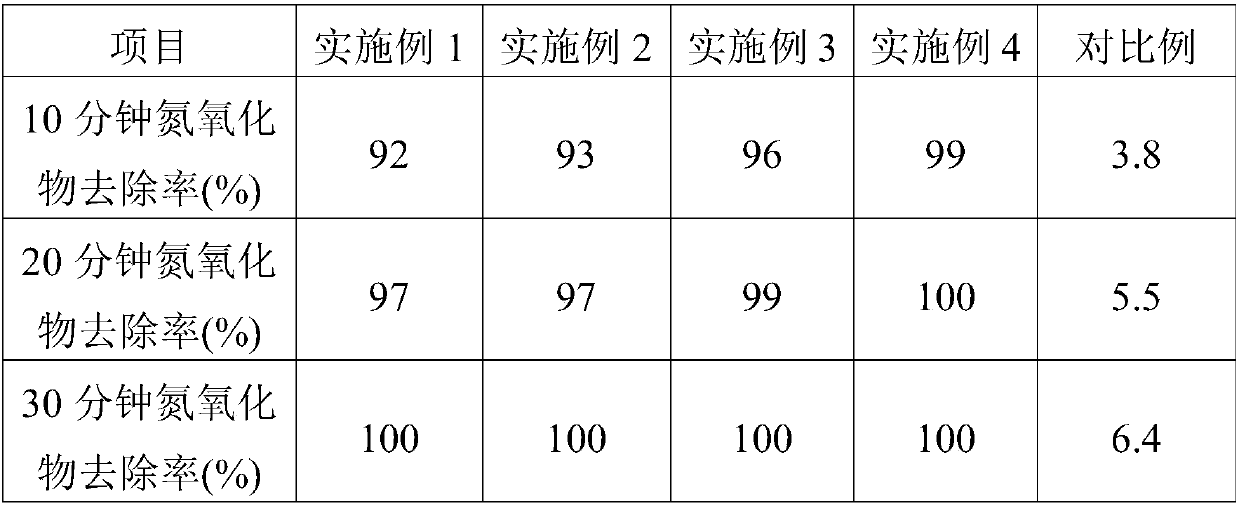

Examples

Embodiment 1

[0026] A preparation method of an environmentally friendly catalyst for automobile exhaust treatment, comprising the steps of:

[0027] 1) Dichloropropanol surface modified nano-titanium dioxide: ultrasonically disperse 30 g of nano-titanium dioxide in 100 g of ether for 15 minutes, then add 20 g of dichloropropanol therein, stir at room temperature for 1 hour, and then obtain a solid product by centrifugation, Then place it in a vacuum drying oven at 60°C for 20 hours;

[0028] 2) Titanium dioxide surface-modified by quaternary ammonium salt: disperse 30 g of nano-titanium dioxide surface-modified dichloropropanol prepared in step 1) in 100 g of ether, and then add N-tris(hydroxymethyl)methyl- 10g of 2-aminoethanesulfonic acid and 10g of perfluorotributylamine were stirred at 40°C for 5 hours, then the solid product was obtained by centrifugation, and dried in a vacuum oven at 60°C for 15 hours;

[0029] 3) Graphene oxide doping: Disperse 10 g of quaternary ammonium salt sur...

Embodiment 2

[0033] A preparation method of an environmentally friendly catalyst for automobile exhaust treatment, comprising the steps of:

[0034] 1) Dichloropropanol surface modified nano-titanium dioxide: ultrasonically disperse 40 g of nano-titanium dioxide in 110 g of acetonitrile for 17 minutes, then add 22 g of dichloropropanol therein, stir at room temperature for 1.2 hours, and then obtain a solid product by centrifugation, Then place it in a vacuum oven at 65°C for 15 hours;

[0035] 2) Titanium dioxide surface-modified by quaternary ammonium salt: 35 g of nano-titanium dioxide surface-modified by dichloropropanol prepared in step 1) are dispersed in 120 g of ether, and then N-tris(hydroxymethyl)methyl- 14g of 2-aminoethanesulfonic acid and 13g of perfluorotributylamine were stirred at 43°C for 6 hours, then the solid product was obtained by centrifugation, and dried in a vacuum oven at 65°C for 18 hours;

[0036] 3) Graphene oxide doping: Disperse 15 g of titanium dioxide and ...

Embodiment 3

[0040] A preparation method of an environmentally friendly catalyst for automobile exhaust treatment, comprising the steps of:

[0041]1) Dichloropropanol surface modified nano-titanium dioxide: ultrasonically disperse 45 g of nano-titanium dioxide in 135 g of ethyl acetate for 18 minutes, then add 25 g of dichloropropanol therein, stir at room temperature for 1.5 hours, and then obtain a solid by centrifugation The product was dried in a vacuum oven at 72°C for 16 hours;

[0042] 2) Titanium dioxide surface-modified by quaternary ammonium salt: 40 g of nano-titanium dioxide surface-modified by dichloropropanol prepared in step 1) is dispersed in 140 g of ether, and then N-tris(hydroxymethyl)methyl- 18g of 2-aminoethanesulfonic acid and 10g of perfluorotributylamine were stirred at 46°C for 7 hours, then the solid product was obtained by centrifugation, and dried in a vacuum oven at 74°C for 19 hours;

[0043] 3) Graphene oxide doping: Disperse 17 g of titanium dioxide and 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com