Environment-friendly formaldehyde remover and preparation method thereof

A purification agent and formaldehyde technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high price and achieve the effect of low price, low equipment requirements, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

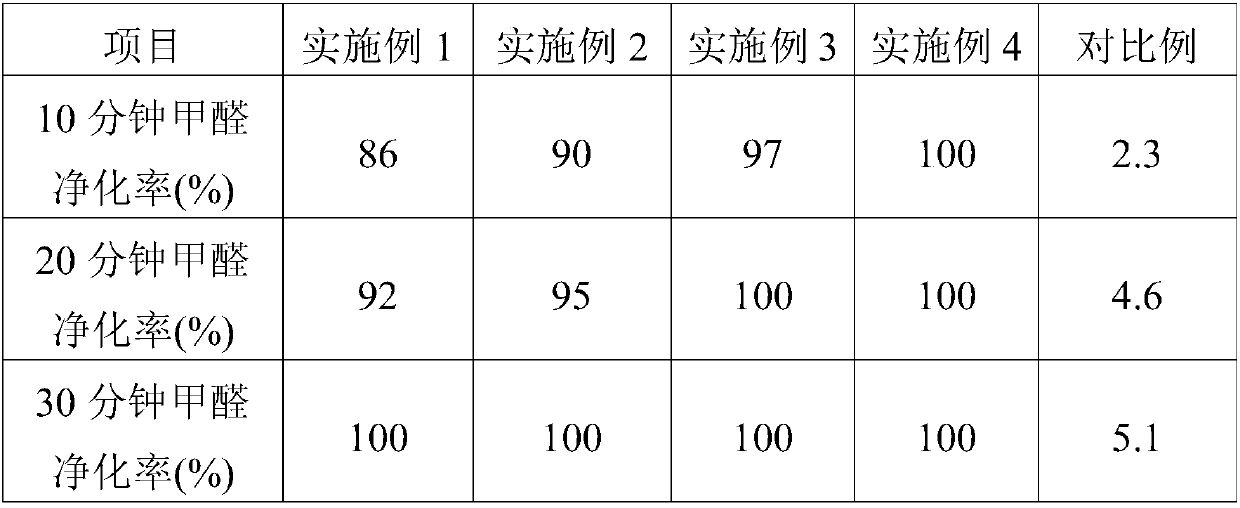

Examples

Embodiment 1

[0028] A preparation method of an environment-friendly formaldehyde purifying agent, comprising the steps of:

[0029] 1) Surface modification of negative ion powder: ultrasonically disperse 50 g of negative ion powder in 150 g of ethanol, then add 5 g of 2-(3,4-epoxycyclohexyl) ethyl triethoxysilane, stir at room temperature for 1 hour, and then centrifuge , washed with ethanol for 5 times and dried in a vacuum oven at 50°C for 10 hours;

[0030] 2) Preparation of polypyrrole tube: FeCl 3 ·6H 2 O 40g was dispersed in 1000g of methyl orange solution with a mass fraction of 2%. When flocculent substances were formed, 20g of pyrrole monomer was added and stirred at room temperature for 20 hours. A black suspension was obtained, which was filtered and dried in a vacuum oven at 60°C for 12 hours;

[0031] 3) Surface modification of polypyrrole tube: Disperse 15 g of polypyrrole tube prepared in step 2) in 45 g of ethanol, add 1.5 g of epichlorohydrin and 3 g of triethylamine, s...

Embodiment 2

[0036] A preparation method of an environment-friendly formaldehyde purifying agent, comprising the steps of:

[0037] 1) Surface modification of negative ion powder: ultrasonically disperse 70 g of negative ion powder in 200 g of isopropanol, then add 7 g of 2-(3,4-epoxycyclohexyl) ethyl triethoxysilane to it, and stir at room temperature for 1.2 hours, Then centrifuge, wash with ethanol centrifugation for 6 times and then dry in a vacuum oven at 53°C for 12 hours;

[0038] 2) Preparation of polypyrrole tube: FeCl 3 ·6H 2O 46g was dispersed in 1080g of methyl orange solution with a mass fraction of 3%. When flocculent substances were formed, 20g of pyrrole monomer was added and stirred at room temperature for 23 hours. A black suspension was obtained, which was filtered and baked in a vacuum oven at 65°C for 14 hours;

[0039] 3) Surface modification of polypyrrole tube: Disperse 17 g of polypyrrole tube prepared in step 2) in 55 g of ethanol, add 2 g of epichlorohydrin an...

Embodiment 3

[0044] A preparation method of an environment-friendly formaldehyde purifying agent, comprising the steps of:

[0045] 1) Surface modification of negative ion powder: ultrasonically disperse 90g of negative ion powder in 300g of ethylene glycol, then add 8.5g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane to it, and stir at room temperature for 1.6 hours , then centrifuged, washed with ethanol for 7 times and then dried in a vacuum oven at 57°C for 14 hours;

[0046] 2) Preparation of polypyrrole tube: FeCl 3 ·6H 2 O 56g was dispersed in 1160g of methyl orange solution with a mass fraction of 5%. When flocculent substances were formed, 20g of pyrrole monomer was added and stirred at room temperature for 28 hours. A black suspension was obtained, which was filtered and dried in a vacuum oven at 73°C for 17 hours;

[0047] 3) Surface modification of polypyrrole tube: Disperse 19 g of polypyrrole tube prepared in step 2) in 68 g of ethanol, add 2.5 g of epichlorohydrin and 5 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com