Supercritical fluid foaming polyolefin material and preparing method thereof

A technology for foaming polyolefin and supercritical fluid, applied in the field of foaming materials, can solve the problems of poor adjustment of cell diameter and cell density, difficulty in obtaining foamed materials with regular shapes, and large amount of supercritical fluid, etc. Achieve the effect of shortening the heating and pressurization time, excellent mechanical strength, and accelerating the gas diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

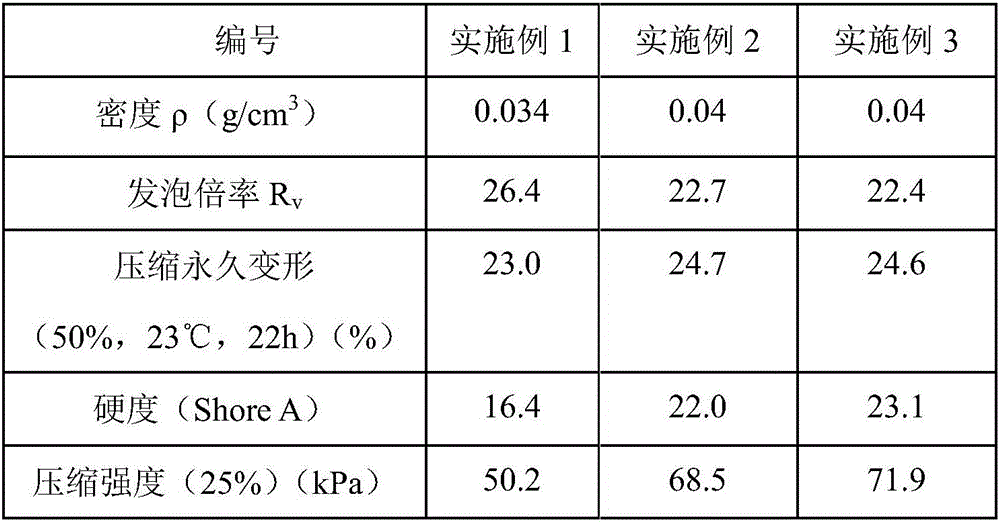

Embodiment 1

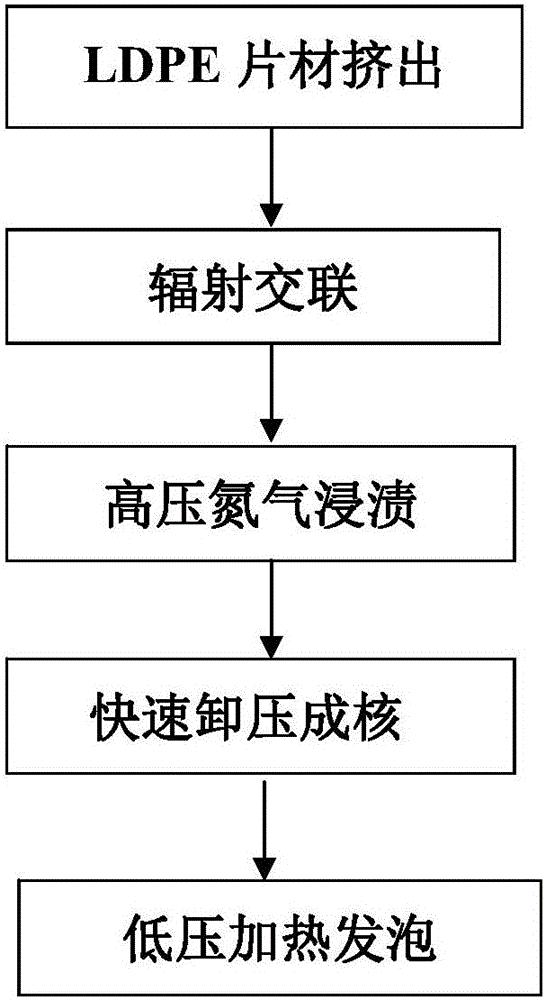

[0052] The process of radiation cross-linked polyethylene foam material, according to figure 1 The process flow chart is carried out, including the following steps:

[0053] 1) LDPE sheet extrusion molding: use an extruder to extrude an LPDE sheet, wherein the melting point of LPDE is T m It is 111°C.

[0054] 2) Radiation cross-linked LDPE: The radiation cross-linked LDPE is obtained by irradiating the LDPE sheet with a high-energy electron beam, wherein the radiation dose is 40 kGy.

[0055] 3) High-pressure nitrogen impregnation process: raise the autoclave to the set temperature, then put the above-mentioned radiation-crosslinked LDPE sample into the autoclave, and then inject nitrogen gas with a high-pressure pump, so that the radiation-crosslinked LDPE sample is immersed at a temperature of 180 °C, Under the impregnation pressure of 40.1MPa, keep the pressure in the autoclave for 1 hour, so that the radiation crosslinked LDPE sample absorbs enough nitrogen.

[0056] 4...

Embodiment 2

[0059] On the basis of Example 1, the irradiation dose of the LDPE sheet in this example is 60kGy, the impregnation pressure is 50MPa, the impregnation temperature is 200°C, the pressure relief time is 10s, the foaming temperature is 150°C, and the foaming pressure is 3MPa.

Embodiment 3

[0061] On the basis of Example 1, the irradiation dose of the LDPE sheet in this example is 80kGy, the impregnation pressure is 30MPa, the impregnation temperature is 220°C, the pressure relief time is 5s, the foaming temperature is 180°C, and the foaming pressure is 1.5Mpa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com