Plasma body cleaning device

A cleaning device and plasma technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of low plasma density, narrow working pressure range, and difficult technology development, so as to avoid electrode pollution and facilitate Control and protection, better cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

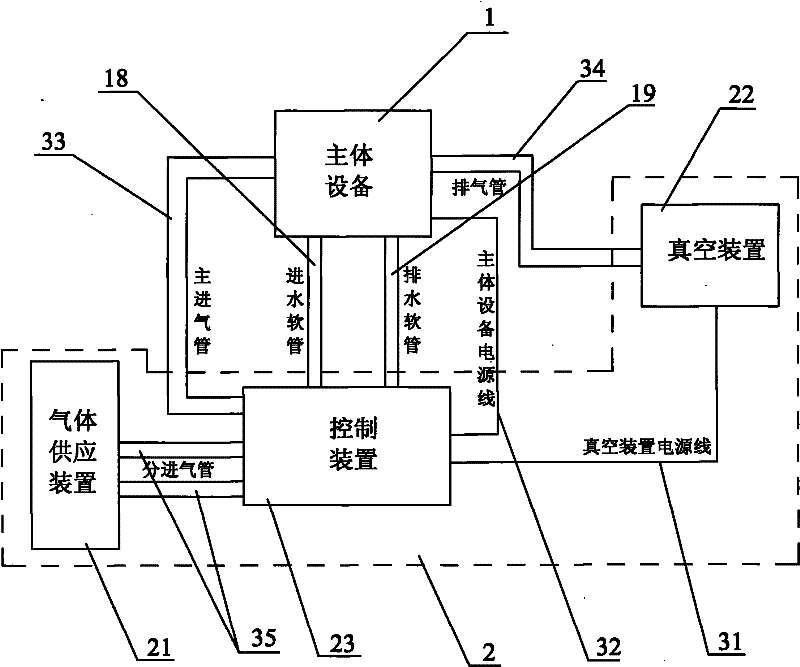

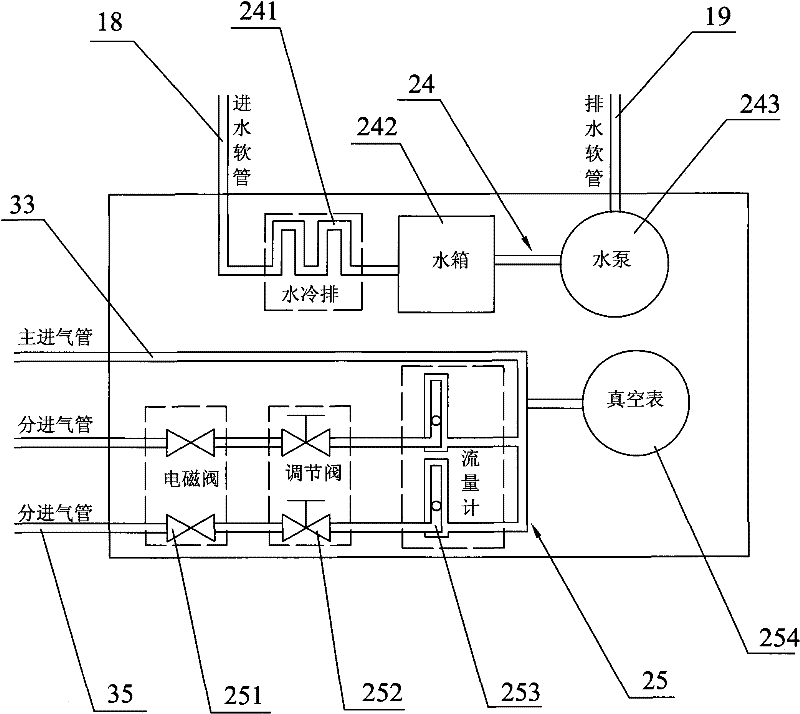

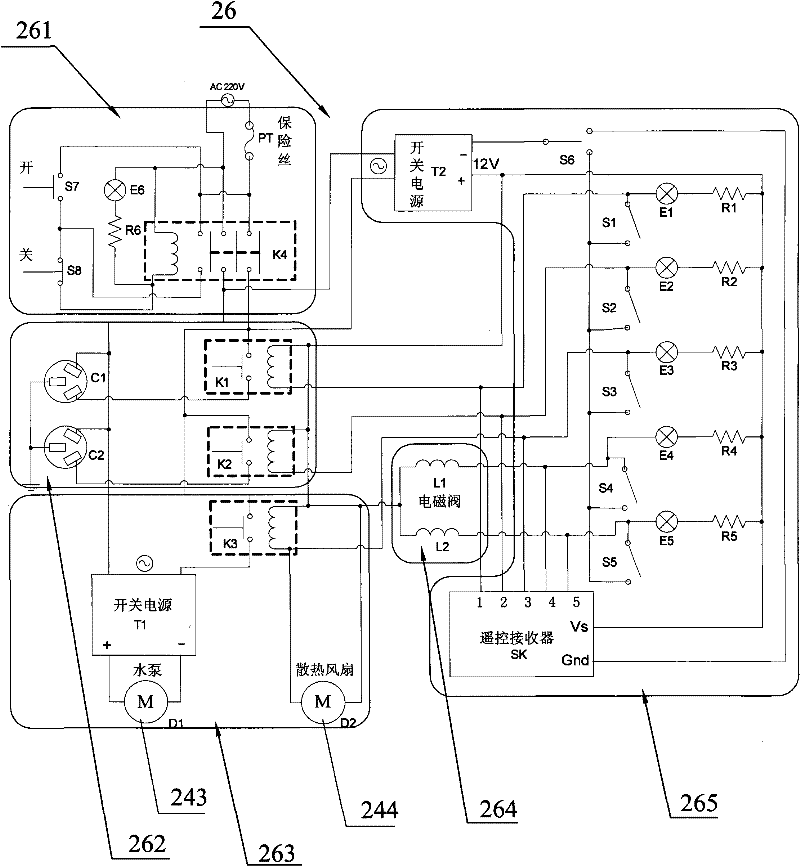

[0029] Such as Figure 1 to Figure 5As shown, a plasma cleaning device includes a main device 1 and a peripheral device 2. The peripheral device 2 is mainly composed of a gas supply device 21, a vacuum device 22 and a control device 23. The control device 23 includes a water circuit unit 24 and a gas circuit unit 25. And circuit unit 26, main body equipment 1 is mainly made up of microwave system 11 and reaction device 12, and microwave system 11 comprises microwave chamber 13, is arranged on the microwave source 14 in microwave chamber 13 and the microwave control circuit (Fig. not shown), the reaction device 12 includes a quartz cover 15 arranged in the microwave chamber 13, a reaction chamber base 16 arranged in the microwave chamber 13 and below the quartz cover 15, and surrounded by the quartz cover 15 and the reaction chamber base 16. The reaction chamber 17 formed by the formed space, the microwave control circuit is connected with the circuit unit 26 through the main e...

Embodiment 2

[0039] Such as Figure 1 to Figure 3 and Image 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that in this embodiment the reaction chamber base 16 is a turntable reaction chamber base, as Image 6As shown, the reaction chamber base 16 is provided with a motor placement groove 51 that runs through the bottom of the microwave chamber cavity 131. The motor placement groove 51 communicates with the reaction chamber 17, and the motor placement groove 51 is provided with a motor 52. When placing the motor 52, the motor shaft 53 of the motor 52 needs to be vertically upward, and the bottom of the motor placement groove 51 is provided with a lead through hole 54 for leading out the power cord of the motor 52, and the power cord of the motor 52 passes through the lead wire The through hole 54 is connected to the external motor power supply, the opening end of the motor placement groove 51 is provided with a metal baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com