A control method for the density of amorphous alloy

An amorphous alloy and density technology, applied in the field of density control of amorphous alloys, to achieve the effects of simple implementation, high efficiency, controllability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

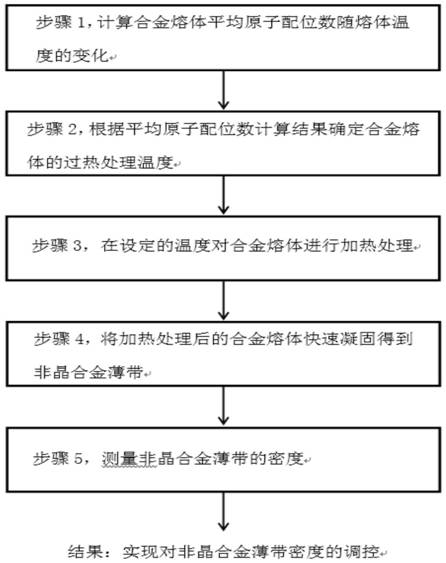

[0034] A regulating method of amorphous alloy density, the specific steps are as follows:

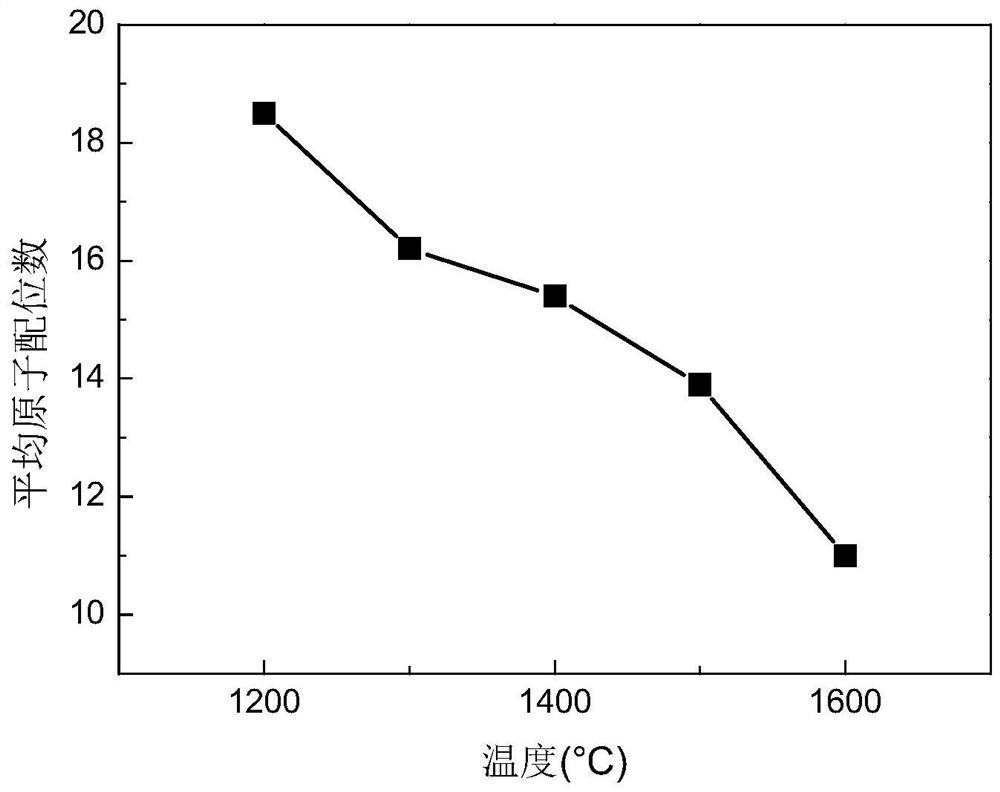

[0035] Step 1, calculate Fe 84 Si 10 B 6 (The subscript in the chemical form is AT%) Alloy melt average atomic coordination number with melt temperature: first use molecular dynamics simulation method to calculate Fe 84 Si 10 B 6 The bibquip distribution function of the alloy melt varies with the melt temperature and then determines from the atomic radius to determine the effective range of 0.2-0.3 nm, and respectively, the first neighborhood in each temperature of each temperature. Integral, the average atomic coordination is obtained. Get FE by establishing a correspondence between the melt temperature and the melt average atomic coordination 84 Si 10 B 6 Mever average atomic coordination calculation results with temperature change, with this as a choice of Fe 84 Si 10 B 6 The basis for the molten density of alloy;

[0036] Step 2, calculate the result according to the average atomic comp...

Embodiment 2

[0042] A regulating method of amorphous alloy density, the specific steps are as follows:

[0043] Step 1, calculate Fe 84 Si 10 B 6 (The subscript in the chemical form is AT%) Alloy melt average atomic coordination number with melt temperature: first use molecular dynamics simulation method to calculate Fe 84 Si 10 B 6 The bibquip distribution function of the alloy melt varies with the melt temperature and then determines from the atomic radius to determine the effective range of 0.2-0.3 nm, and respectively, the first neighborhood in each temperature of each temperature. Integral, the average atomic coordination is obtained. Get FE by establishing a correspondence between the melt temperature and the melt average atomic coordination 84 Si 10 B 6 Mever average atomic coordination calculation results with temperature change, with this as a choice of Fe 84 Si 10 B 6 The basis for the molten density of alloy;

[0044] Step 2, calculate the result according to the average atomic comp...

Embodiment 3

[0050] A regulating method of amorphous alloy density, the specific steps are as follows:

[0051] Step 1, calculate Fe 84 Si 10 B 6 (The subscript in the chemical form is AT%) Alloy melt average atomic coordination number with melt temperature: first use molecular dynamics simulation method to calculate Fe 84 Si 10 B 6 The bibquip distribution function of the alloy melt varies with the melt temperature and then determines from the atomic radius to determine the effective range of 0.2-0.3 nm, and respectively, the first neighborhood in each temperature of each temperature. Integral, the average atomic coordination is obtained. Get FE by establishing a correspondence between the melt temperature and the melt average atomic coordination 84 Si 10 B 6 Mever average atomic coordination calculation results with temperature change, with this as a choice of Fe 84 Si 10 B 6 The basis for the molten density of alloy;

[0052] Step 2, calculate the result according to the average atomic comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com