Patents

Literature

97results about How to "Avoid thermal effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

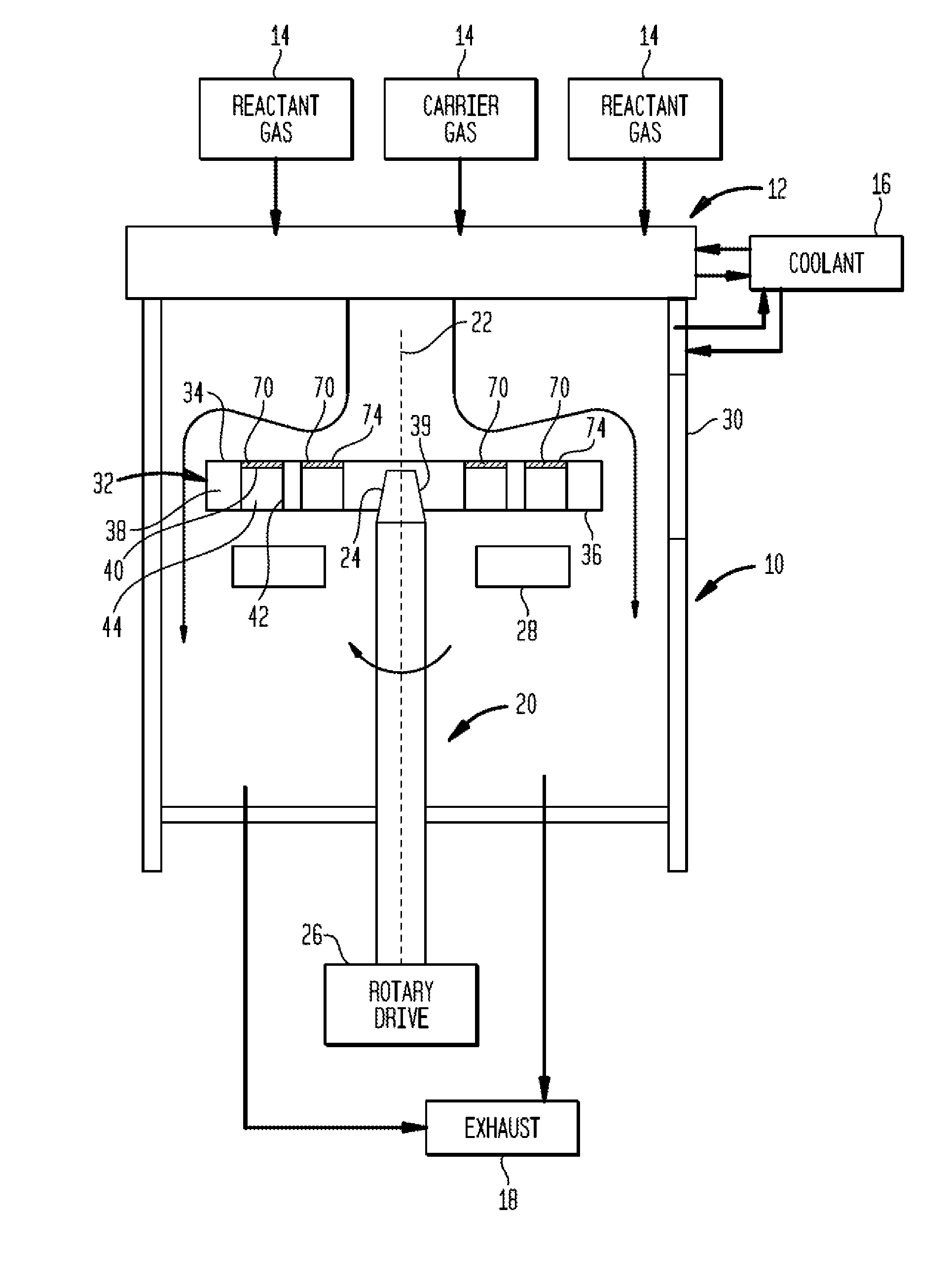

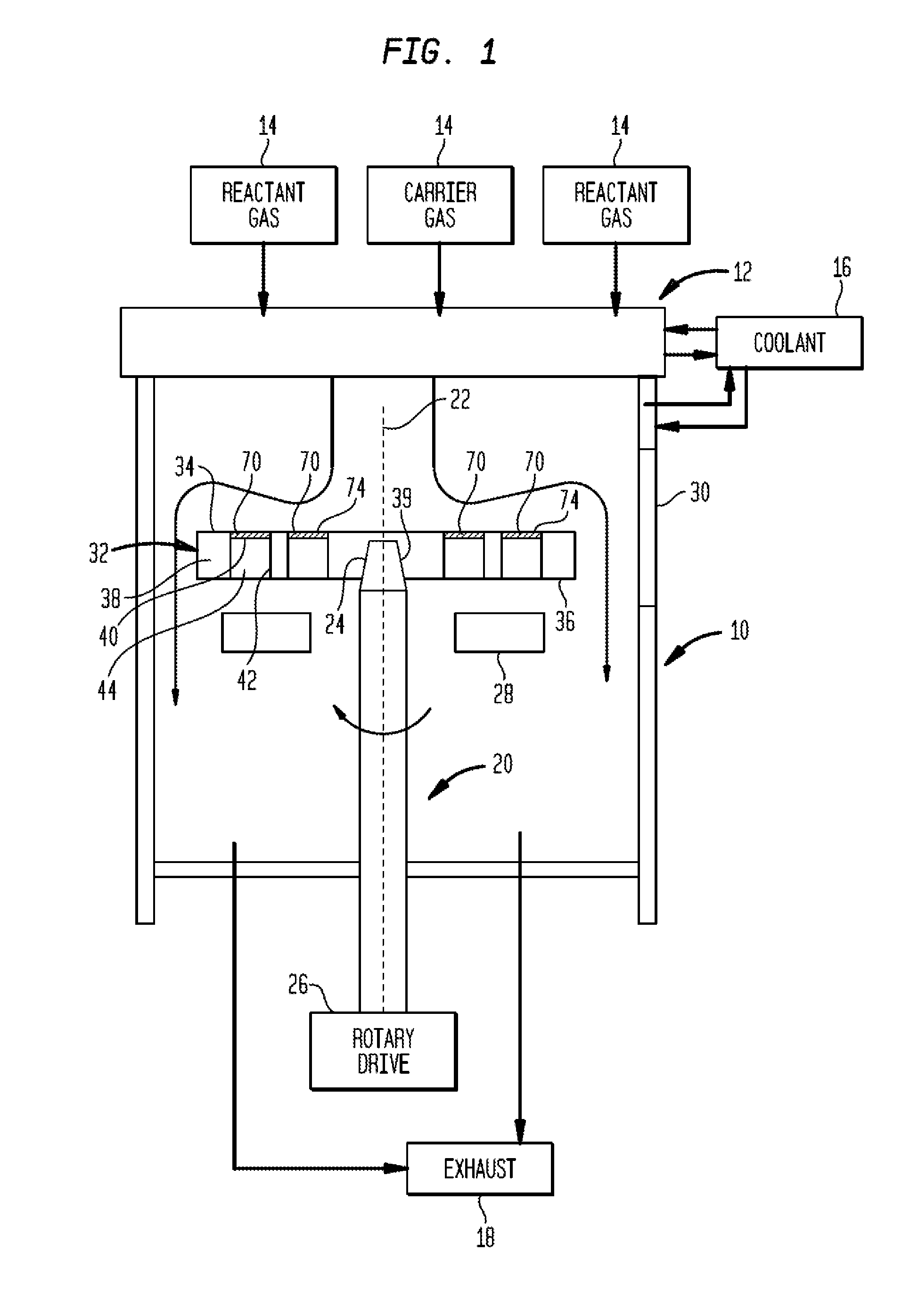

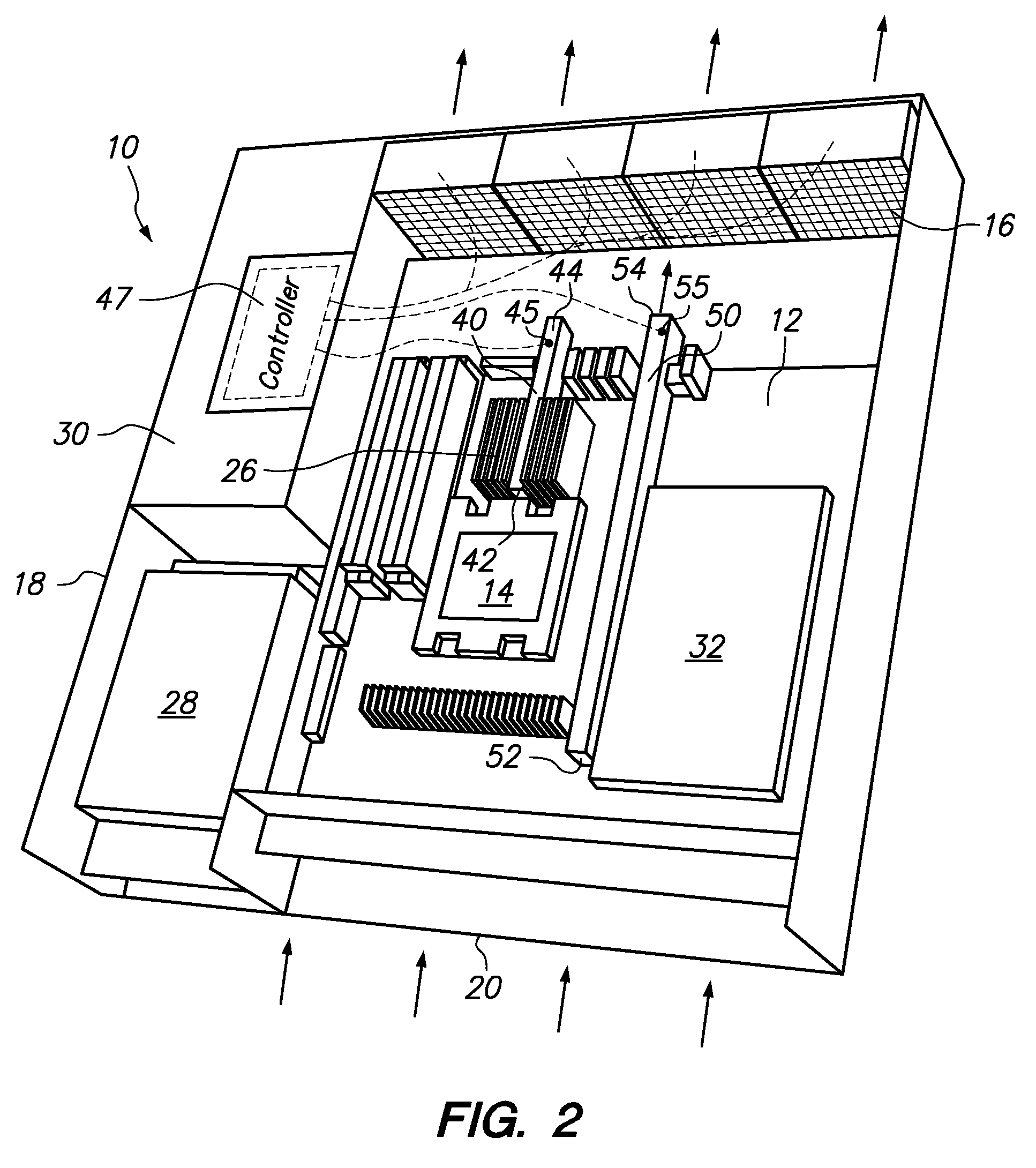

Wafer carrier having thermal uniformity-enhancing features

InactiveUS20140360430A1Heat flow is limitedAvoiding historic flow heating effectFrom chemically reactive gasesChemical vapor deposition coatingChemical vapor depositionThermal control

A wafer carrier assembly for use in a system for growing epitaxial layers on one or more wafers by chemical vapor deposition (CVD), the wafer carrier assembly includes a wafer carrier body formed symmetrically about a central axis, and including a generally planar top surface that is situated perpendicularly to the central axis and a planar bottom surface that is parallel to the top surface. At least one wafer retention pocket is recessed in the wafer carrier body from the top surface. Each of the at least one wafer retention pocket includes a floor surface and a peripheral wall surface that surrounds the floor surface and defines a periphery of that wafer retention pocket. At least one thermal control feature includes an interior cavity or void formed in the wafer carrier body and is defined by interior surfaces of the wafer carrier body.

Owner:VEECO INSTR

Composite cutting with optical ablation technique

InactiveUS20050077275A1Avoid delaminationAvoid thermal effectsWelding/soldering/cutting articlesLaser beam welding apparatusAudio power amplifierAblation Techniques

The present invention relates to methods and systems for dynamically controlled laser amplifier configuration for composite cutting includes the steps of generating an initial wavelength-swept-with-time optical pulse in an optical pulse generator, amplifying the initial optical pulse, compressing the amplified optical pulse to a duration of less than 10 picoseconds and applying the compressed optical pulse on the composite with an ablating energy density, to controllably remove a slice of material from the composite.

Owner:RAYDIANCE

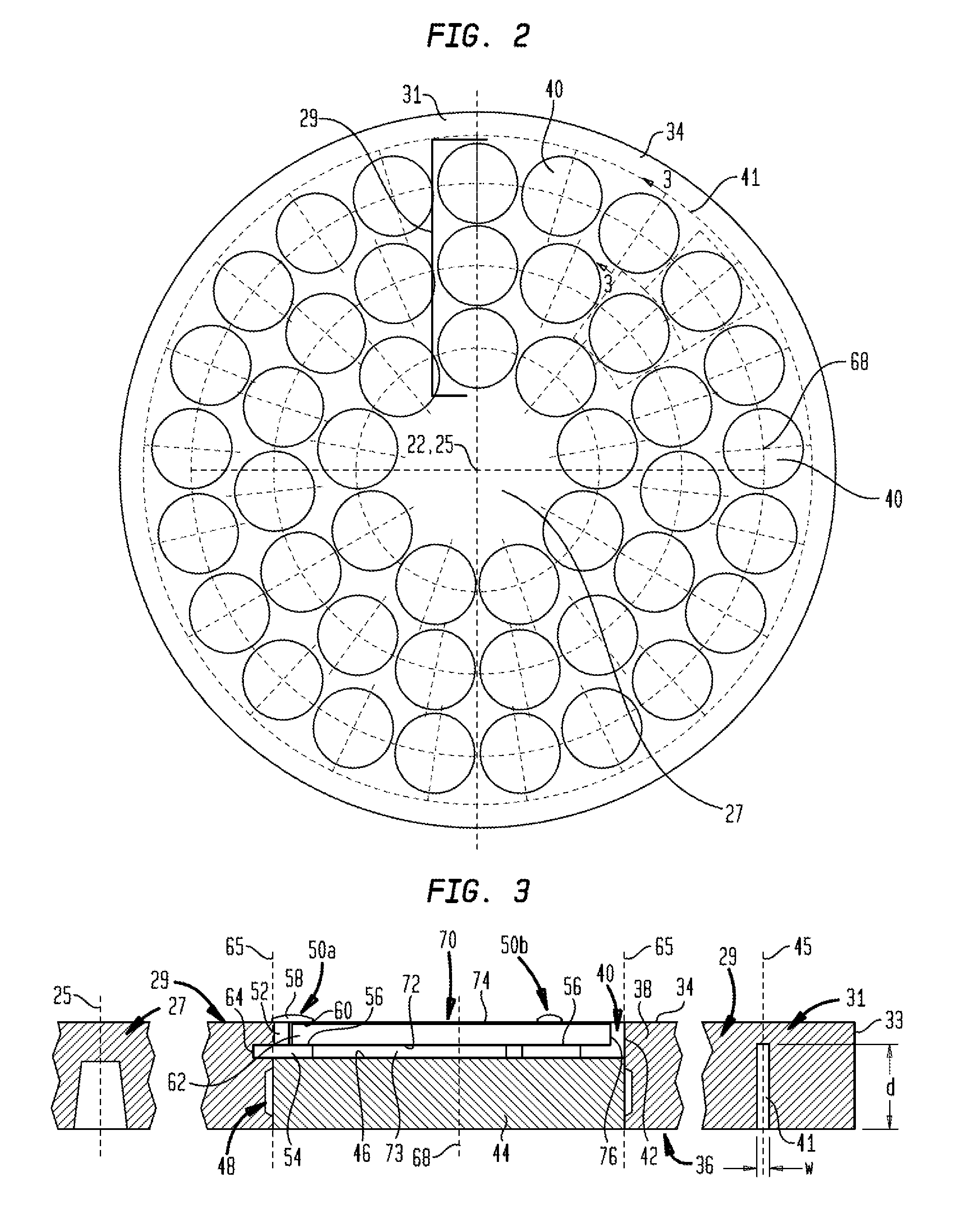

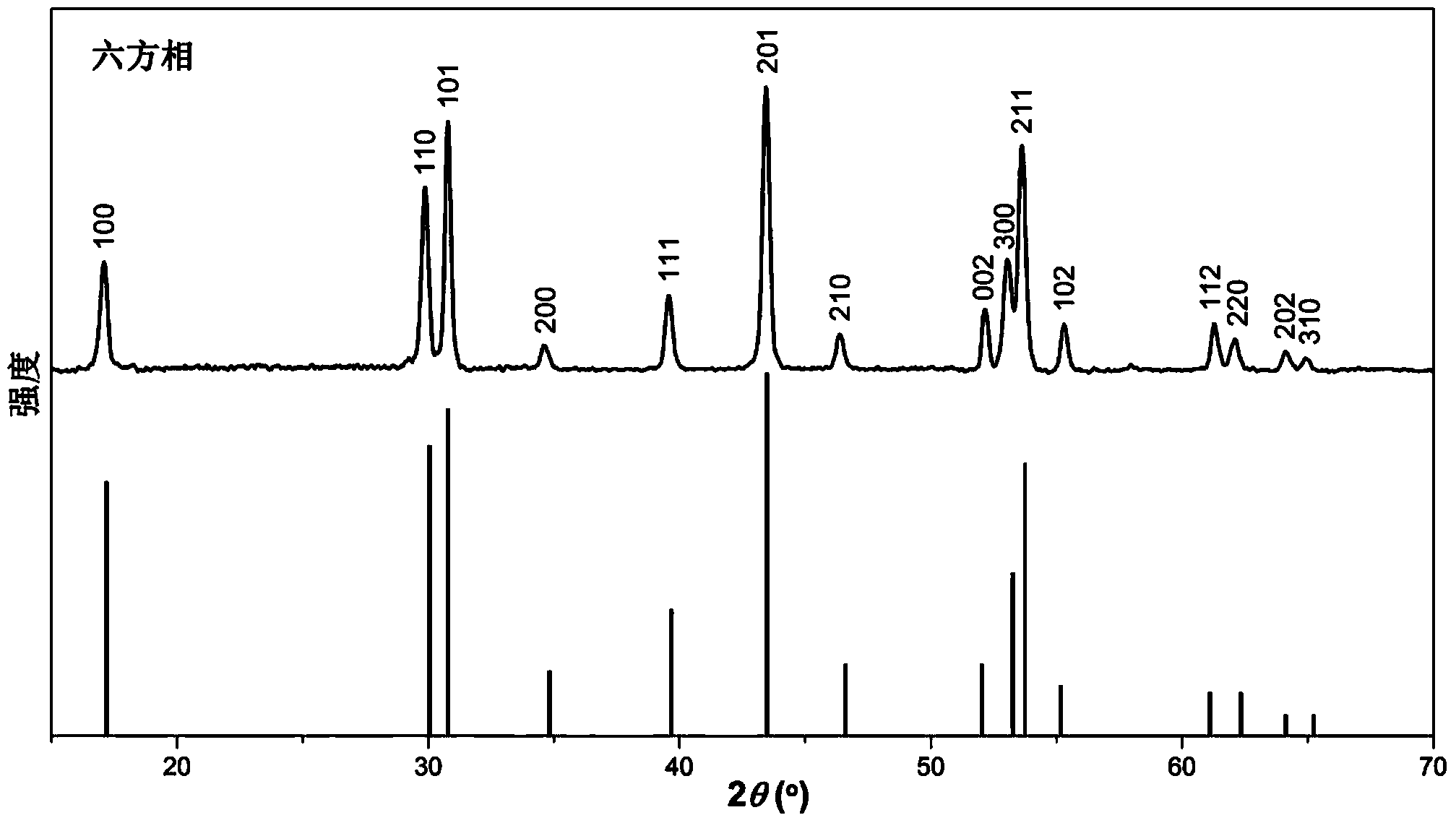

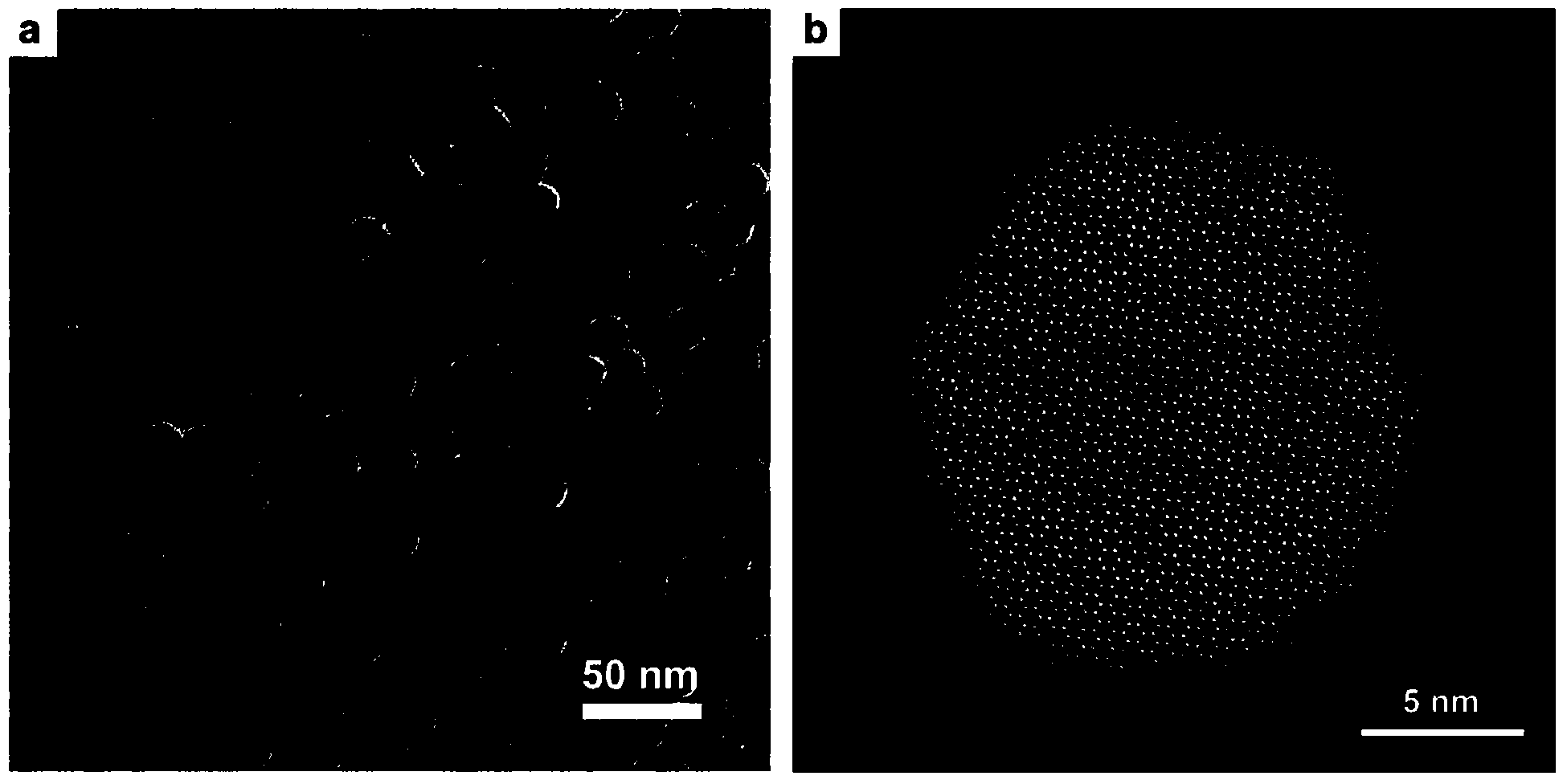

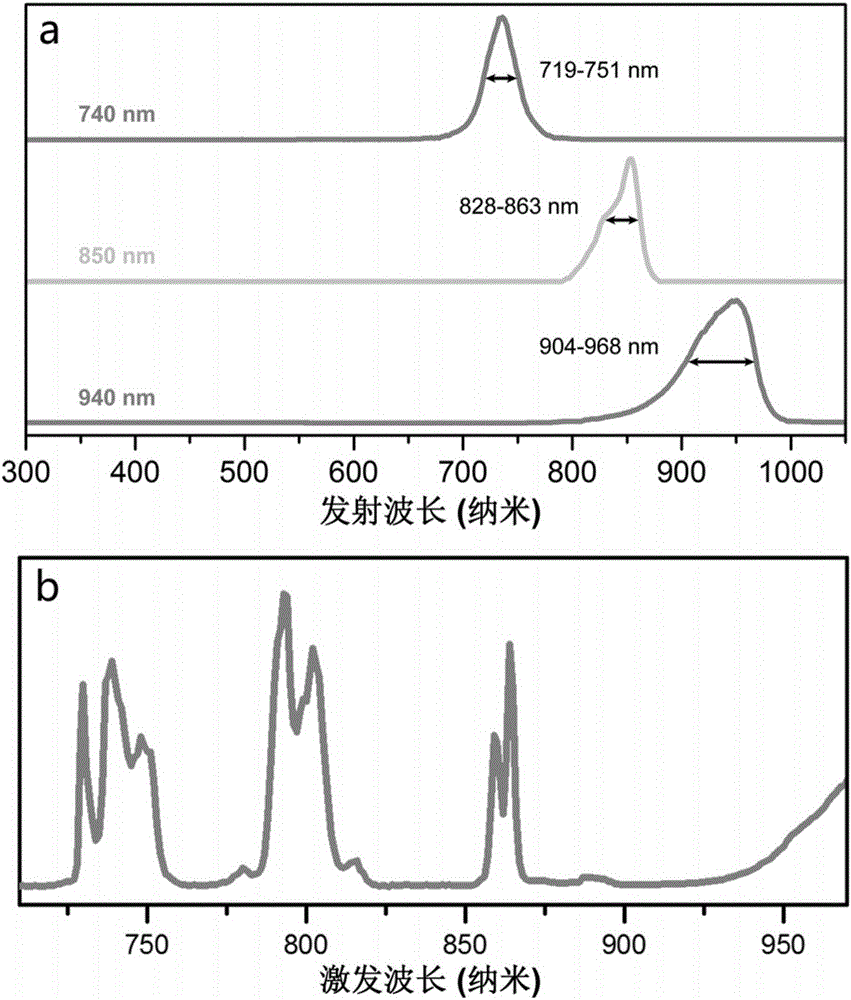

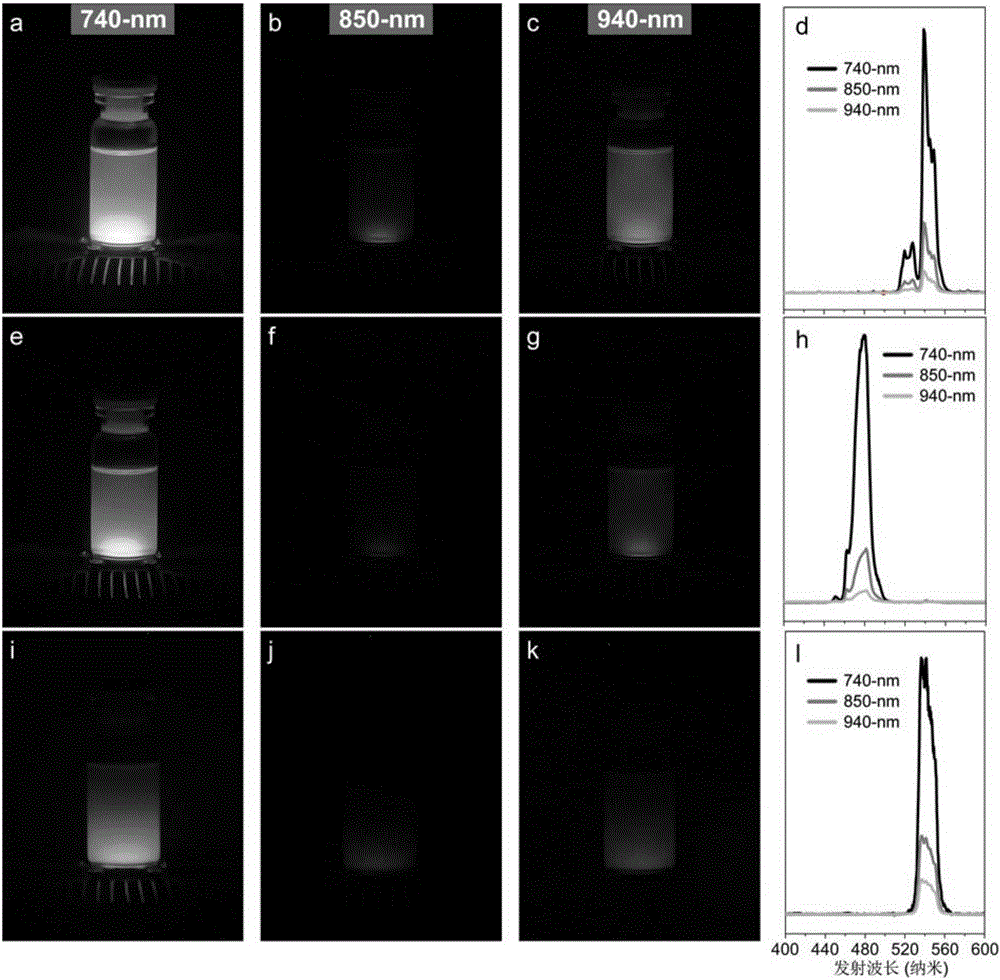

800-nanometer continuous laser excited rare earth upconversion nanoparticles (UCNPs), and preparation method and application thereof

ActiveCN103450875AEffective absorptionAvoid quenchingLuminescent compositionsFluorescenceNanoparticle

The invention provides 'core-shell-shell' rare earth upconversion nanoparticles (UCNPs) using Nd as a sensitizing agent. The rare earth UCNPs are characterized in that the shell layer of the rare earth UCNPs contains Nd<3+> and each layer contains Yb<3+>. The special microscopic nanostructure solves the problem about the quenching effect on upconversion fluorescence in an Nd doping process, so bright upconversion fluorescence can be obtained. Compared with the traditional Yb-sensitized UCNPs, the Nd-sensitized UCNPs have higher infrared absorption intensity so as to greatly improve upconversion efficiency and fluorescence. The Nd-sensitized UCNPs adopt 800-nanometer instead of 980-nanometer laser as an exciting light source, so the Nd-sensitized UCNPs have smaller overheating effect and stronger biological tissue penetrating power. Therefore, the novel rare earth upconversion material is expected to be widely applied in the field of biomedicines.

Owner:INST OF CHEM CHINESE ACAD OF SCI

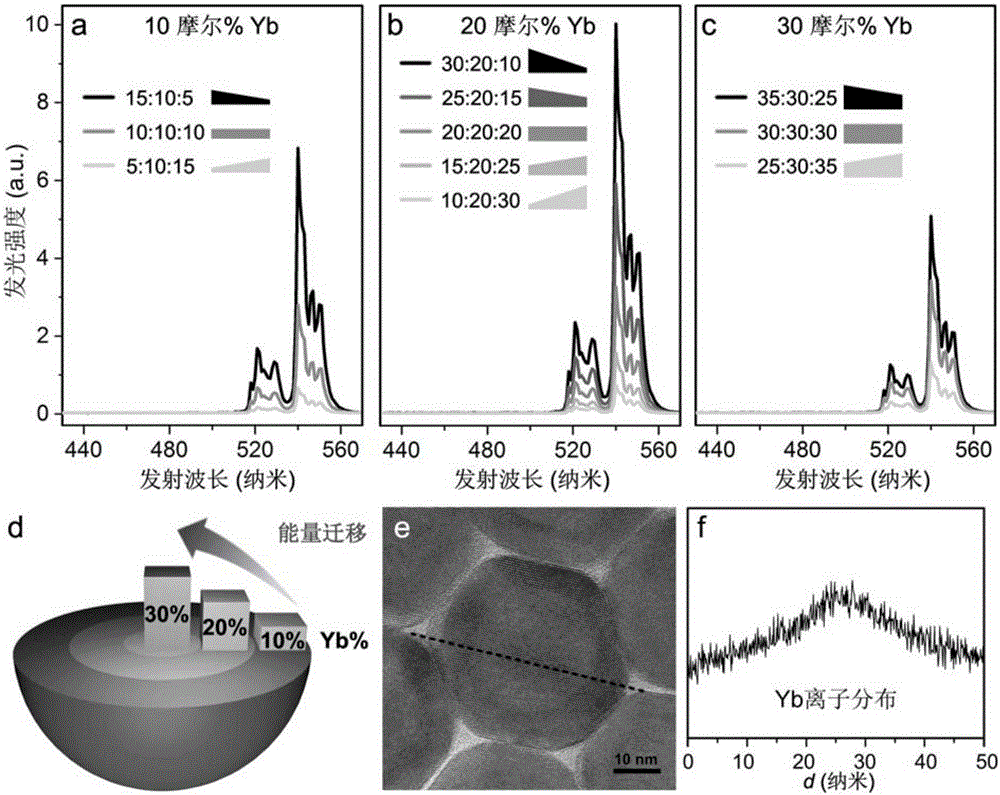

Rare earth upconversion nanoparticles, preparation method and uses thereof

ActiveCN105176515AImproving the Quantum Yield of Upconversion LuminescenceUp-conversion Luminous IntensityAnalysis by material excitationLuminescent compositionsQuantum yieldUpconversion luminescence

The present invention relates to rare earth upconversion nanoparticles, a preparation method and uses thereof, wherein the rare earth upconversion nanoparticles sequentially comprise an activator shell layer, an energy transfer agent shell layer and a sensitizing agent shell layer from inside to outside, each layer contains Yb<3+>, and the doping concentration of Yb<3+> is gradually reduced from inside to outside. According to the present invention, the ytterbium ion doping concentration gradient is set to effectively transfer the excitation state energy of the sensitizing agent to the activator, such that the upconversion luminescence quantum yield of the rare earth upconversion nanoparticles is effectively improved and achieves 0.22%, and the 800 nm continuous laser excitation at the excitation light source intensity of 2W / cm<2> is achieved; and the rare earth upconversion nanoparticles can produce strong upconversion luminescence under the infrared LED light source excitation, and the potable detection equipment based on the rare earth upconversion nanoparticle luminescence probe can be designed by using the unique packaging and array technology of the infrared LED light source so as to further expand the application of the upconversion luminescence material in the biomedical field.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

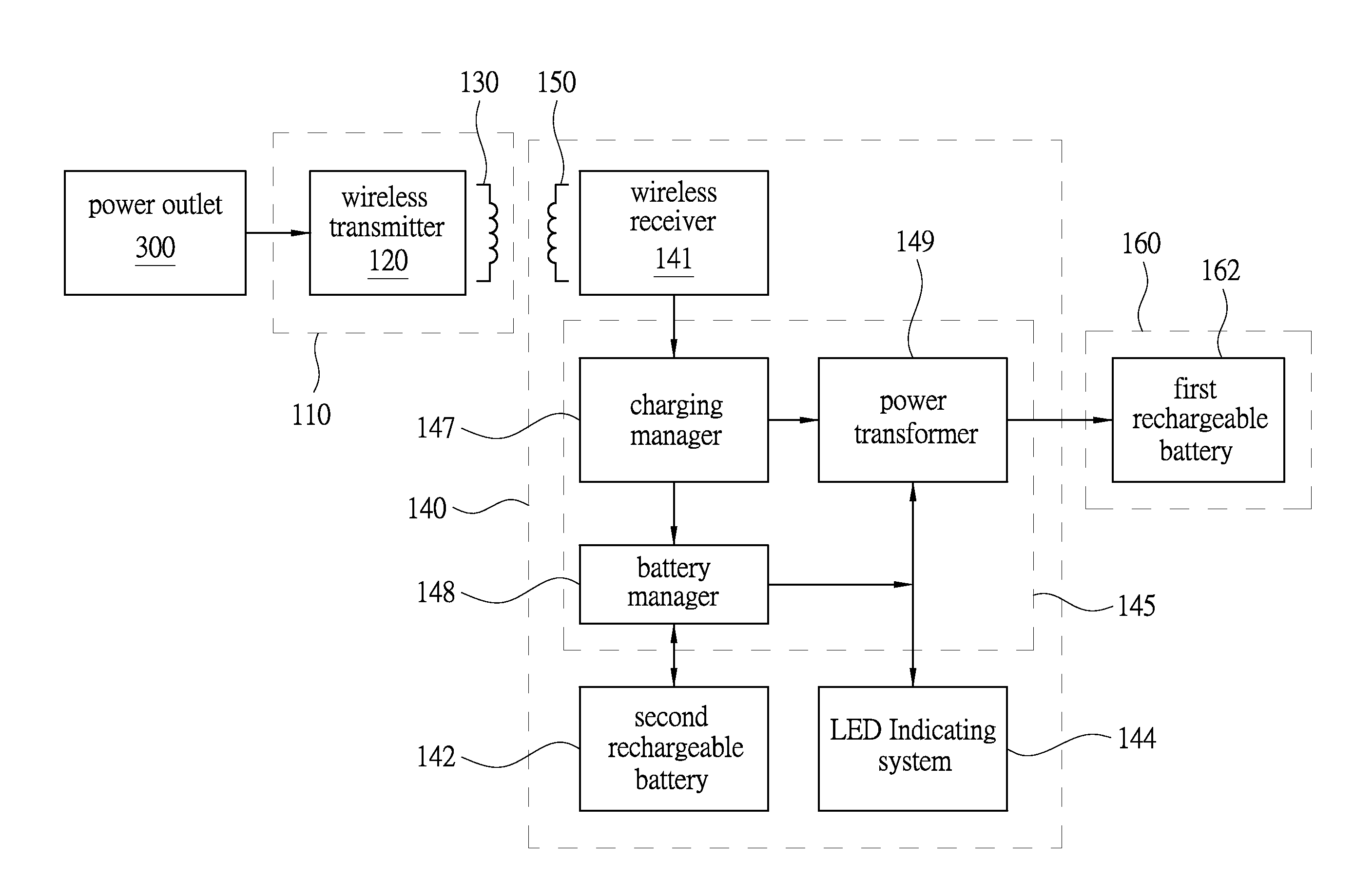

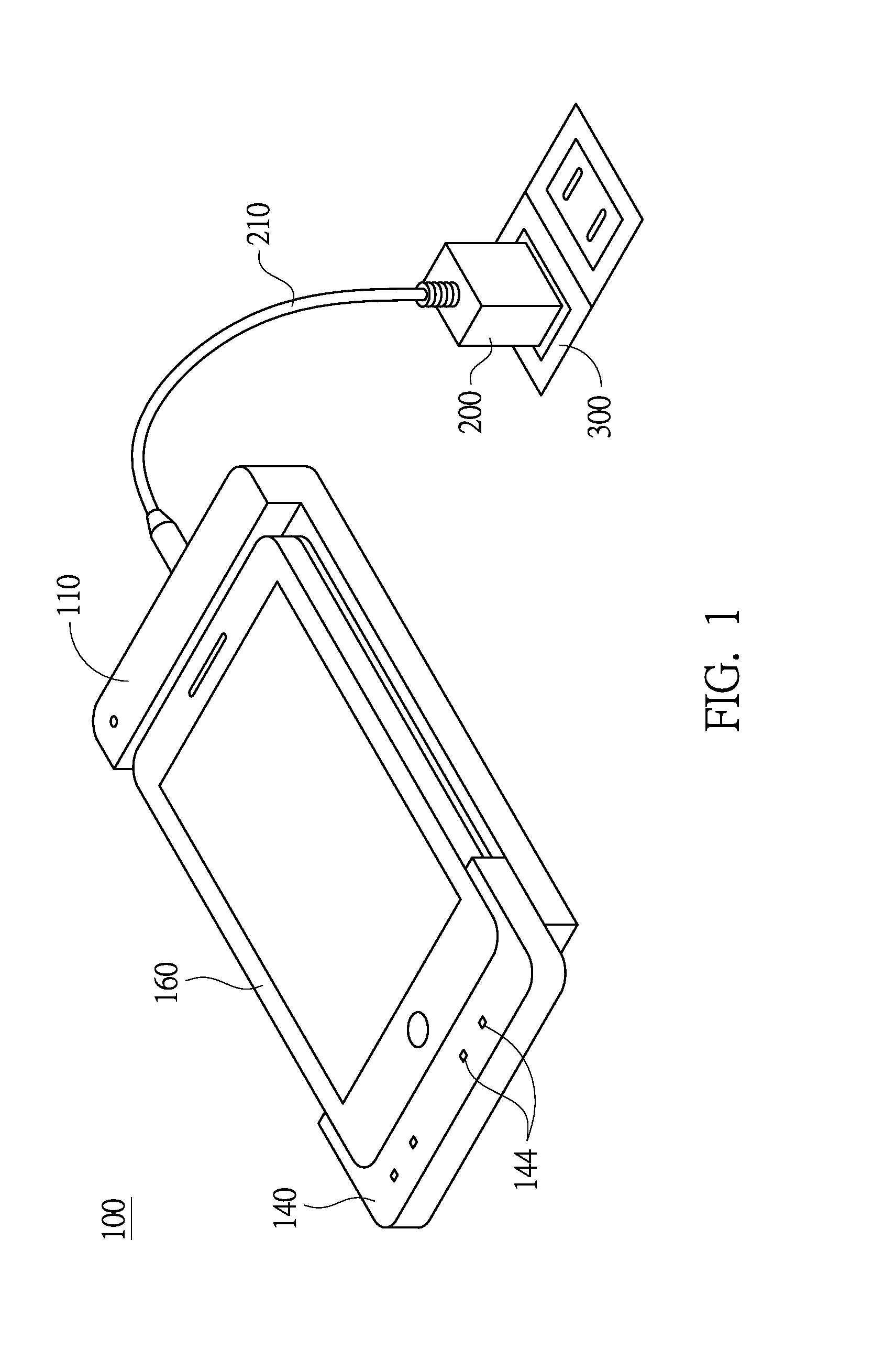

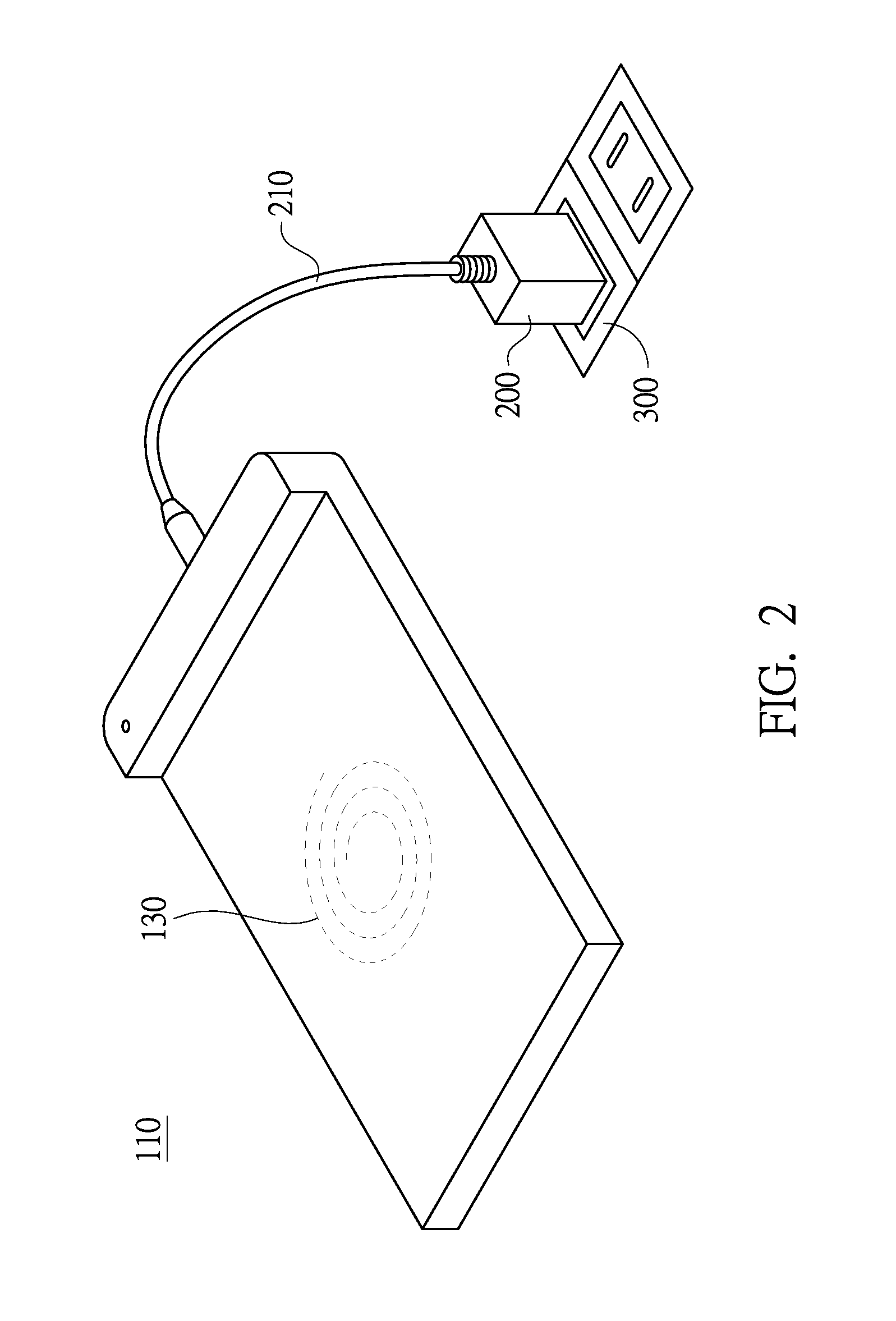

Wireless power charger

InactiveUS20150050881A1Good choiceImprove securityPower managementNear-field transmissionElectricityElectrical battery

The invention provides a wireless power charger comprising a wireless and a power bank. The wireless charging base including a wireless transmitter configured to transmit an identification signal. The power bank is electrically connected to a portable device including a first rechargeable battery, and the power bank including a second rechargeable battery, a wireless receiver, and a control unit. The wireless receiver is configured to receive the identification signal and transmit a response signal to the wireless transmitter while the power bank is placed onto the wireless charging base. The control unit is configured to control and output the power to the first rechargeable battery or the second rechargeable battery.

Owner:QUANTA COMPUTER INC

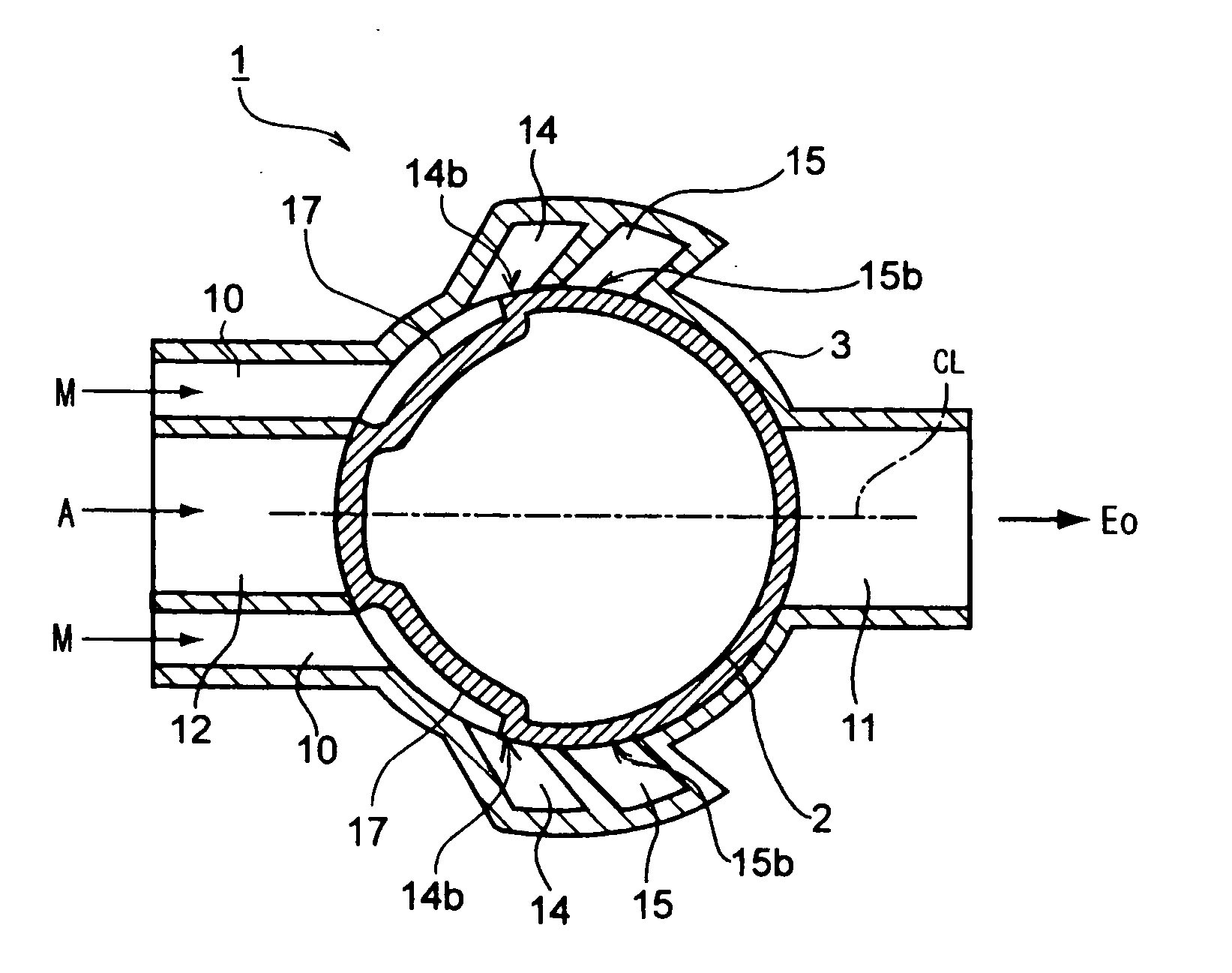

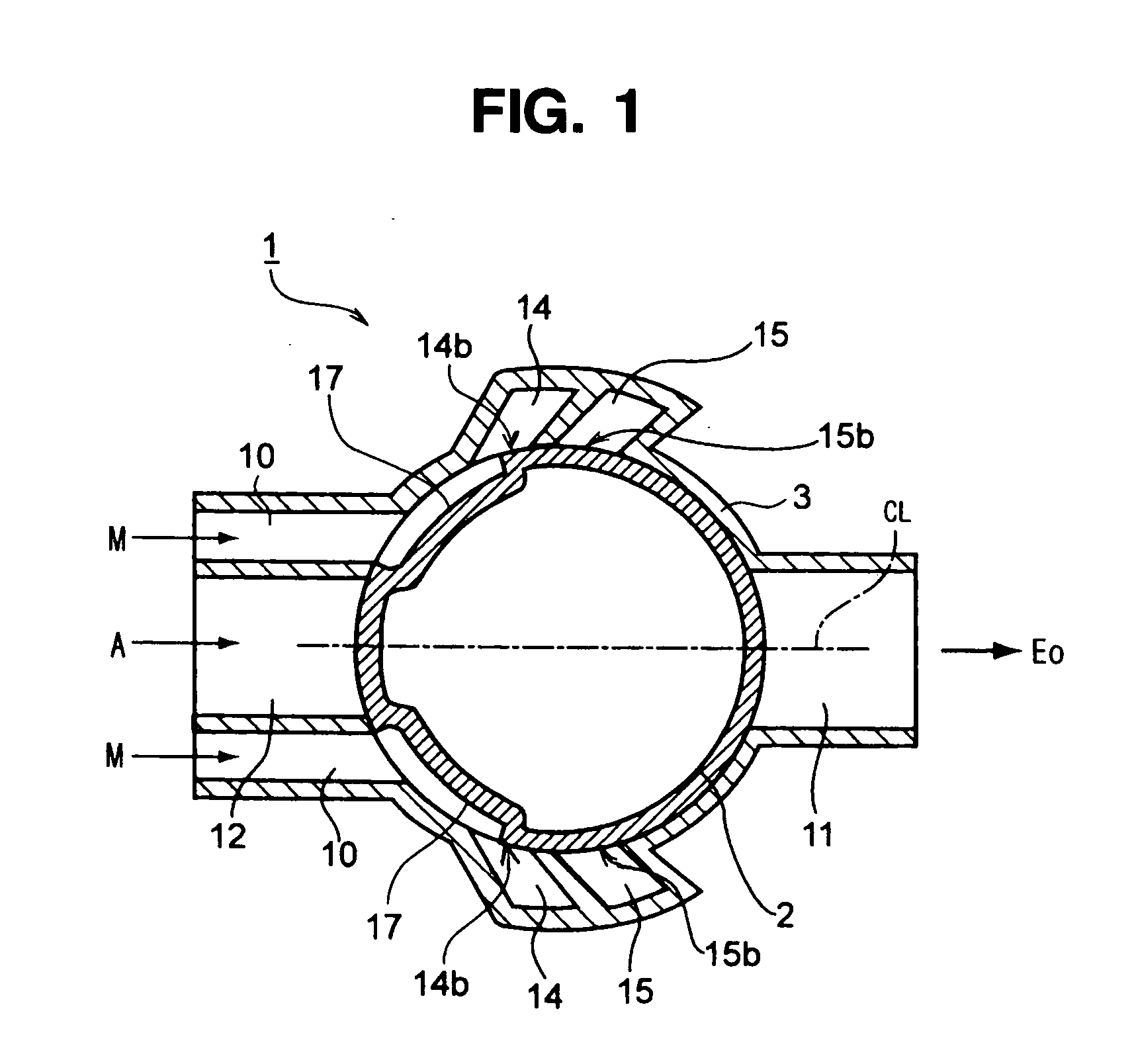

Stratified-scavenging two-stroke internal combustion engine

InactiveUS20070028868A1Effective preventionEfficient removalCylinder headsCombustion enginesCombustionEngineering

In a stratified-scavenging two-stroke internal combustion engine, air-fuel mixture outlets (14b) and air outlets (15b) are provided on either side of a cylinder (3), and the air-fuel mixture outlets (14b) and the air outlets (15b) communicate with a crank chamber (6) via air-fuel mixture passageways (14) and air passageways (15). The crank chamber (6) is charged with air from an air-feeding port (12). An inlet port (10) is disposed on either side of the air-feeding port (12), and mixture (M) from each inlet port (10) is charged into the air-fuel mixture passageways (14) via air-fuel mixture introduction recesses (17) formed in the outer surface of a piston (2). The air outlets (15b) are positioned nearer to the exhaust port (11), while the air-fuel mixture outlets (14b) are positioned nearer to the inlet ports (10). In the exhaust stroke, the cylinder chamber (7) is scavenged via air (A) supplied from the crank chamber (6) through the air outlets (15b) and interposed between the combustion gas (E) in the cylinder chamber (7) and the mixture (M) from the air-fuel mixture outlets (14b).

Owner:YAMABIKO CORP

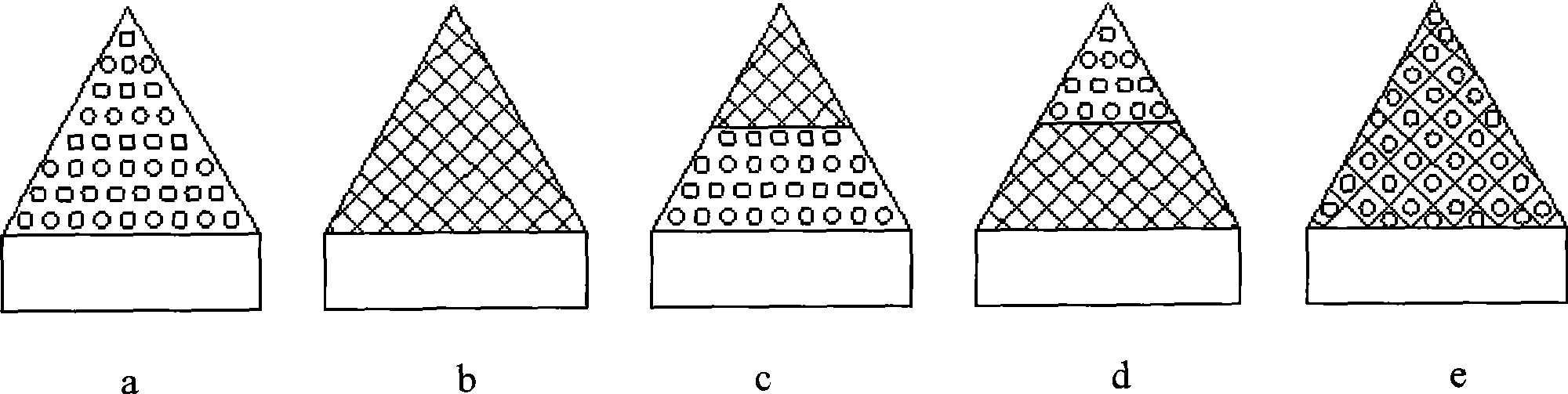

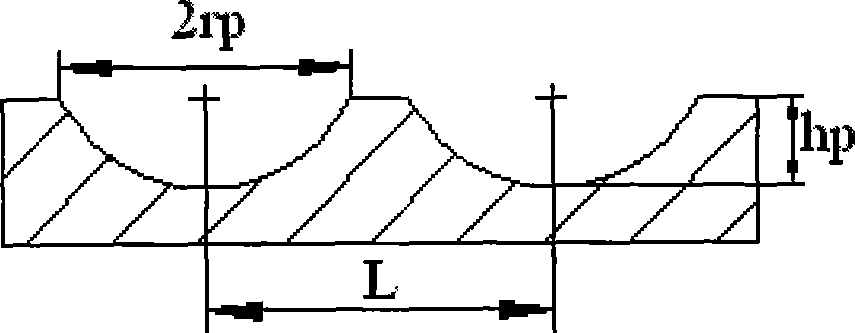

Micro-molding finial on surface prepared by laser and preparation method thereof

InactiveCN101376176AImprove processing qualityImprove wear resistance and anti-wear performanceTailstocks/centresLaser beam welding apparatusEngineeringMicroscopic scale

The invention provides a laser surface micro-processing tip and the preparation method thereof. The laser surface micro-processing tip is a metallographic structure, on the tip surface of which a micro-geometrical structure composed of a micro-pit or a cross groove and the combination thereof is formed, wherein the geometric parameters of the pit-shaped micro-geometrical structure are as follows: the pit radius rp is equal to 20 to 80 Mum, the pit depth hp is equal to 2 to 20 Mum, and the adjacent pits space L is equal to 50 to 200 Mum; the geometric parameters of the cross groove-shaped micro-geometrical structure are as follows: the groove width B is equal to 50 to 150 Mum, the groove depth is equal to 5 to 20 Mum, the adjacent groove space D is equal to 400 to 600 Mum, and the groove inclination angle A is equal to 30 DEG to 75 DEG. Since the tip surface is subjected to the laser micro-processing treatment, the laser surface micro-processing tip remarkably improves the wear-resisting performance, improves the lubricating conditions of the tip in the work-piece center hole and reduces the frictional noise, and at the same time, the stored lubricant can be effectively cooled, thereby prolonging the service life of the tip.

Owner:JIANGSU UNIV

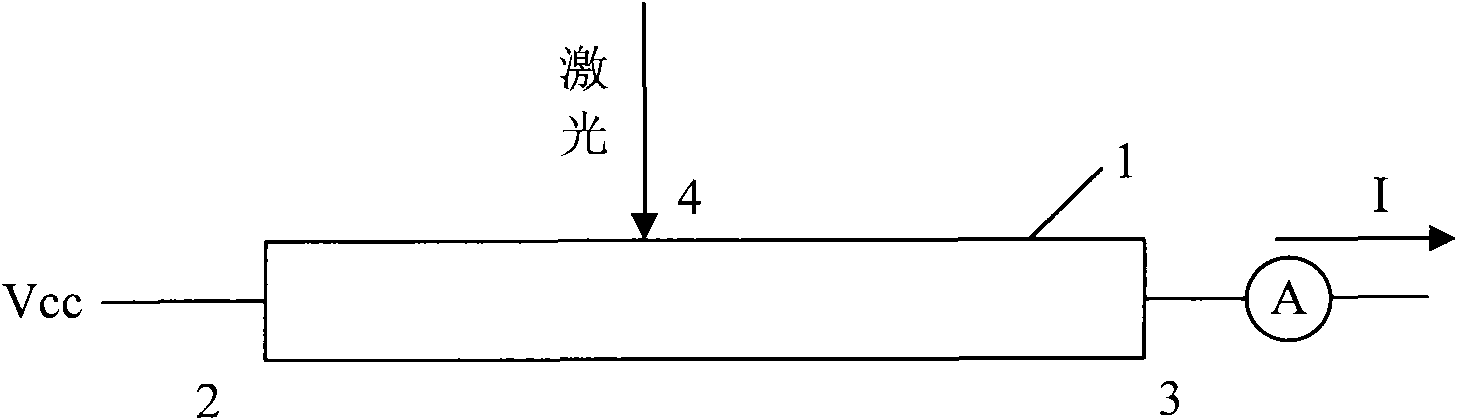

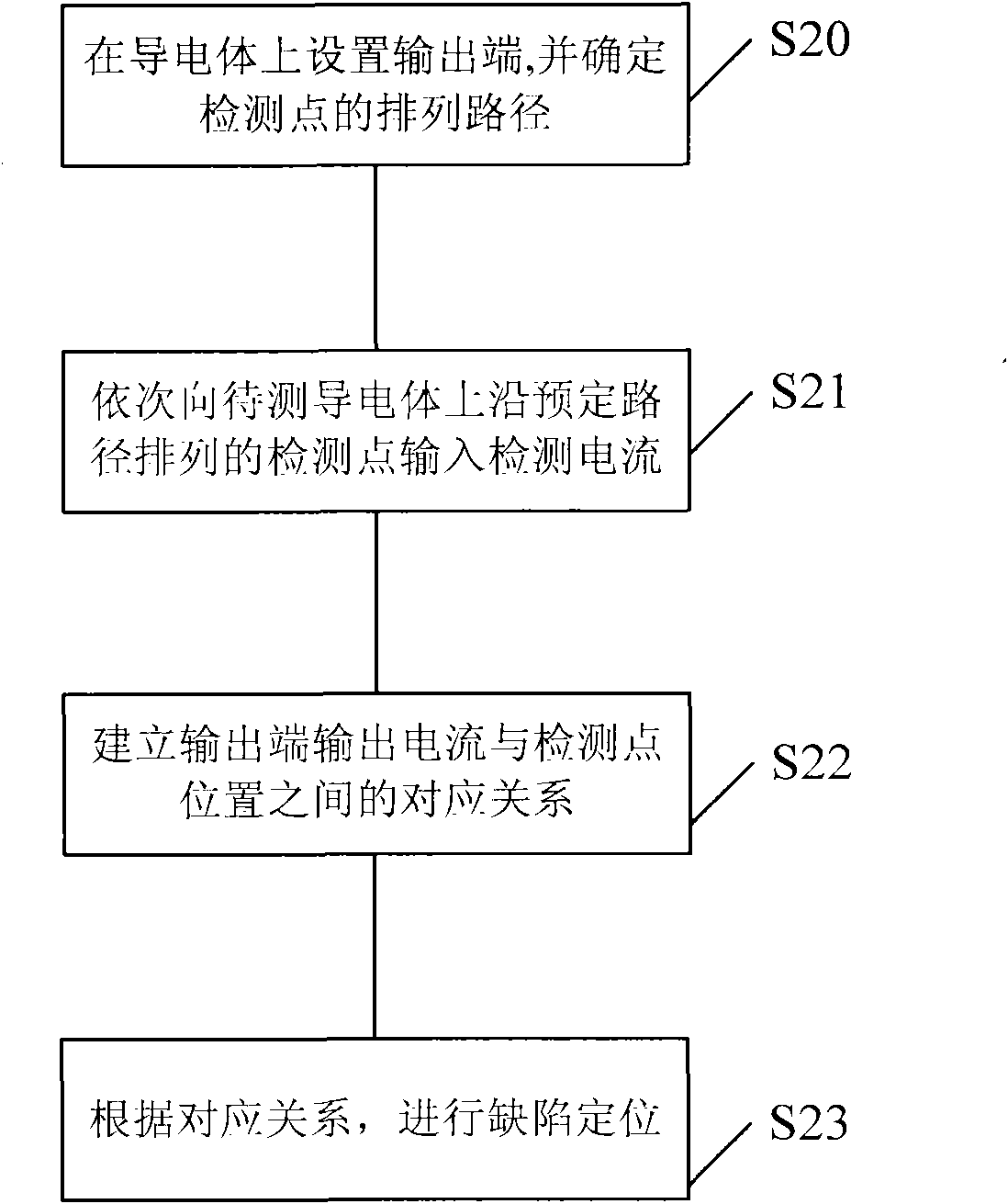

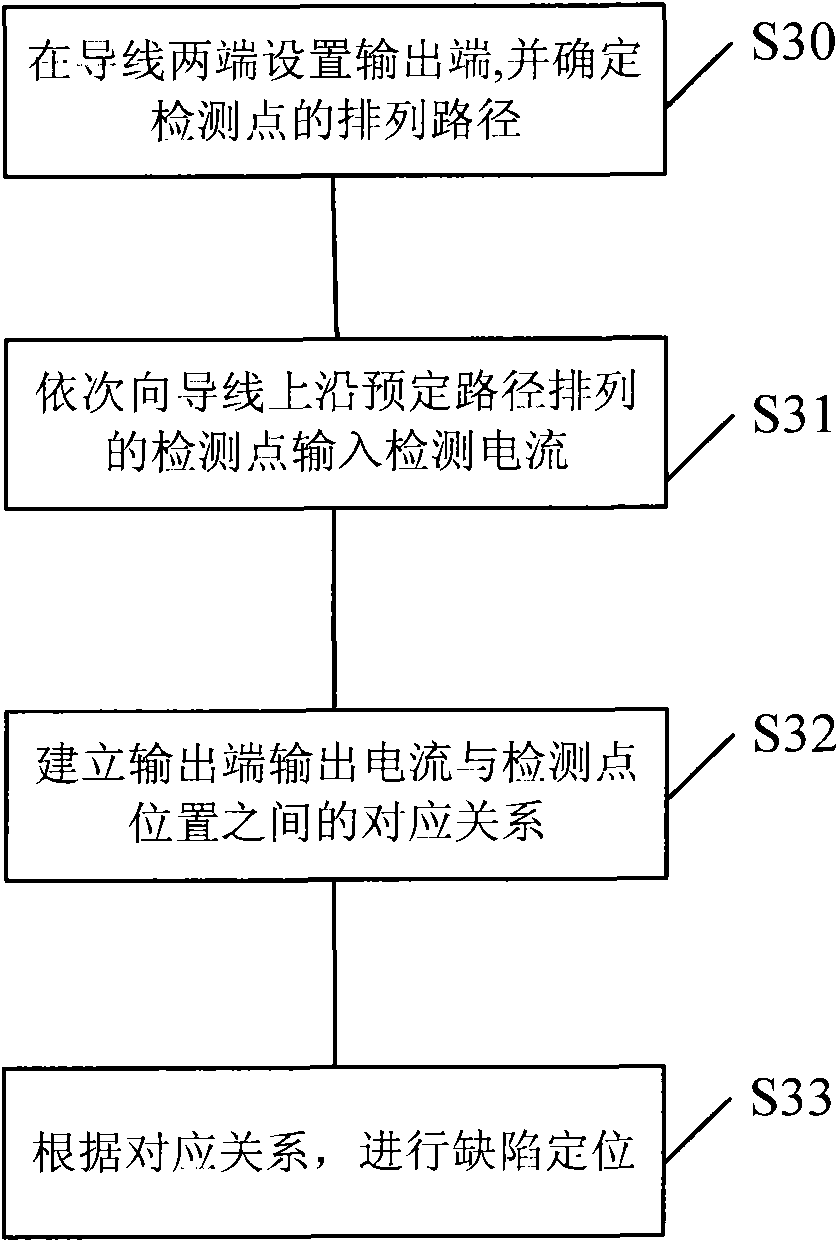

Failure detection method and device

InactiveCN101958262AAvoid sizeAvoid thermal effectsSemiconductor/solid-state device testing/measurementCurrent/voltage measurementEngineeringFailure analysis

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

High-temperature alloy disc die forging method

ActiveCN104707929AReduce projected areaReduced tonnage requirementsWheelsHeating/cooling devicesSuperalloyTurbine

The invention belongs to the technical field of high-temperature alloy die forging, and particularly relates to a high-temperature alloy turbine disc forge piece organization and performance thermal machining method. A performing die forging plus bearizing plus die forging method includes the steps that the specification and size of the wild shape required by finish forging are determined, a finish forging die and a performing die forging die are prepared, performing die forging is conducted, bearizing is conducted till the wild shape required by the finish forging is formed, and the finish forging is conducted; an annular blank is determined according to the forge piece shape to serve as the wild shape; first-fire forging of a titanium alloy bar is forged through the performing die, and the heating number integrates traditional upsetting, punching and saddling processes; preformed forge piece core materials generated after forming die forging is conducted are removed; bearizing is conducted on a performing forge piece till the wild shape size required by finish forging is formed; one-fire finish forging is conducted till forming is finished. According to the method, the problems that the final forge piece of the high-temperature alloy turbine disc forge piece is uneven in organization and residual stress due to the blank making process of more heating numbers and smaller deformation are avoided.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Method for manufacturing CNT (carbon nanotube) composite transmission conductor

InactiveCN101948988AImprove mechanical propertiesImprove thermal performanceSingle bars/rods/wires/strips conductorsInsulated cablesMultiwalled carbonThermal deformation

The invention discloses a method for manufacturing a CNT (carbon nanotube) composite transmission conductor, which comprises the following steps: filling MCNT (multiwalled carbon nanotube) powder accounting for 1 to 7 percent of the total mass into small holes uniformly drilled on electrotechnical aluminium blocks; stacking two aluminium blocks in which the MCNT powder has been filled inversely by using a blind-hole method; after the two aluminium blocks are prepared into composite materials through a friction extrusion process, carrying out tandem rolling and drawing on the composite materials so as to prepare the composite materials into required CNT / aluminum based composite material round wires; and finally, stranding the round wires by a wire twisting machine, then through a back-twisting stress eliminating device, obtaining a single-stranded CNT composite transmission conductor. The method of the invention has the advantages: 1) the coefficient of linear expansion of the conductor is small, and the thermal deformation resistance performance is strong, the method can reduce the influence of the temperature on sag change, improve the sag characteristics, improve the security of overhead lines, and reduce the construction cost of the lines; 2) the method is helpful to improve the conductivity of the conductor along the line, and further reduce the transmission losses; and 3) the process is relatively simple, and the loosening and skid phenomenon and the like of composite cores and aluminium strands due to various reasons do not exist.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

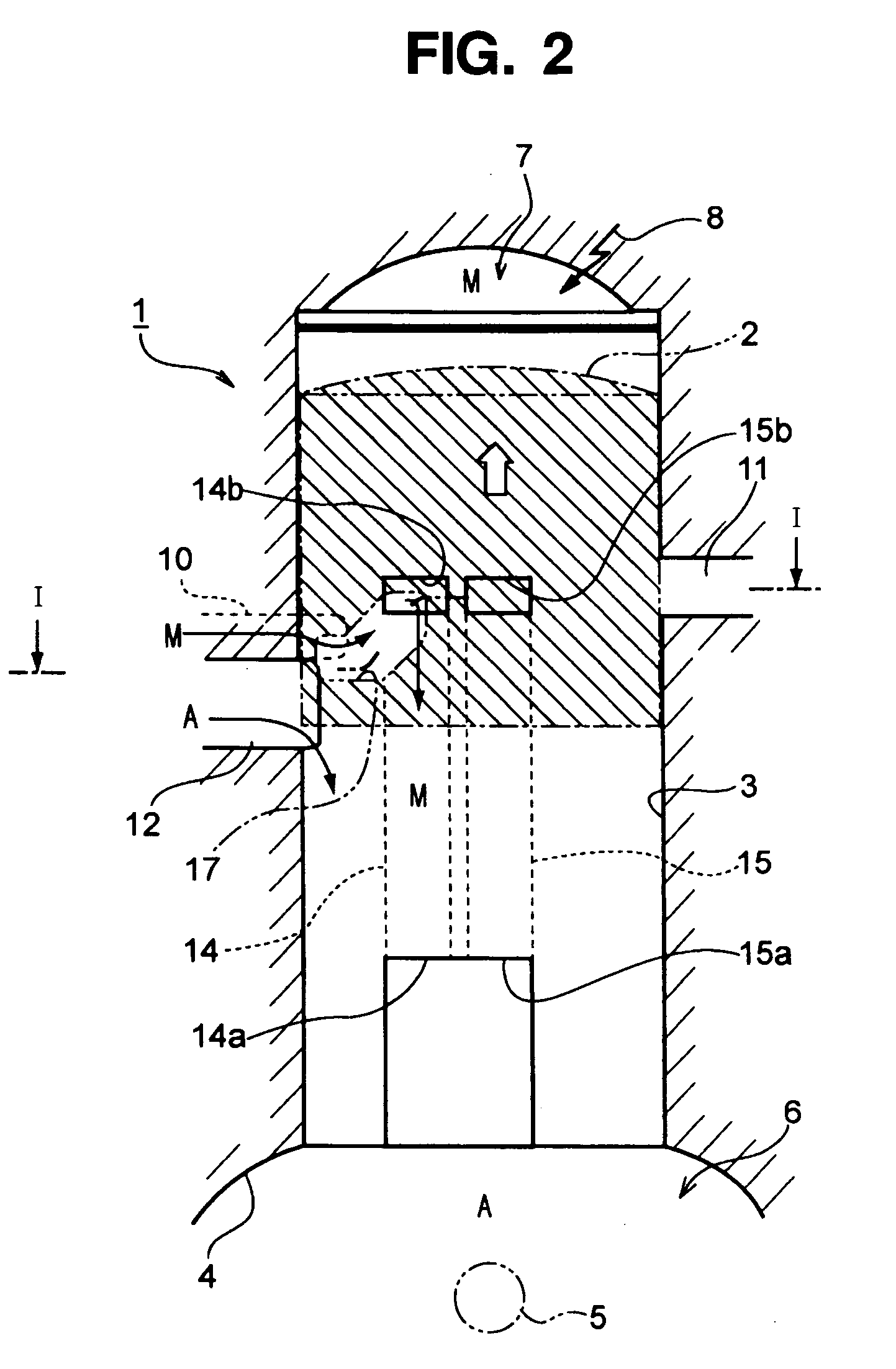

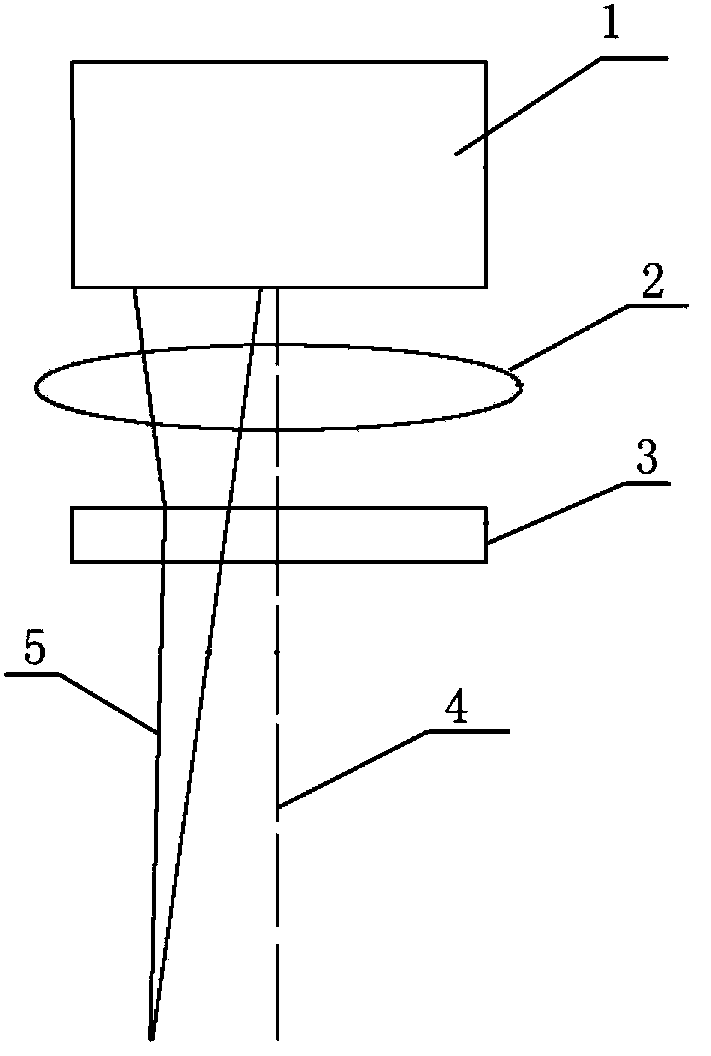

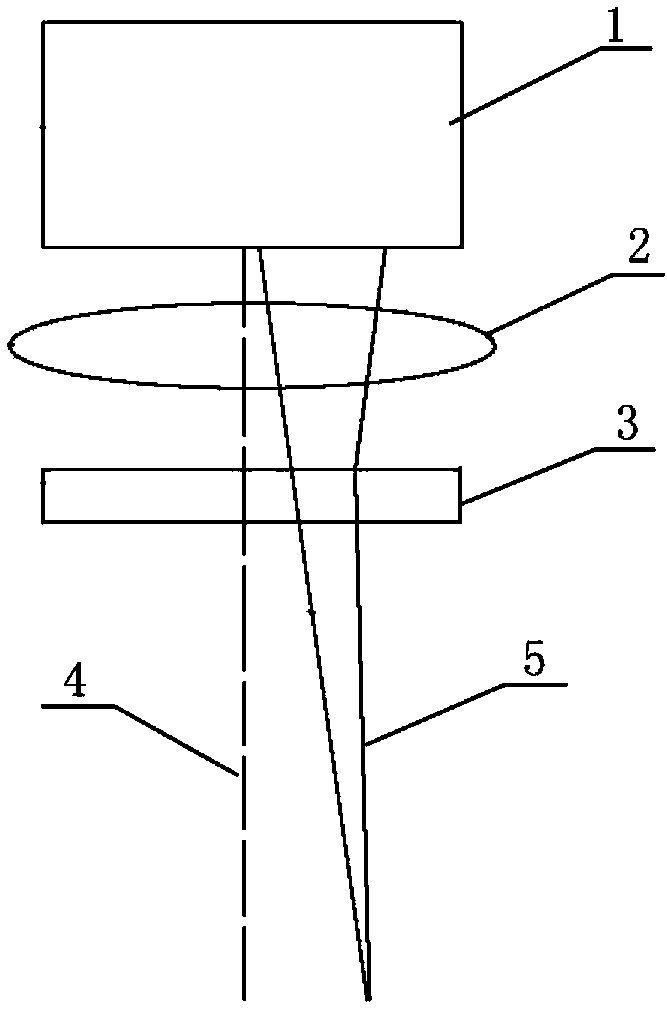

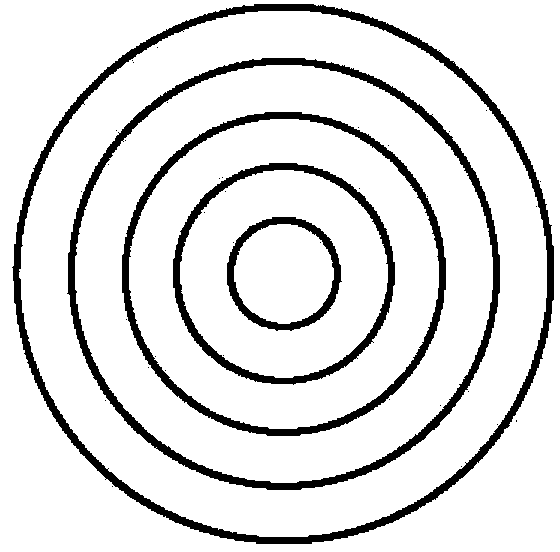

Device for machining small hole by using ultrashort pulse laser and small hole machining method

The invention provides a device for machining small holes by using ultrashort pulse laser and a small hole machining method. The device comprises a scanning galvanometer, a laser scanning focus lens and a wedge lens. The scanning galvanometer, the laser scanning focus lens and the wedge lens are arranged on the same central axis. A laser beam rotates around the central axis along a concentric circle track through the scanning galvanometer, is focused through the laser scanning focus lens and is deflected far away from the central axis through the wedge lens. The wedge lens and the laser beam rotate synchronously to keep the inclination angle of the laser beams to be the same. The device for machining small holes by using ultrashort pulse laser and the small hole machining method have the advantages that the small hole machining depth is increased and the machining quality and stability of the small holes are improved.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

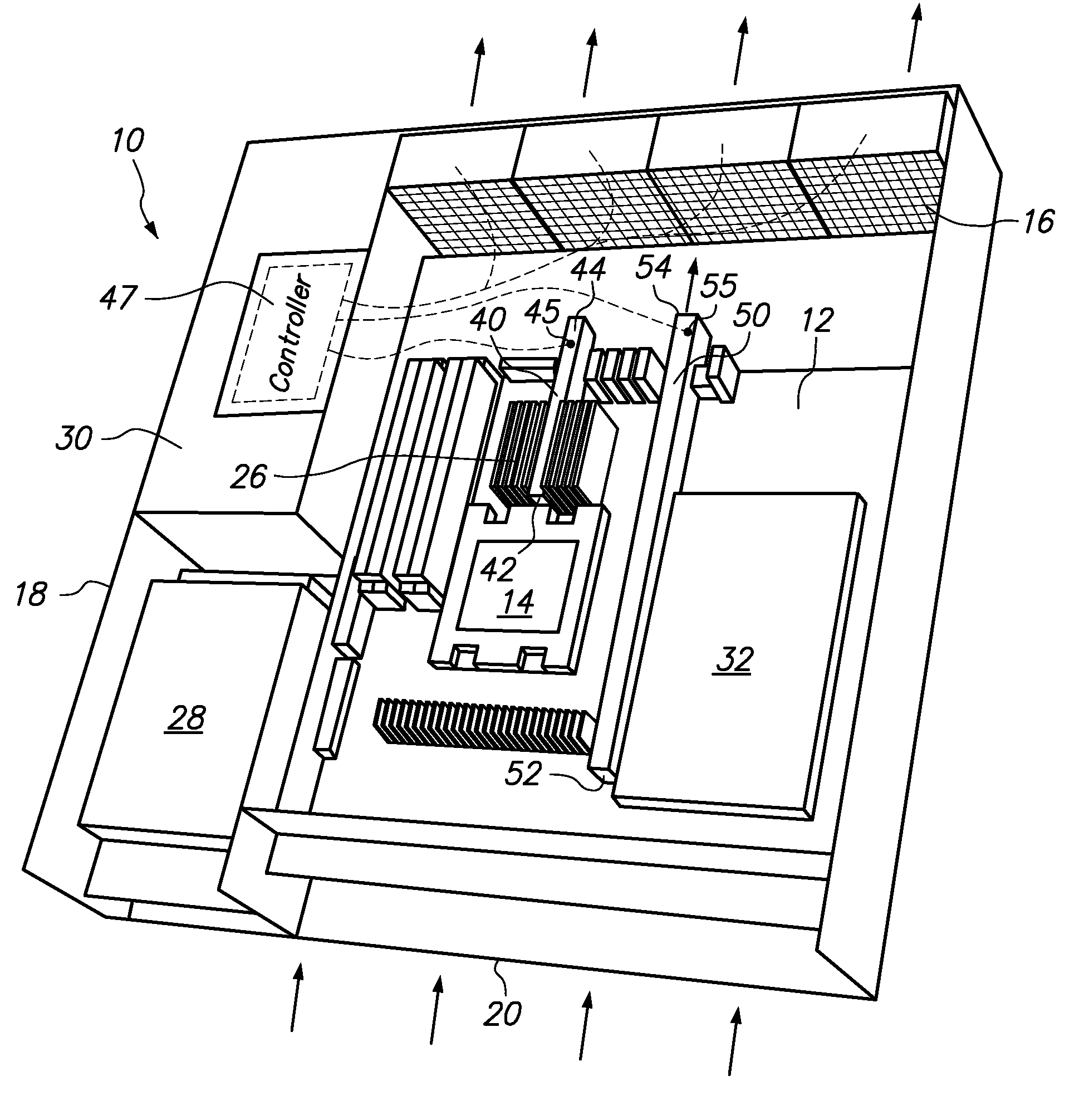

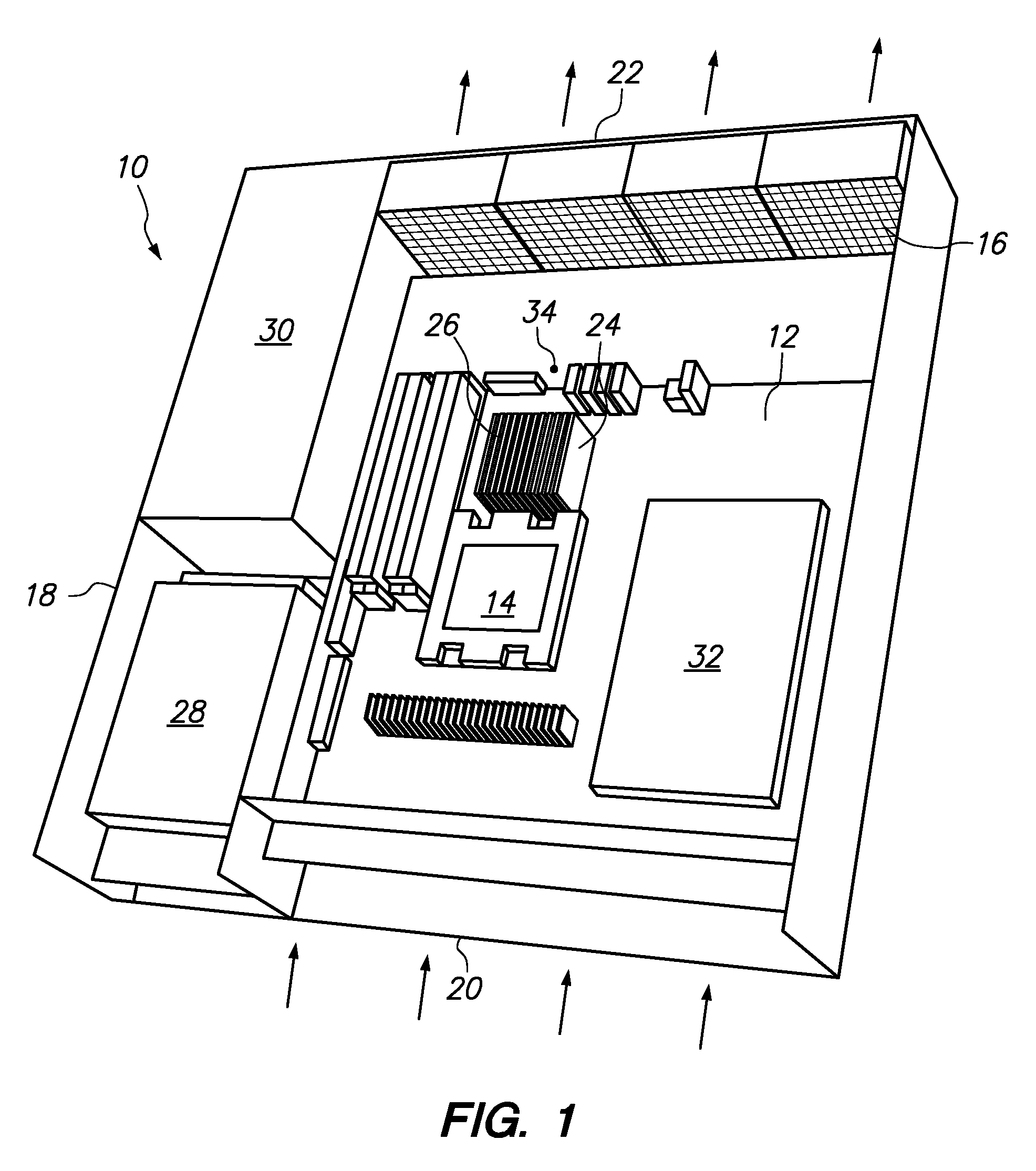

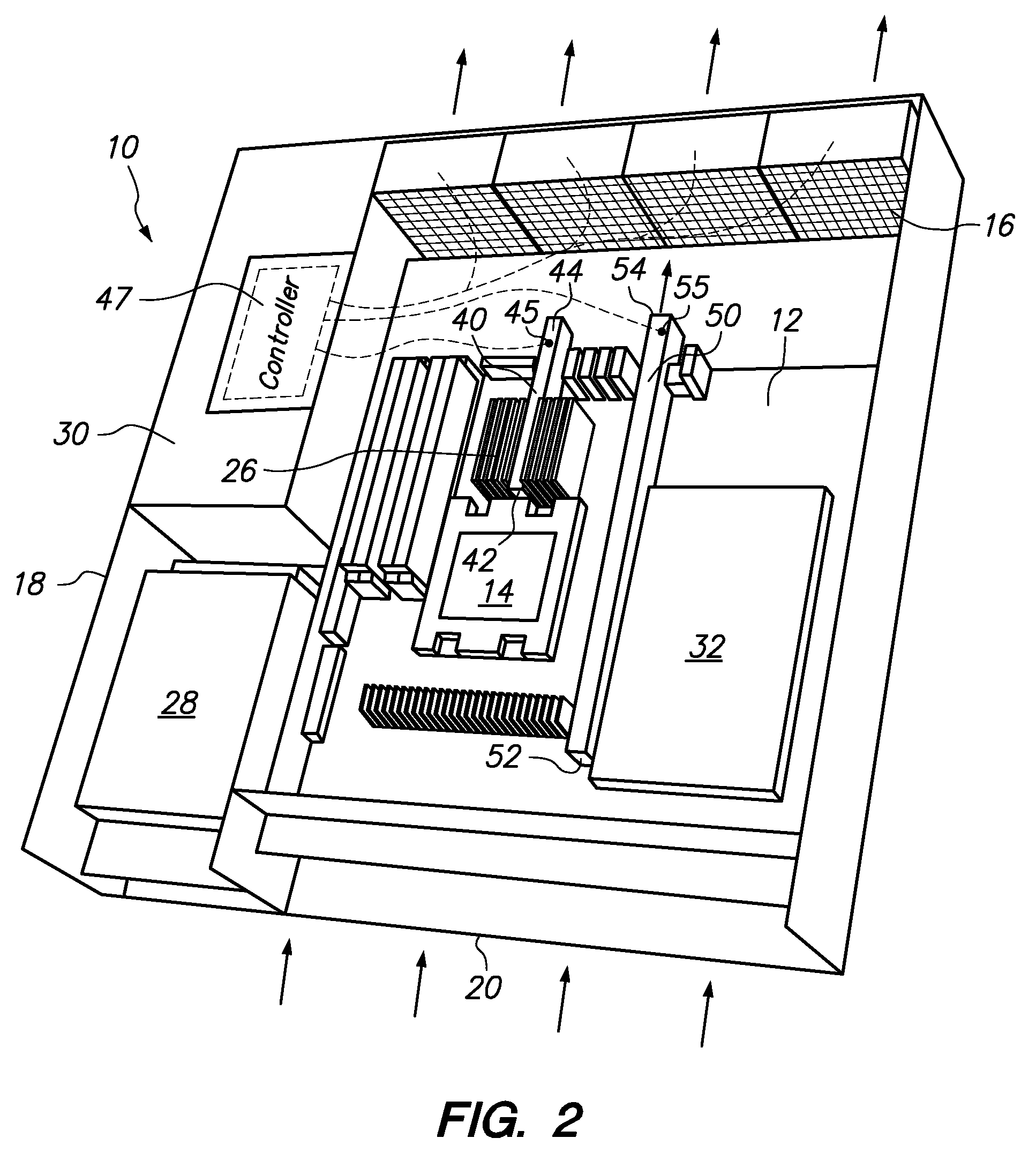

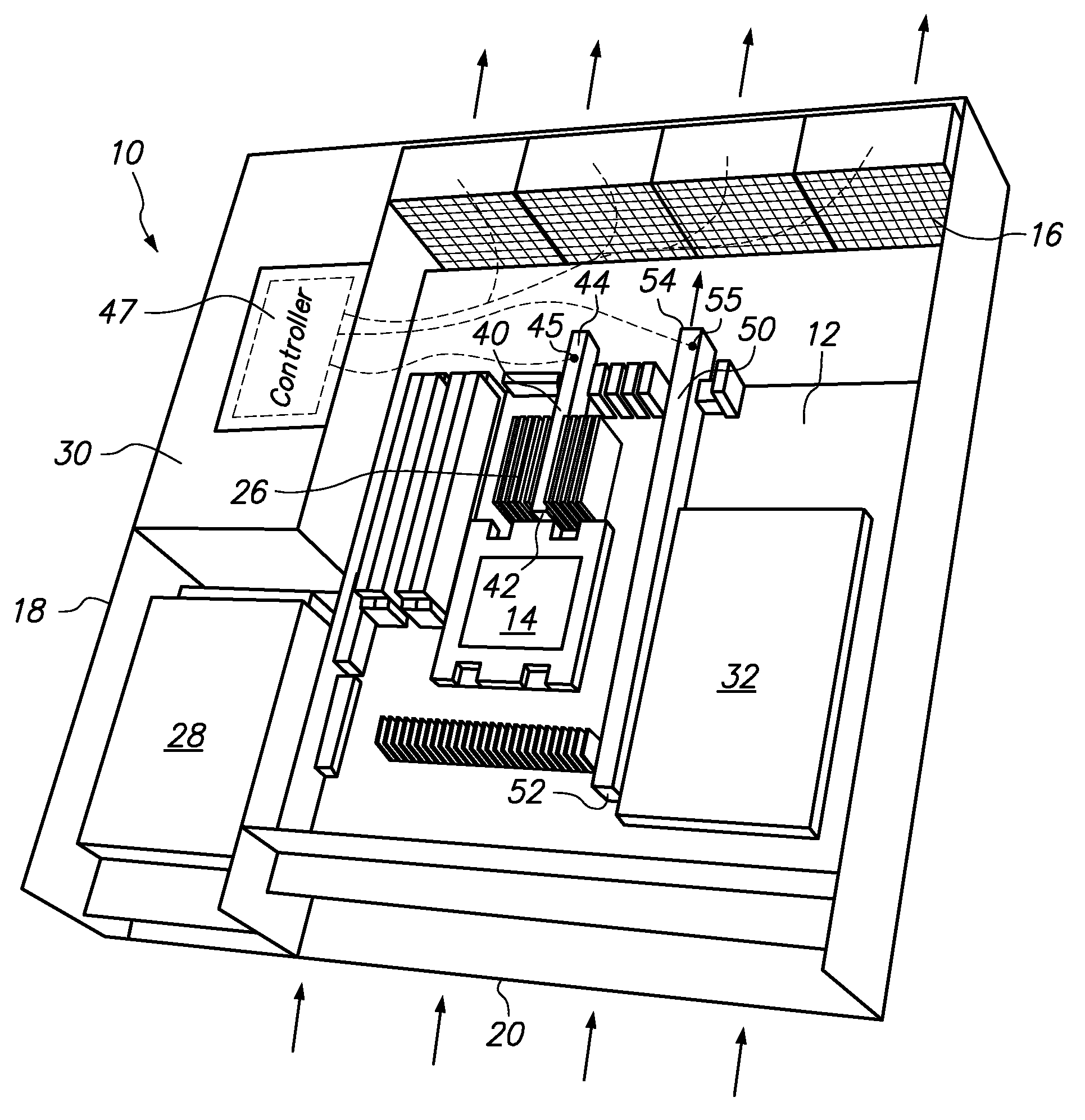

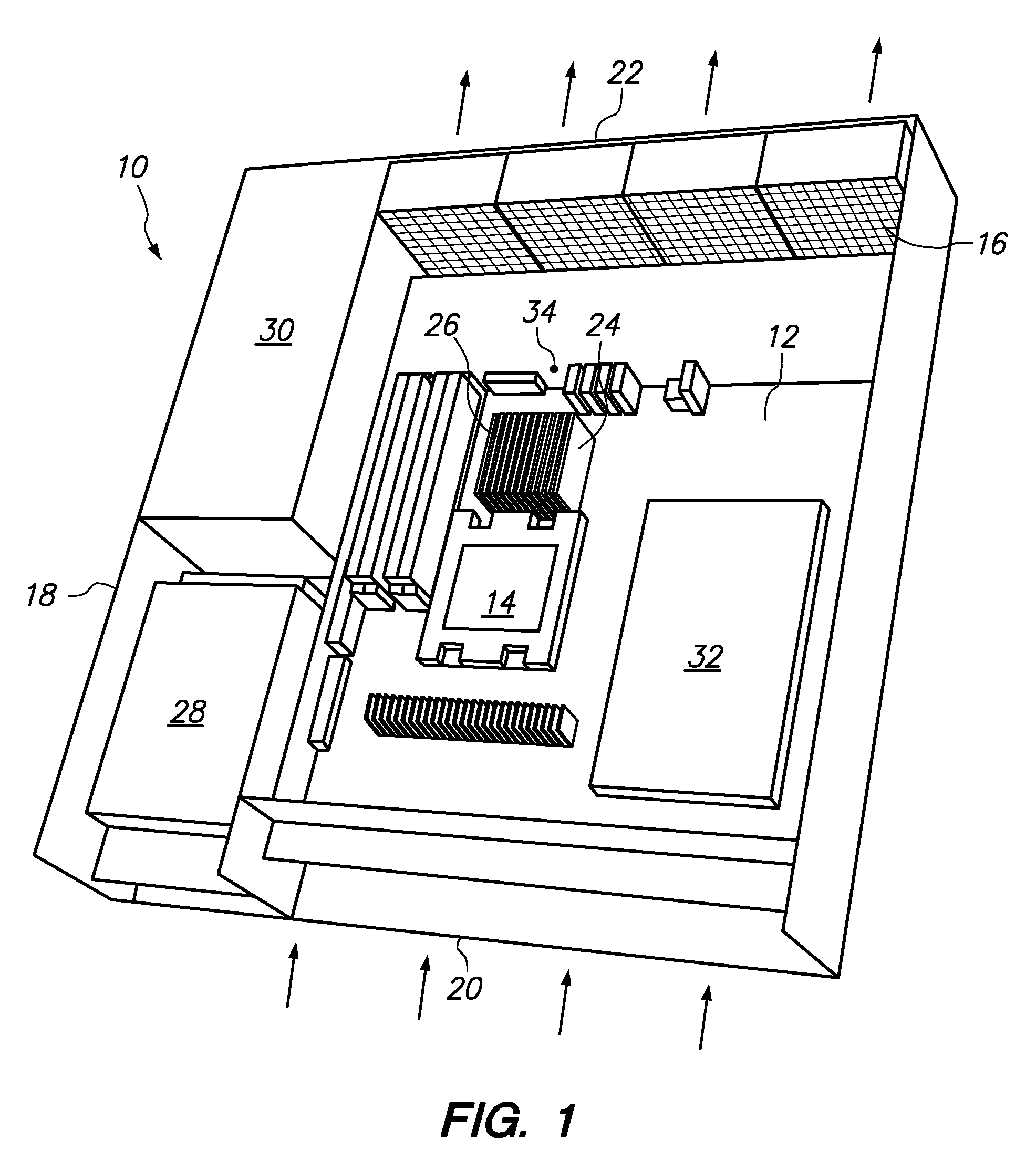

Ducted air temperature sensor

ActiveUS7826215B2Avoid thermal effectsDigital data processing detailsTemperatue controlElectronic communicationComputerized system

A temperature isolation duct in a computer system comprising a chassis securing a circuit board and a fan system that draws air through the chassis, and a heat-generating component is mounted on the circuit board and exposed to the air flow. The hot air duct passively directs air heated by the heat-generating component from a single hot air duct inlet in direct downstream alignment with the heat-generating component to a single hot air duct outlet. A thermal sensor is secured within, or in direct alignment with, the hot air duct near the duct outlet for sensing the temperature of air flowing through the hot air duct and generating a temperature signal. A controller is in electronic communication with the thermal sensor for receiving the temperature signal and in electronic communication with the fan system for sending a fan speed control signal.

Owner:LENOVO GLOBAL TECH INT LTD

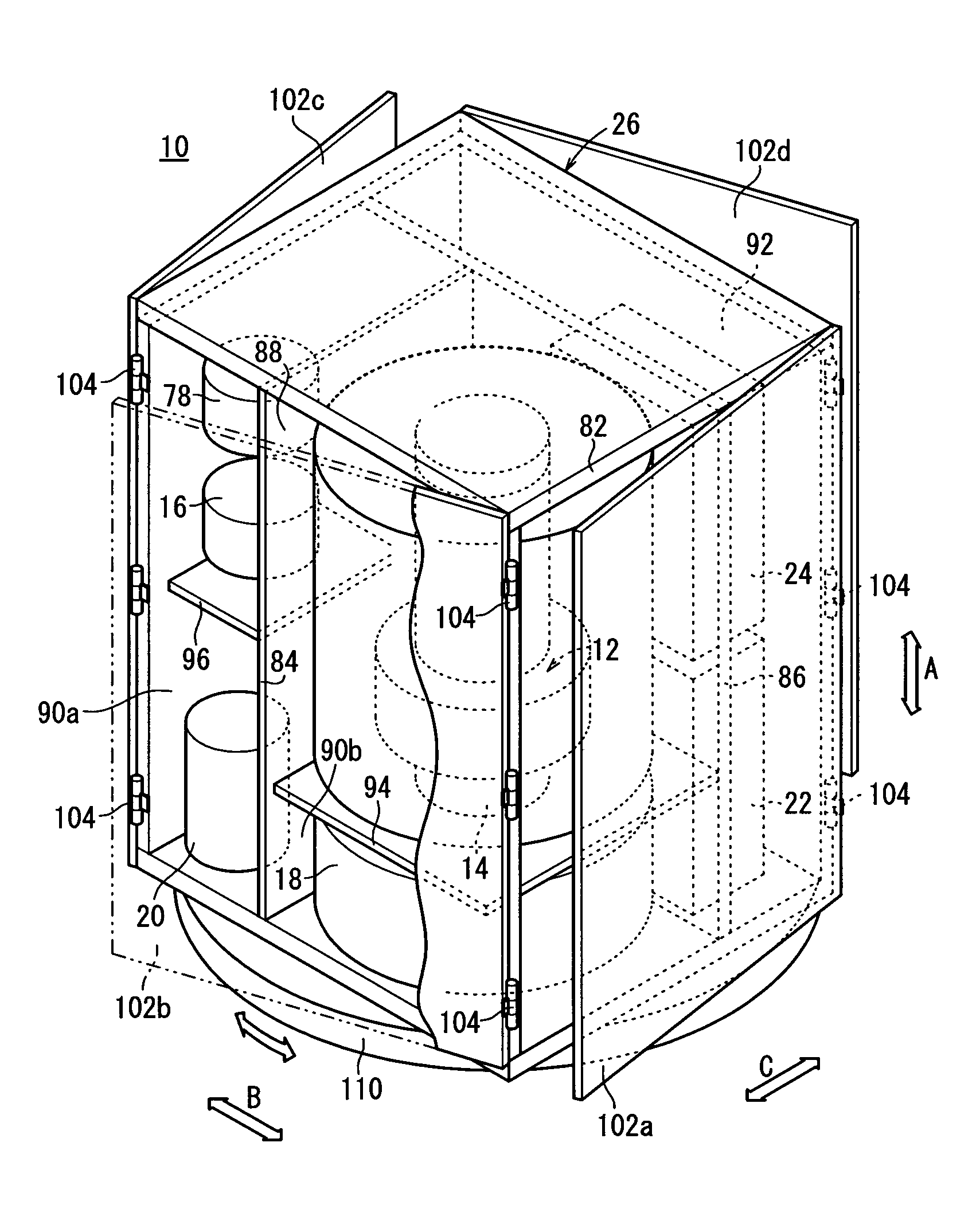

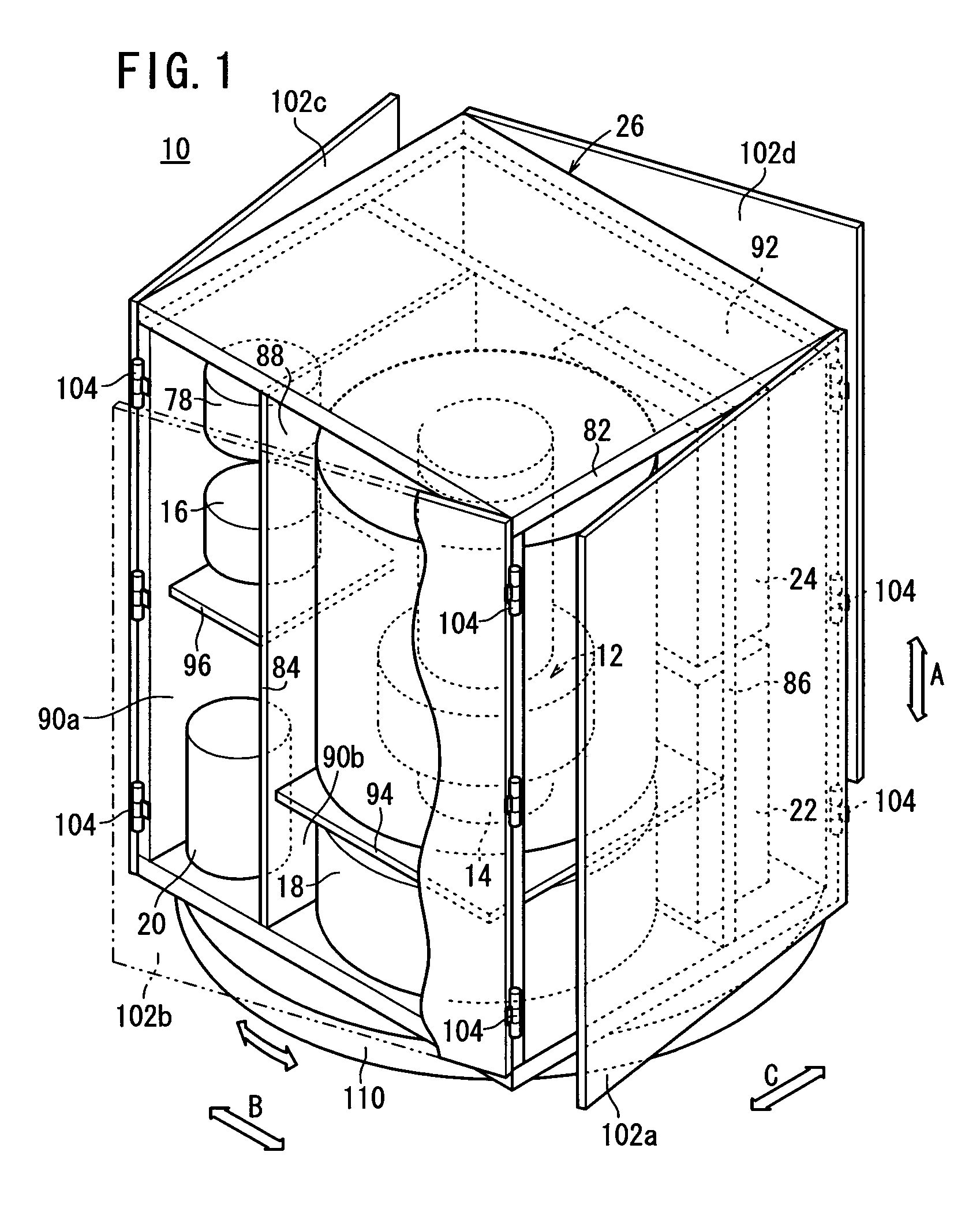

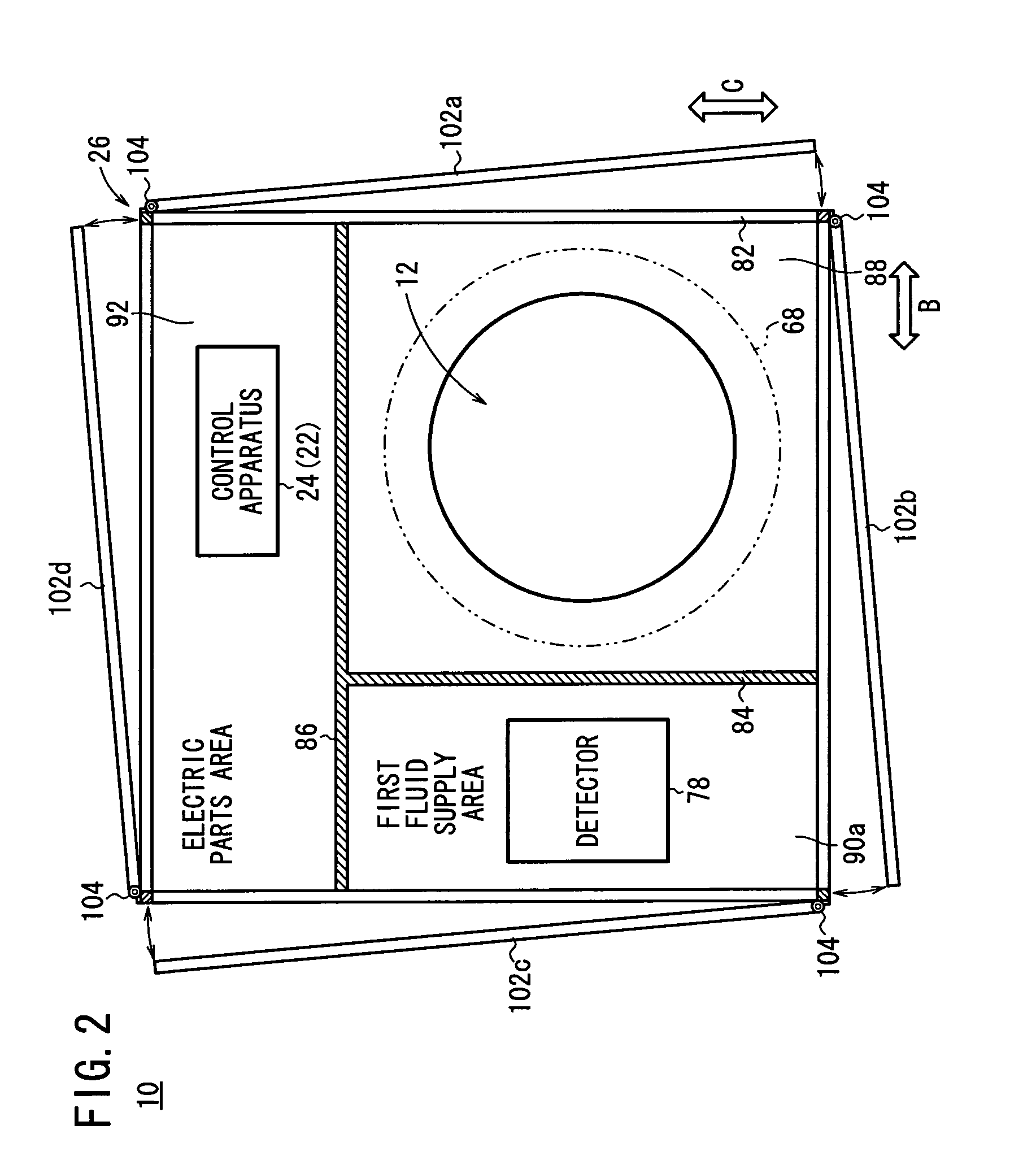

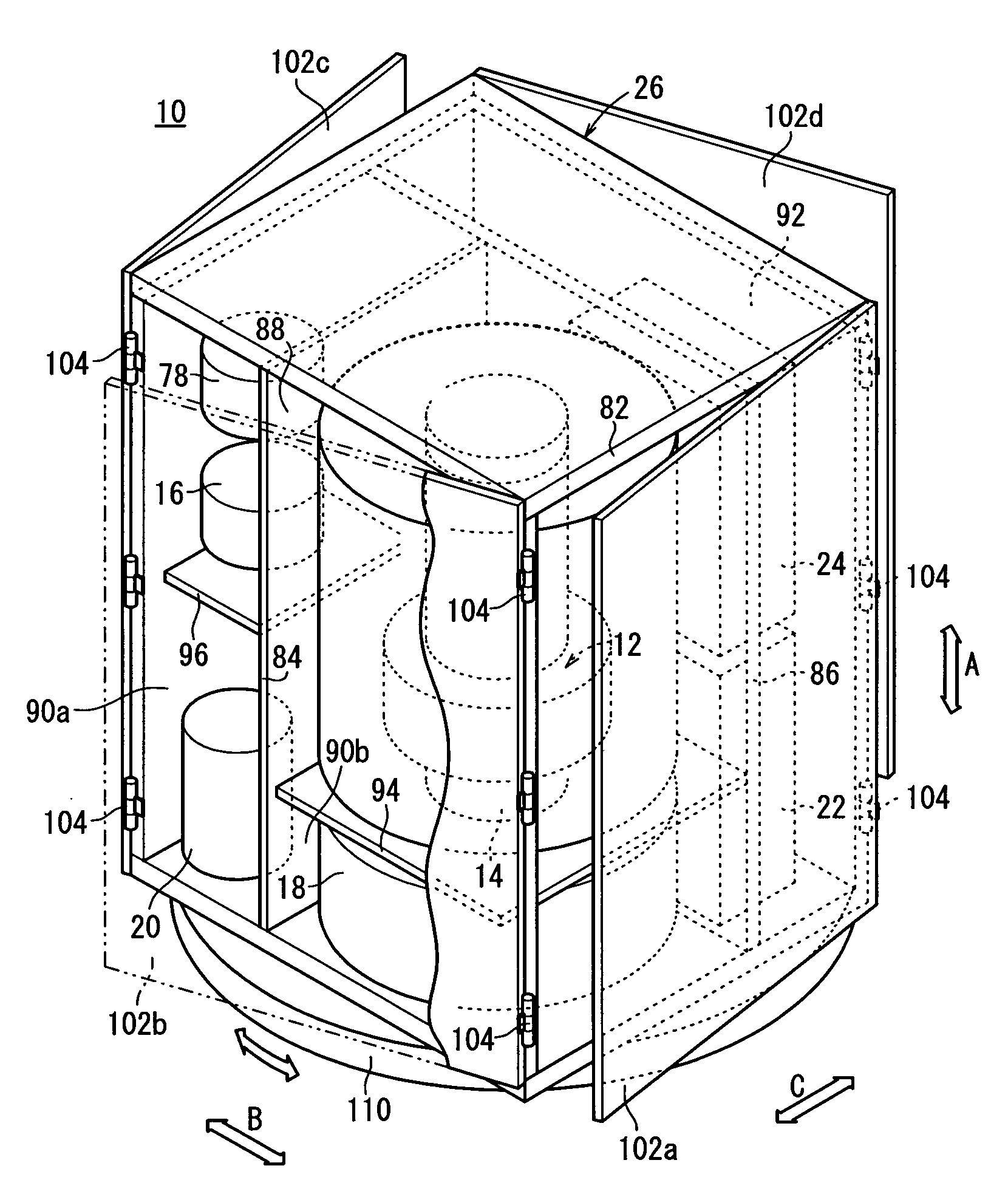

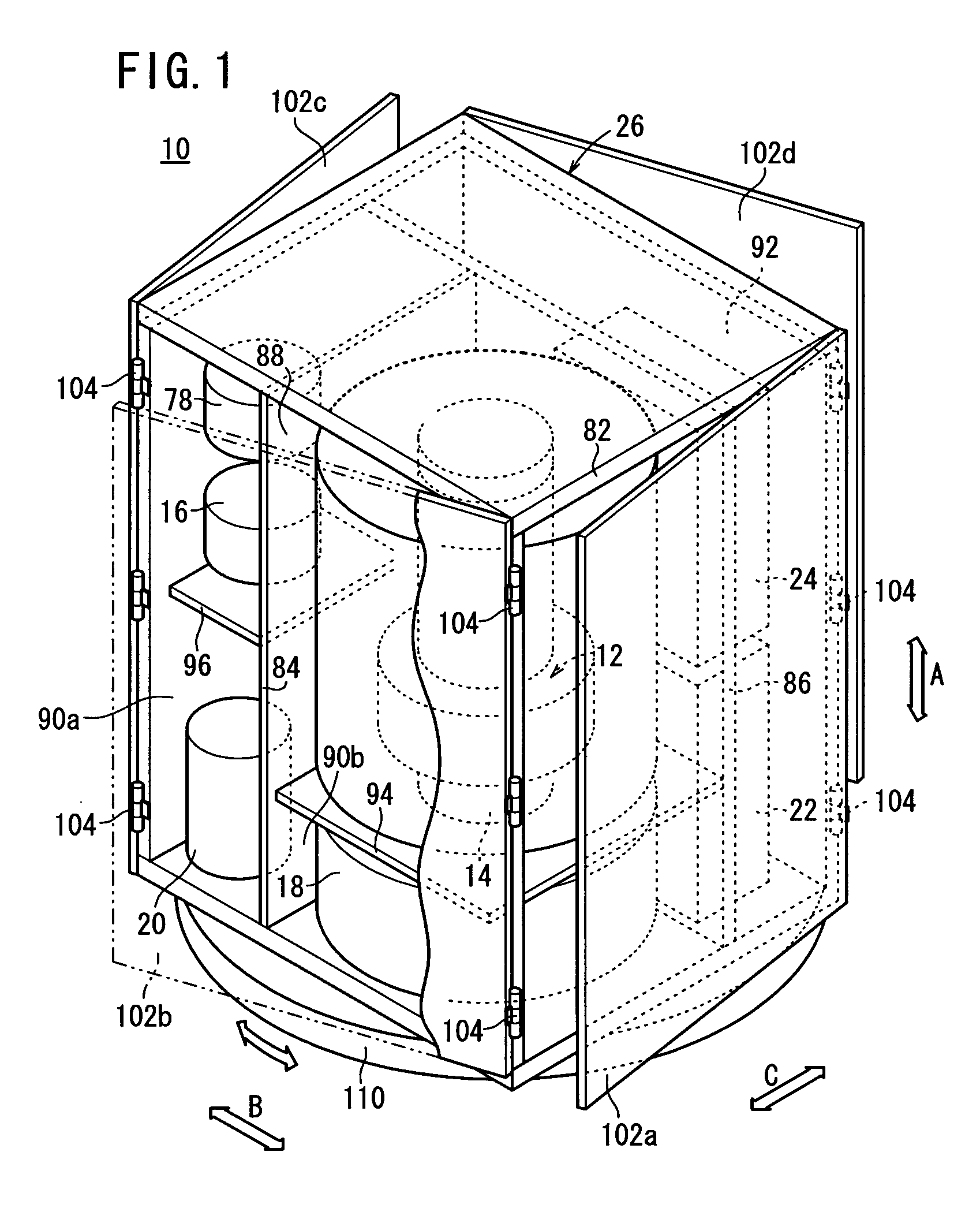

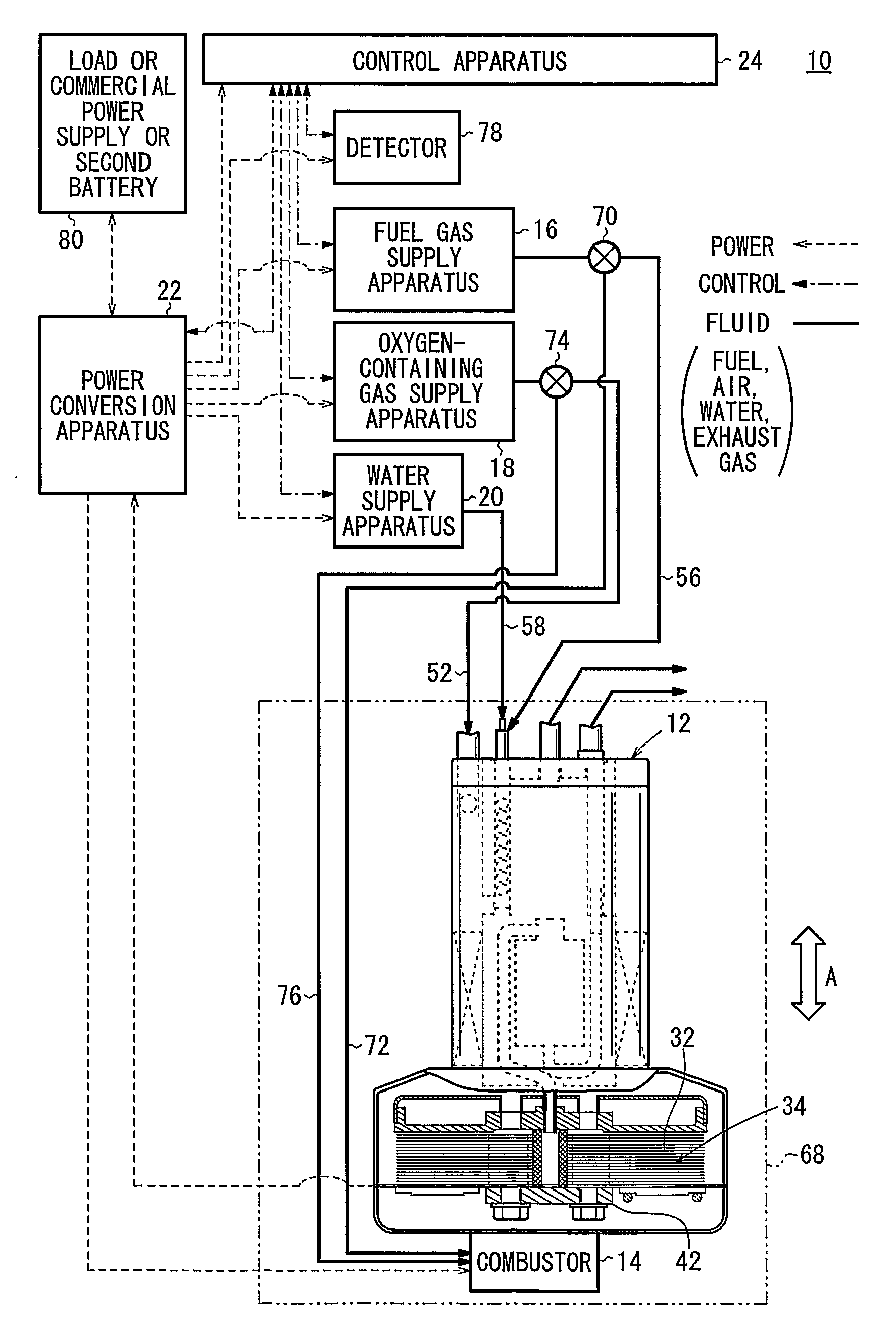

Fuel cell system

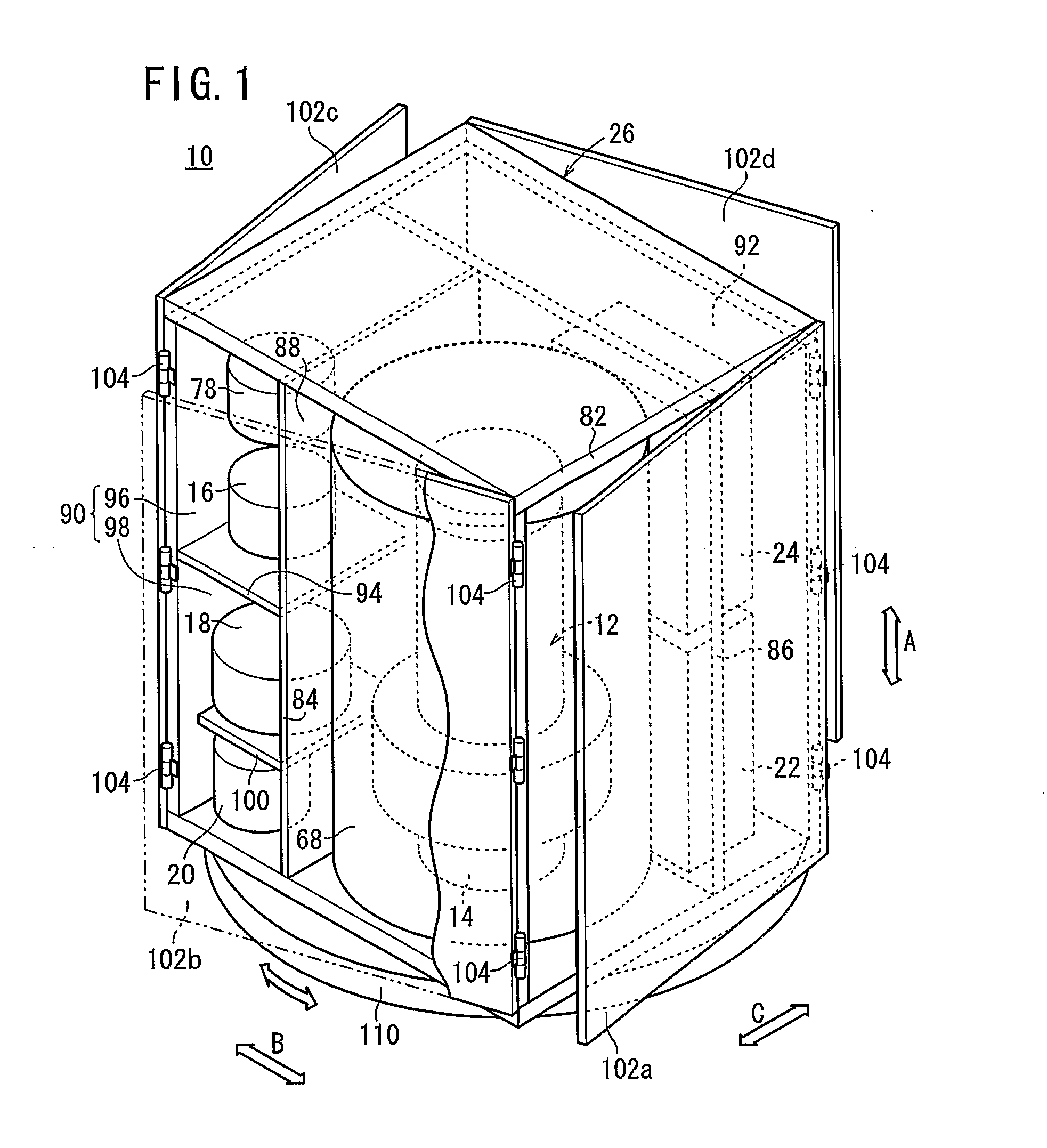

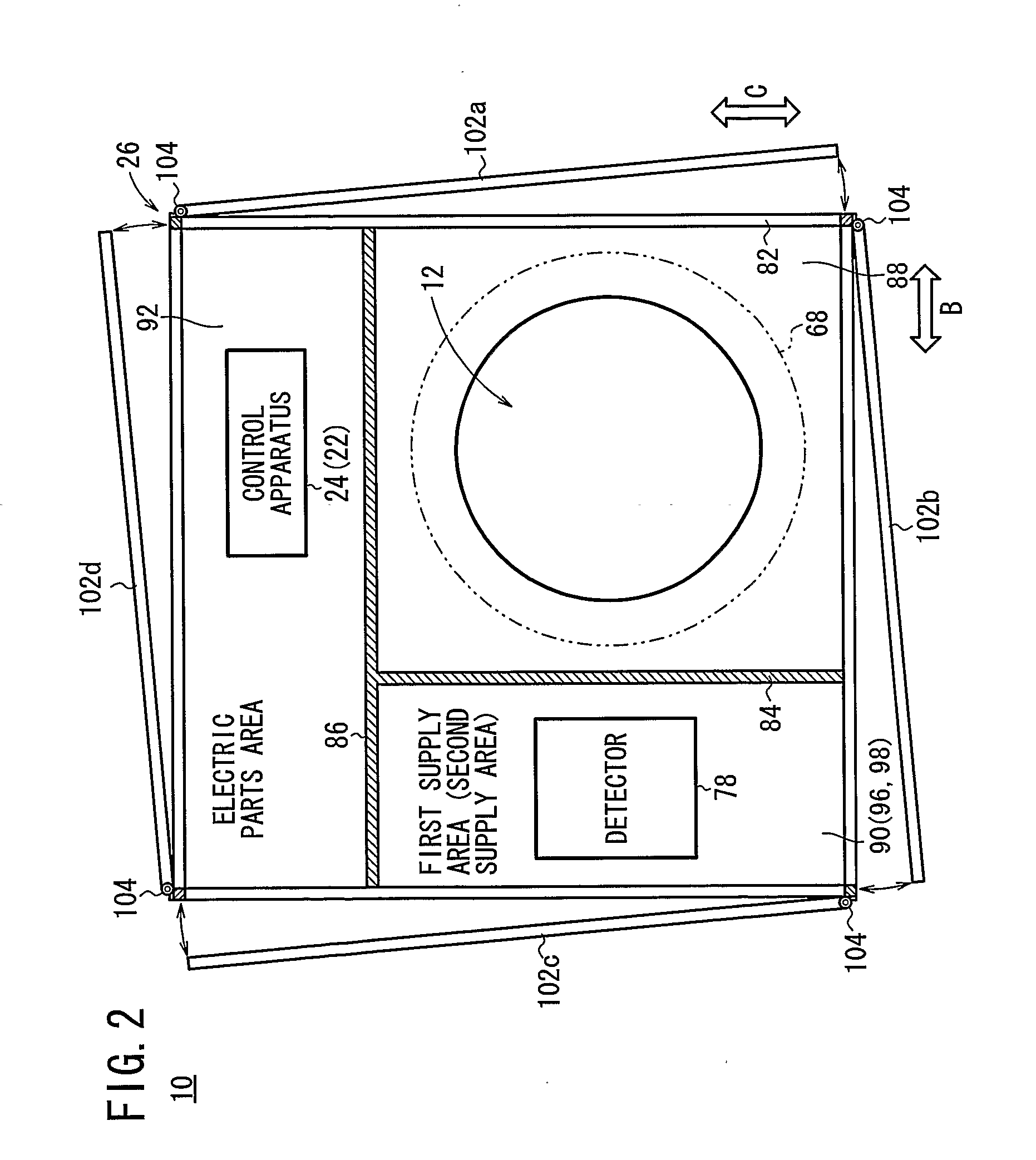

ActiveUS8178256B2Minimize diffusionAvoid thermal effectsFuel cell heat exchangeFuel cells groupingCombustorFuel cells

A casing of a fuel cell system is divided into a module area, a first fluid supply area, a second fluid supply area, and an electric parts area. The first fluid supply area is provided on a first side surface of the module area, and an electric parts area is provided on a second side surface of the module area. The second fluid supply area is provided under a bottom surface of the module area. A fuel cell module and a combustor are provided in the module area.

Owner:HONDA MOTOR CO LTD

Ducted Air Temperature Sensor

ActiveUS20090207565A1Avoid thermal effectsDigital data processing detailsTemperatue controlElectronic communicationAspect ratio

A temperature isolation duct in a computer system comprising a chassis securing a circuit board and a fan system, wherein the fan system draws air through the chassis in an airflow direction, and a heat-generating component is mounted on the circuit board and exposed to the air flow. The hot air duct passively directs air heated by the heat-generating component from a single hot air duct inlet in direct downstream alignment with the heat-generating component to a single hot air duct outlet, wherein the hot air duct has a length to width aspect ratio of greater than four. A first thermal sensor is secured within, or direct alignment with, the hot air duct near the duct outlet for sensing the temperature of air flowing through the hot air duct and generating a first temperature signal. A controller is in electronic communication with the first thermal sensor for receiving the temperature signal and in electronic communication with the fan system for sending a fan speed control signal. Optionally, the hot air duct may extend through, over or around a second component on the circuit board to avoid thermal effects of the second component.

Owner:LENOVO GLOBAL TECH INT LTD

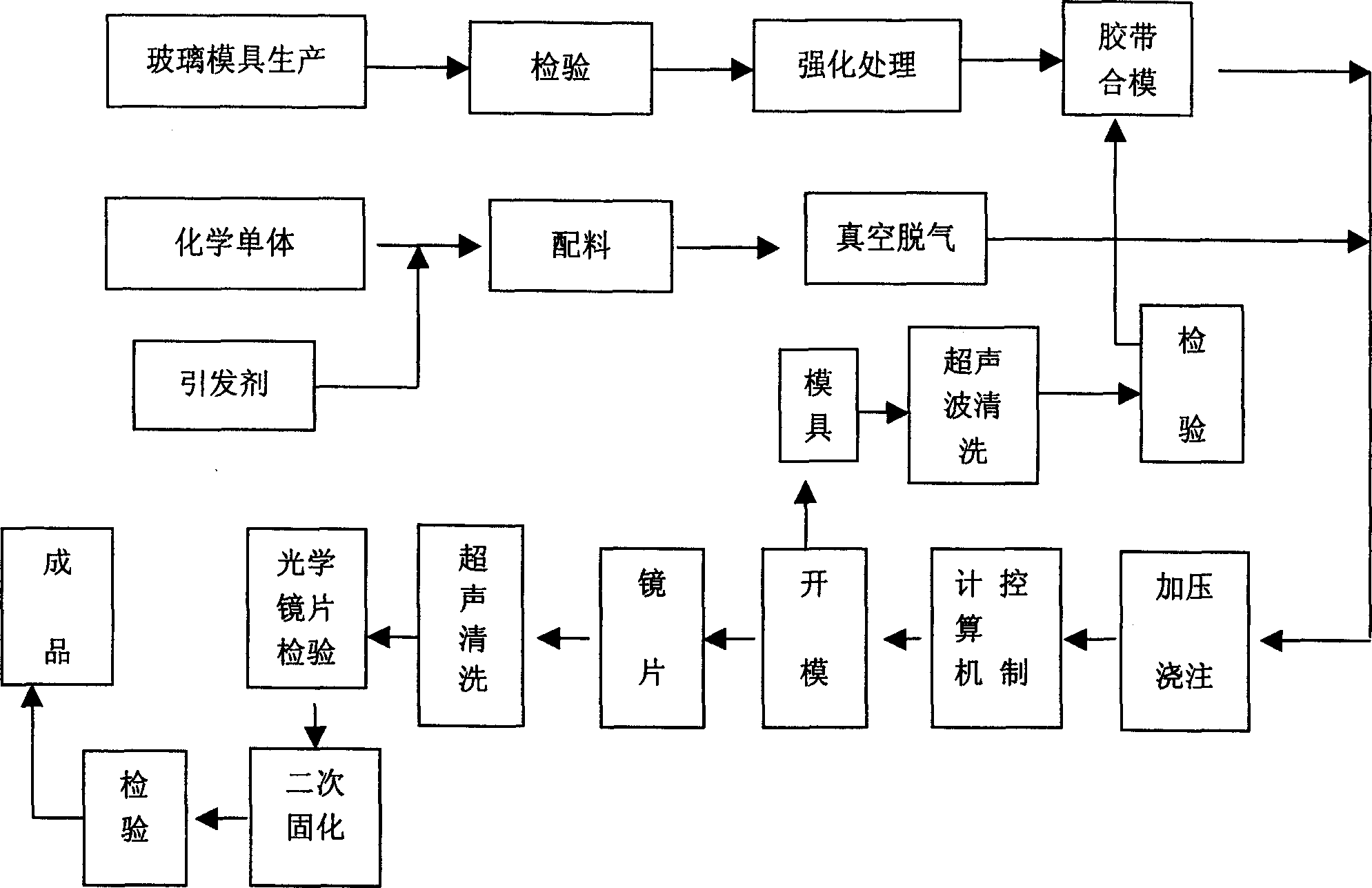

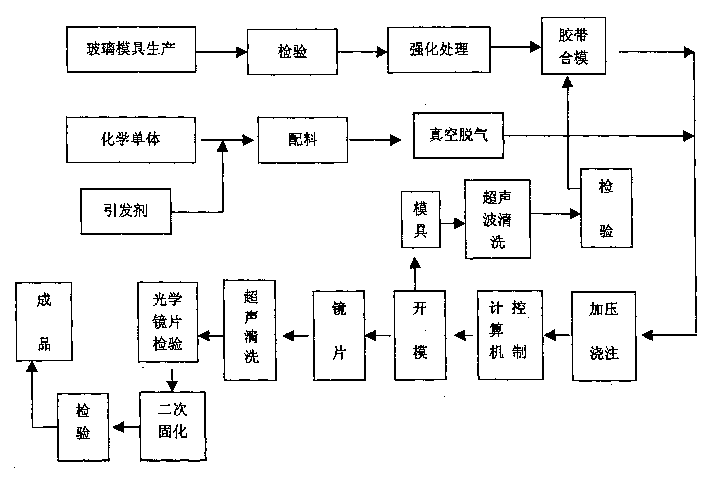

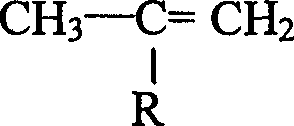

Manufacture of superthin high-refractivity optical resin lens

InactiveCN1548285AAvoid thermal effectsSolve the error of optical surface shape variationOptical articlesTemperature controlRefractive index

The manufacture process of superthin high-refractivity optical resin lens includes the following steps: making mold, reinforcing treatment and closing mold with tape machine; weighing chemical monomer and initiator, mixing and vacuum deairing; depositing the mixture in the mold, curing to form, demolding and cleaning. The present invention features the chemical monomer with one kind of alkenyl radical containing organic compound additive, the initiator being tert-butyl peroxide, the ratio among the chemical monomer, the additive and the initiator of 100 to 0.1-0.3 to 0.7-0.9, computerized temperature control during the polymerization, and the secondary curing of lens after demolding and cleaning. The present invention eliminates the lens profile variation caused by the polymerization and raises the optical precision of the lens.

Owner:SHANGHAI CONANT OPTICS CO LTD

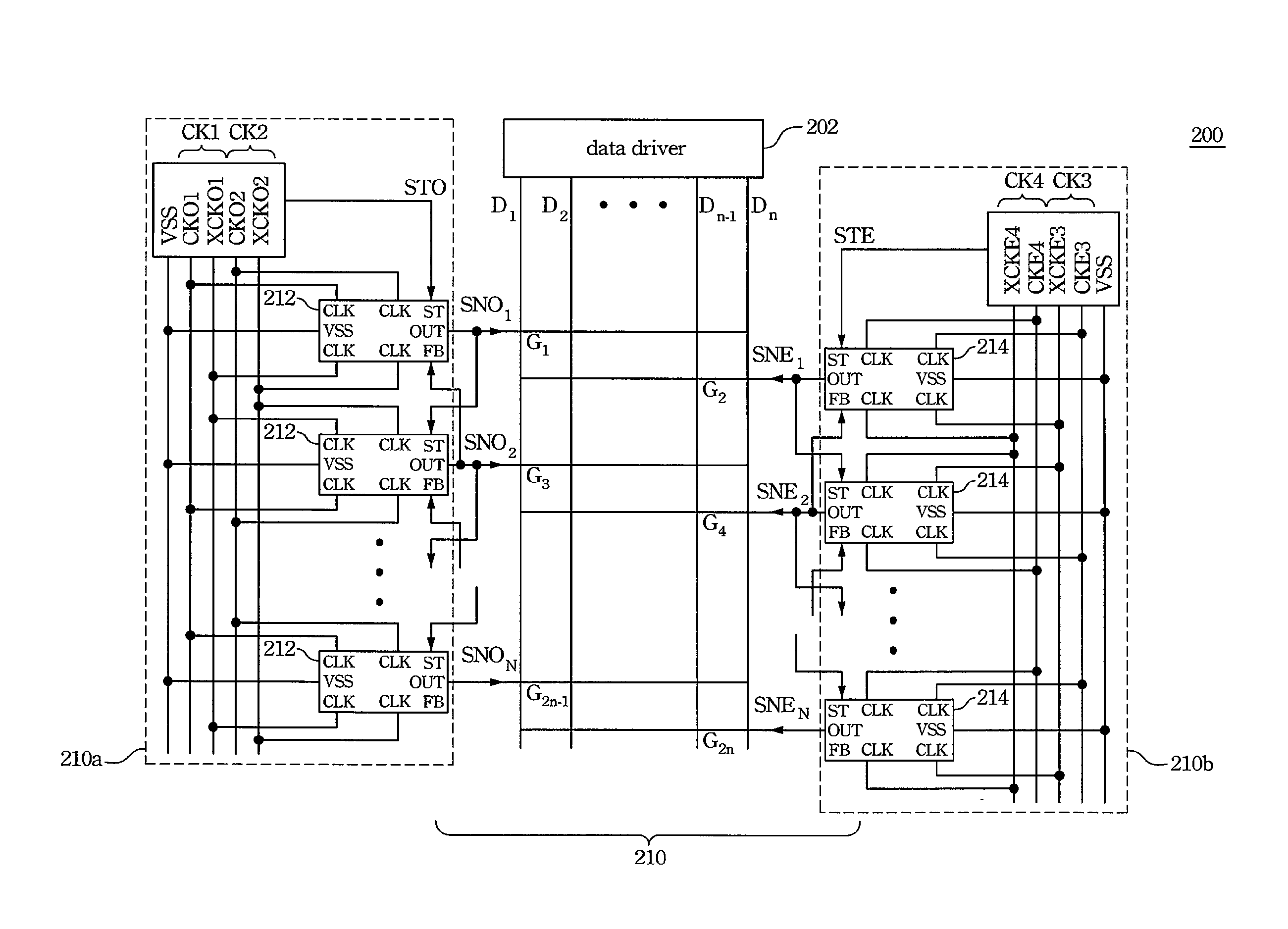

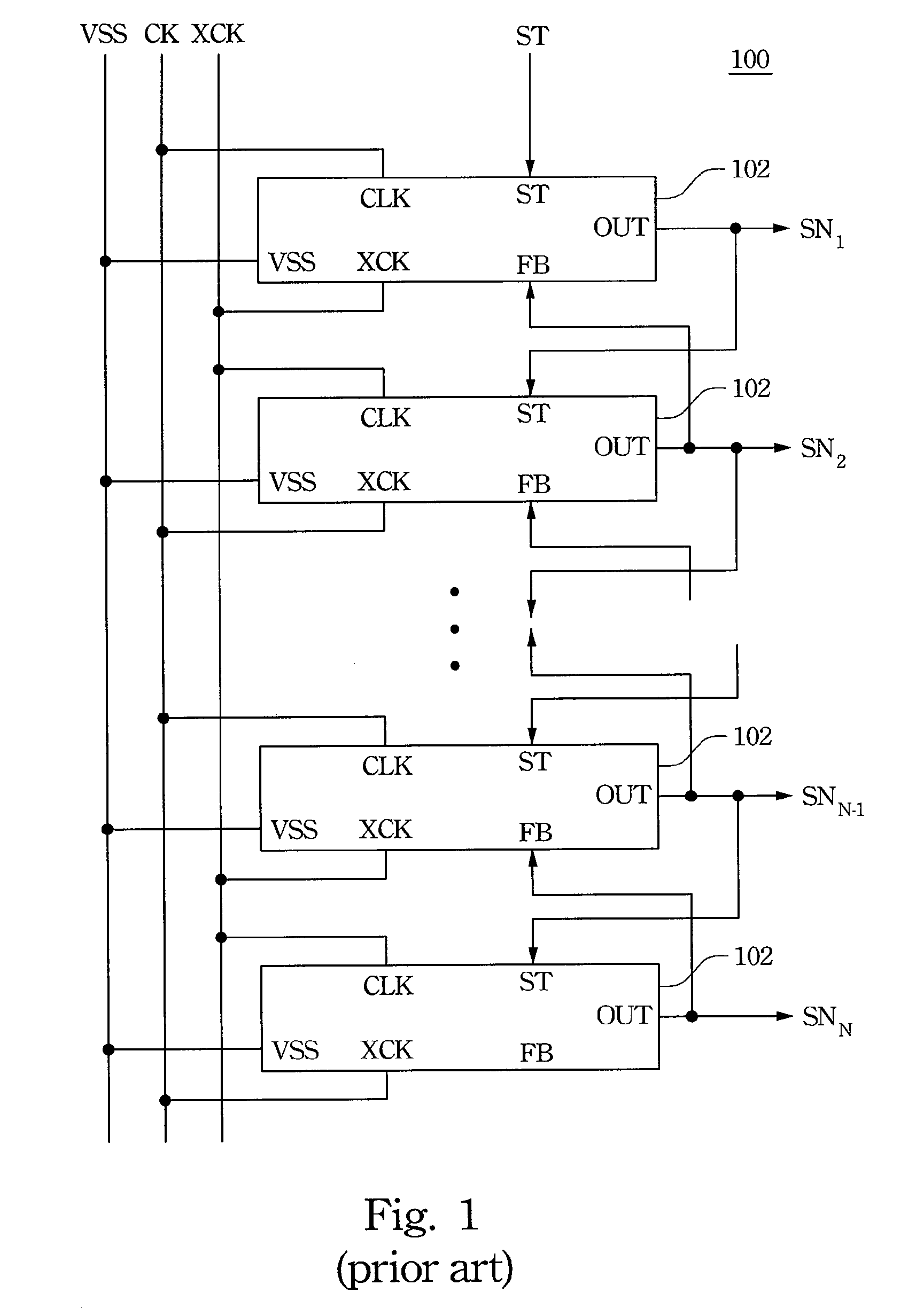

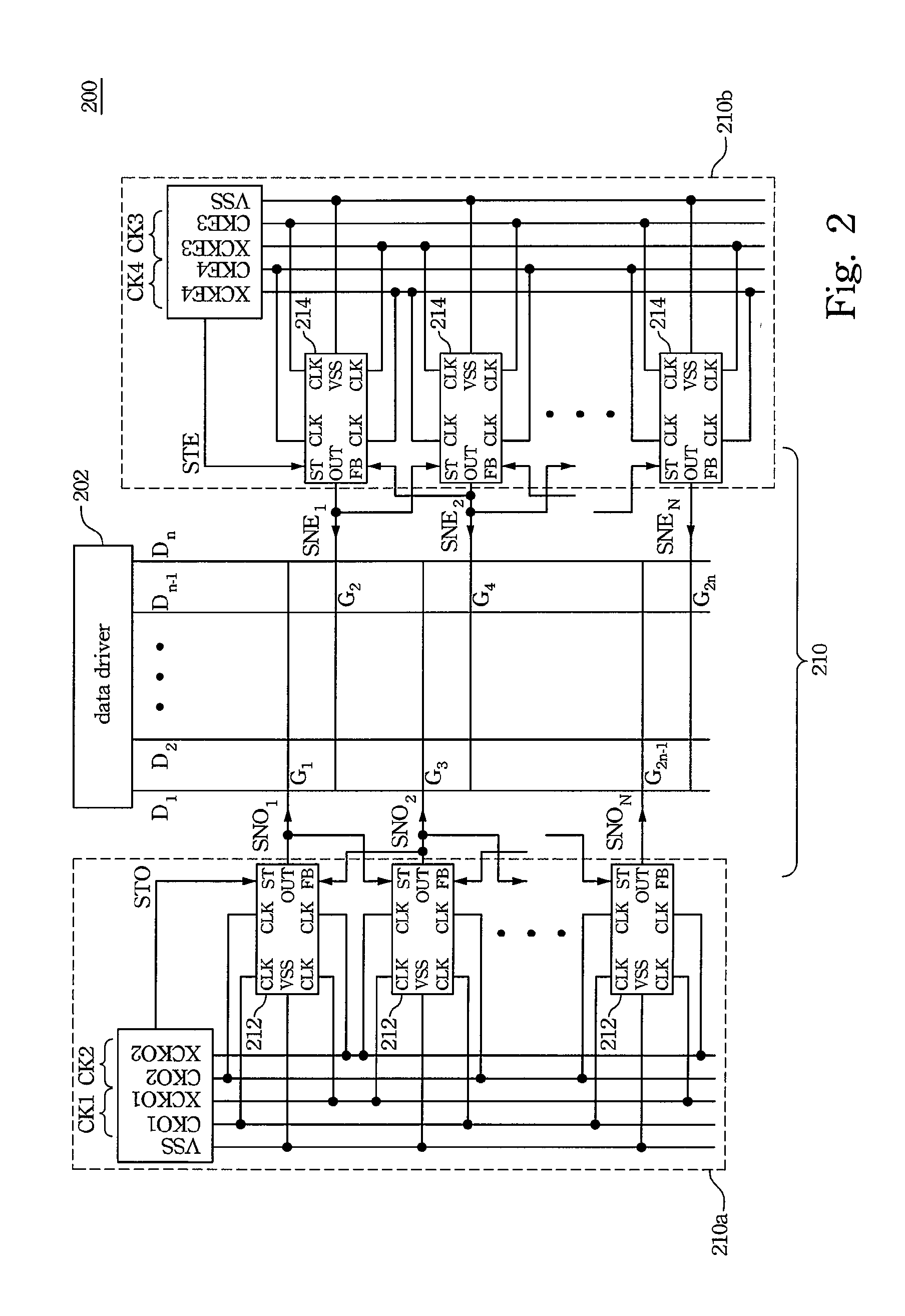

Gate driving circuit and driving circuit unit thereof

ActiveUS7898558B2Avoid thermal effectsEnhanced signalCathode-ray tube indicatorsDigital storageEngineeringDriving circuit

A driving circuit unit outputting a driving signal includes an input unit, an assistant output unit and an output unit. The input unit is coupled to an input node and receives a start signal to make the input node have a potential. The assistant output unit receives a first clock signal to increase the potential of the input node. The output unit receives a second clock signal to increase the potential of the input node and outputs the driving signal. A gate driving circuit is also disclosed.

Owner:AU OPTRONICS CORP

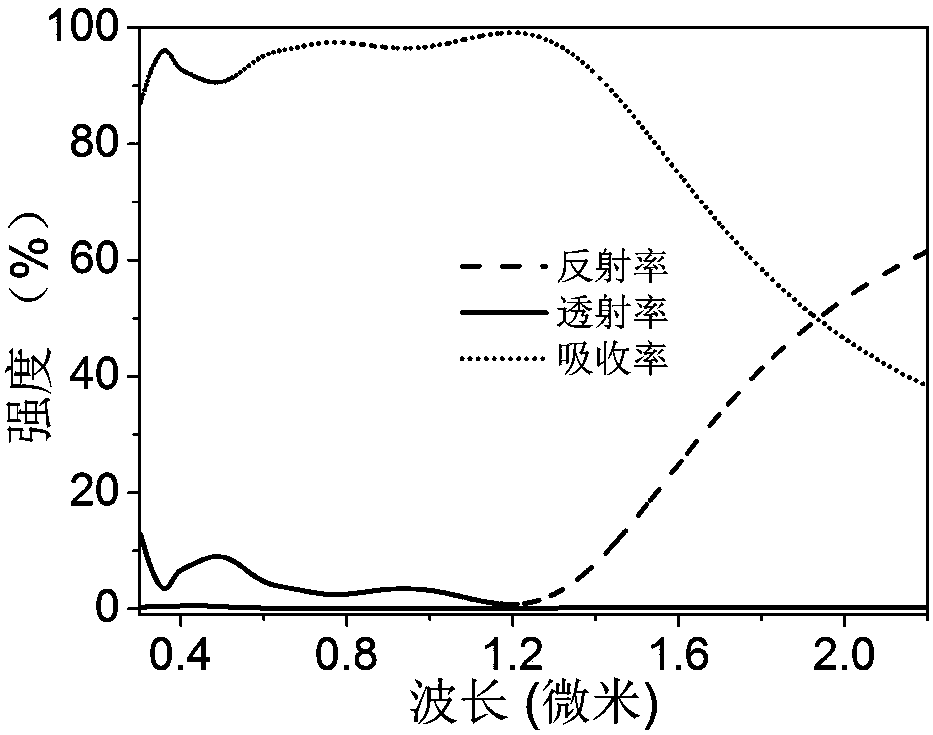

Ultra-wideband optical perfect absorber and preparation method thereof

InactiveCN107797167AStrong electromagnetic resonance modePromote absorptionOptical elementsUltra-widebandUltraviolet

The invention discloses an ultra-wideband optical perfect absorber and a preparation method thereof. The ultra-wideband optical perfect absorber comprises a substrate, the substrate is provided with atitanium nitride film layer, a dielectric film layer and a titanium nitride-titanium dioxide structural layer in sequence from bottom to top, the titanium nitride-titanium dioxide structural layer comprises a titanium nitride particle array and a titanium dioxide particle array, the titanium nitride particle array is arranged on the upper surface of the dielectric film layer, and the titanium dioxide particle array is arranged on the upper surface of the titanium dioxide particle array. Ultra-wideband absorption with the coverage of ultraviolet-visible-near-infrared wavebands is realized withthe combination of the titanium nitride particle array and the titanium dioxide particle array through good absorption effect of lights with different wavelengths by titanium nitride and titanium dioxide materials.

Owner:JIANGXI NORMAL UNIV

Cassia Tuckahoe composition and preparation method thereof

InactiveCN101310739AAvoid thermal effectsReduce lossesCapsule deliverySexual disorderAdemetionineTreatment effect

The invention relates to the technical field of traditional Chinese medicine preparation process, in particular to a cinnamon twig and poria composition and a preparation method thereof. The cassia twig and poria composition is designed to overcome the problems that the treatment effects of drugs in the prior art are not ideal, the drugs can not be prepared against the characteristics of active ingredients of the drugs and the loss of the active ingredients is great, the currently provided technical proposal is that: the cassia twig and poria composition is prepared by using the following method: five medicines of cassia twig, poria, peach seed, red paeony root and tree peony bark with equal quantity are taken and screened by a 10 to 24-mesh sieve; the four medicines of the cinnamon twig, the tree peony bark, the red paeony root and the peach seed are mixed and extracted, extract is collected for standby; the medicine residues are mixed with the poria for carrying out alcohol extraction and then carrying out water extraction, filtrate is merged, and liquid extract is obtained by the concentration; the liquid extract and the extract are merged, and a preparation is prepared by even mixing and processing. Compared with the prior art, the cinnamon twig and poria composition has the advantages that: 1. the treatment effect of the drug is improved; 2. the preparation process is reasonable; 3. and the cassia twig and poria composition has significant realistic significance.

Owner:西安天健医药科学研究所

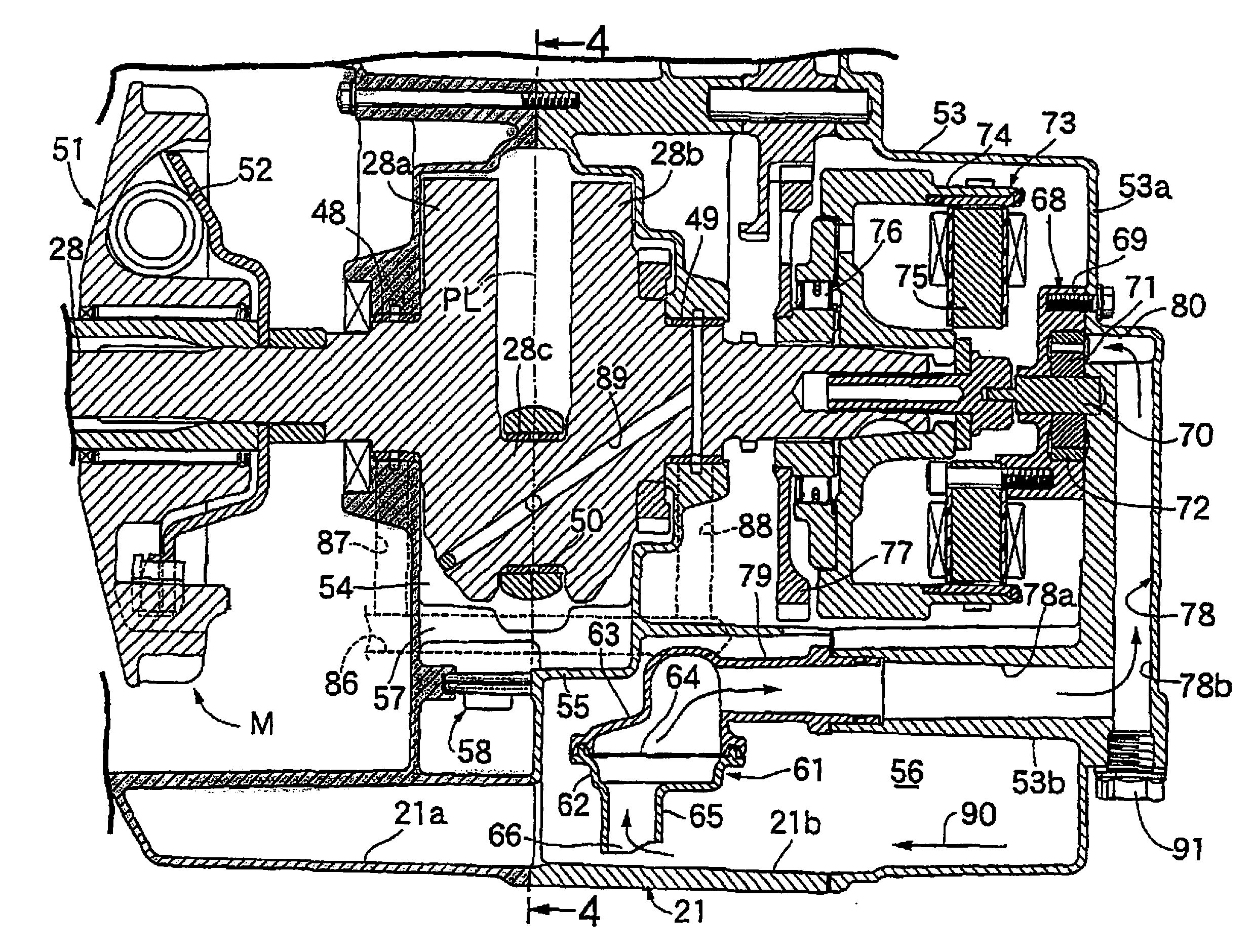

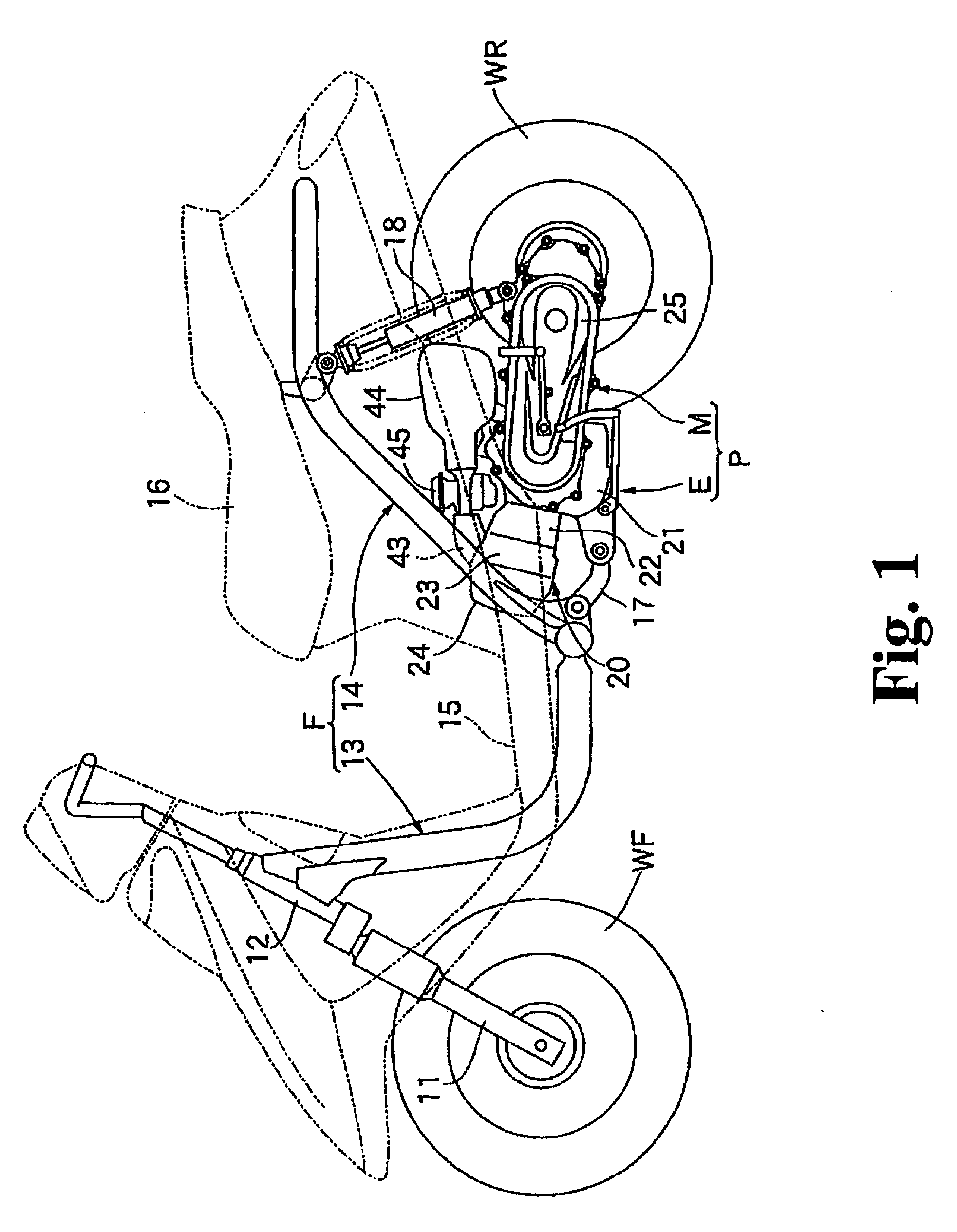

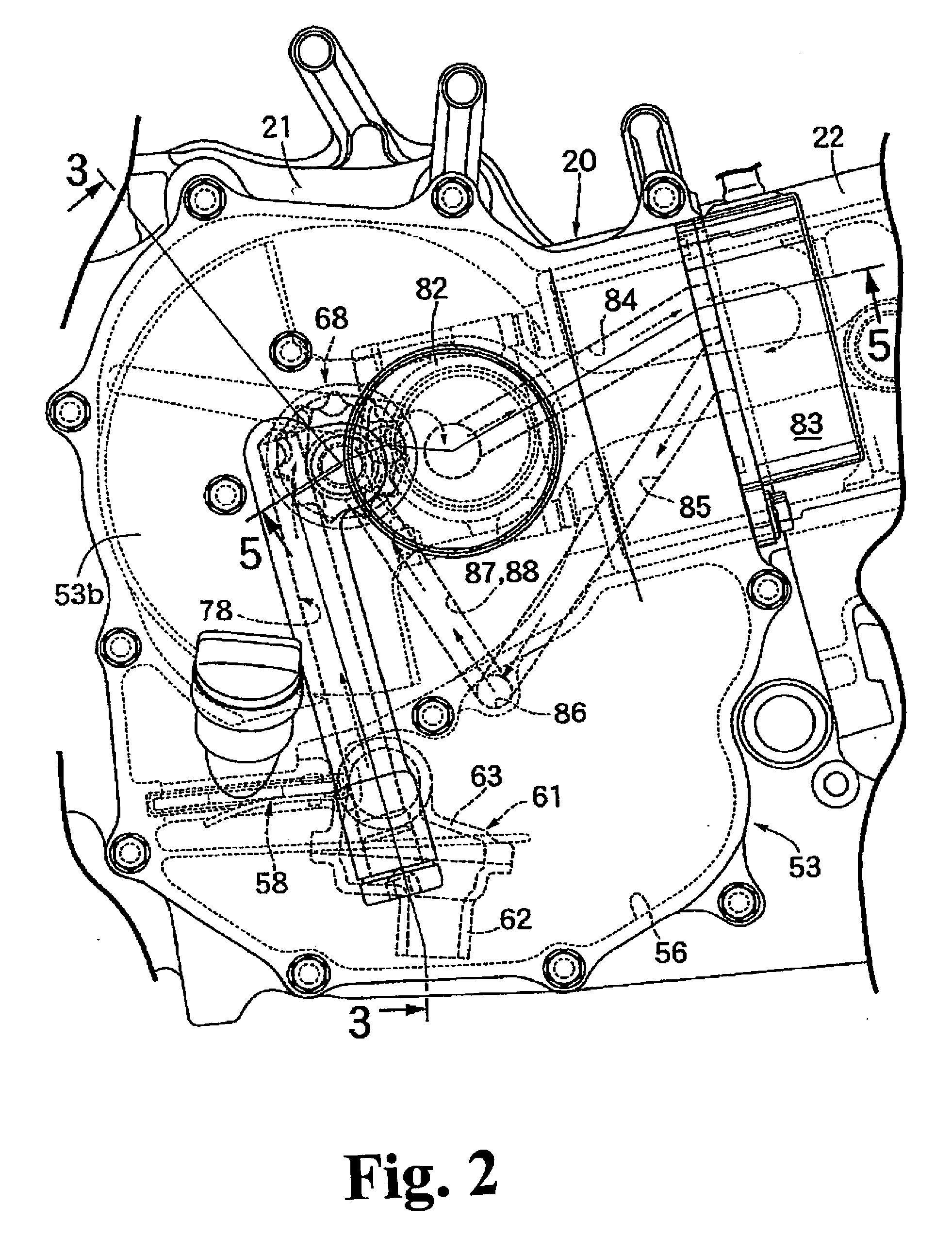

Lubricating device for engine

InactiveUS20070079789A1Increase oil temperatureReduce overall man-hoursLubrication of auxillariesLubricant conduit arrangementsFree rotationEngineering

An lubrication device for an engine includes: a crank case which freely rotatably supports a crank shaft and also which stores oil at its lower part; an oil strainer which is so arranged as to be fixed in the crank case; and an oil pump which suctions the oil at the lower part in the crank case via the oil strainer. In the lubricating device, the machining efficiency can be improved by reducing the time of machining to a crank case to thereby decentralize machining processes, and also the oil temperature can be reduced. A crank case cover covering part of a crank case and coupled with the crank case is provided with an oil suction passage which leads to an oil pump, and an oil strainer communicates with the oil suction passage via a connecting pipe which is a member different from the crank case

Owner:HONDA MOTOR CO LTD

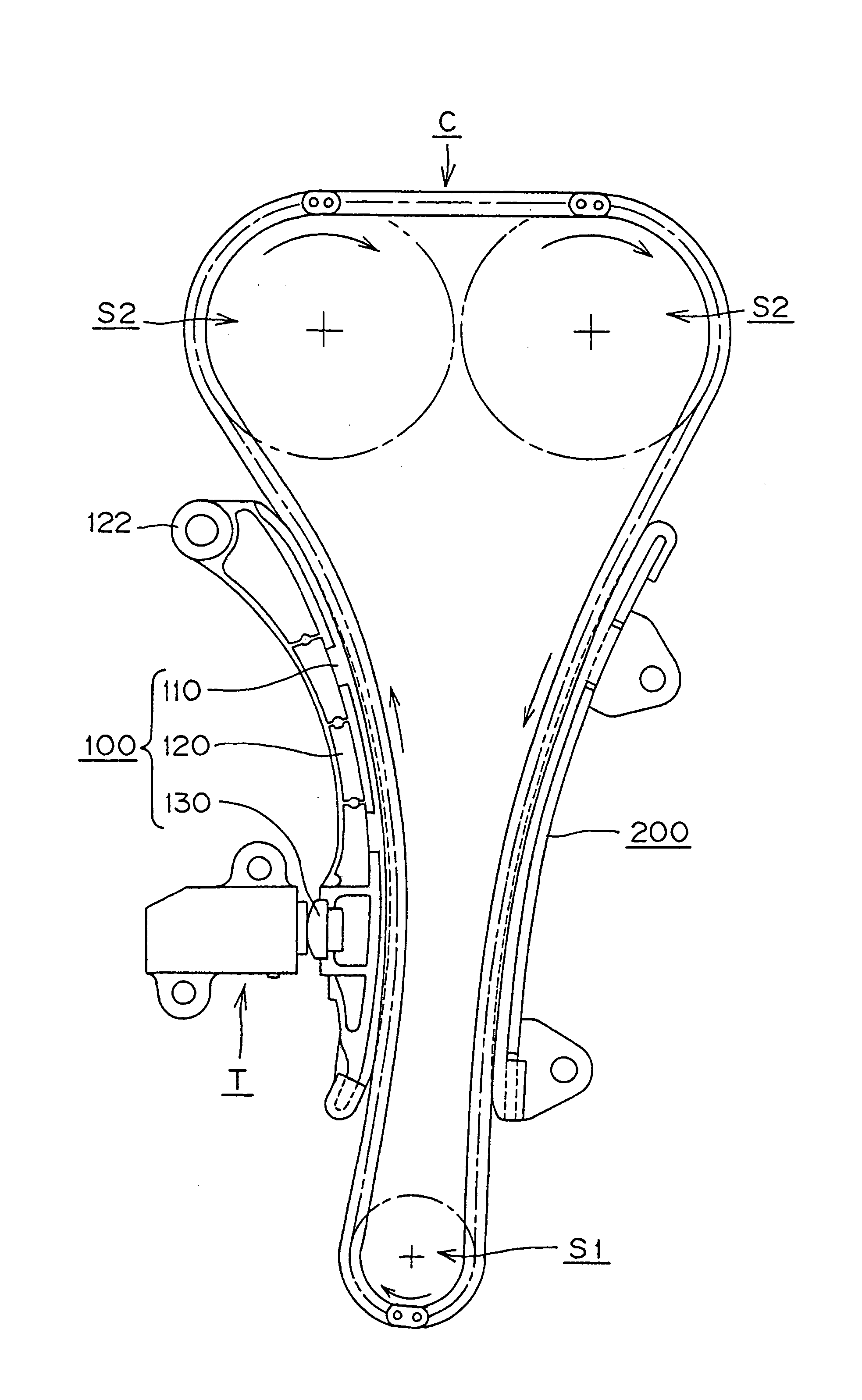

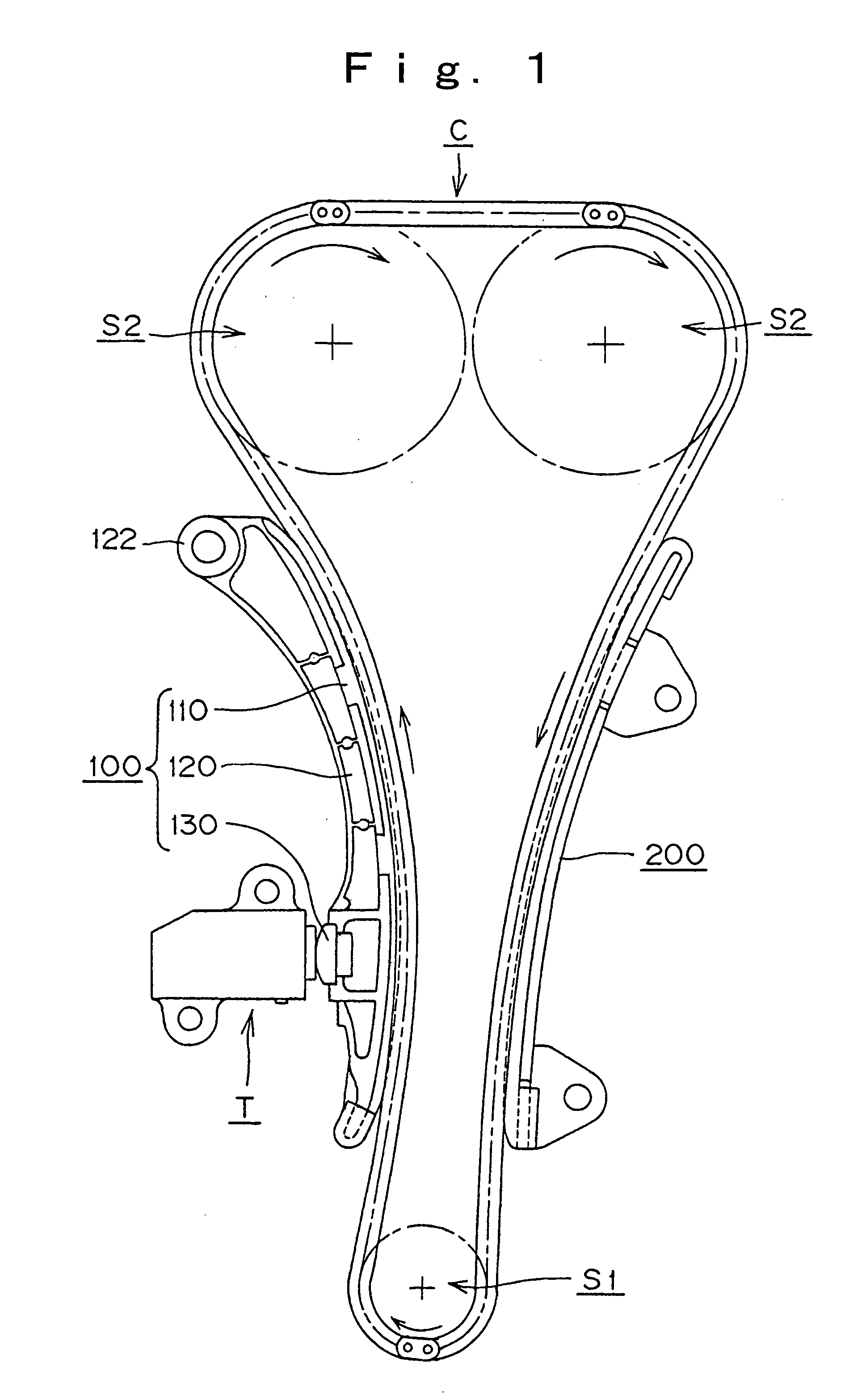

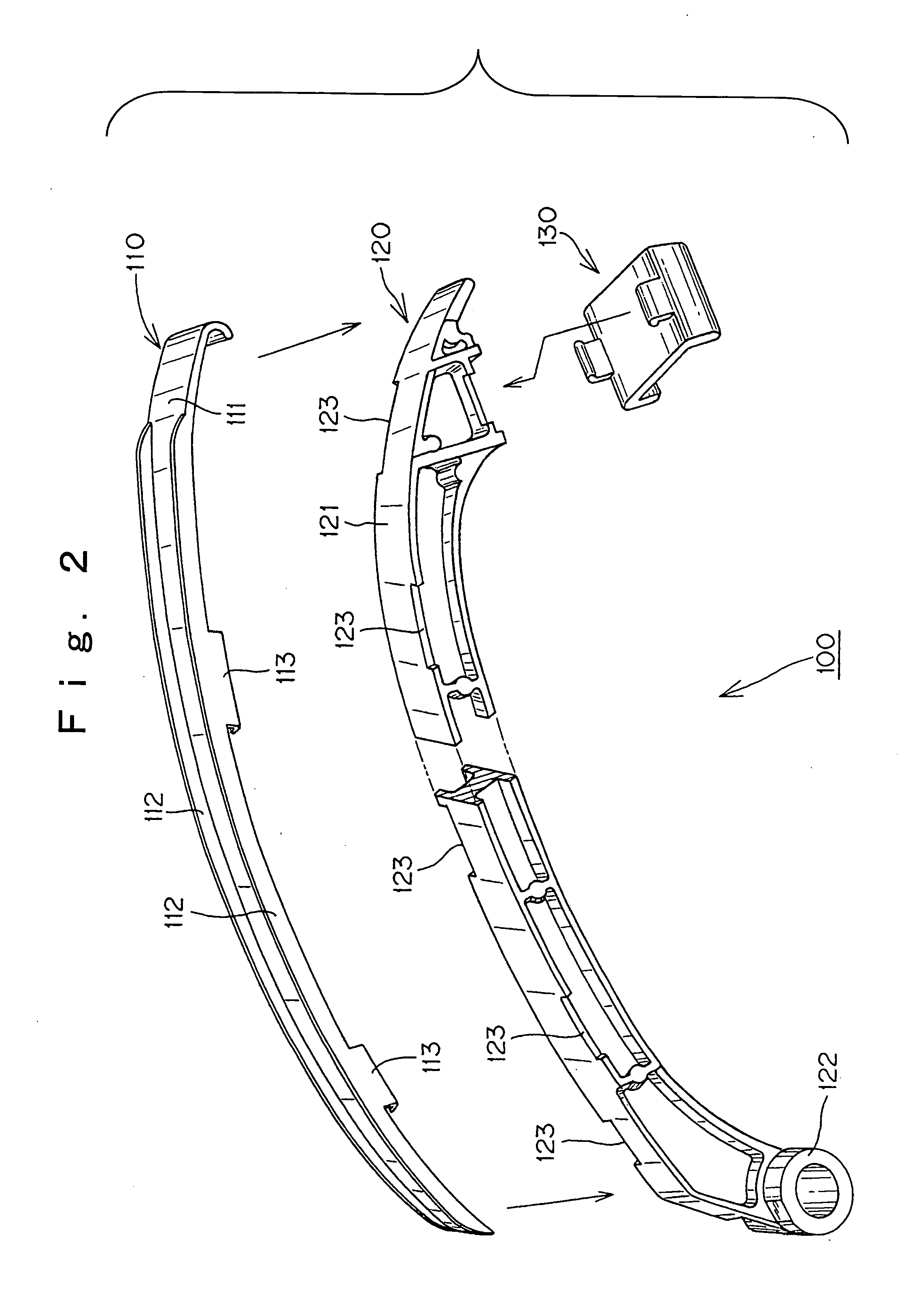

Guide for transmission device

A guide for a traveling transmission medium such as a timing chain comprises a resin shoe for sliding contact with the transmission medium, supported on a base frame having an two flanges and a web in an I-shaped cross-section. The base frame is produced from aluminum by die casting, using a three-part mold. Two parts of the mold cooperate to form a part of the mold cavity that forms one of the flanges and the web of the base frame, and a third part of the mold cooperates with the first two parts to form a part of the cavity in which the other flange of the base frame is formed without a draft.

Owner:TSUBAKIMOTO CHAIN CO

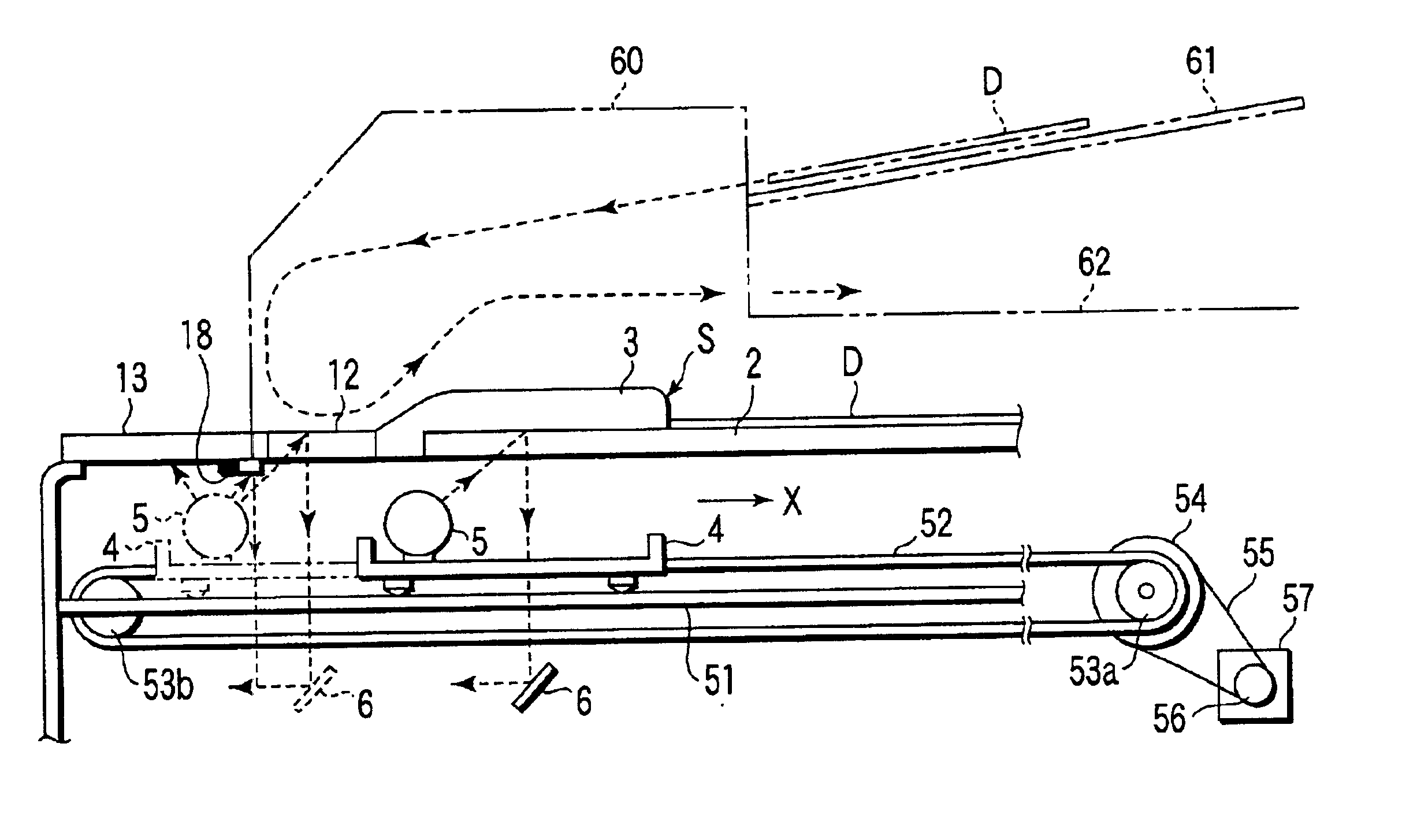

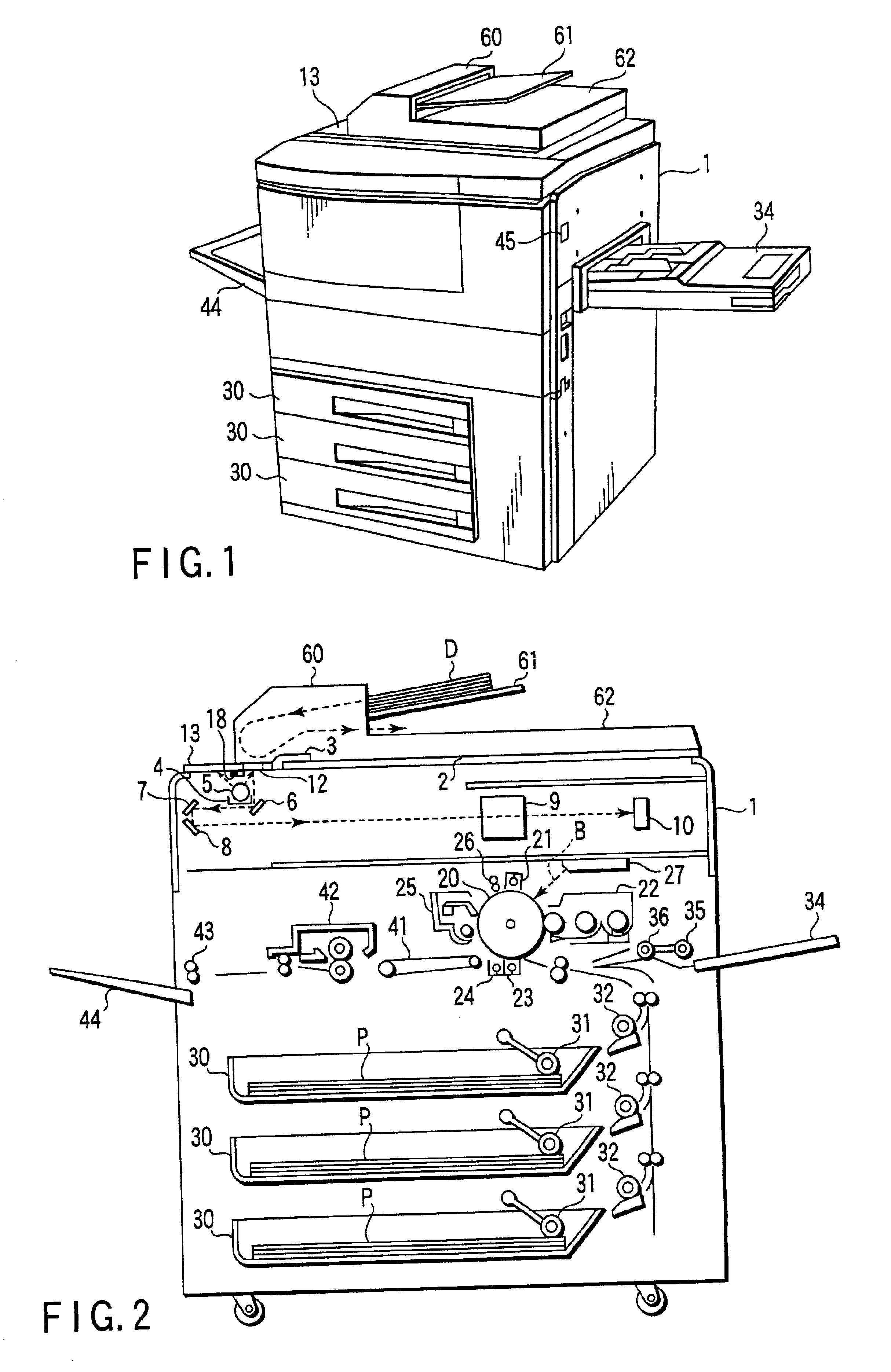

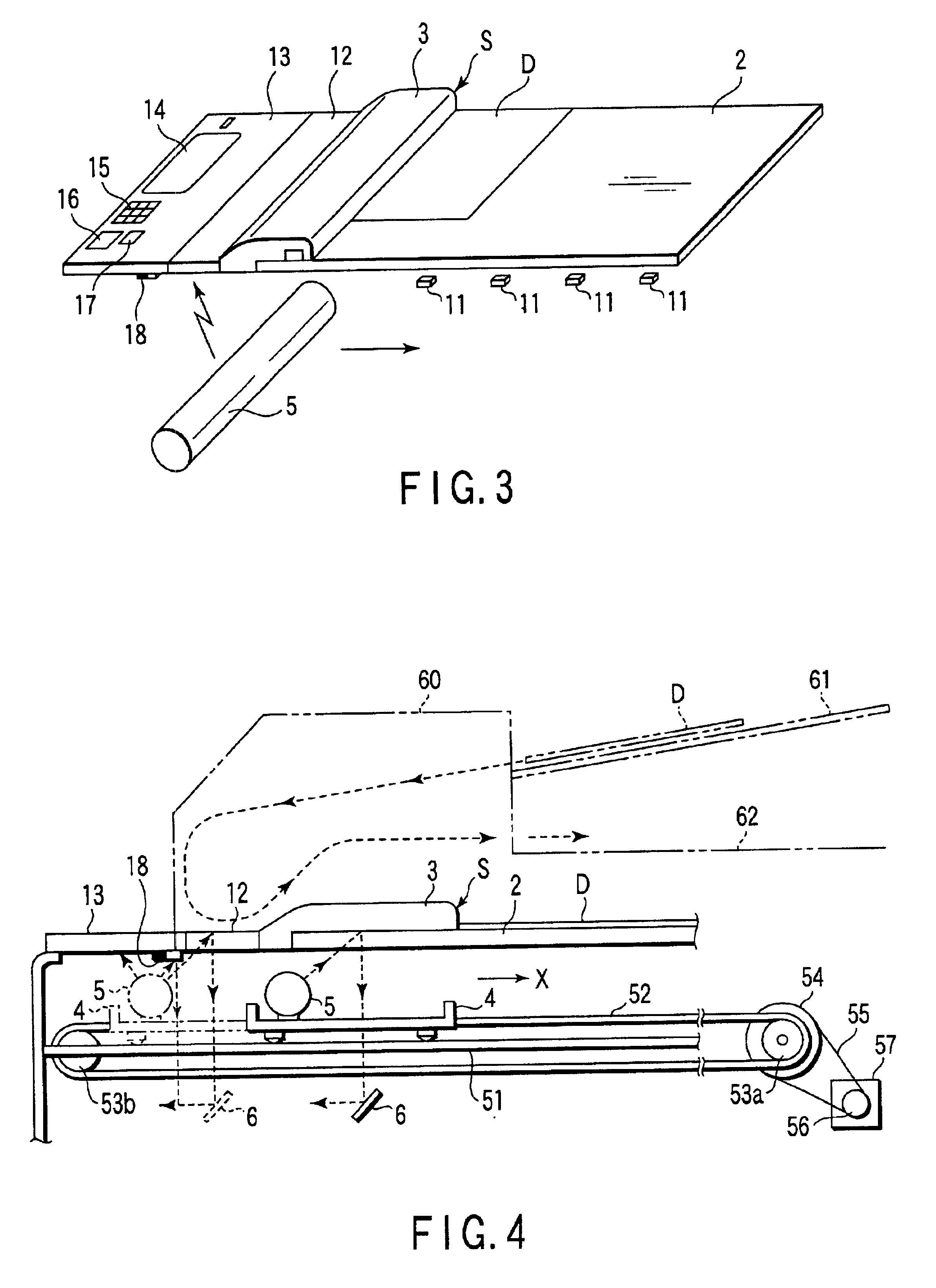

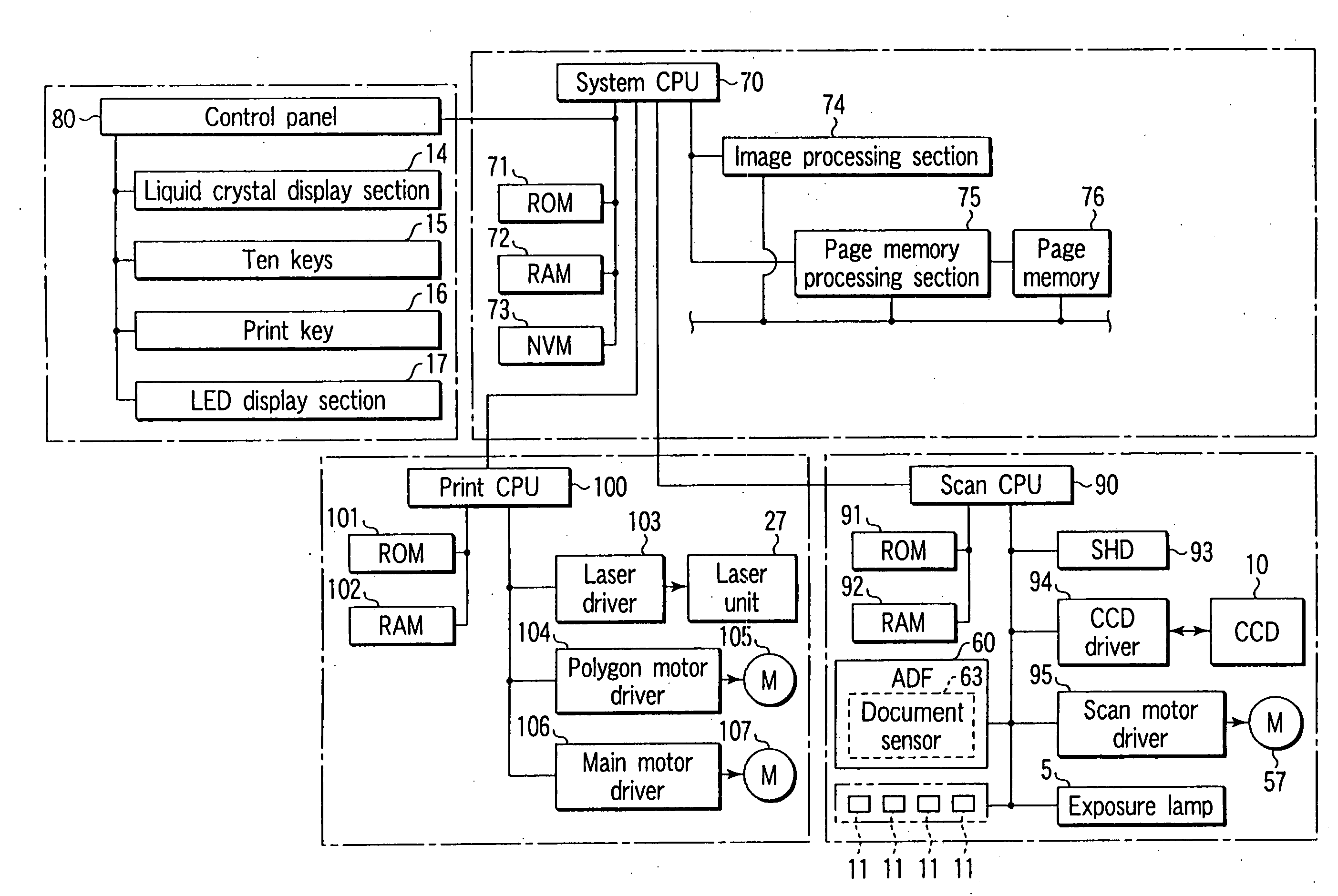

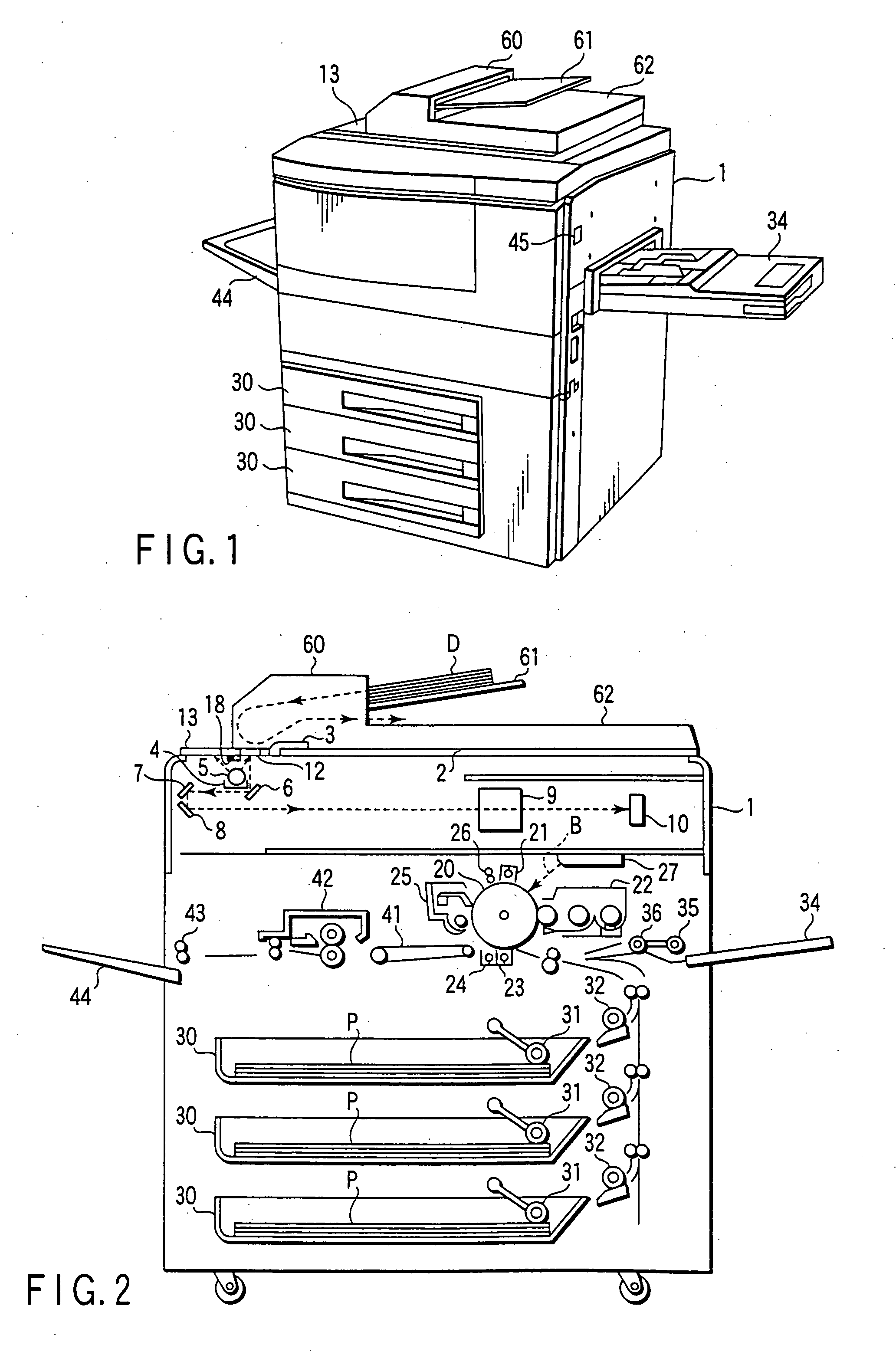

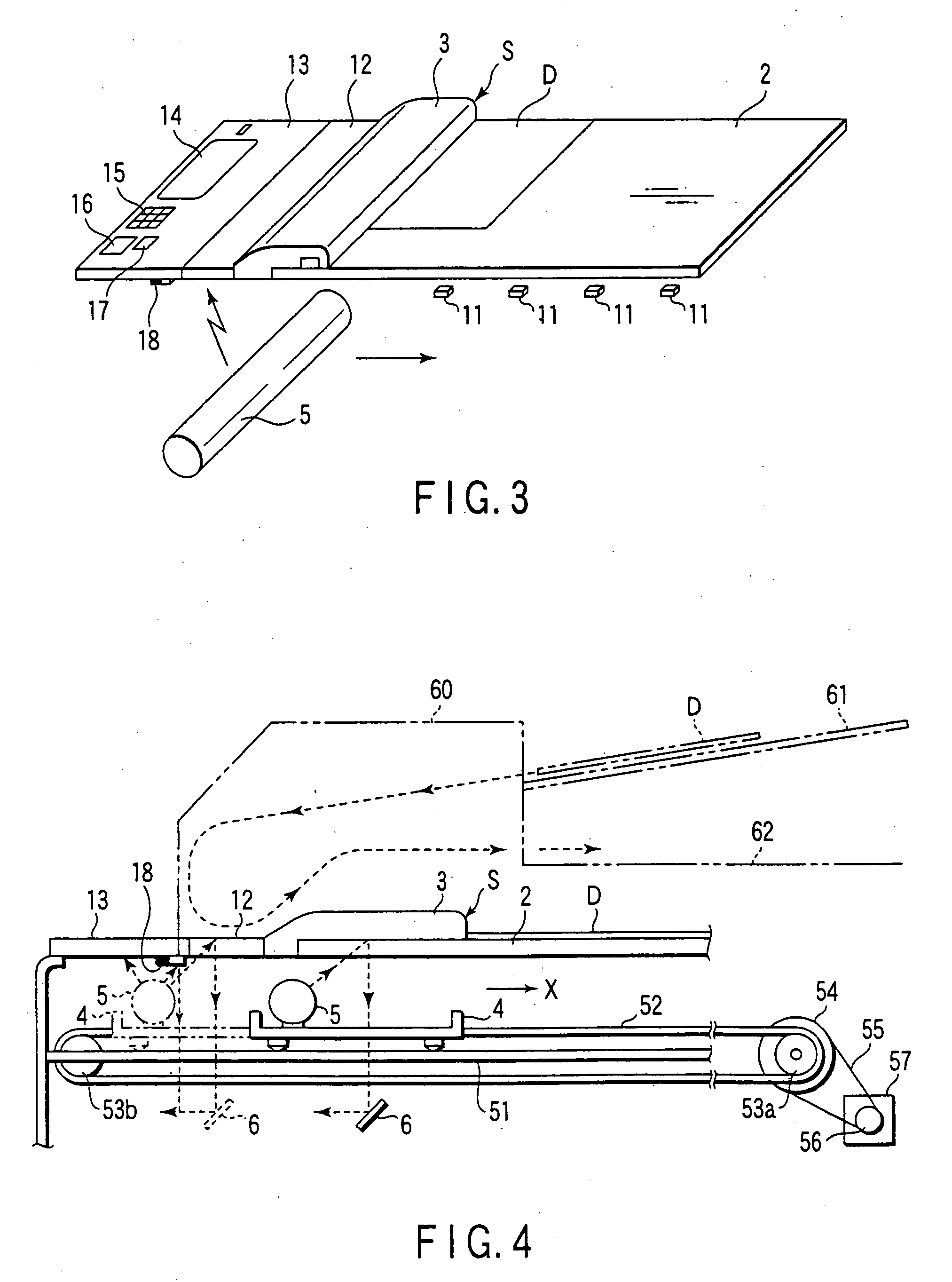

Image forming apparatus and method of controlling the apparatus

InactiveUS6891647B2Fast readAvoid thermal effectsPictoral communicationLiquid-crystal displayCold cathode

A cold-cathode ray tube is adopted as an exposure lamp and the exposure lamp is always lit. When the exposure lamp exists at a standby position, a light of the exposure lamp is irradiated at a lower surface side of a control panel. By this irradiation, the liquid crystal display section of the control panel is irradiated in a state of looking bright and clear.

Owner:KK TOSHIBA +1

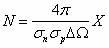

Method for detecting distribution of deuterium particle beams

InactiveCN102608650AAvoid interference from foreign particlesOvercoming thermal effectsNeutron radiation measurementParticle beamMicroscope

The invention provides a method for detecting the distribution of deuterium particle beams. The method is characterized by comprising the following steps: (1) arranging a CR-39 solid state nuclear track detector on the rear surface of a deuterium target or a tritium target of an accelerator based neutron source; (2) recording a number of tracks on the surface of the CR-39 solid state nuclear track detector after the accelerator based neutron source is irradiated by a microscope; and (3) by a mapping relation between a deuterium particle number N on the surface of the deuterium target or the tritium target and the number X of the tracks on the surface of the CR-39 solid state nuclear track detector, inverting the distribution of the deuterium particle beams by the number X of the tracks. According to the method, the measurement on the distribution of the deuterium particle beams can be implemented and the interference of impurity particles is effectively avoided; the distribution of high-current deuterium particle beams in an order range of milliampere to ampere can be measured; and the thermal effect generated by energy deposition in the direct action process of the high-current particle beams and the CR-39 solid state nuclear track detector is effectively overcome.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

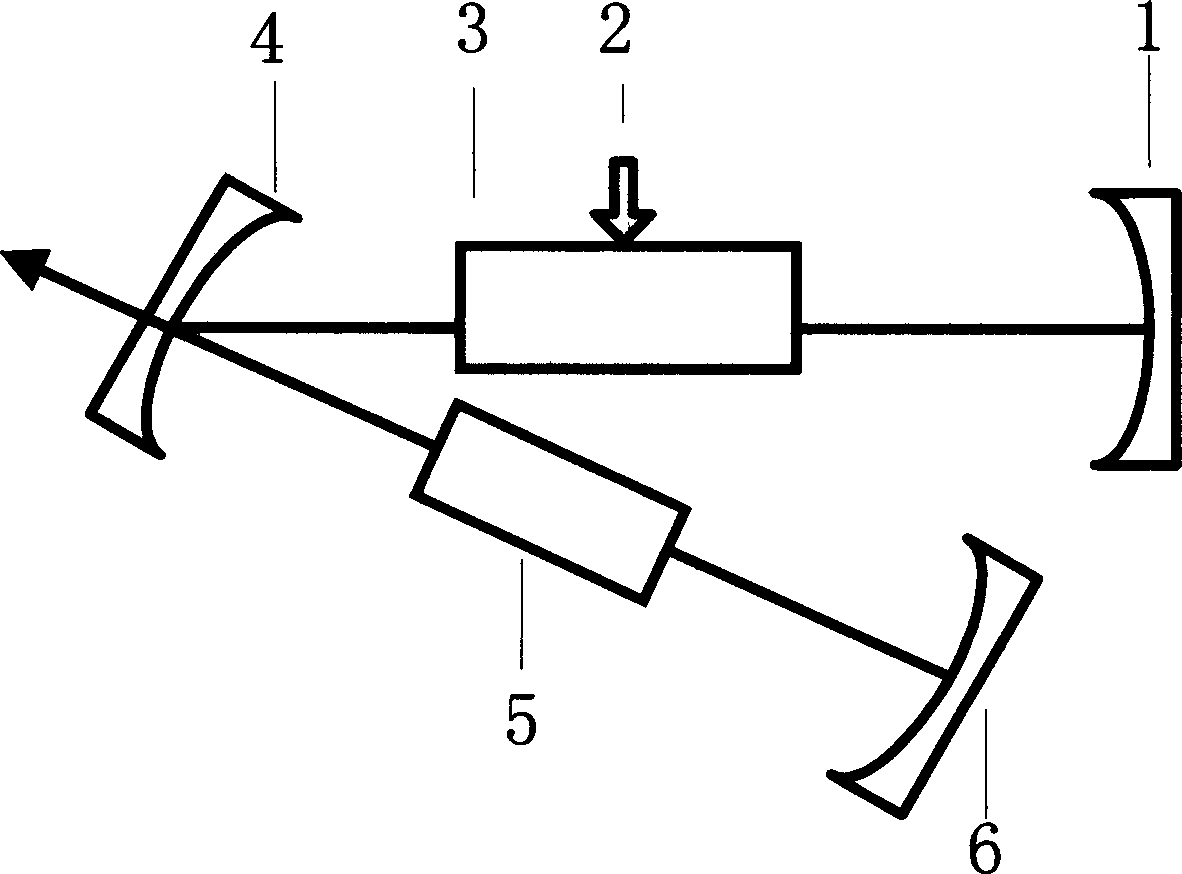

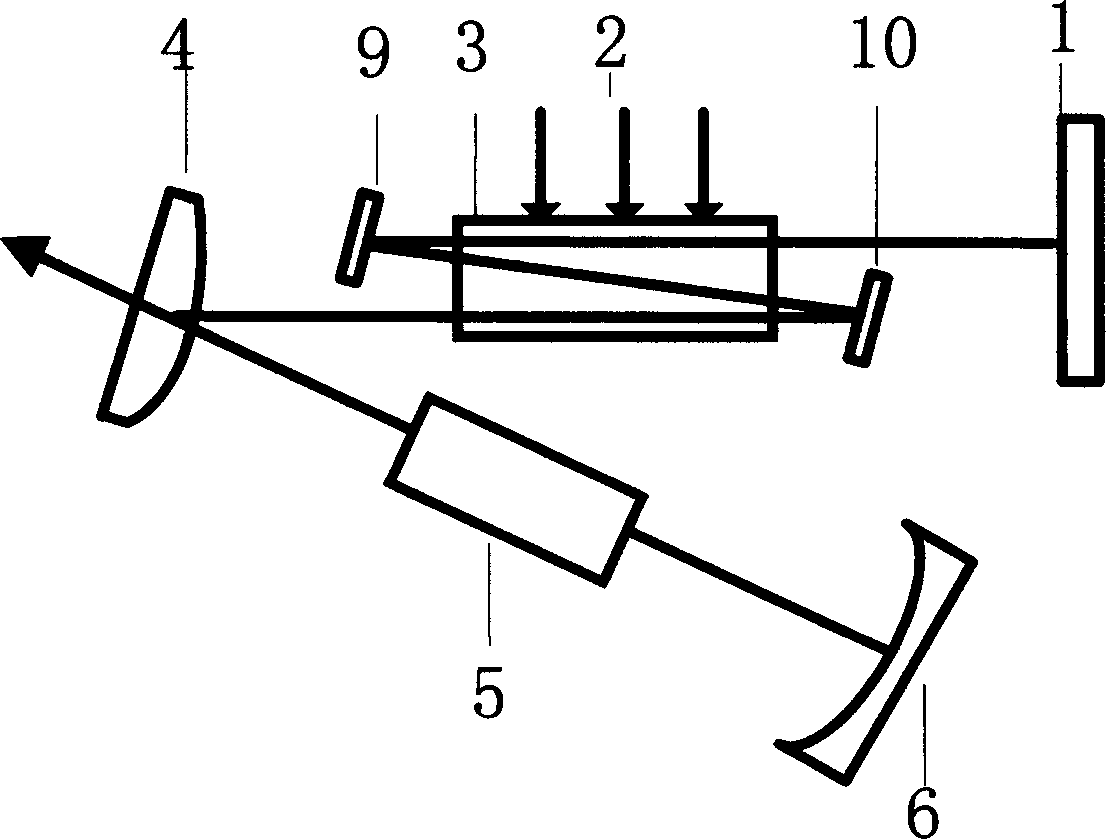

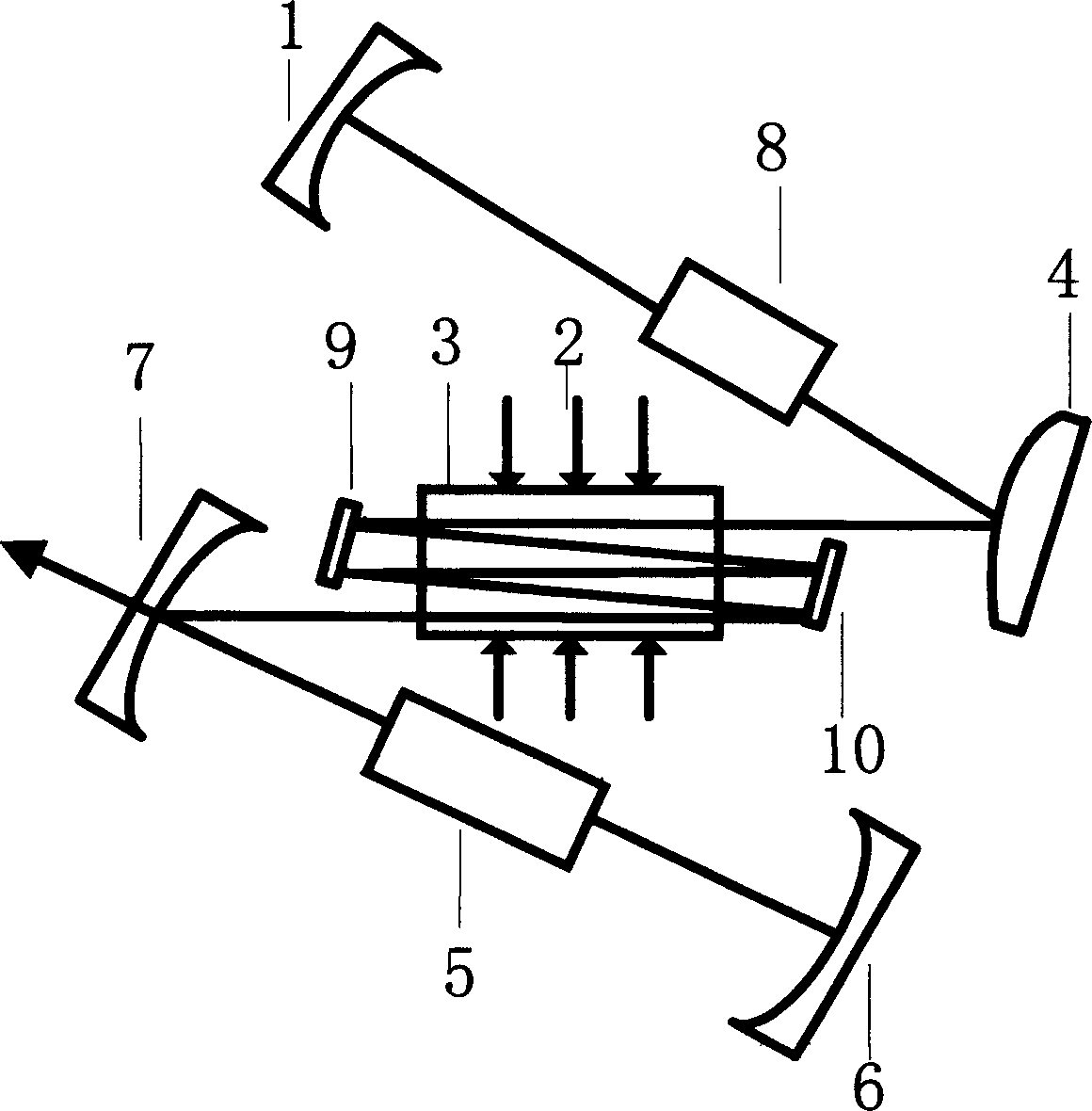

Frequency multipliver plate strip laser device in folding chamber for compensating astigmatism

InactiveCN1588715ASimple structureMature processing technologyActive medium materialOptical pathAstigmatism

In this invention, along its light-pass, arranged respectively are: first cavity resonator mirror, latch crystal, spherical surface folding mirror; and along the reflection light-pass of said spherical surface mirror arranged respectively are: frequency doubling crystal and second cavity resonator mirror. Pumping light source is placed by the side of lath crystal for pumping it. In this invention, lath crystal is used as activated material, folding cavity for inner cavity frequency doubling, and lath crystal for overcoming heat effect. Advantages are: astigmatism produced by two effects in resonator can be compensated by regulating turning angle of spherical surface folding mirror.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

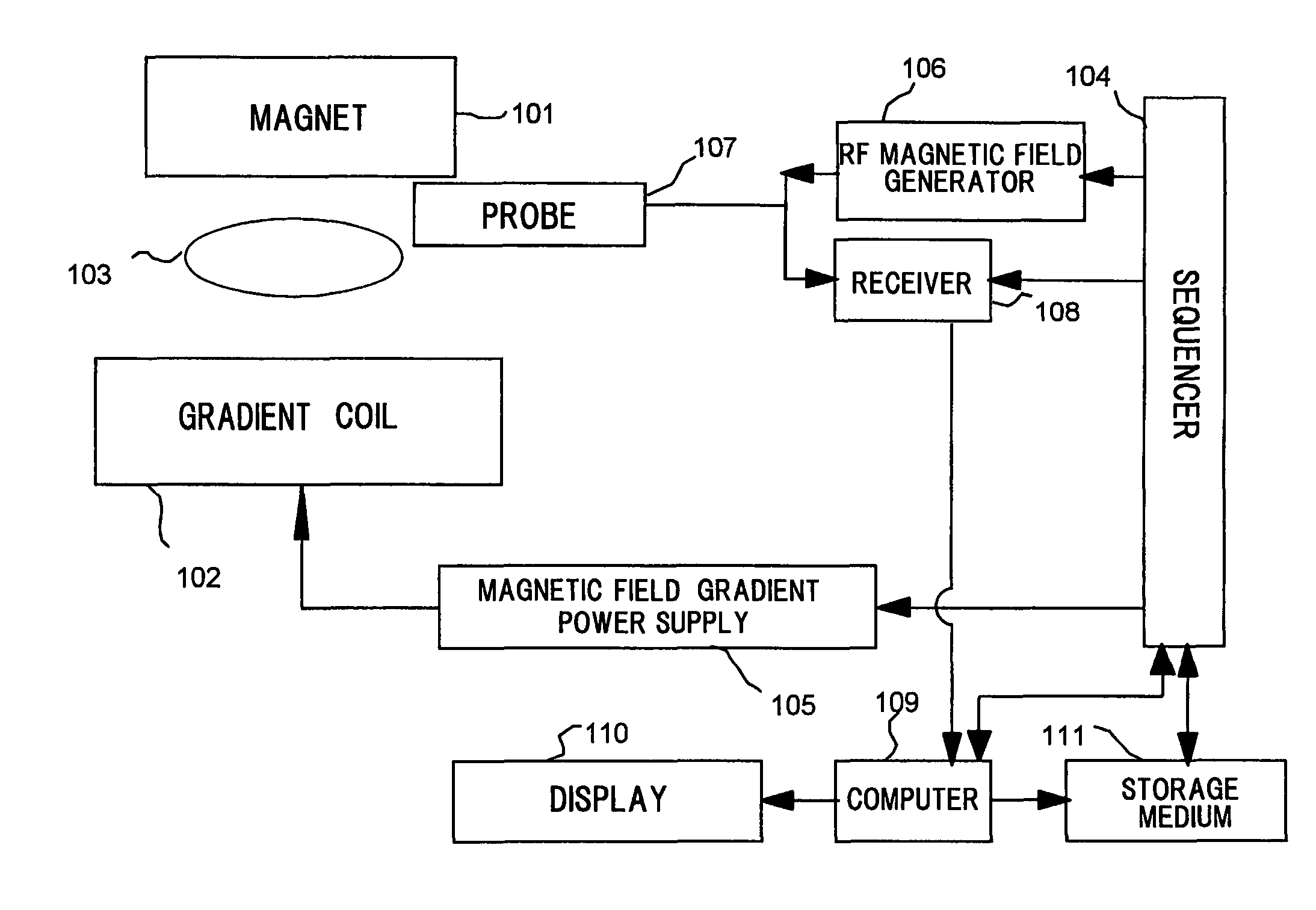

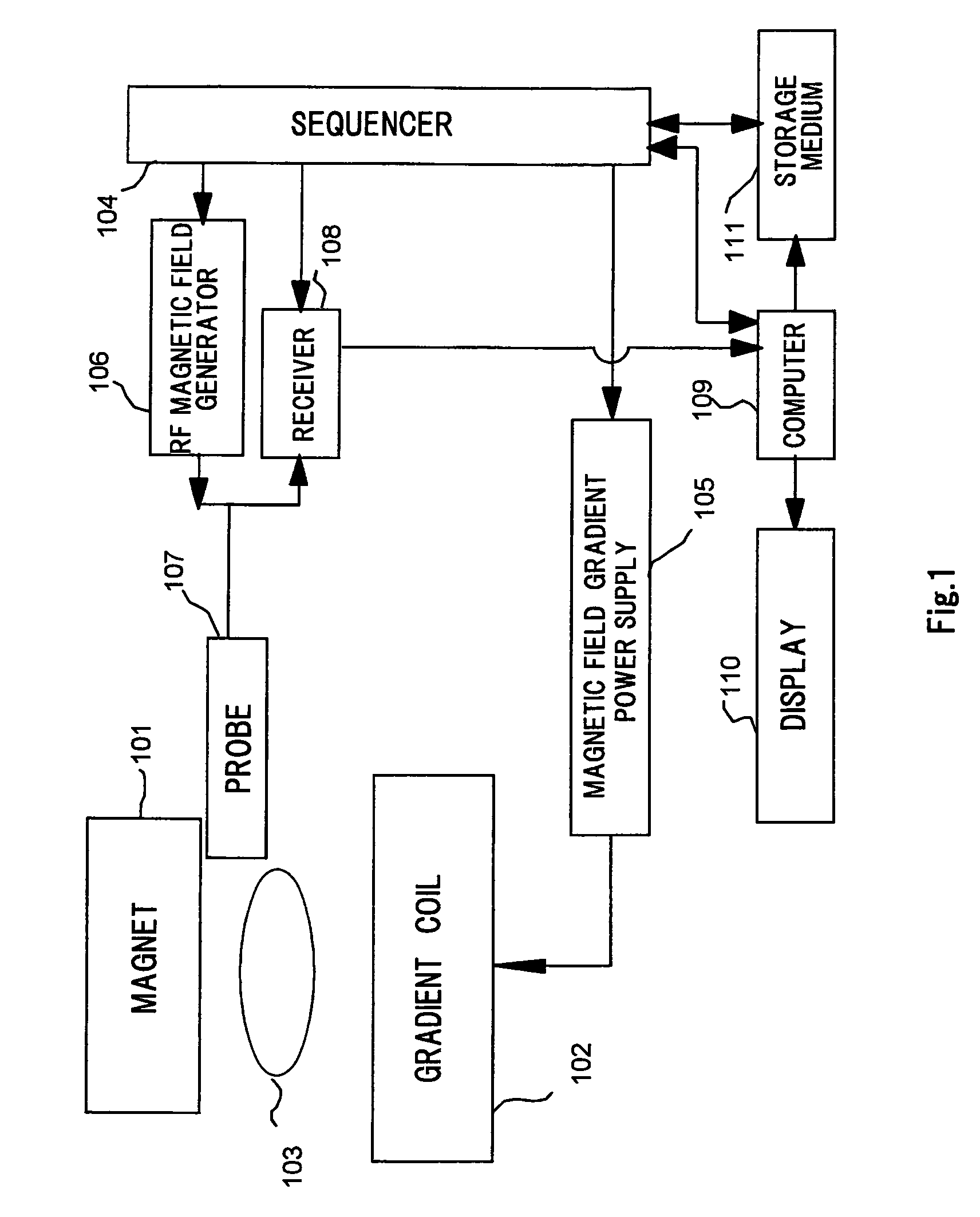

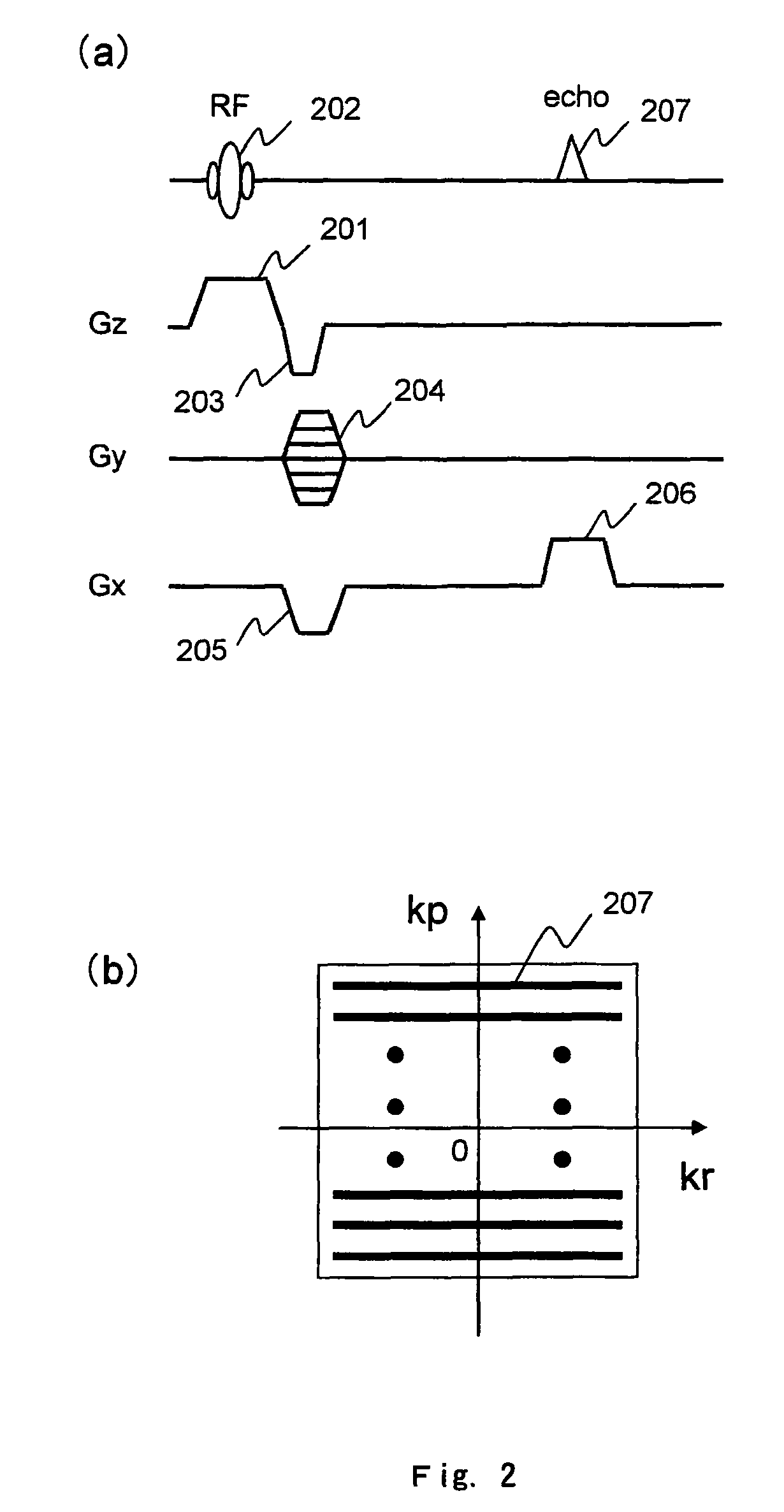

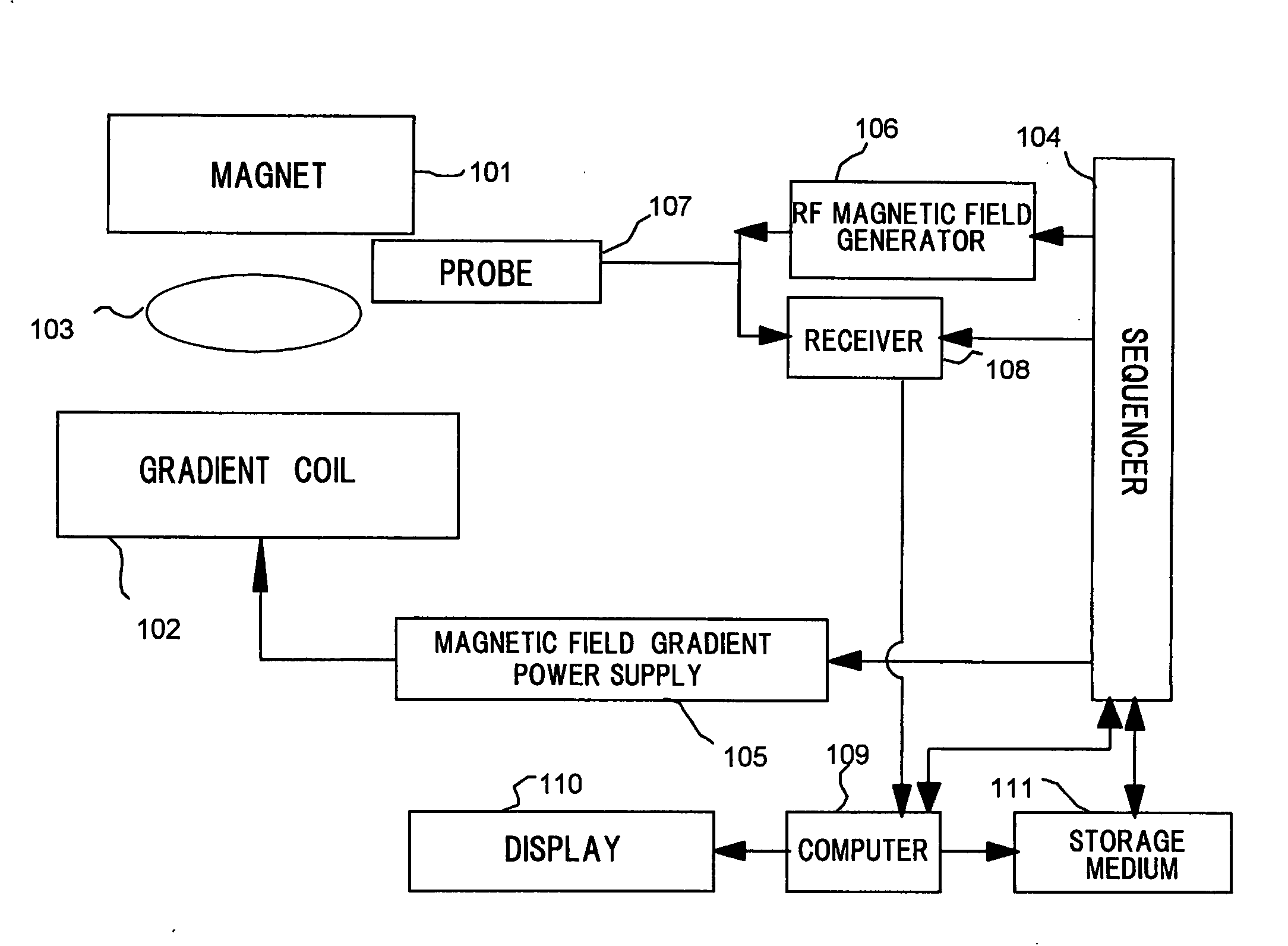

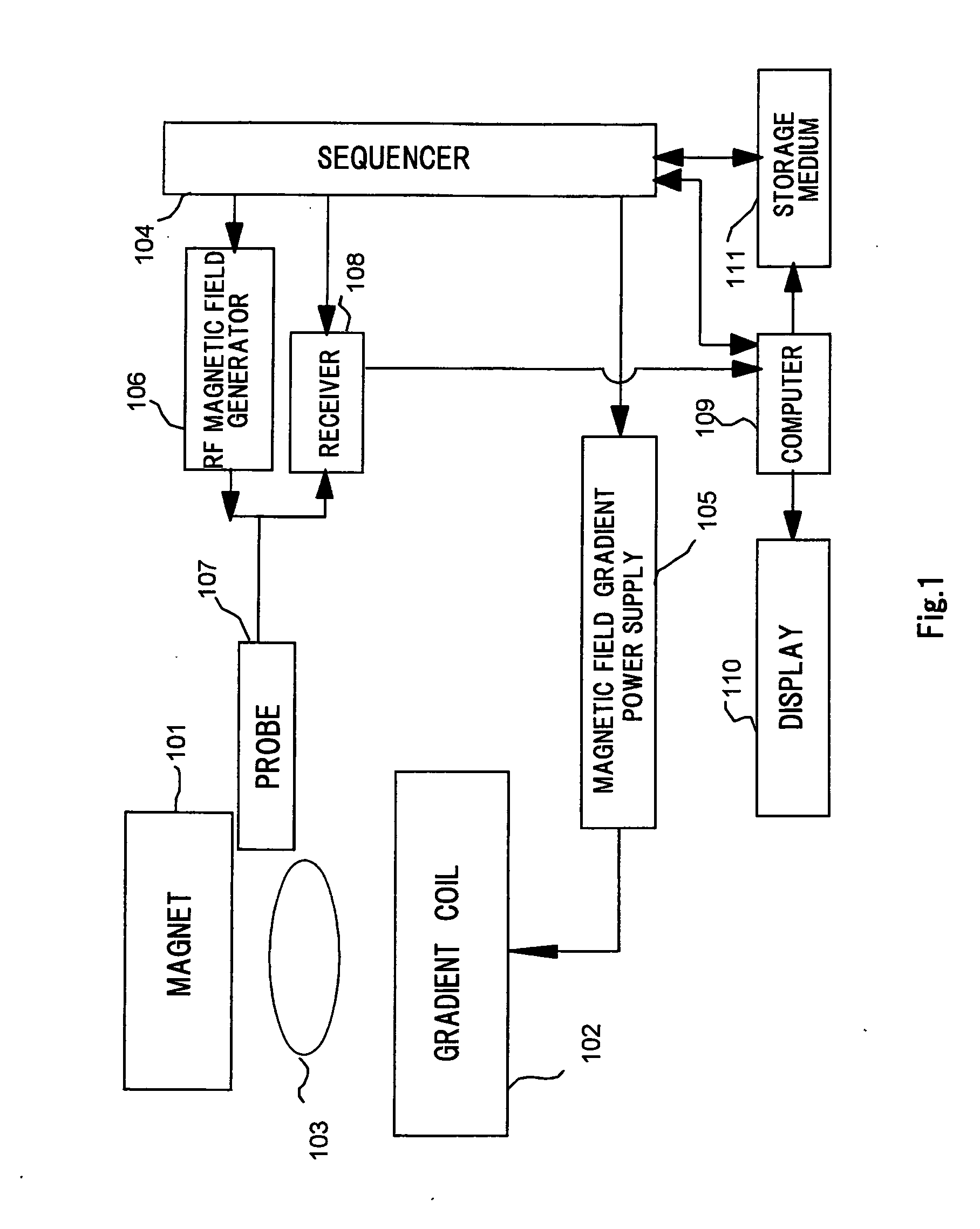

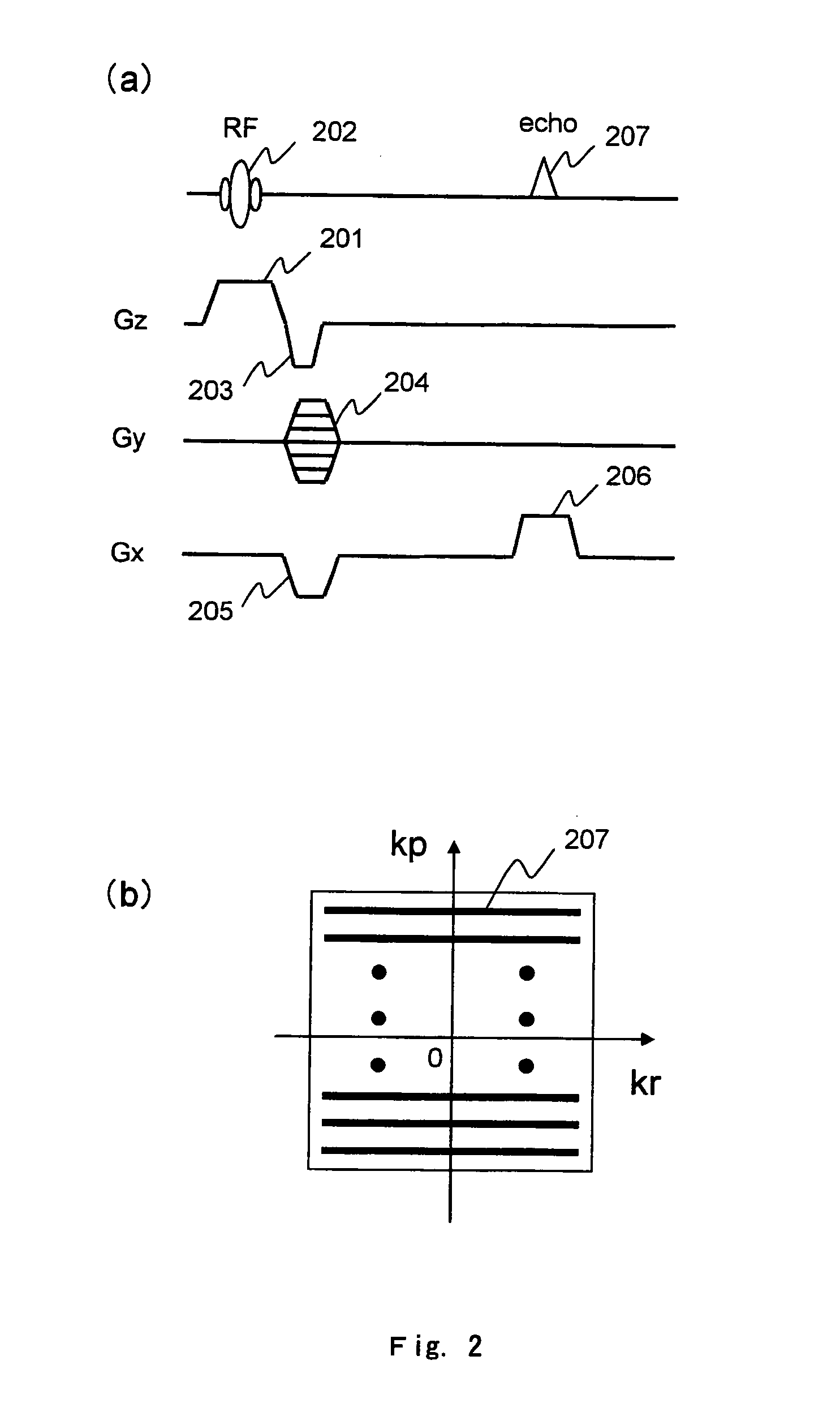

Magnetic resonance imaging apparatus

InactiveUS7868618B2Image contrastAvoid thermal effectsMagnetic measurementsDiagnostic recording/measuringImage contrastMagnetization

Owner:HITACHI LTD

Magnetic Resonance Imaging Apparatus

InactiveUS20090251142A1Image contrastAvoid thermal effectsDiagnostic recording/measuringMeasurements using NMR imaging systemsImage contrastMagnetization

The MRI apparatus of the present invention executes a non-imaging mode 501 for obtaining a steady state of magnetization and an imaging mode 502 for measuring echoes for images. In the non-imaging mode 501 and the imaging mode 502, imaging is performed by using a GrE type pulse sequence. In the imaging, RF pulses are irradiated while flip angle of nuclear magnetization in the imaging mode 502 is changed in a range of values not larger than a certain value determined by flip angle of nuclear magnetization used in the non-imaging mode 502 is irradiated. This certain value is, for example, the maximum value of flip angle of nuclear magnetization used in the non-imaging mode, or flip angle provided by an RF pulse used at the end of the non-imaging mode. SAR observed with use of a GrE type pulse sequence can be thereby reduced without degrading image contrast, and thus influence on human bodies can be reduced.

Owner:HITACHI LTD

Fuel cell system

ActiveUS20100104902A1Minimize diffusionAvoid thermal effectsFuel cell heat exchangeFuel cells groupingCombustorFuel cells

A casing of a fuel cell system is divided into a module area, a first fluid supply area, a second fluid supply area, and an electric parts area. The first fluid supply area is provided on a first side surface of the module area, and an electric parts area is provided on a second side surface of the module area. The second fluid supply area is provided under a bottom surface of the module area. A fuel cell module and a combustor are provided in the module area.

Owner:HONDA MOTOR CO LTD

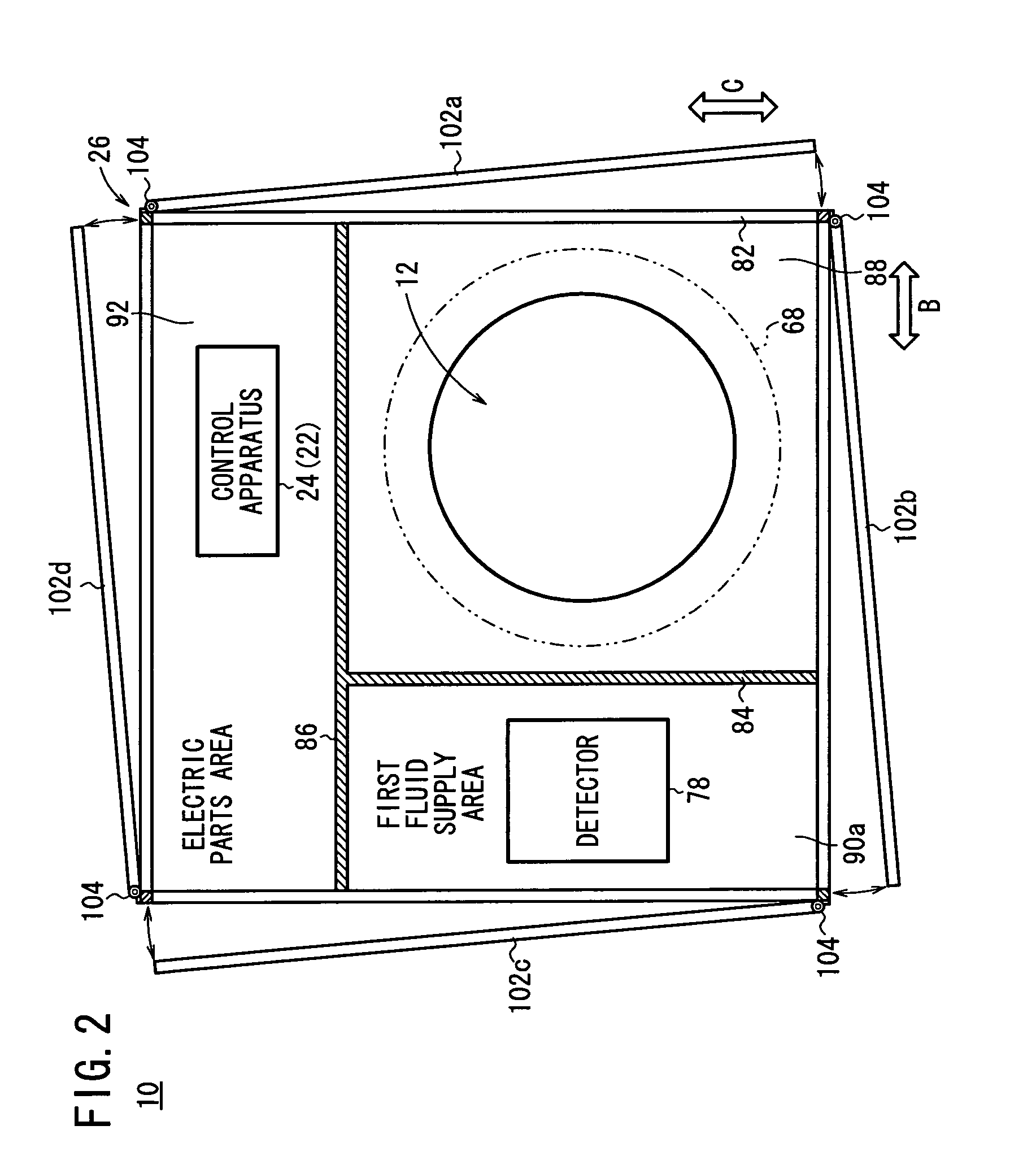

Method for extracting total flavonoids from psidium guajava leaves

The invention discloses a method for extracting total flavonoids from psidium guajava leaves. The method is characterized by comprising the steps of putting the psidium guajava leaves in an aqueous solution of a surfactant, carrying out extraction under the assistance of microwaves and ultrasonics, and then, carrying out solid-liquid separation, thereby obtaining an extract containing the total flavonoids, wherein the mass percent of the surfactant in the aqueous solution of the surfactant is 1% to 3%, the microwave power is 100W to 150W, and the ultrasonic power is 600W to 650W. According the method, an organic solvent is replaced with an aqueous solution, and the wetting and solubilization actions of the surfactant, a bulk-heating principle of microwave extraction and an cavitation effect of the ultrasonics are fully combined, so that the traditional problem, i.e., organic solvent residue is solved, meanwhile, the extraction time can be greatly shortened, the extraction ratio is increased, the production cost of enterprises is reduced, and the method has a broad popularization prospect.

Owner:广东番石榴健康产业有限公司 +1

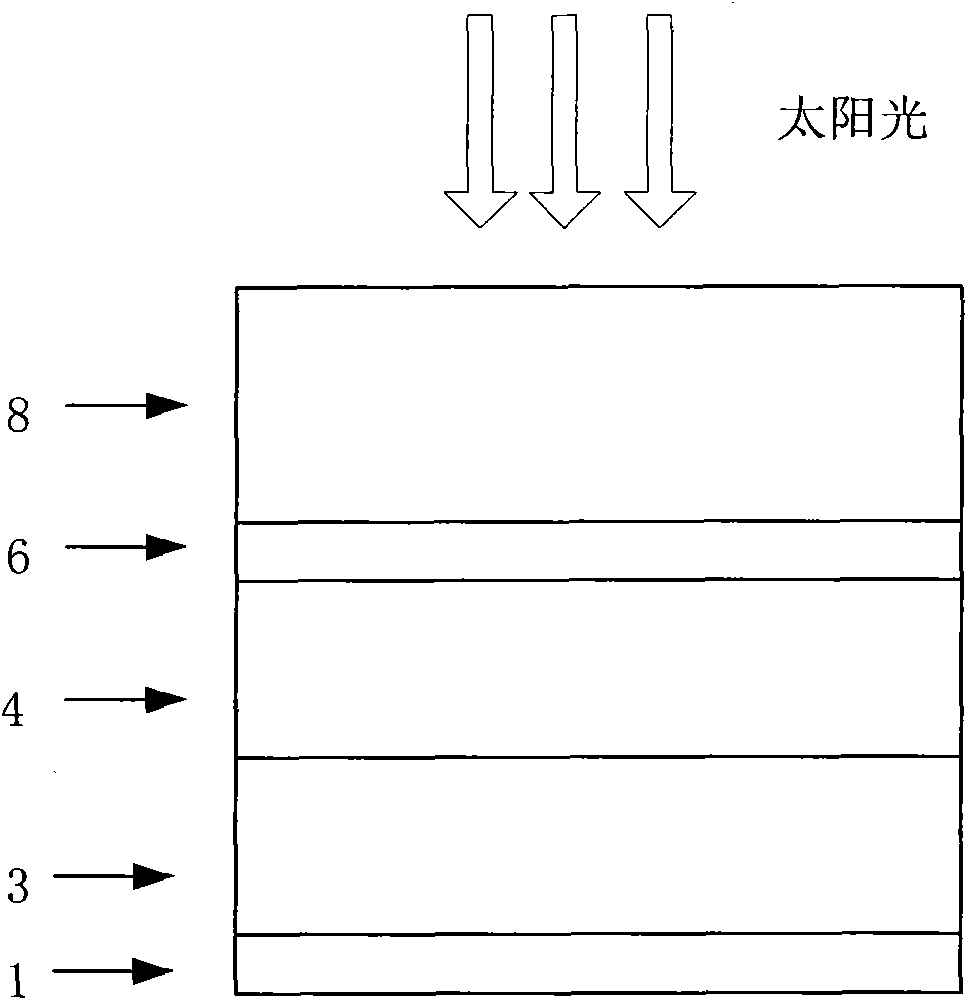

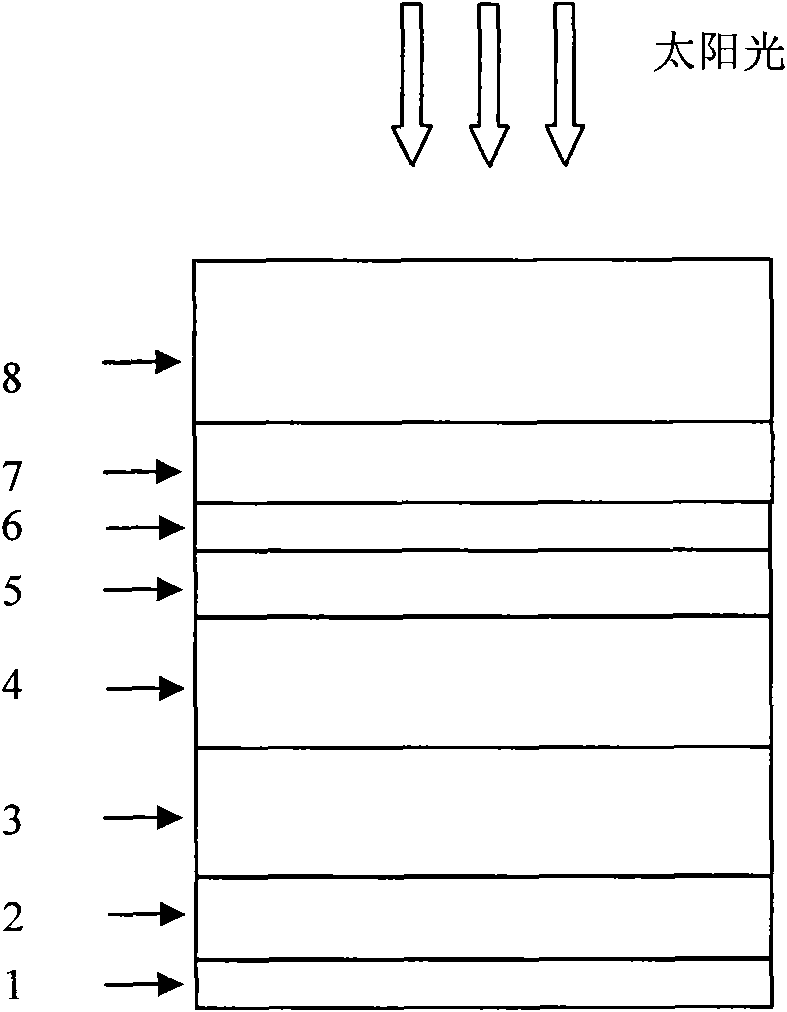

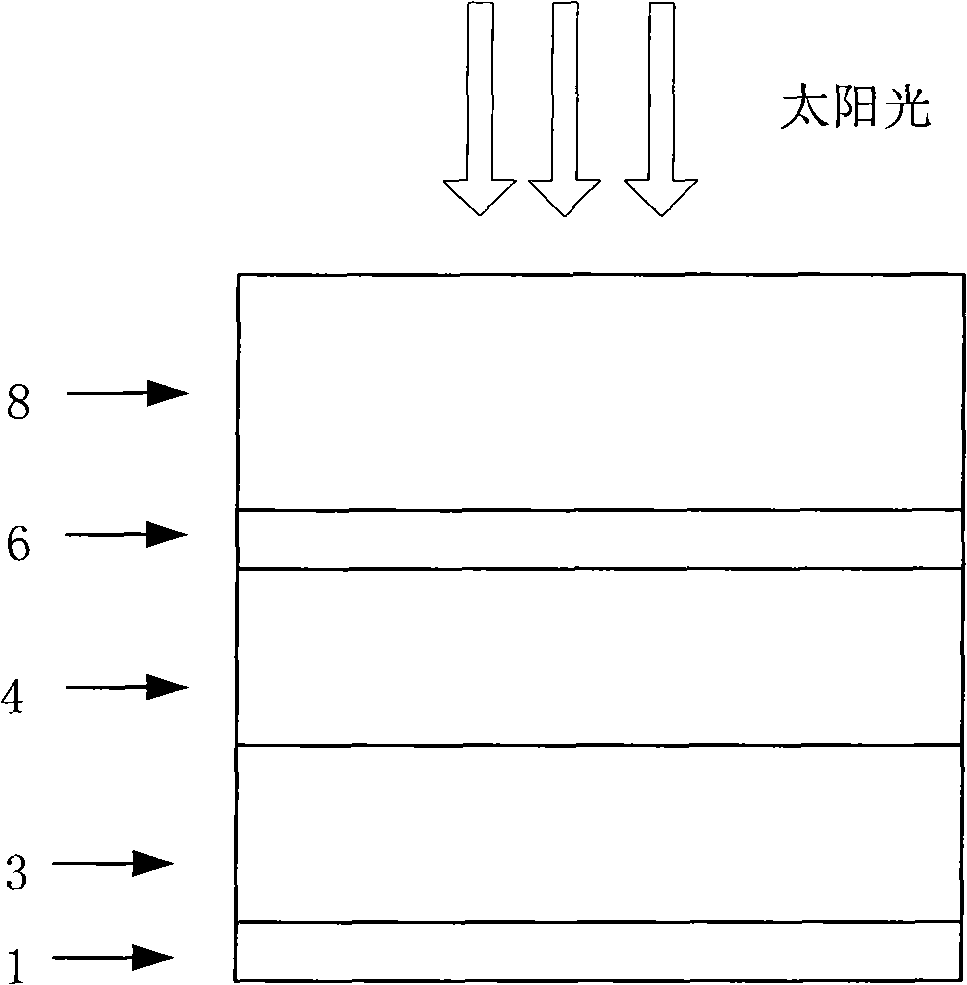

Solar battery

InactiveCN102201288AImprove photoelectric conversion performanceIncrease profitLight-sensitive devicesSolid-state devicesHeterojunctionCharge carrier

The invention discloses a solar battery comprising a first electrode, a first photosensitive layer, a second photosensitive layer, a second electrode and a lower conversion layer, which are sequentially arranged from the bottom up. The first photosensitive layer and the second photosensitive layer form an electron donor-electron acceptor heterojunction. The solar battery disclosed by the invention has high utilization ratio of a solar spectrum, the problem of the thermal effect of current carriers is overcome, and the energy conversion efficiency of the solar battery is largely increased.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Fuel cell system

InactiveUS20100112395A1Minimize diffusion of heatMinimize diffusionFuel cell heat exchangeFuel cells groupingFuel cellsCombustor

A casing of a fuel cell system is divided into a module area, a fluid supply area, and an electric parts area. The fluid supply area is provided on a first side surface of the module area, and an electric parts area is provided on a second side surface of the module area. A fuel cell module and a combustor are provided in the module area.

Owner:HONDA MOTOR CO LTD

Image forming apparatus and method of controlling the apparatus

InactiveUS20050174611A1Avoid thermal effectsFast readPictoral communicationLiquid-crystal displayCold cathode

A cold-cathode ray tube is adopted as an exposure lamp and the exposure lamp is always lit. When the exposure lamp exists at a standby position, a light of the exposure lamp is irradiated at a lower surface side of a control panel. By this irradiation, the liquid crystal display section of the control panel is irradiated in a state of looking bright and clear.

Owner:KK TOSHIBA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com