Rare earth upconversion nanoparticles, preparation method and uses thereof

A rare earth up-conversion and nano-particle technology, applied in the field of nanoparticles, can solve the problems of high excitation light source intensity and low conversion luminescence quantum yield, and achieve the effect of improving the up-conversion luminescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

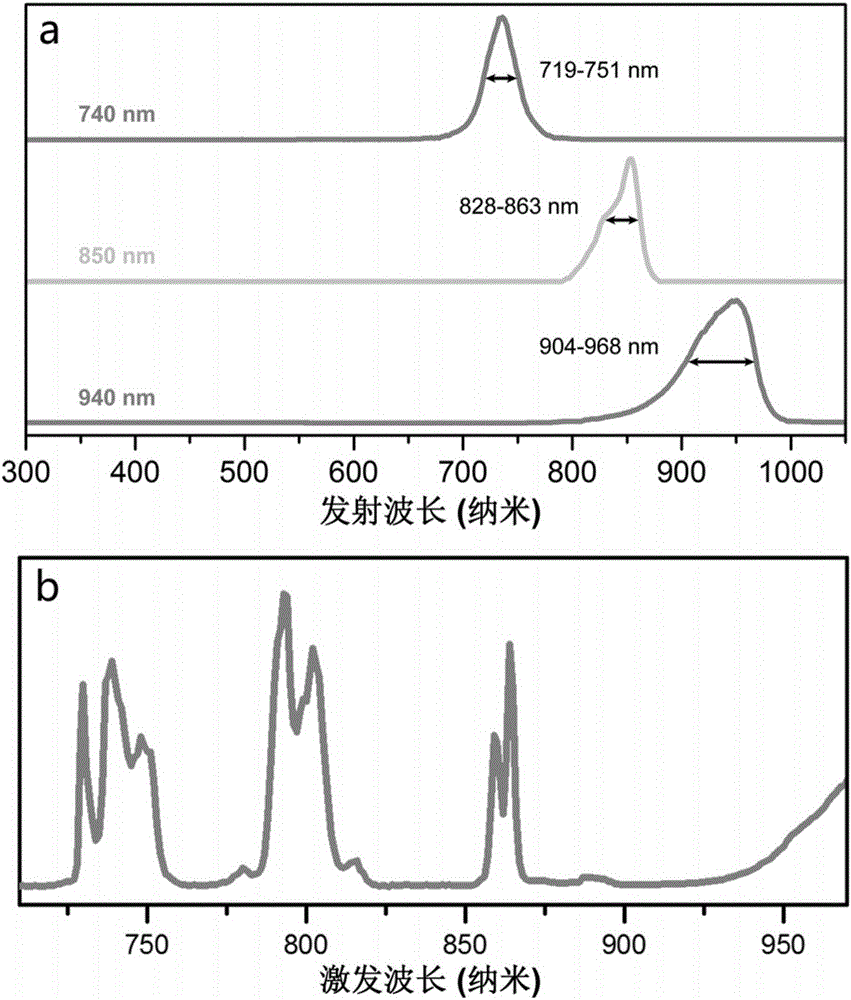

[0067] Example 1: Rare earth up-conversion nanoparticles NaYF 4 :Yb,Er@NaYF 4 :Yb@NaNdF 4 :Yb

[0068] Will be stoichiometric ratio CF 3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb:(CF 3 COO) 3 Er=1mmol: 0.78mmol: 0.3mmol: 0.02mmol The prepared mixed powder was added to the mixed system of oleic acid (10mL) and octadecene (20mL), stirred under vacuum at 120°C for 30min, and then heated to 320°C for 1 hour; after cooling, centrifuge, wash with ethanol for 1-2 times, and disperse with 2mL cyclohexane to obtain dispersion I.

[0069] Add dispersion I to CF 3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb=0.3mmol:0.27mmol:0.9mmol, in a mixed solution of oleic acid (20mL) and octadecene (20mL), stirred under vacuum at 120°C for 30min, then heated to 300°C under argon protection and continued for 1h; cooled Afterwards, centrifuge, wash with ethanol for 1-2 times, and disperse with 2 mL of cyclohexane to obtain dispersion II.

[0070] Add dispersion II to CF 3 COONa:(CF 3 COO) 3 Y:...

Embodiment 2

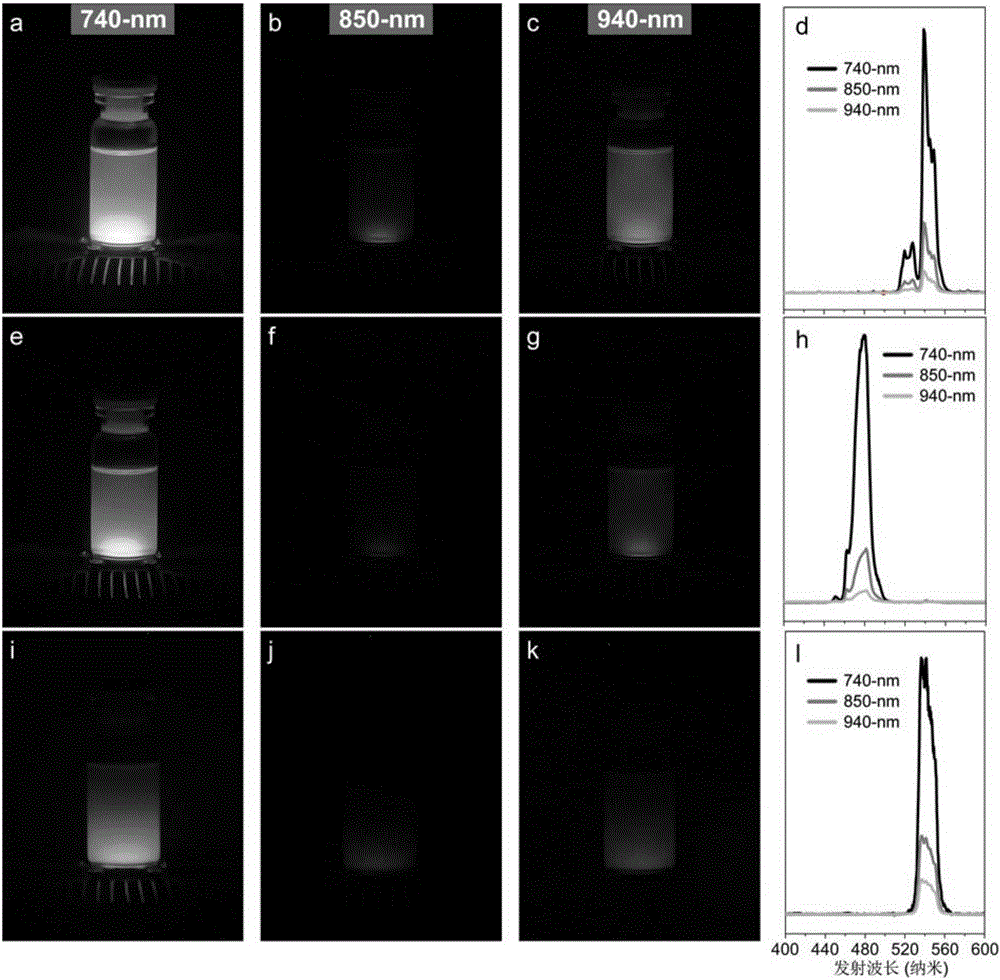

[0073] Example 2: Rare earth up-conversion nanoparticles NaYF 4 :Yb,Tm@NaYF 4 :Yb@NaNdF 4 :Yb

[0074] Will be stoichiometric ratio CF3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb:(CF 3 COO) 3 Tm=1mmol: 0.71mmol: 0.32mmol: 0.005mmol The prepared mixed powder was added to the mixed system of oleic acid (10mL) and octadecene (20mL), stirred at 120°C for 30min under vacuum, and then heated up to 320°C for 1 hour; after cooling, centrifuge, wash with ethanol for 1-2 times, and disperse with 2mL cyclohexane to obtain dispersion I.

[0075] Add dispersion I to CF 3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb=1mmol:0.75mmol:0.25mmol, in a mixed solution of oleic acid (20mL) and octadecene (20mL), stirred at 120°C under vacuum for 30min, then heated to 300°C under the protection of argon for 1h; after cooling , centrifuged, washed with ethanol for 1-2 times, and then dispersed with 2 mL of cyclohexane to obtain dispersion II.

[0076] Add dispersion II to CF 3 COONa:(CF 3 COO) 3 Y...

Embodiment 3

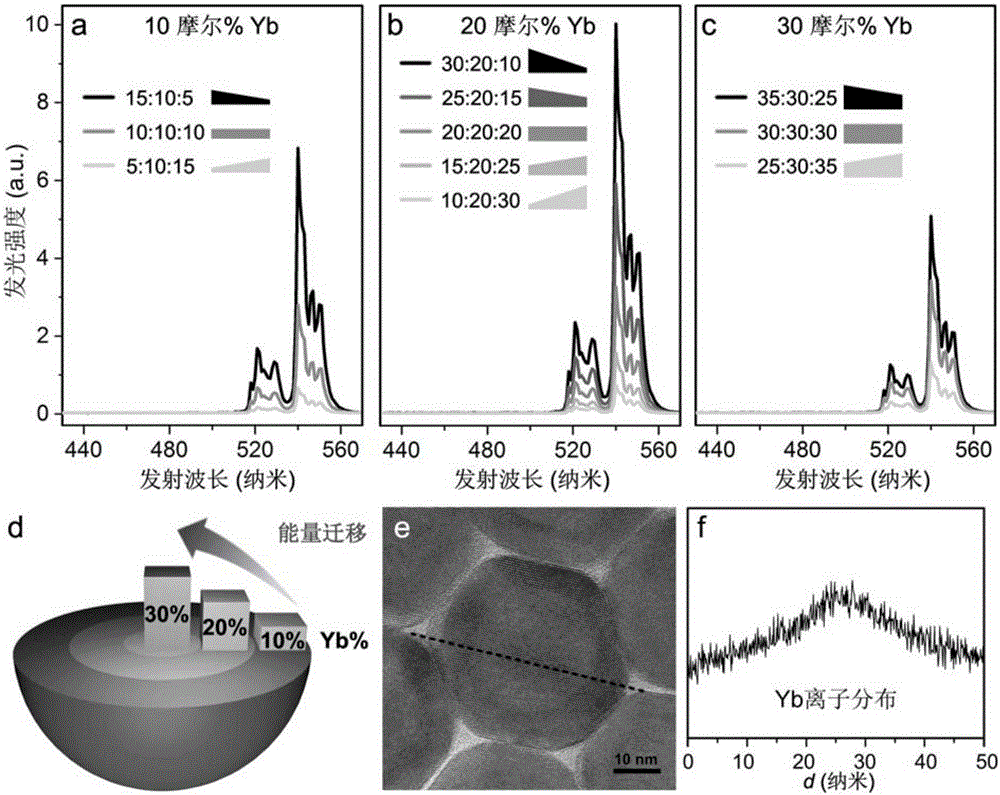

[0078] Example 3: Rare earth up-conversion nanoparticles NaYF 4 :Yb,Ho@NaYF 4 :Yb@NaNdF 4 :Yb

[0079] Will be stoichiometric ratio CF 3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb:(CF 3 COO) 3 Ho=1mmol: 0.9mmol: 0.35mmol: 0.015mmol The prepared mixed powder was added into the mixed system of oleic acid (10mL) and octadecene (20mL), stirred under vacuum at 120°C for 30min, and then heated to 320°C for 1 hour; after cooling, centrifuge, wash with ethanol for 1-2 times, and disperse with 2mL cyclohexane to obtain dispersion I.

[0080] Add dispersion I to CF 3 COONa:(CF 3 COO) 3 Y:(CF 3 COO) 3 Yb=1mmol:0.9mmol:0.9mmol, in a mixed solution of oleic acid (20mL) and octadecene (20mL), stirred under vacuum at 120°C for 30min, then heated to 300°C under argon protection and continued for 1h; after cooling , centrifuged, washed with ethanol for 1-2 times, and then dispersed with 2 mL of cyclohexane to obtain dispersion II.

[0081] Add dispersion II to CF 3 COONa:(CF 3 COO)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com