Manufacture of superthin high-refractivity optical resin lens

An optical resin lens, high refractive index technology, applied in optical components, household appliances, other household appliances, etc., can solve the problems of insufficient visible light transmittance, thick lens, etc., to solve a large number of thermal effects, increase the pass rate, improve The effect of optical precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

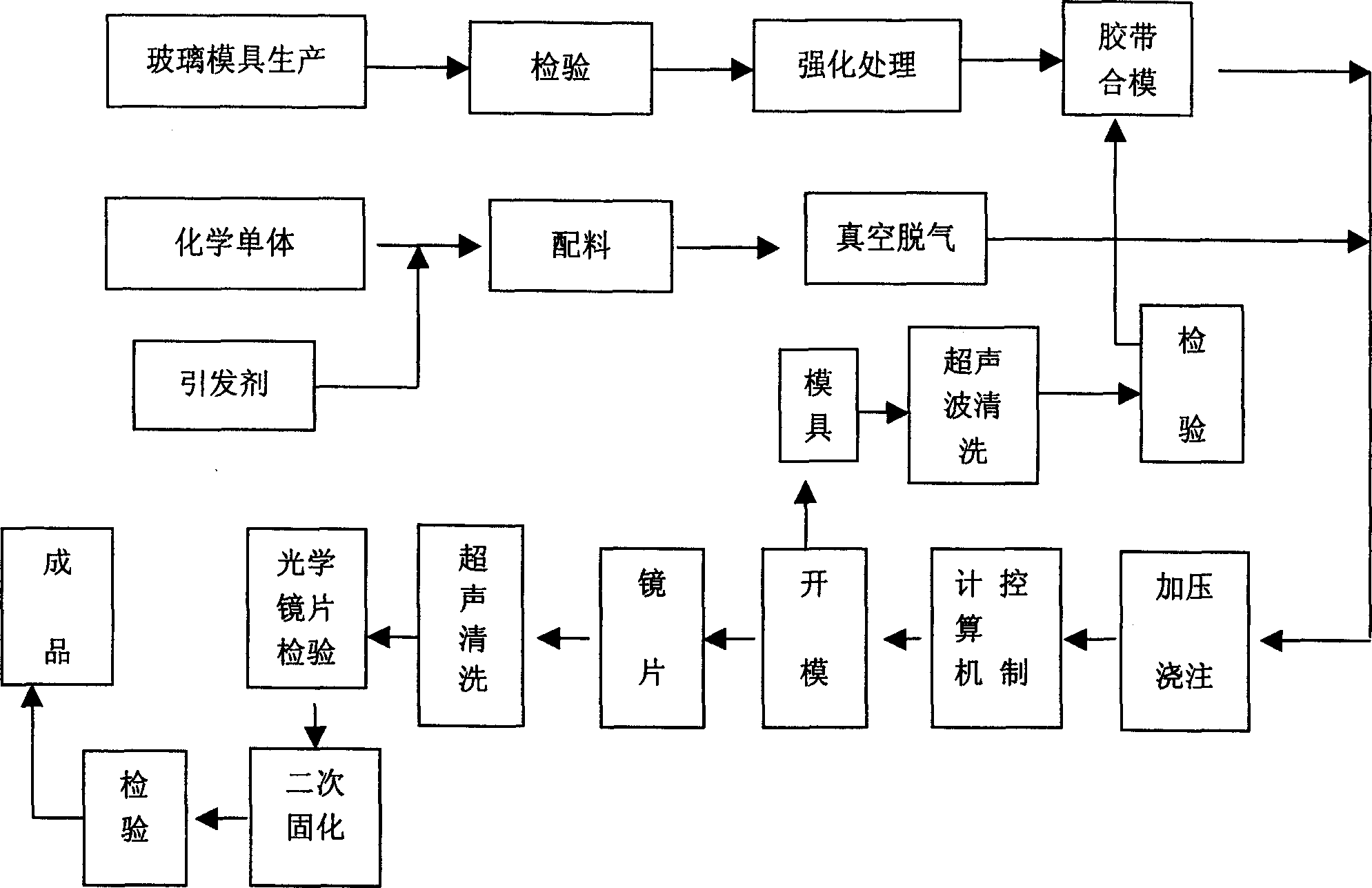

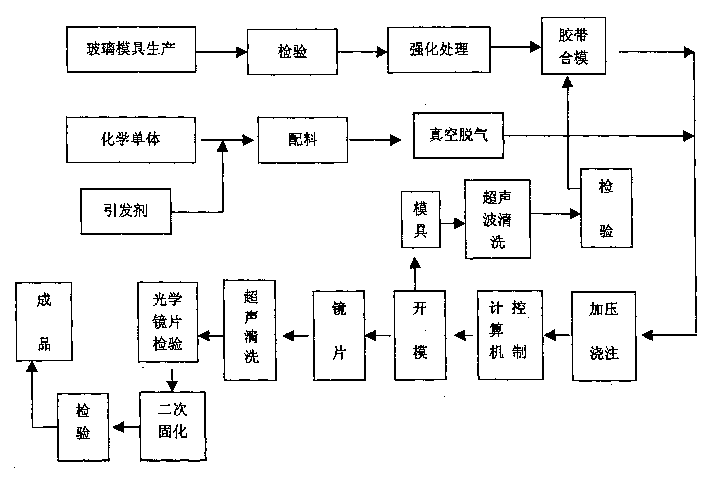

Method used

Image

Examples

Embodiment

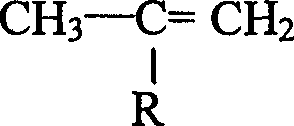

[0033] Take out a barrel of 20kg from the cold storage, and the main components are 2-hydroxy-3-phenoxypropyl acrylate, α-methylstyrene, diallyl terephthalate and isocyanate high-refractive-index optical resin material for production The basic raw material of high refraction optical resin lens, the preparation method of this raw material is as follows: at room temperature, first mix 5% of 1,3-bis(acrylic acid glyceryl) glycerin and 5% of diallyl terephthalate , 3% Dipropylene Dicarbonate Diethylene Glycol After the two compounds are mixed and stirred evenly, add 27% a-methylstyrene, 13% styrene and 12% tetrabromobisphenol A bis( 2-hydroxyethyl) ether, while stirring, continue to add 25% of 2-hydroxy-3-phenoxypropyl acrylate and 10% of m-xylylene diisocyanate, stir for 2 hours; add 0.3% of ultraviolet light Absorbent and 0.2ppm ~ 1ppm blue agent. Stir in the dissolving tank, raise the temperature to 40°C, keep it warm for 10 minutes, then cool it down to 30°C with cooling wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com