Patents

Literature

135 results about "Tert-butyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

Production process of polypropylene resin composite containing long branched chain

A production process of polypropylene resin composite containing long branched chain and with strain hardening characteristic, high melt strength and no gel includes the steps of: dissolving 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane and 1,6-butanediol biacrylate in acetone at room temperature to form acetone solution of peroxide and polyfunctional group monomer; feeding polypropylene powderto double-screw extruder heated to reaction temperature via its feeding port; feeding the acetone solution via the middle feeding port so as to make peroxide, polyfunctional group monomer and polypropylene melt react inside the double-screw extruder while turning on the vacuum pump in the tail of the extruder to pump out solvent and other volatile matters; mixing with antioxidant, extruding and stoving to obtain the final product.

Owner:YANGZI PETROCHEM

Fluororubber cloth clamp combination V seal ring and method for producing the same

The invention provides a V-shaped seal ring with a fluororubber canvas combination which is characterized in that the seal ring is produced by materials with the following portions by weight: 100 portions of peroxide vulcanized fluororubber, 20-50 portions of light-colored filler, 3-5 portions of zinc oxide, 2-5 portions of iron oxide red, 3-5 portions of 2,5-dimethyl-2,5-di-(tert-butyl peroxide) hexane, 4-6 portions of triallyl glycicy isocyanuratel and 0.5-1.5 portion of processing agent. A preparation method of the invention indicates that the materials with the portions by weight are first made into fluororubber dry mix which is then dissolved in mixed solvent so as to prepare adhesive cement; then the adhesive cement is dip coated on glass fiber cloth to prepared the fluororubber glass fiber canvas which is then die pressed by a vulcanized product combination to prepare the V-shaped seal ring with the fluororubber canvas combination. In addition, the obtained V-shaped seal ring with the fluororubber canvas combination has long service life and is resistant to high temperature, high pressure and hydraulic safety fluid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Ethylene vinyl acetate (EVA) glue film for encapsulating solar battery

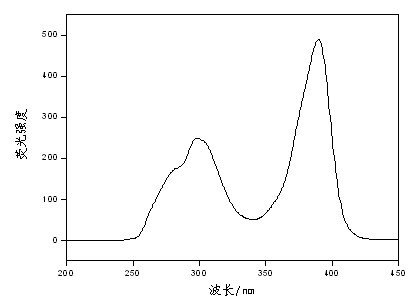

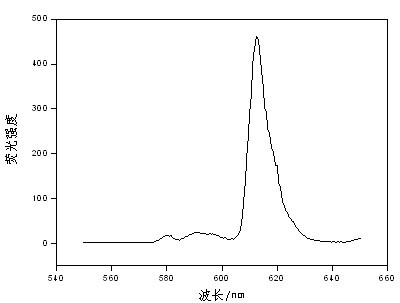

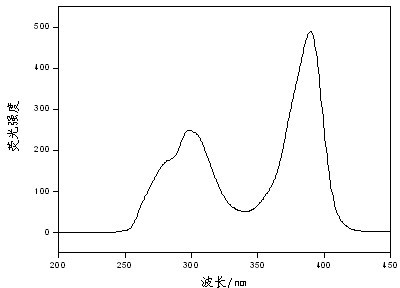

InactiveCN102559079AAvoid churnGuaranteed service lifeNon-macromolecular adhesive additivesFilm/foil adhesivesFluorescenceSilanes

The invention discloses an ethylene vinyl acetate (EVA) glue film for encapsulating a solar battery. The EVA glue film comprises the following components in part by mass: 100 parts of ethylene-vinyl acetate copolymer, 0.7 to 1.1 parts of crosslinking curing agent, 0.4 to 0.8 part of crosslinking aid, 0.4 to 0.8 part of coupling agent, 0.1 to 0.5 part of antioxidant and 0.1 to 0.5 part of fluorescence complex, wherein the mass percentage of the ethylene-vinyl acetate copolymer is 20 to 40 percent; the crosslinking curing agent is tert-butyl peroxide 2-ethyl hexyl carbonic ester; the crosslinking aid is triene propyl isocyanate trimer; and the coupling agent is gamma-(methyl propylene acyloxy)propyl trimethoxy silane. After the battery pack is heated and encapsulated, the olefinic bond of the fluorescence complex and the EVA perform copolymerization, so that the fluorescence complex is firmly fixed in the crosslinking cured EVA glue film through the chemical bond, loss of the fluorescence complex is effectively avoided, the service life of the battery pack is guaranteed, and ultraviolet light is effectively utilized.

Owner:SUZHOU TECHN SOLAR FILM MATERIAL

High-melt index polypropylene composition and preparation method thereof

The invention discloses a high-melt index polypropylene composition comprising following ingredients, by weight, 100 parts of polypropylene, 13 to 21 parts of a peroxide master batch, and 1.0 to 2.0 parts of a nucleating agent master batch. The melt index of the high-melt index polypropylene composition ranges from 0.2 to 4g / 10min. The peroxide master batch comprises, by weight, 98 to 99 parts of polypropylene powder and 1.0 to 2.0 parts of a peroxide; the peroxide is a tert-butyl peroxide or 2, 5-dimethyl-2, 5-Di-(tert-butylperoxy) hexane; the nucleating agent master batch comprises, by weight, 90 parts of polypropylene powder, 10 parts of a nucleating agent, 0.1 part of a main anti-oxidant, 0.1 part of an auxiliary anti-oxidant and 0.1 part of a stabilizing agent; the nucleating agent is a rigid nucleating agent selected from TMP-5 or NAP-71, the main anti-oxidant is pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate or octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate; and the auxiliary anti-oxidant is 2, 4-bis(1, 1-dimethylethyl)-phenophosphite(3:1). The preparation method comprises following steps: the ingredients are mixed at a certain ratio; the mixture is subjected to blend extrusion using a double screw extruder (length-diameter ratio 40, and screw diameter 35cm) at a temperature of 170 to 220 DEG C; and the obtained product is cooled, and subjected to granulation so as to obtain the high-melt index high-performance polypropylene resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment and resource-utilizing technology of tert-butyl peroxy benzoate production wastewater

InactiveCN102092906AHigh purityQuality improvementPreparation from carboxylic acid saltsSulfur-trioxide/sulfuric-acidBenzoic acidHigh concentration

The invention discloses a treatment and resource-utilizing technology of the production wastewater of tert-butyl peroxy benzoate (initiator is C). The technology is as follows: high concentration production wastewater is collected from the sewage outlet of a production device to perform stabilization treatment, and after the risk that the organic peroxide in wastewater is violently decomposed when heated is basically eliminated, the mixture of tertiary butanol and tert-butyl peroxide, sulfuric acid, benzoic acid and sodium chloride are recycled from wastewater. the mixture of tertiary butanol and tert-butyl peroxide, benzoic acid and sulfuric acid can be used repeatedly in production and sodium chloride is a by-product. After most of tertiary butanol and tert-butyl peroxide are removed and benzoic acid, sulfuric acid and sodium chloride are recycled, the wastewater performs hydrolysis-contact oxidation and C-Fe micro-electrolysis decoloring treatment and the main indexes of discharged water meet the requirements of the discharge standard of water pollutants for pharmaceutical industry chemical synthesis products category (GB21904-2008) on the water pollutants emission limits of new business.

Owner:NORTHWEST NORMAL UNIVERSITY

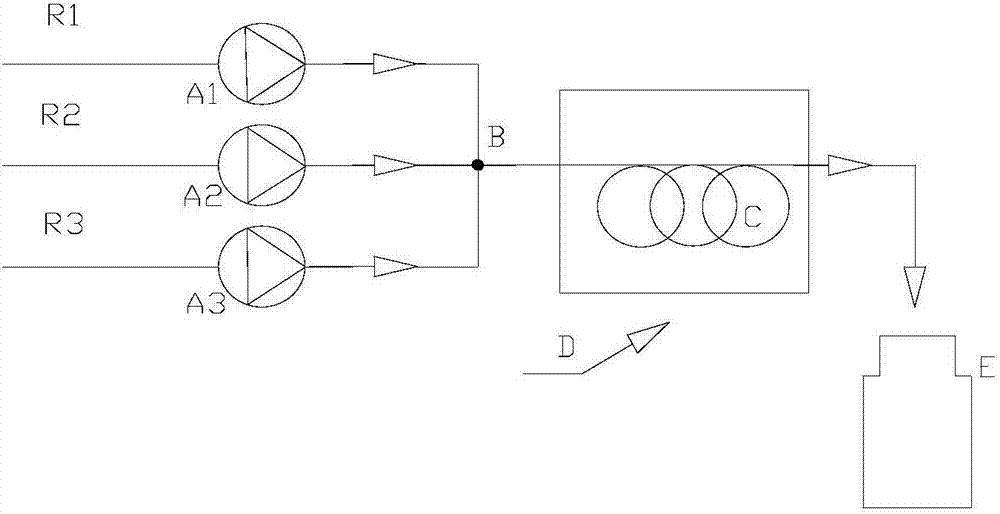

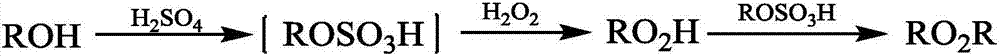

Preparation method of di-tert-butyl peroxide

ActiveCN107056670ARapid peroxidationWith operational continuityOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideTert-butyl peroxide

The invention discloses a preparation method of di-tert-butyl peroxide. Tert-butyl alcohol, hydrogen peroxide and a catalyst are continuously introduced into a micro-reactor, so that tert-butyl alcohol and hydrogen peroxide are subjected to a peroxidation reaction, and a material flow containing a di-tert-butyl peroxide is prepared; the material flow containing the di-tert-butyl peroxide is led out from the micro-reactor, and the di-tert-butyl peroxide is obtained through separation, washing and drying, wherein the molar ratio of tert-butyl alcohol to hydrogen peroxide is 1:2-1:2.2, and the catalyst accounts for 10-20% of the total mass of tert-butyl alcohol, hydrogen peroxide and the catalyst. The process is simple, the micro-reactor good in safety is used for continuous production, the prepared di-tert-butyl peroxide is high in reaction selectivity and good in yield, the production procedures are reduced, and the production cost is reduced.

Owner:西安万德能源化学股份有限公司

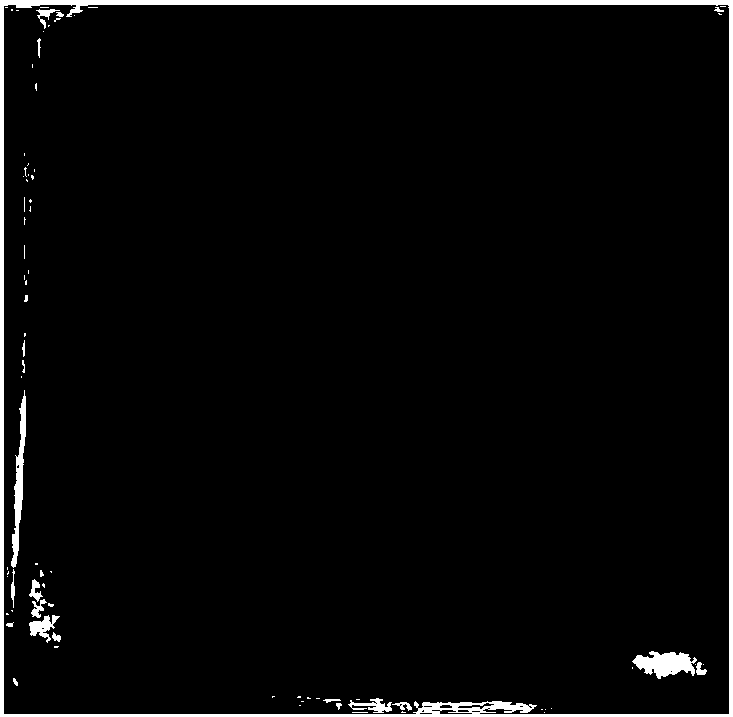

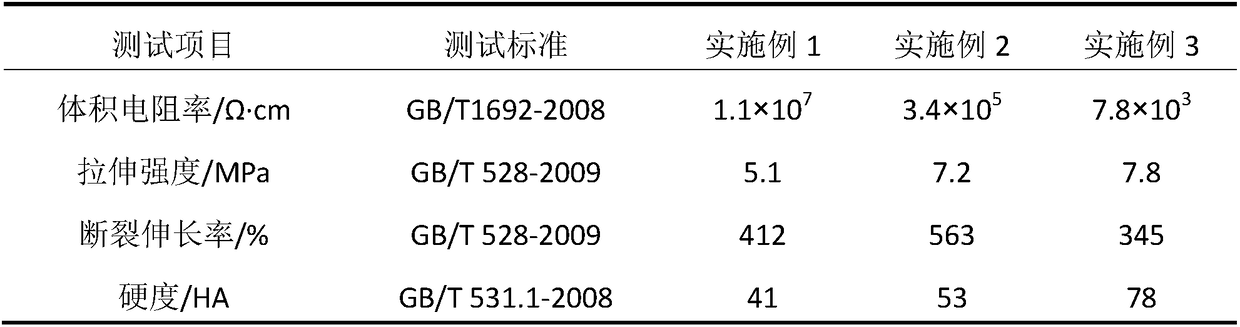

Non-black appearance conductive silicon rubber material and preparation method thereof

The invention relates to a non-black appearance conductive silicon rubber material and a preparation method thereof. The silicon rubber material comprises the following components in parts by weight:100 parts of methyl vinyl silicone rubber, 20-45 parts of white carbon black, 1-5 parts of hydroxyl silicone oil, 2-6 parts of dimethyl diethyoxyl silane, 30-150 parts of conductive packing, 2-15 parts of an anti-electrostatic agent and 1-2 parts of 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane. The preparation method specifically comprises the following steps: mixing the methyl vinyl silicone rubber, the white carbon black, the hydroxyl silicone oil, the dimethyl diethyoxyl silane, the conductive packing and the anti-electrostatic agent, further uniformly mixing with the 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane, and performing vulcanization, thereby obtaining the non-black appearance conductive silicon rubber material. Compared with the prior art, the silicon rubber material provided by the invention is relatively high in tension strength, excellent in electric property, excellent in high-temperature resistance and excellent in flame retardancy and has a non-black appearance.

Owner:SHANGHAI JIAO TONG UNIV +1

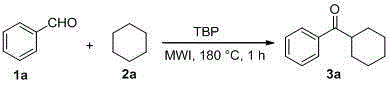

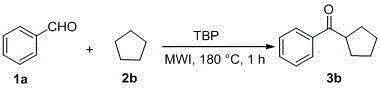

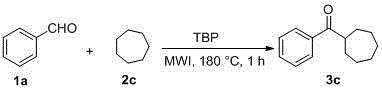

Method for synthesizing ketone compound

ActiveCN105152830AAvoid wastingAvoid pollutionCarbonyl group formation/introductionCarbonyl compound preparation by condensationAlkaneMeth-

The invention discloses a method for synthesizing a ketone compound. The method comprises the following steps: mixing or dissolving an aldehyde compound and cycloparaffin in an organic solvent; and under the condition of microwave radiation, reacting at 140-180 DEG C in the presence of a free radical initiator, thereby preparing a target product, namely, the ketone compound. The reaction equation of the method is as shown in the specification, wherein R1 is phenyl or substituted phenyl, and the substituent group on the substituted phenyl benzene ring is one or more of fluorine, chlorine, bromine, methyl, methoxyl, trifluoromethyl or hydroxyl. The substituent group is in the ortho-position, meta-position or para-position on the benzene ring, n is an integer within 1-4, the free radical initiator is benzoyl peroxide, di-tert-butyl peroxide or dicumyl peroxide, and the organic solvent is alkane or phenyl. The method for synthesizing the ketone compound has the advantages that the raw material are cheap and easy to obtain, the atom economy is good, the substrate application range is wide, and the like; and the method is applicable to industrial production.

Owner:HENAN NORMAL UNIV

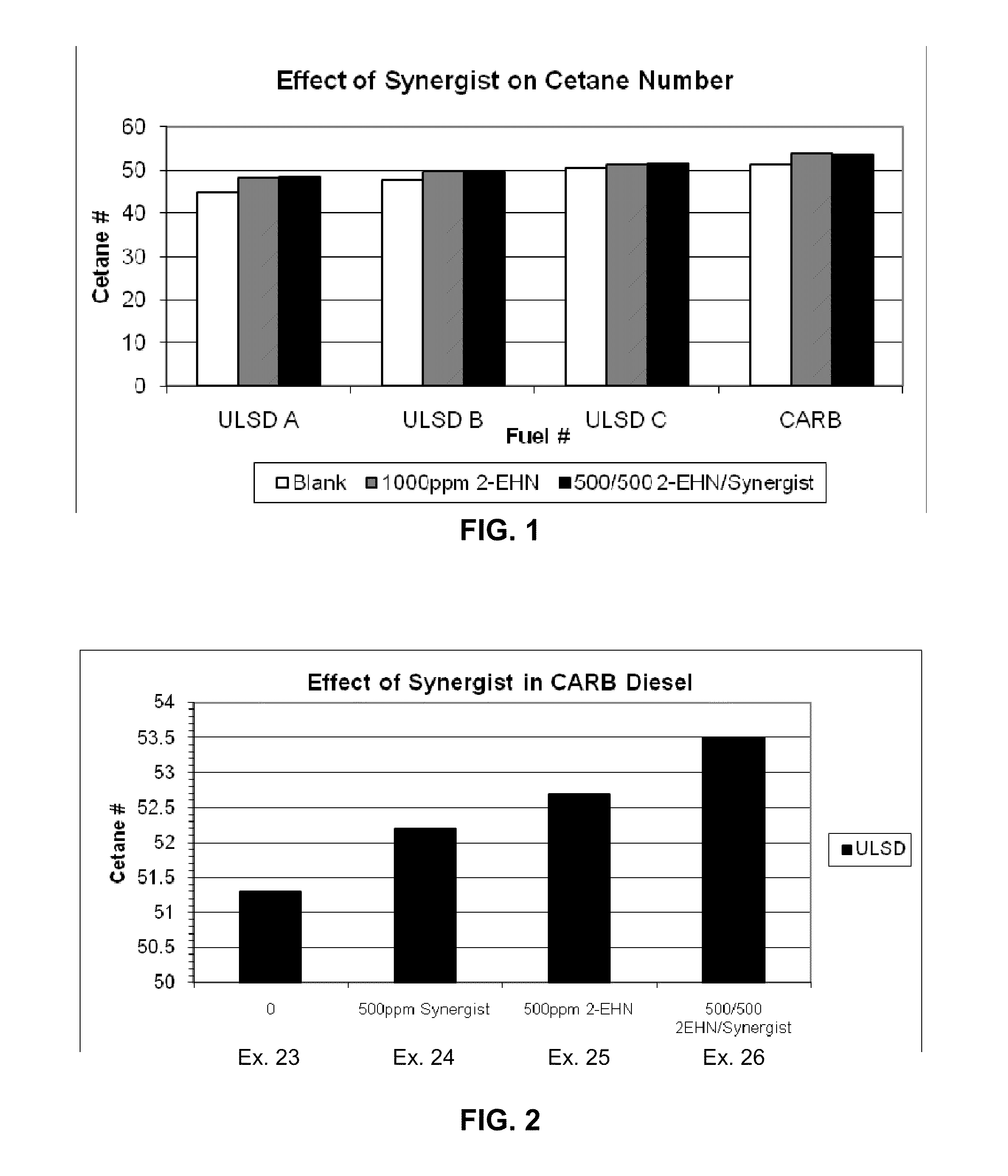

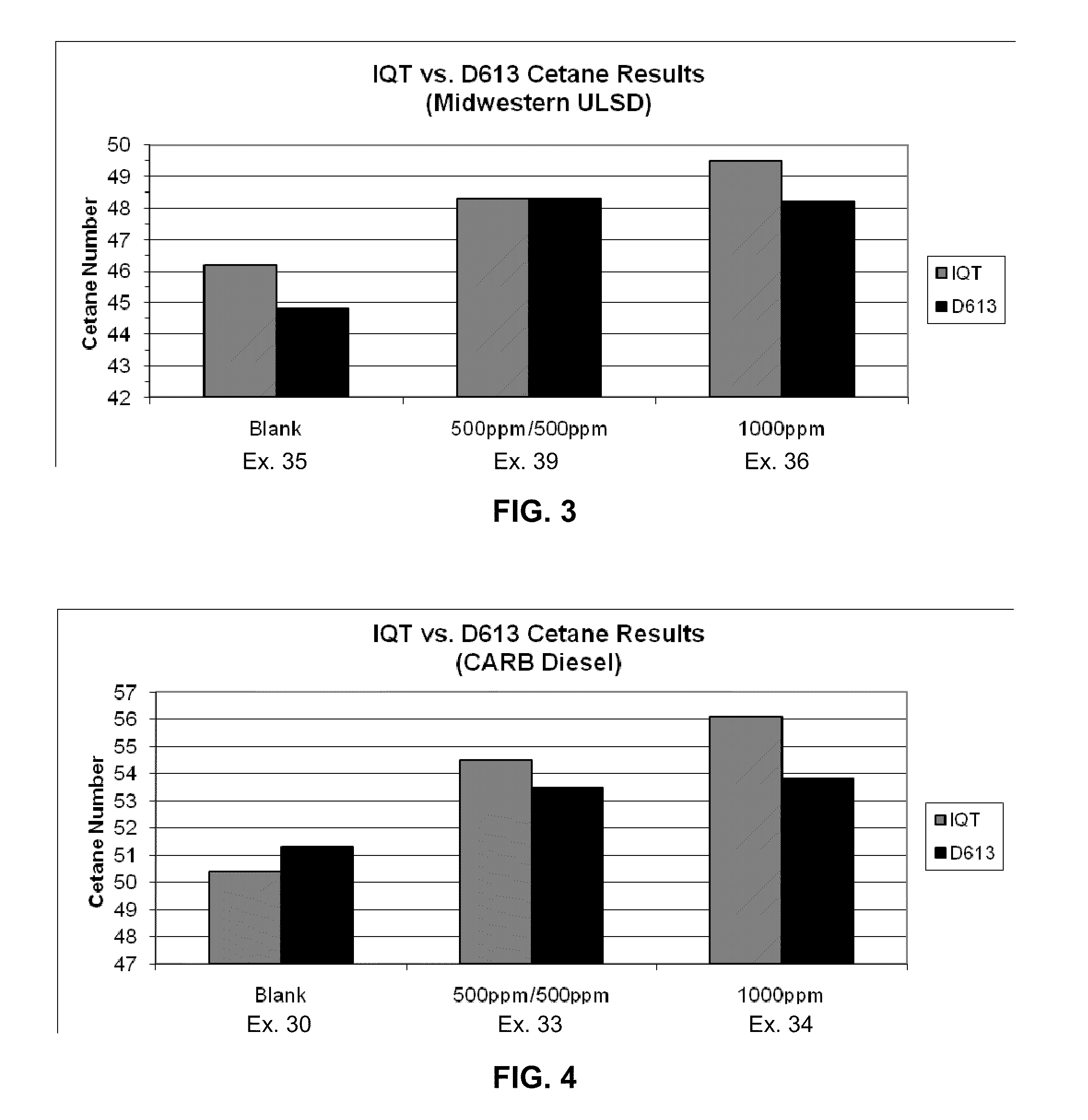

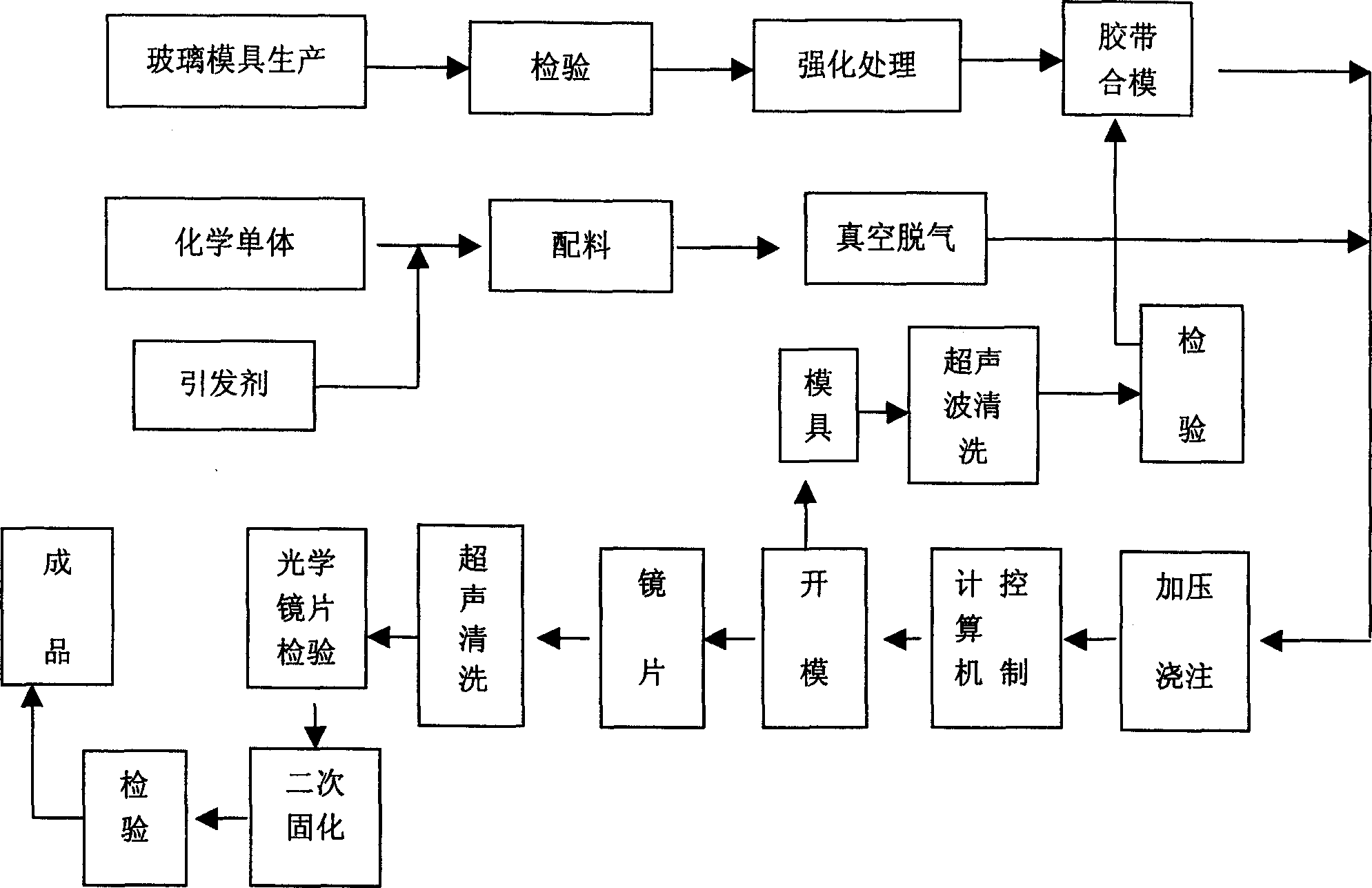

Additives for Cetane Improvement in Middle Distillate Fuels

InactiveUS20100325944A1Increase cetane numberLiquid carbonaceous fuelsFuel additivesEthylene HomopolymersSolvent

The cetane number of middle distillate fuels may be increased using an additive composition including a polymer that may be a homopolymer or copolymer of olefins, and the like, where the polymer has a weight average molecular weight ranging from about 200,000 to about 5,000,000. The additive composition also includes a free radical initiator component, which may be an alkyl nitrate such as 2-ethylhexylnitrate (2-EHN), and / or a peroxide, such as t-butyl peroxide. In one non-limiting embodiment the amount of polymer in the additive composition is greater than the free radical initiator component. A solvent is also present, which the solvent may include alcohol, an alkyl substituted phenol and / or a heavy aromatic distillate.

Owner:BAKER HUGHES INC

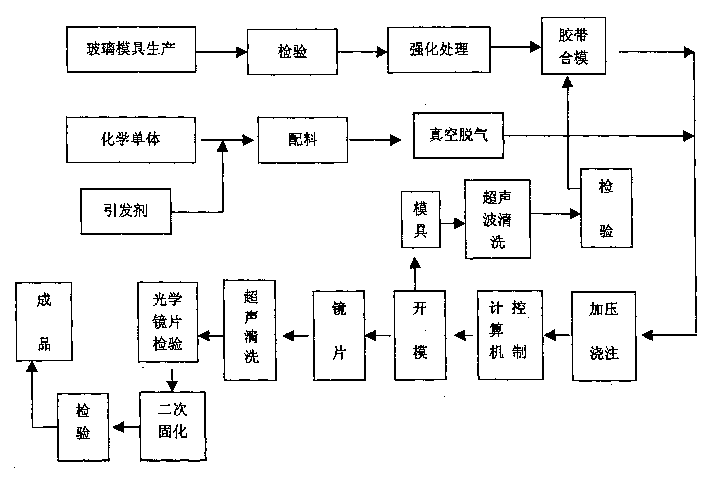

Manufacture of superthin high-refractivity optical resin lens

InactiveCN1548285AAvoid thermal effectsSolve the error of optical surface shape variationOptical articlesTemperature controlRefractive index

The manufacture process of superthin high-refractivity optical resin lens includes the following steps: making mold, reinforcing treatment and closing mold with tape machine; weighing chemical monomer and initiator, mixing and vacuum deairing; depositing the mixture in the mold, curing to form, demolding and cleaning. The present invention features the chemical monomer with one kind of alkenyl radical containing organic compound additive, the initiator being tert-butyl peroxide, the ratio among the chemical monomer, the additive and the initiator of 100 to 0.1-0.3 to 0.7-0.9, computerized temperature control during the polymerization, and the secondary curing of lens after demolding and cleaning. The present invention eliminates the lens profile variation caused by the polymerization and raises the optical precision of the lens.

Owner:SHANGHAI CONANT OPTICS CO LTD

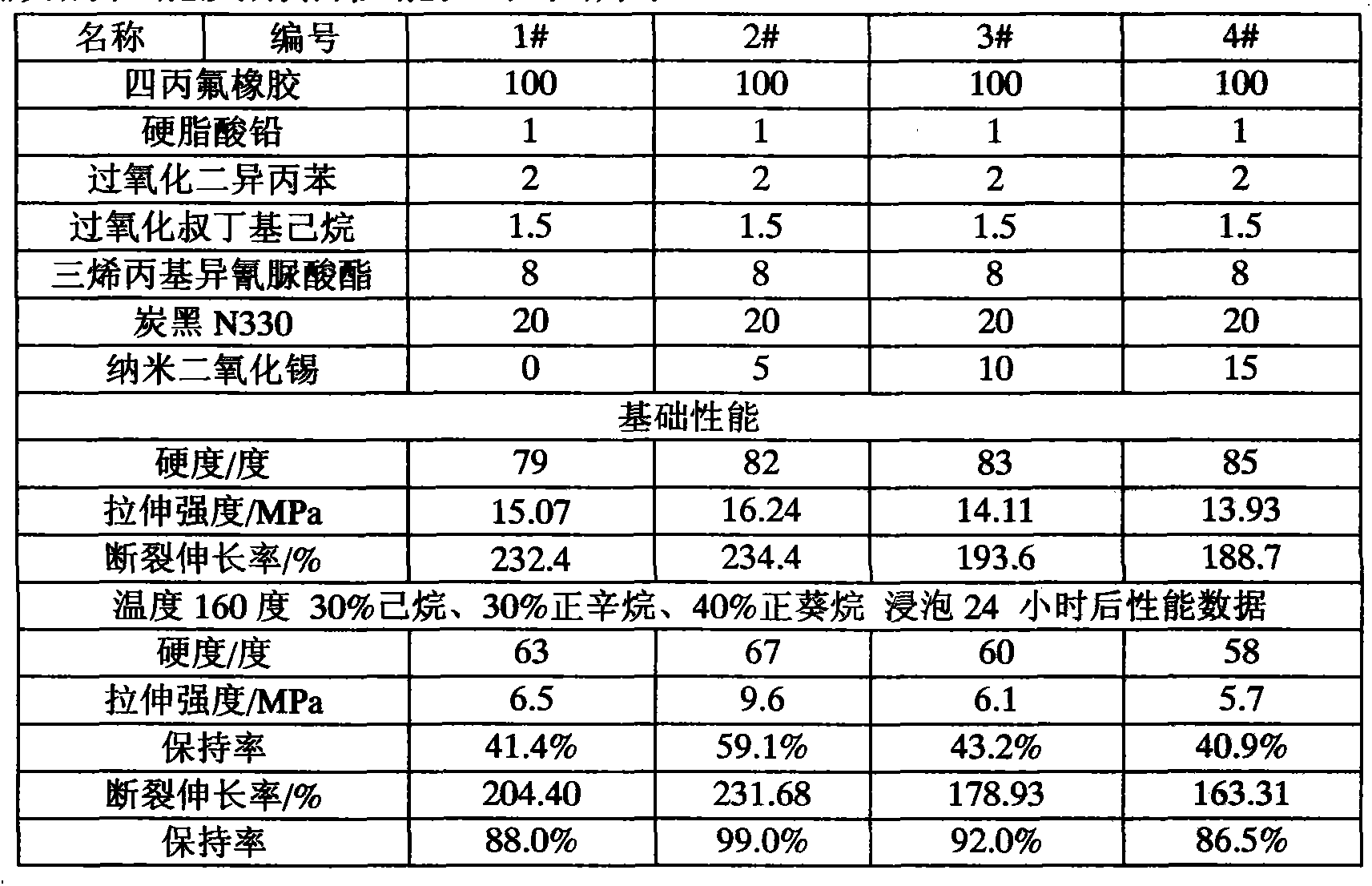

Oil resistant rubber

Owner:青岛宝丽曼高分子材料研究院有限公司

Annular chemical packer material for water plugging of horizontal well

The invention relates to an annular chemical packer material for the water plugging of a horizontal well, which comprises the following components in part by weight: 10 to 30 parts of thixotropy control agent, 0.1 to 10 parts of structure strengthening agent, 5 to 20 parts of strength controlling agent, 0.01 to 1 part of crosslinker assistant and 100 parts of water, wherein the thixotropy control agent is one or more of aluminum-iron mixed layer metal hydroxides, aluminum-magnesium mixed layer metal hydroxides and sodium-based imvite; the structure strengthening agent is one or more of dibromo-bis(dimethyldodecyl)ethyl diammonium and amide gemini quaternary ammonium surfactant; the strength control agent is the polymer of one or more of polyacrylamide, m-phenol and polyoxyethylene ether, which have double bond, methylene or phenyl functional groups; the crosslinker assistant consists of N-methylol acrylamide and a tert-butyl peroxide in a mass ratio of 1:0.1-5; and gelatinization is realized within 1 to 6 hours, and the gelatinization strength is improved by 100 to 1,000 times.

Owner:PETROCHINA CO LTD

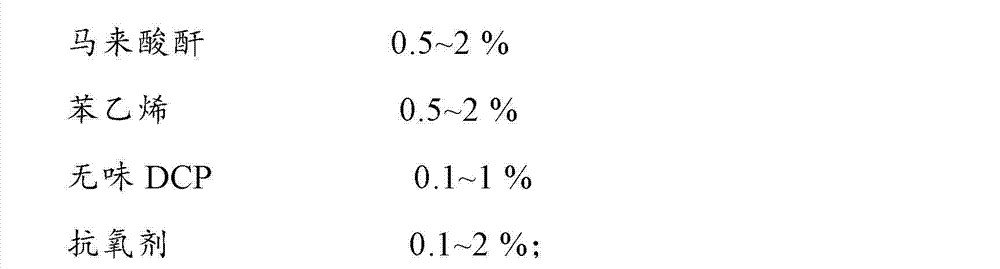

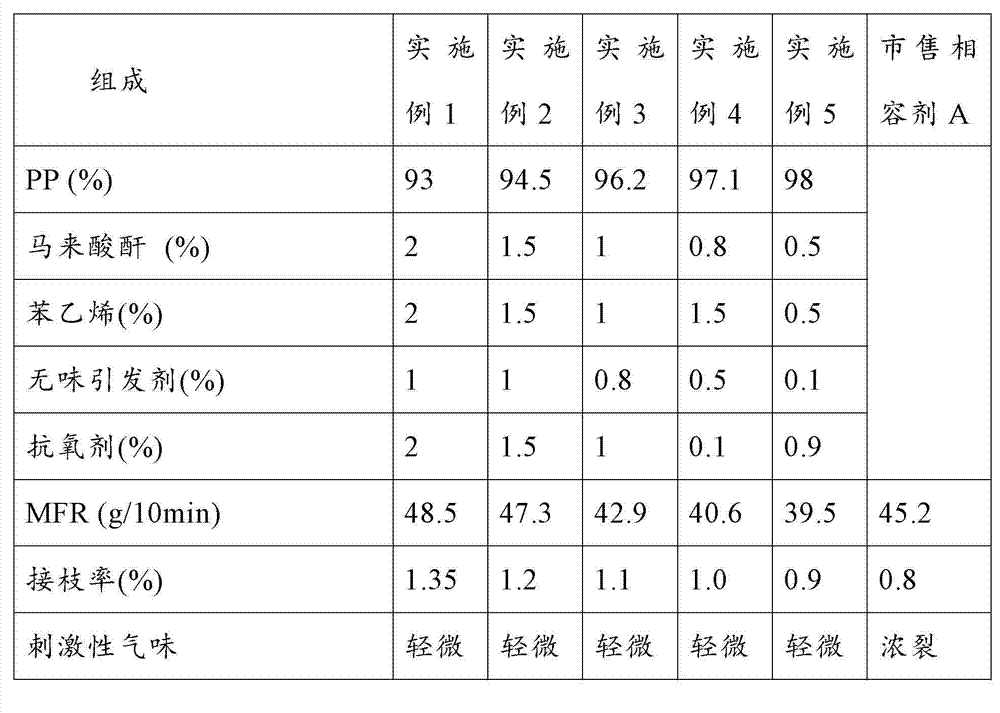

Faint-odor polypropylene stem grafting maleic anhydride extruded by double screws and preparation method thereof

The invention discloses a faint-odor polypropylene (PP) stem grafting maleic anhydride extruded by double screws and a preparation method of the faint-odor polypropylene stem grafting maleic anhydride extruded by double screws. The faint-odor polypropylene stem grafting maleic anhydride extruded by the double screws consists of the following components by weight percent: 93-98% of PP, 0.5-2% of maleic anhydride, 0.5-2% of styrene, 0.1-1% of initiating agent, namely bis-(tert-butyl peroxide isopropyl) benzene (tasteless dicumyl peroxide (DCP)) and 0.1-2% of antioxidant, wherein the appearance of the 96% of tasteless DCP is light-yellow tabular crystal, the melting point of the tasteless DCP is 46 DEG C-52 DEG C, and 9.08% of active oxygen is contained in the tasteless DCP. According to the faint-odor PP stem grafting maleic anhydride extruded by the double screws, as the tasteless DCP is taken as the initiating agent to replace conventional dicumyl peroxide (DCP), and is high in efficiency, the additive amount is small, the decomposed taste is faint, and the operation environment is good; and meanwhile, due to the introduction of second monomer styrene, the stem grafting efficiency of the PP stem grafting maleic anhydride is improved.

Owner:SHENZHEN KEJU NEW MATERIAL

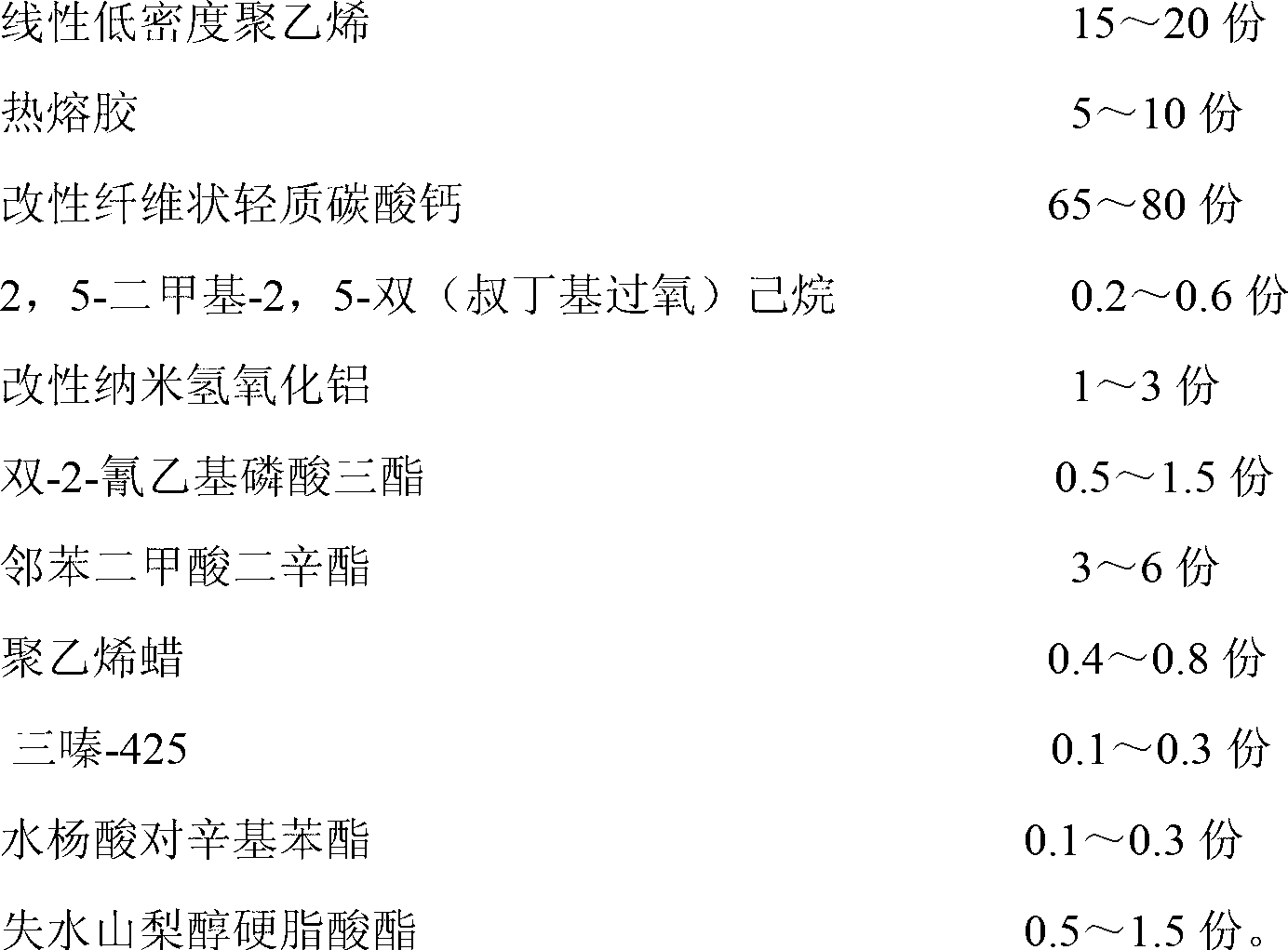

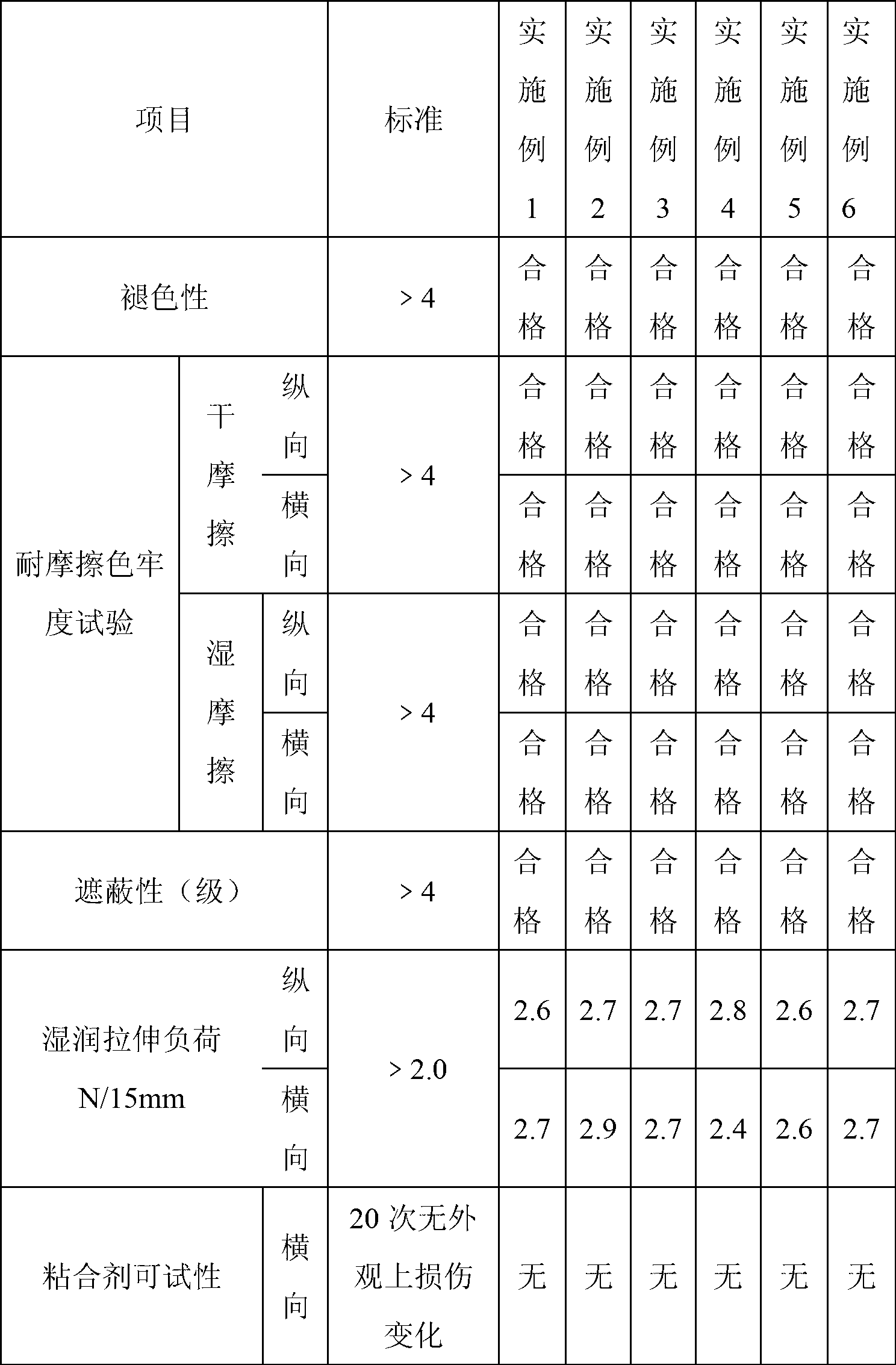

Flame-retardant mineral paper and preparation method thereof

ActiveCN103012948AProtect natural resourcesReduce fire accidentsCalcium/strontium/barium carbonatesFiberLinear low-density polyethylene

The invention discloses a piece of flame-retardant mineral paper and a preparation method thereof, wherein the flame-retardant mineral paper consists of the following components in parts by weight: 15-20 parts of linear low density polyethylene, 5-10 parts of hot melt adhesive, 65-80 parts of modified fiber-like light calcium carbonate, 0.2-0.6 part of 2,5-dimethyl-2,5-di (tert-butyl peroxide) hexane, 1-3 parts of modified nano-aluminum hydroxide, 0.5-1.5 parts of di-2-cyanoethyl phosphotriester, 3-6 parts of dioctyl phthalate, 0.4-0.8 part of polyethylene wax, 0.1-0.3 part of triazine-425, 0.1-0.3 part of p-octyl benzene salicylate and 0.5-1.5 parts of sorbitan stearate. The flame-retardant mineral paper disclosed by the invention can be used as protective package of an exterior wall insulating material and wall paper for home decoration, and has good significances on reducing fire accident, saving energy, protecting the natural resource and improving the environment.

Owner:张家港禾福新材料科技有限公司

Treatment and recycling process for initiator CH335 wastewater

InactiveCN102173522AHigh purityQuality improvementMultistage water/sewage treatmentNature of treatment waterChemical synthesisElectrolysis

The invention discloses a treatment and recycling process for production wastewater of 1,1-di-tert-butyl peroxide-3,3,5-trimethyl-cyclohexane (an initiator CH335). In the process, the production wastewater is collected directly from a drain outlet of a production device and is subjected to stabilized treatment, and after the danger of severe decomposition of organic peroxides in the wastewater due to heating is eliminated basically, tertiary butanol, tert-butyl peroxide and sulfuric acid are separated and recovered from the wastewater, wherein the recovered tertiary butanol, tert-butyl peroxide and sulfuric acid can be recycled repeatedly in the production process. Low-concentration wastewater is separated while chemical raw materials are recovered, and after the separated low-concentration wastewater is subjected to hydrolysis-contact oxidization and C-Fe micro-electrolysis decoloration, the major index of the drained wastewater meets the requirement on water pollutant emission limits of newly built enterprises in 'Discharge Standards of Water Pollutants for Chemical Synthesis Pharmaceutical Industry (GB21904-2008)'.

Owner:GANSU AGRI UNIV

Environment-friendly foaming material taking OBSH as foaming agent and preparation method thereof

The invention relates to an environment-friendly foaming material taking OBSH as a foaming agent and a preparation method thereof. The environment-friendly foaming material is prepared from the following components: 100 weight parts of base materials, 20-60 weight parts of OBSH foaming agent, 0.4-5.9 weight parts of cross-linking agent and 0.5-3 weight parts of zinc stearate, wherein 4,4'-oxybis (benzenesulfonyl hydrazine) is served as the OBSH foaming agent; triallyl isocyanurate is served as the TAIC cross-linking agent; bi-tertiary butyl peroxide diisopropyl benzene is served as the BIPB cross-linking agent. The invention also provides the preparation method for the foaming agent. The environment-friendly foaming material and the preparation method thereof have the advantages that the formula is reasonable; the primary foaming temperature is controlled at 120-149 DEG C and the steam pressure is 0.2-0.47Mpa; the multiplying power for the first foaming is controlled within 1.2-1.8 times; the primary foaming is controlled under the three parameter conditions, so that the OBSH cross-linking agent can effectively prevent adverse reaction with the cross-linking agent and the technology for producing the environment-friendly foaming material is stable.

Owner:宁波高新区万盟新材料科技有限公司

Biodegradable mulching film

ActiveCN101831097AMeet the requirements of heat preservation and moisture retention periodDoes not affect plantingClimate change adaptationPlant protective coveringsMicrocrystalline waxMaterial consumption

The invention discloses a biodegradable mulching film, which comprises the following components in percentage by weight: 33 to 68 percent of alloy master particle, 30 to 65 percent of 7042(LDPE), and 5 to 7 percent of 1F7B. The alloy master particles comprise the following components in percentage by weight: 0.01 to 0.03 percent of tert-butyl peroxide isopropyl benzene, 1.50 to 2.25 percent of fumaric acid, 4.50 to 5.60 percent of microcrystalline wax, 3.60 to 5.40 percent of polyethylene wax, 3.00 to 4.20 percent of MG70, 9.00 to 13.0 percent of N210 and 68 to 80 percent of cornstarch. The biodegradable mulching film has the advantages that: the biodegradable mulching film can adapt to different climates and soil environments in various places as well as the requirements of different crops, the mulching film is degraded in the design life without influencing the planting of the crops, and the mulching film is degraded uniformly and thoroughly; the balance problem of water resistance and hydrophily is solved, and the mulching film has higher ground adherence; and the specific gravity is small, the thickness of the mulching film is only 0.005mm, the material consumption is low and use cost is low, and the biodegradable mulching film can be popularized and applied on a large scale.

Owner:常州百利基生物材料科技有限公司

Foamed rubber and preparation method thereof

The invention provides foamed rubber. The foamed rubber comprises ethylene propylene diene monomer, montmorillonite, polyethylene glycol-di(meth)acrylate oligomer, surface-modified silicon dioxide, an organic foaming agent mixture, a gallic acid foaming additive and a vulcanizing agent di(tert-butyl peroxide)-diisopropylbenzene, wherein the weight average molecular weight of the polyethylene glycol-di(meth)acrylate oligomer is 200-400, the particle diameter of the surface-modified silicon dioxide is 30-50 nm, the organic foaming agent mixture is formed by azodicarbonamide and azobisisobutyronitrile, and the weight ratio between the azodicarbonamide and the azobisisobutyronitrile is 90:10 to 95:5. Compared with the prior art, the foamed rubber provided by the invention has the advantages of sufficiency in foamed pores, evenness in foamed pores, high hardness and density, and higher viscosity, and thus, the foamed rubber can be applied to a lot of precise instruments.

Owner:SHANDONG UNIV OF SCI & TECH

Nano-sepiolite powder modified chlorosulfonated polyethylene rubber cable material

ActiveCN102964704AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceMicrocrystalline wax

The invention discloses a nano-sepiolite powder modified chlorosulfonated polyethylene rubber cable material, which is prepared from the following raw materials in parts by weight: 100-200 parts of chlorosulfonated polyethylene rubber CSM2305, 20-30 parts of nitrile rubber N230S, 10-15 parts of epichlorohydrin rubber H45, 5-10 parts of dioctyl nylon acid ester, 5-10 parts of acetyl triethyl citrate, 10-15 parts of tris(2-chloropropyl)phosphate, 3-6 parts of 5-di(tert-butyl peroxide)hexane, 2-3 parts of microcrystalline wax, 2-3 parts of stearic acid, 1-2 parts of lead oxide, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Radiation-resistant cable insulation material for nuclear power plant

InactiveCN104672628AEvenly dispersedImprove radiation resistanceRubber insulatorsEthyl butyrateTert butyl

The invention discloses a radiation-resistant cable insulation material for a nuclear power plant. The radiation-resistant cable insulation material comprises the following raw materials in parts by weight: 100-120 parts of EPDM, 70-80 parts of fluorinated silicone rubber, 30-40 parts of polyimide, 10-20 parts of ETFE, 20-30 parts of lead oxide, 20-40 parts of rare earth oxide, 15-25 parts of zinc oxide, 5-15 parts of boron nitride, 18-22 parts of titanium nitride, 10-15 parts of organic bentonite, 35-45 parts of mica powder, 2-3 parts of di-(di-octyl phosphite) tetraisopropyl titanate, 2-5 parts of 3,3-bi-(tert-butyl peroxide) ethyl butyrate, 0.4-1 part of sulfur powder, 0.5-1 part of TAIC, 0.8-1.4 parts of HVA-2, 2-4 parts of sodium cinnamate, 4-6 parts of magnesium oxide, 2-5 parts of acetyl trioctyl citrate, 3-6 parts of stearic acid, 2-5 parts of anti-aging agent 1010-A and 1-2 parts of anti-aging agent D-503-4,2-(2'-hydroxyl-3',5'-tert-amyl phenyl) benzotriazole.

Owner:ANHUI SPECIAL CABLE GRP

High melting point polypropylene composition and its preparation method

The invention discloses a high-melt index polypropylene composition comprising following ingredients, by weight, 100 parts of polypropylene, 13 to 21 parts of a peroxide master batch, and 1.0 to 2.0 parts of a nucleating agent master batch. The melt index of the high-melt index polypropylene composition ranges from 0.2 to 4g / 10min. The peroxide master batch comprises, by weight, 98 to 99 parts of polypropylene powder and 1.0 to 2.0 parts of a peroxide; the peroxide is a tert-butyl peroxide or 2, 5-dimethyl-2, 5-Di-(tert-butylperoxy) hexane; the nucleating agent master batch comprises, by weight, 90 parts of polypropylene powder, 10 parts of a nucleating agent, 0.1 part of a main anti-oxidant, 0.1 part of an auxiliary anti-oxidant and 0.1 part of a stabilizing agent; the nucleating agent is a rigid nucleating agent selected from TMP-5 or NAP-71, the main anti-oxidant is pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate or octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate; and the auxiliary anti-oxidant is 2, 4-bis(1, 1-dimethylethyl)-phenophosphite(3:1). The preparation method comprises following steps: the ingredients are mixed at a certain ratio; the mixture is subjected to blend extrusion using a double screw extruder (length-diameter ratio 40, and screw diameter 35cm) at a temperature of 170 to 220 DEG C; and the obtained product is cooled, and subjected to granulation so as to obtain the high-melt index high-performance polypropylene resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylic epoxy resin powder paint for ceramics

ActiveCN104292903AGood weather resistanceSparkling noAnti-corrosive paintsPowdery paintsCobaltRaw material

The invention discloses acrylic epoxy resin powder paint for ceramics. The acrylic epoxy resin powder paint for ceramics is prepared from the following raw materials: epoxy resin, methyl tetrahydrophthalic anhydride, butyl maleic acid, maleic anhydride, 2-methylimidazole, phthalic anhydride, a leveling agent, dimethyl benzene, 2-tert-butyl peroxide, propylene glycol, a plasticizer, cobalt iso-octoate butyl acetate, styrene, methyl ethyl ketone peroxide and n-butyl methacrylate. The acrylic epoxy resin powder paint for ceramics disclosed by the invention has the advantages that weather resistance is excellent and the glossiness is 100%-140%, bubbling and dropping phenomena can not generate after the paint is soaked in water for 30-40 days, drying time is 15-25 minutes, no abnormity generates after the paint is soaked in 5% hydrochloric acid solution for 25-35 days, adhesive force reaches levels 1-2, no bubbling and wrinkling phenomena generate after the paint is soaked in saturated calcium hydroxide for 20-30 days, shore hardness is 50-70H, and the paint has the capacity of not exposing bottom after being scrubbed for 1200-1800 times due to scrubbing resistance.

Owner:盐城市盐龙水务有限公司

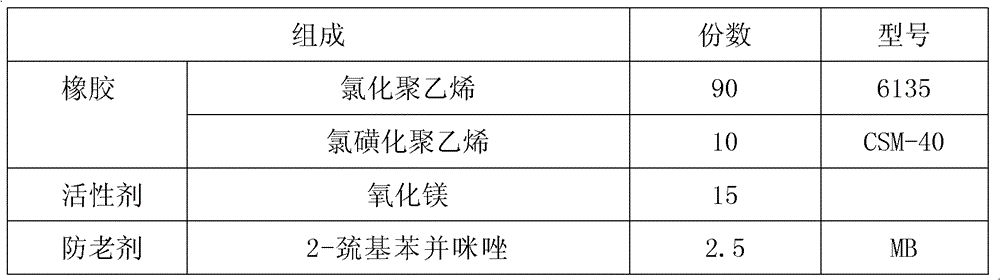

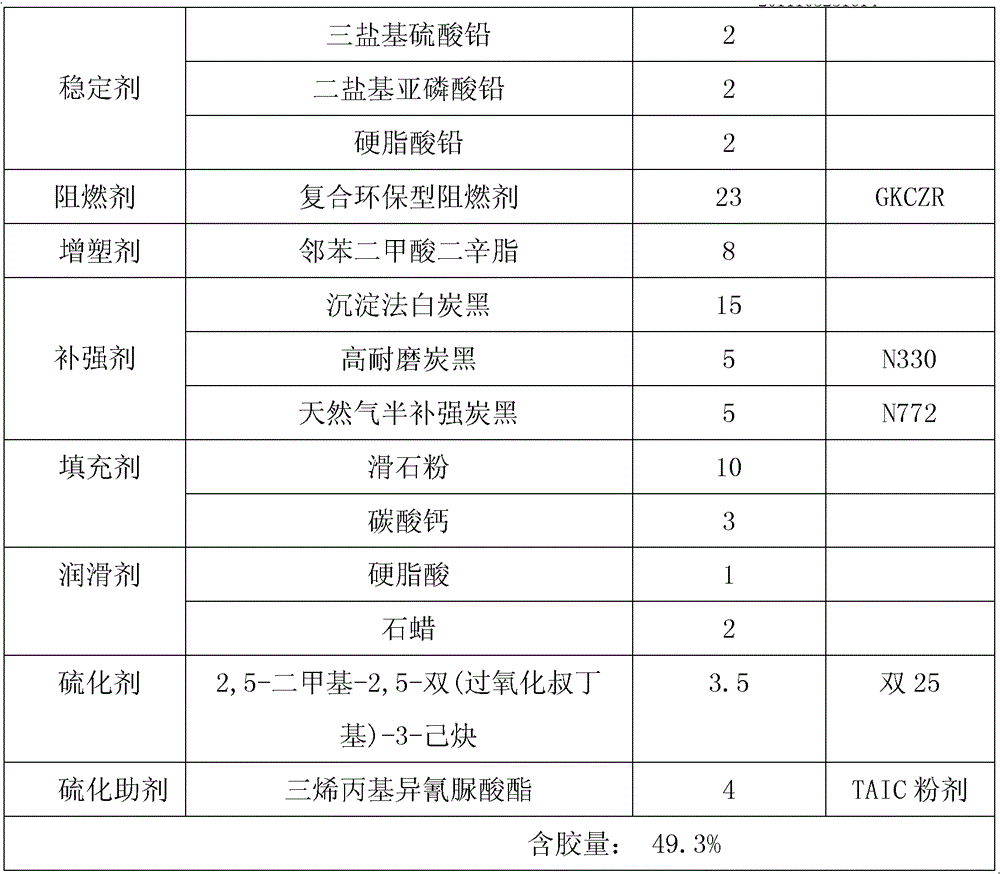

Protective jacket rubber without peculiar smell for marine cable

InactiveCN103059424AGood vulcanization effectLow costPlastic/resin/waxes insulatorsInsulated cablesAdjuvantActive agent

The invention relates to a protective jacket rubber without peculiar smell for a marine cable. The protective jacket rubber comprises following components in parts by weight: 90-100 parts of chlorinated polyethylene, 10-15 parts of active agent, 1-3 parts of anti-aging agent, 2-6 parts of stabilizing agent, 20-25 parts of fire retardant, 5-20 parts of plasticizer, 20-30 parts of reinforcing agent, 10-70 parts of filling agent, 2-4 parts of lubricating agent, 2-4 parts of vulcanizing agent and 3-5 parts of vulcanizing adjuvant, wherein the gel content of the protective jacket rubber is 40-50%, and the gel content is (the weight of the chlorinated polyethylene (CPE)+the weight of chlorosulfonated polyethylene (CSM)) / the total weight*100%. According to the invention, 2,5-dimethyl-2,5-di (tert-butyl peroxide) hexane is used for realizing an aim that the CPE and CSM co-used protective jacket rubber does not have a peculiar smell, and the protective jacket rubber can meet the requirements of SH type relative indexes in the international standard Sheathing Materials for Shipboard Power and Telecommunication Cables IEC 60092-359.

Owner:FAR EAST CABLE +2

Water resistance thermal dissipation coating and preparation method thereof

InactiveCN103333586AImprove adhesionImprove cooling effectEpoxy resin coatingsEthyl acetateSodium sulfate

The invention discloses a water resistance thermal dissipation coating and a preparation method thereof. The composed raw materials are E-12 epoxy resin, amide curing agent, ethyl acetate, modified nano titanium dioxide, dimethicone, polyethylene wax powder, phthalic anhydride, anti-oxidant DLTP, sodium tripolyphosphate, tert-butyl peroxide, laurinol sodium sulfate, and propylene glycol. The method adopts E-12 epoxy resin as the main material, because the E-12 epoxy resin has the advantages of aging resistance, large adhesivity, good thermal dissipation effect, and can be used under 160 DEG C for a long time. The nano titanium dioxide and the dimethicone are modified, through coupling the silane coupling agent KH 550, complex structures of the nano titanium dioxide and the dimethicone are increases, which is benefit for the dispersion of the titanium dioxide and the hydrophobicity and has an effective waterproof performance. The coating film has the advantages of durability, water resistance, corrosion resistance and good adhesiveness.

Owner:BENGBU TIMES ELECTRONICS

Method for selectively oxidizing toluene to synthesize benzaldehyde

InactiveCN103172505AGood choiceThe reaction equipment is simpleCarbonyl compound preparation by oxidationAlcoholBenzaldehyde

The invention discloses a method for selectively oxidizing toluene to synthesize benzaldehyde and relates to the field of industrial catalysis of petrochemical industry. Hydrotalcite-like compound (Cox / Al-LDH) and roasted product (Cox / Al-LDO) thereof are adopted as catalysts (x=1-4); acetonitrile, dichloromethane or chloroform is taken as a solvent; and tert-butyl peroxide alcohol is taken as an oxidant, and thus high benzaldehyde selectivity can be obtained. The catalyst is simple to prepare, low in cost, good in stability, and convenient to recover, and can be repeatedly used.

Owner:CHANGZHOU UNIV

Preparation method of high salt resistant polyacrylamide oil displacement agent

InactiveCN108250359AAnti-salt hasSalt resistance hasDrilling compositionAmmonium ferrous sulfateRedox

The invention discloses a high salt resistant polyacrylamide oil displacement agent. The high salt resistant polyacrylamide oil displacement agent is formed by polymerization of 149-153 parts of acrylamide, 178-181 parts of 2-acrylamide-2-methylpropane sulfonic acid, 19-21 parts of vinylpyrrolidone, and 0.025-0.031 part of EDTA under the action of a redox-azo compound initiation system, and the redox-azo compound initiation system is composed of 0.28-0.25 part of azo-azobisisoheptonitrile, 0.001-0.0015 part of tert-butyl peroxide and 0.005-0.008 part of ammonium ferrous sulfate.

Owner:TIANJIN BO HONG CHEM

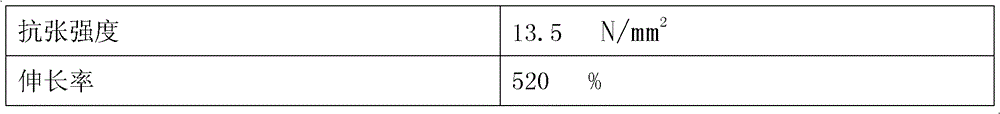

Preparation method of rubber material

The invention discloses a preparation method of a rubber material. The method includes the steps of dissolution, modifying and mixing, wherein raw silicone rubber is placed in a mixing machine for mixing, and then polyorganometallosiloxane, alkoxy-terminated polysiloxane, fumed silica, hydroxyl silicone oil, methyl-ethyl silicone oil and heat-resisting additives are added into the mixing machine for full mixing and vulcanization. After being placed still for 10-24 h, mixing products are put into the mixing machine for remilling and added to a vulcanizing agent (2,5-dimethyl-2,5-di(tert-butyl peroxide)hexane) for vulcanization in a drying oven, and then the rubber is obtained, wherein the temperature of the drying oven is maintained at 160-200 DEG C. The rubber made according to the preparation method has the advantages of being great in abrasive resistance, light in weight and resistant to high temperature, and overcomes the defect of poor high-temperature aging resistance in normal rubber of the prior art; the tear resistance of the rubber is enhanced, compared with the original rubber, the prepared novel material is greater in heat resistance and convenient to use, and the quality of the rubber products made of the rubber material is improved.

Owner:福清市汇华塑胶制品有限公司

High-waterproofness heat preservation rock wool board and manufacturing method thereof

InactiveCN106639011AReasonable density gradientSurface layer densityRoof covering using slabs/sheetsHeat proofingAbsorption capacitySilanes

The invention discloses a high-waterproofness heat preservation rock wool board and a manufacturing method thereof and belongs to the field of building materials. The rock wool board is made from the raw materials of, by weight, 55-65 parts of iron ore, 10-15 parts of perlite, 12-16 parts of slag, 10-13 parts of glass, 6-8 parts of a water repellent, 5-6 parts of urea, 8-10 parts of phenol-formaldehyde resin, 1-2 parts of 3-aminopropyltriethoxysilane and 3-5 parts of vinyltri tert-butyl peroxide silane. By adoption of a formula of the rock wool board, the proportion of manganese, calcium and iron can reach triangular balance, high-quality rock wool fibers are obtained and used in cooperation with the water repellent and a bonding agent to enable the rock wool board to have a reasonable density gradient, the rock wool board is high in surface layer density and compact in fiber structure, the water absorption capacity is greatly lowered, and therefore the hydrophobic property of the whole system structure is improved.

Owner:MAANSHAN HONGDA INSULATION MATERIAL

Outer layer glue of carbon dioxide refrigerant air conditioner rubber hose

The invention relates to an outer layer glue of a carbon dioxide refrigerant air conditioner rubber hose. The outer layer glue comprises the following components in parts by mass: 70-90 parts of low ethylene propylene terpolymer, 10-30 parts of high ethylene propylene terpolymer, 4-8 parts of chloroprene rubber, 70-90 parts of fast extruding carbon black, 20-40 parts of paraffin oil, 1-3 parts of polyethylene glycol, 0.5-1 parts of triallyl cyanurate, 3.0-5.0 parts of 1,3-di(tert-butyl peroxide diisopropyl)benzene and 8-12 parts of adhesive PN. Compared with the traditional industry level, the outer layer glue has remarkable effect and the physical characteristics of 75A rigidity, 14.0 MPa tensile-strength and 320% elongation at failure; the adhesive force of the outer layer glue and fabrics reaches 4.0 KN / m; the permeability of the refrigerant CO2 reaches 0.79 g / y; and the bursting pressure of the product is 56MPa. The outer layer glue is safe and environmentally-friendly.

Owner:江苏鹏翎胶管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com