Oil resistant rubber

A technology of oil-resistant rubber and rubber, which is applied in the field of oil-resistant rubber, can solve problems such as corrosion of rubber sealing materials, and achieve the effect of reducing losses

Inactive Publication Date: 2013-04-03

青岛宝丽曼高分子材料研究院有限公司

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The invention proposes an oil-resistant rubber, which solves th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

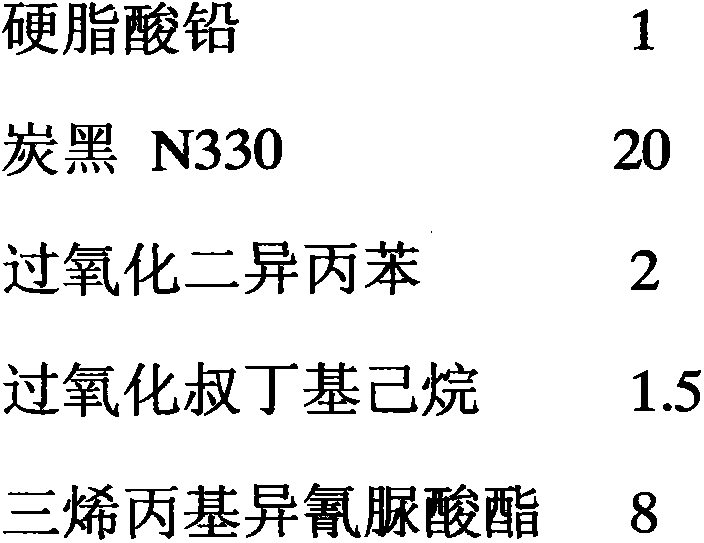

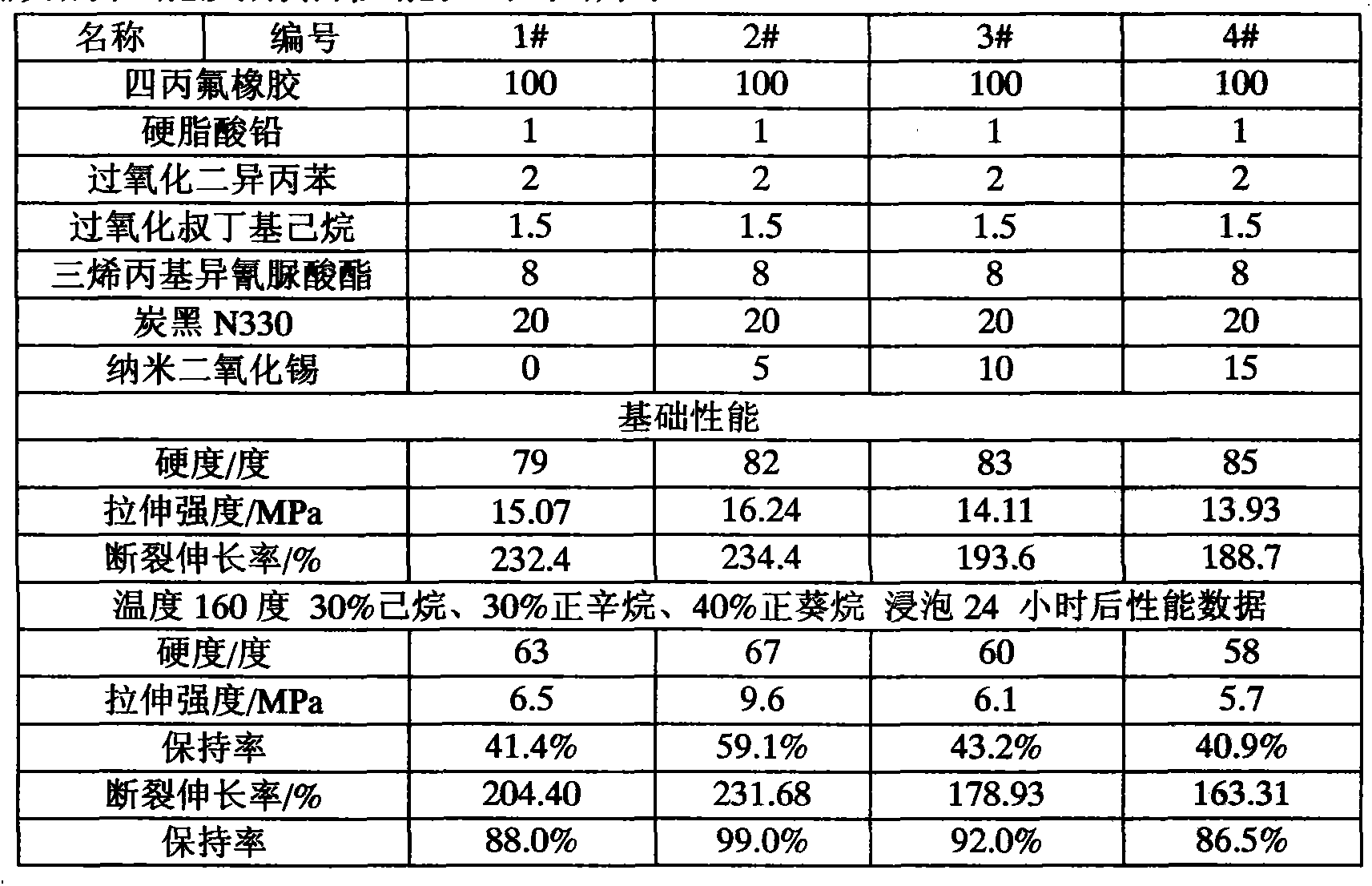

The invention proposes oil resistant rubber, wherein the composition comprises the following components in pars by weight of 100 parts of tetrafluoropropene rubber, 1 part of sodium stearate, 2 parts of dicumyl peroxide, 1.5 parts of tert-butyl peroxide hexane, 8 parts of triallyl isocyanurate, 20 parts of carbon black N330 and 0-15 parts of stannic oxide. The rubber prepared from the composition, a preparation method and an oil resistant evaluation method are also provided, and the oil resistance of the rubber is the best when the dosage of nano tin dioxide is 5 parts.

Description

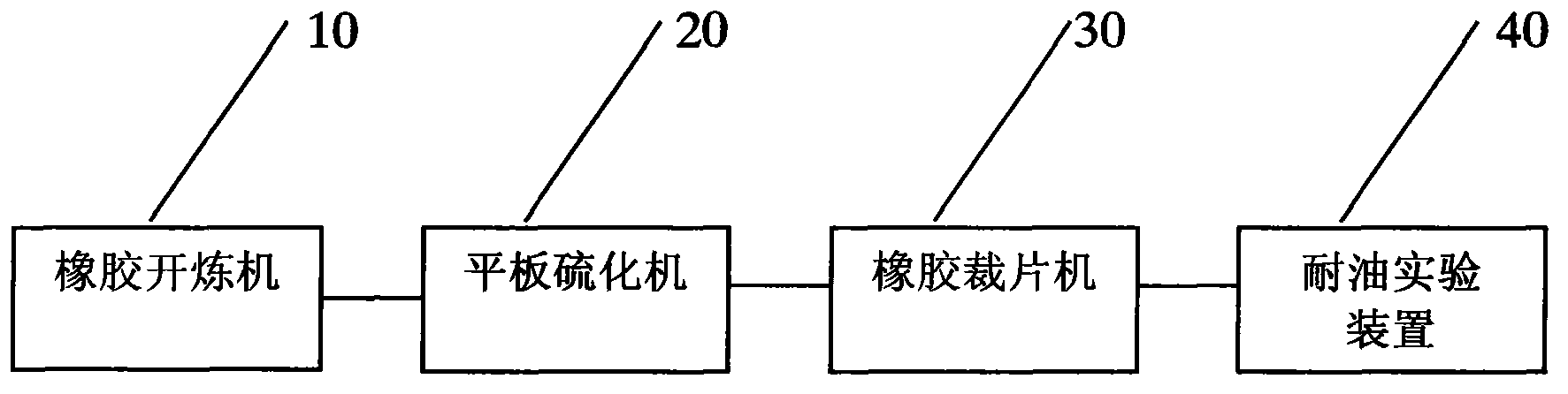

technical field [0001] The invention relates to the field of oilfield chemical industry, in particular to an oil-resistant rubber. Background technique [0002] The oil resistance of rubber refers to the ability of vulcanized rubber to resist the action of oil. When rubber products are in contact with various oils in the oil field for a long time, the oil can penetrate into the rubber to make it expand or increase in volume; at the same time, the oil medium can extract soluble compounding agents (such as plasticizers) from the vulcanized rubber. agent, anti-aging agent, anti-degradation agent, etc.), resulting in shrinkage or volume reduction of the vulcanizate. Generally, the swelling increases with the contact time of the vulcanized rubber and the oil until the oil is no longer absorbed, and then the volume expansion remains stable, resulting in the expansion of the originally tightly arranged three-dimensional cross-linked network, and the performance of the rubber produ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/12C08K13/02C08K5/098C08K5/14C08K5/3492C08K3/04C08K3/22

Inventor 张勇朱春林郑典君王莉

Owner 青岛宝丽曼高分子材料研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com