Ethylene vinyl acetate (EVA) glue film for encapsulating solar battery

A technology of solar cells and adhesive films, applied in circuits, adhesives, photovoltaic power generation, etc., can solve the problems of easy loss of materials, difficulty in guaranteeing the life of EVA adhesive films, loss of fluorescent complexes, etc., to ensure service life and improve photoelectric conversion Efficiency, the effect of ensuring the ability to resist ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

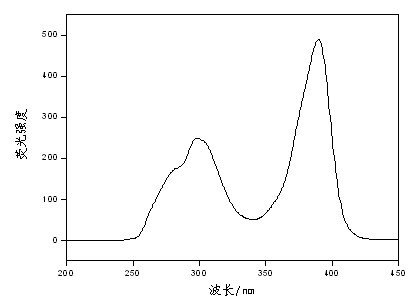

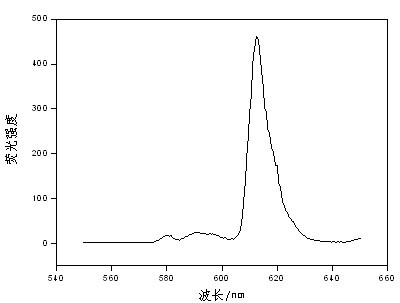

[0031] A kind of EVA adhesive film that is used for solar cell encapsulation, by mass, 100 parts of ethylene-vinyl acetate copolymer (VA is 32, MI is 40), adds cross-linking curing agent tert-butyl peroxide 2-ethylhexyl 0.9 parts of carbonate, 0.7 parts of triallyl isocyanurate as a cross-linking agent, 0.6 parts of coupling agent γ-(methacryloyloxy)propyl trimethoxysilane, 1,3 antioxidants, 5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-tri 0.3 parts of ketone, 0.2 parts of fluorescent complex, its structural formula is Rare earth ions Ln 3+ for Eu 3+ , the group R in the β-diketone ligand 1 and R 2 Both are phenyl, R in the enoic acid ligand 3 and R 4 Both are hydrogen. For the excitation spectrum of the europium fluorescent complex, see figure 1 as shown, figure 2 It is the emission spectrogram of the europium fluorescent complex, which shows that the fluorescent complex of the present invention can convert 280-400nm ultraviolet...

Embodiment 2

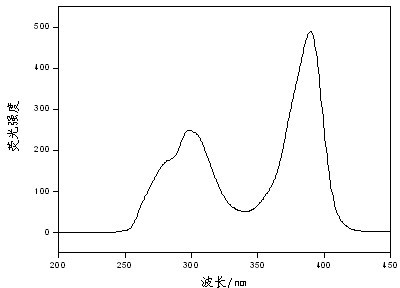

[0034] A kind of EVA adhesive film that is used for solar cell encapsulation, by mass, 100 parts of ethylene-vinyl acetate copolymer (VA is 32, MI is 40), adds cross-linking curing agent tert-butyl peroxide 2-ethylhexyl 0.9 parts of carbonate, 0.7 parts of triallyl isocyanurate as a cross-linking agent, 0.6 parts of coupling agent γ-(methacryloyloxy)propyl trimethoxysilane, 1,3 antioxidants, 5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-tri 0.3 parts of ketone, 0.2 parts of fluorescent complex, its structural formula is Rare earth ions Ln 3+ for Eu 3+ , the group R in the β-diketone ligand 1 and R 2 Both are phenyl, R in the enoic acid ligand 3 and R 4 Both are hydrogen.

[0035] The above combination is the formula and 0.14 parts of petroleum ether through mixing, vacuum feeding, extrusion molding, zero tension traction, cutting and winding and packaging processes to obtain an EVA film, which is called film (II).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com