Faint-odor polypropylene stem grafting maleic anhydride extruded by double screws and preparation method thereof

A technology of grafting maleic anhydride and twin-screw extrusion is applied in the field of twin-screw extrusion of low-odor polypropylene grafted maleic anhydride and its preparation, and can solve the irritating odor of PP grafted maleic anhydride, which is unfavorable to workers. Physical health, the effect is not very ideal, etc., to achieve the effect of a good working environment, less addition, and less taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of above-mentioned PP graft maleic anhydride of the present invention may further comprise the steps:

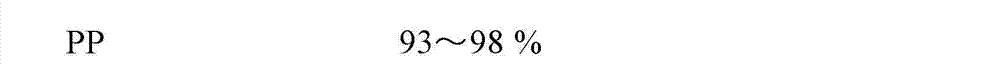

[0025] S1. According to PP 93-98%, maleic anhydride 0.5-2%, styrene 0.5-2%, odorless DCP 0.1-1%, antioxidant 0.1-2%, weigh maleic anhydride, odorless DCP, antioxidant , PP and styrene, and add maleic anhydride, odorless DCP, and antioxidant to the weighed styrene and stir for a predetermined time, which can be set as required; and the weighed PP Dry at 80-85°C for 2-3 hours;

[0026] S2. Add the dried PP and the styrene mixture evenly stirred in step S1 into the high-speed batching mixer, and stir for a predetermined time, which can be set as required;

[0027] S3. Place the mixture stirred in step S2 in a twin-screw machine for melt extrusion and granulation.

[0028] Wherein, the process conditions in step S3 can be: twin-screw first-stage temperature 140-150°C, second-stage temperature 150-160°C, third-stage temperature 155-165°C, main scre...

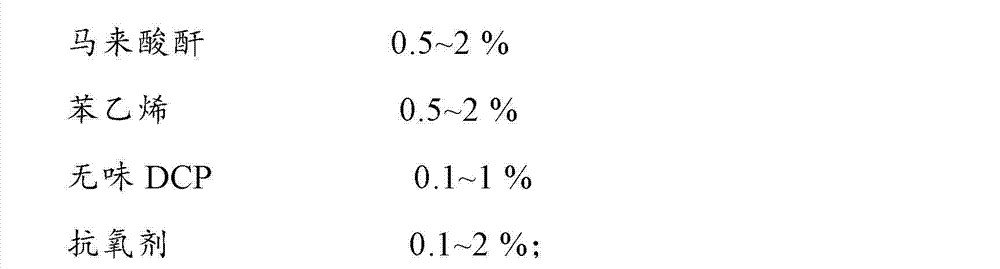

Embodiment 1

[0032] Dissolve maleic anhydride 2%, odorless DCP 1%, and antioxidant 2% into 2% styrene liquid, pre-mix in a high-speed batch mixer for 3 minutes, then add baked 93% PP into the high-speed batch mixer , and then stirred together for 5 minutes. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first stage temperature 140~150°C, second stage temperature 150~160°C, third stage temperature 155~165°C, main screw speed 80-100 rev / min, feeding screw speed 30-45 rev / min.

Embodiment 2

[0034] Dissolve 1.5% maleic anhydride, 1.0% odorless DCP, and 1.5% antioxidant into 1.5% styrene liquid, pre-mix in a high-speed batch mixer for 3 minutes, then add the baked 94.5% PP into the high-speed batch mixer , and then stirred together for 5 minutes. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first stage temperature 140~150°C, second stage temperature 150~160°C, third stage temperature 155~165°C, main screw speed 80-100 rev / min, feeding screw speed 30-45 rev / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com