Flame-retardant mineral paper and preparation method thereof

A stone paper, linear low-density technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of potential safety hazards, loss of people's lives and property in insulation materials, and easy fire accidents, so as to save energy, reduce fire accidents, protect The effect of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

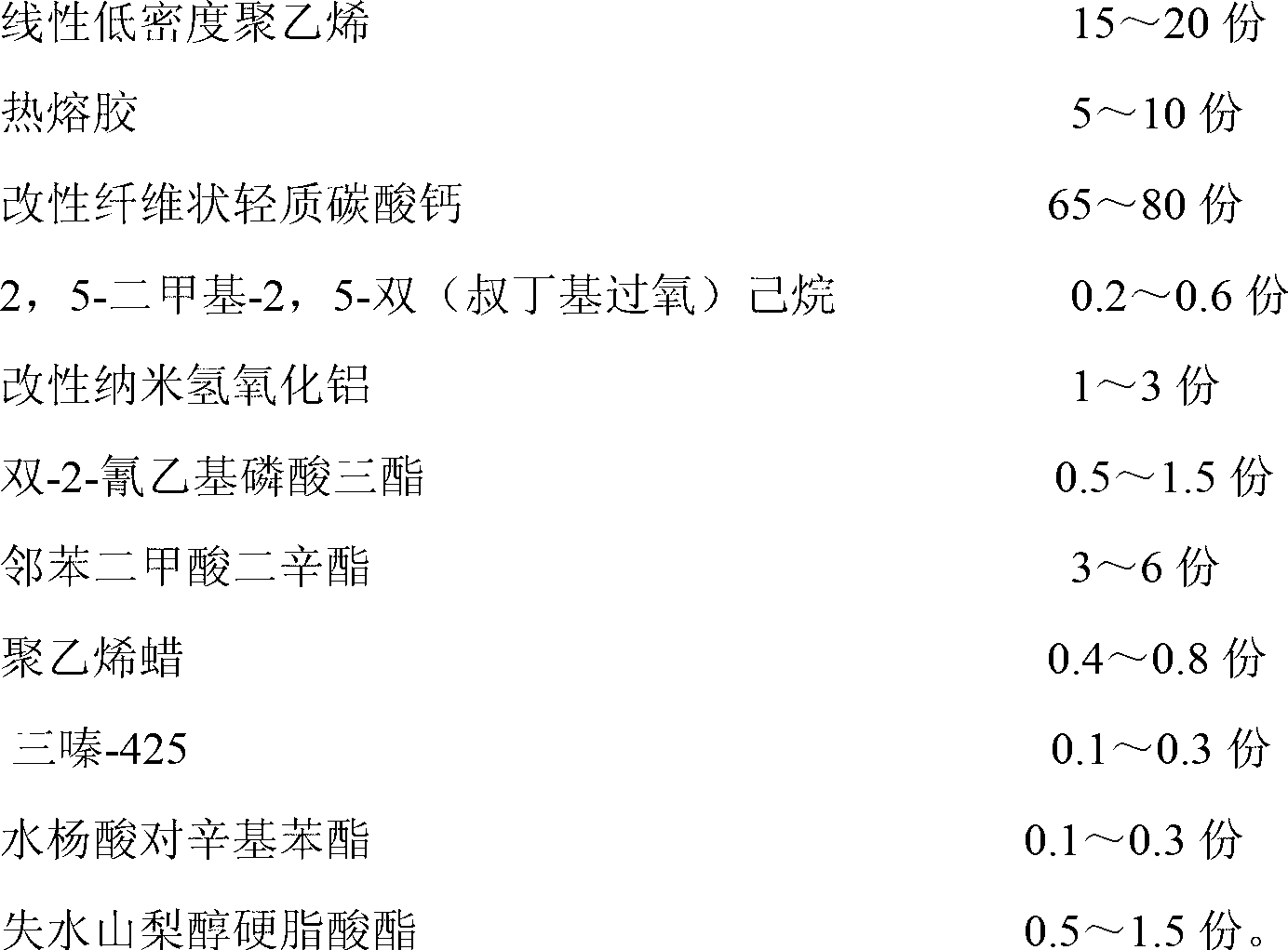

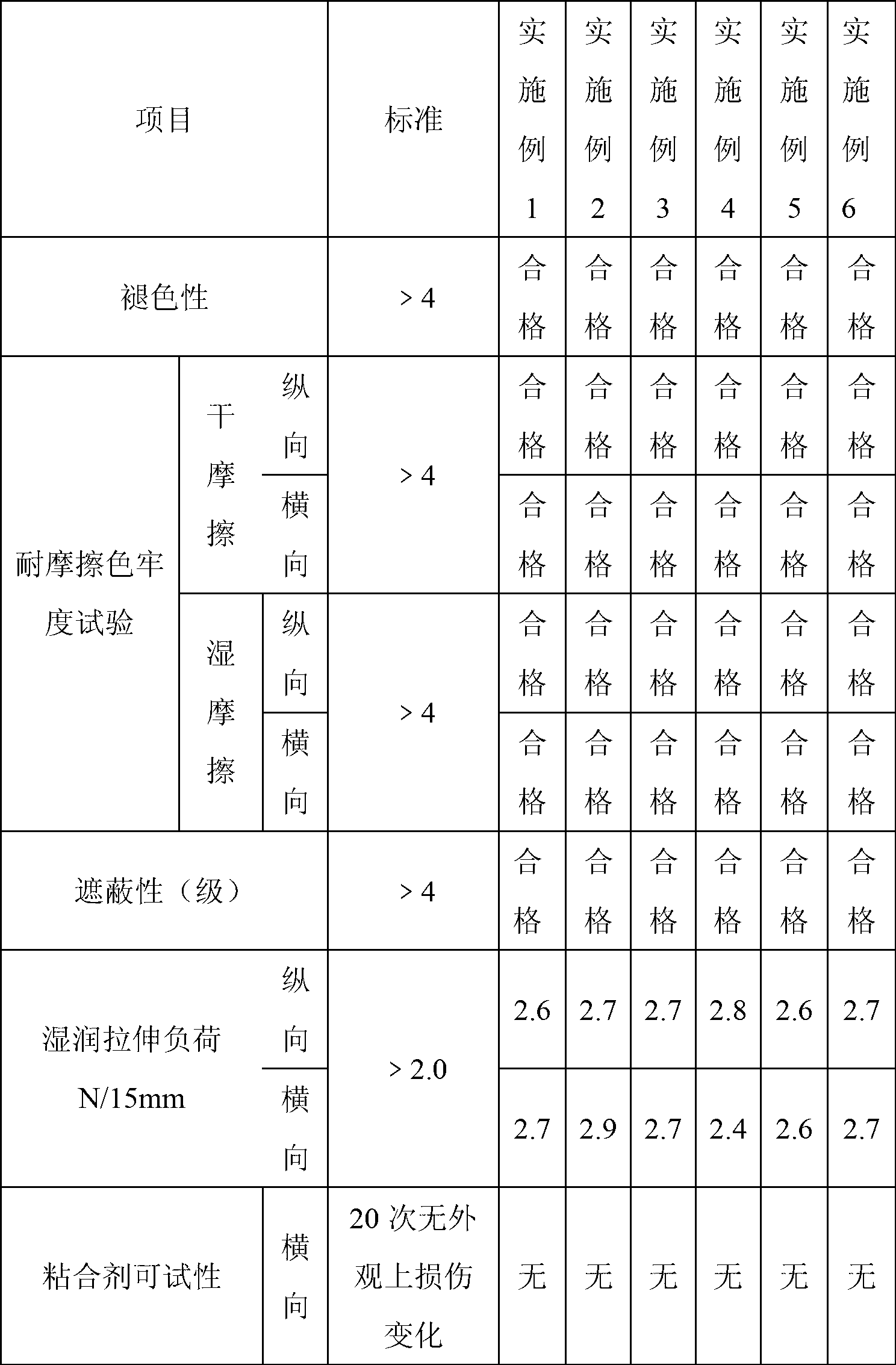

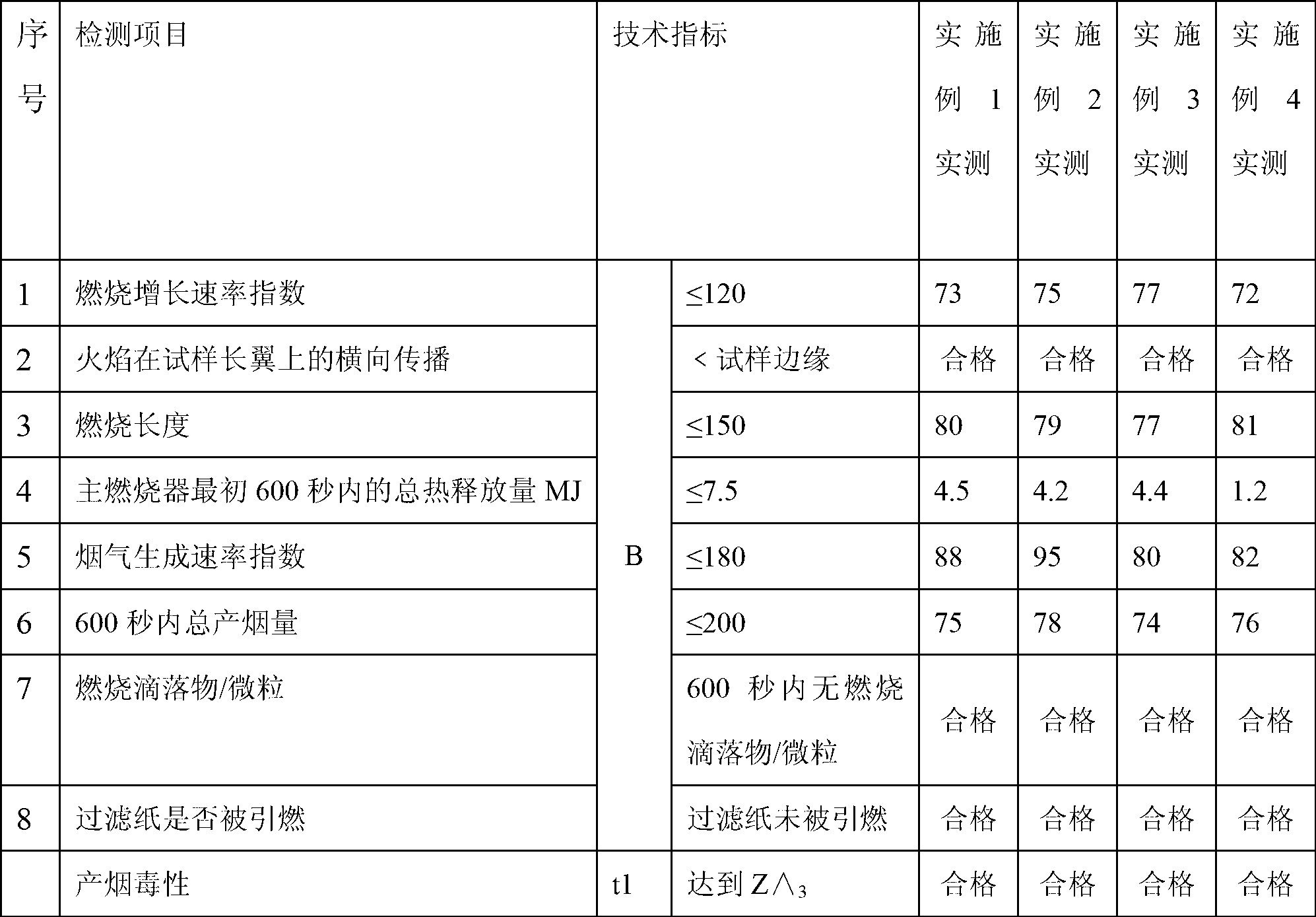

Embodiment 1

[0024] 15 parts of linear low-density polyethylene, melt index MI0.6, 10 parts of hot-melt adhesive (hot-melt adhesive is ethylene-vinyl acetate copolymer, also known as EVA), melting point of 115 ° C, modified fibrous light calcium carbonate 65 0.2 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1 part of modified nano-aluminum hydroxide, 0.5 parts of bis-2-cyanoethyl phosphate triester, ortho Dioctyl phthalate 3, polyethylene wax 0.4 parts, triazine-4250.1 parts, p-octylphenyl salicylate 0.1 parts, sorbitan stearate 1.5 parts.

[0025] Preparation method of modified fibrous light calcium carbonate: at 80°C, 3 parts of γ-aminopropyltriethoxysilane diluted with 1:1 liquid paraffin oil are evenly sprayed on 100 parts of fibrous light calcium carbonate , stir with a mixer for 30 minutes.

[0026] Fibrous light calcium carbonate can be prepared by the following method: 0.1m 3 0.1mol / L of MgCl 2 6H 2 O solution with 0.1m 3 0.12mol / L NaOH solution reacts to prepare Mg(O...

Embodiment 2

[0033]16 parts of linear low-density polyethylene, melt index MI0.7, 9 parts of hot melt adhesive (ethylene-vinyl acetate copolymer, also known as EVA), melting point of 105 ° C, 70 parts of modified fibrous light calcium carbonate, 2 , 0.3 parts of 5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 2 parts of modified nano aluminum hydroxide, 1 part of bis-2-cyanoethyl phosphate triester, phthalic acid 4 parts of dioctyl ester, 0.5 part of polyethylene wax, 0.2 part of triazine-4255, 0.3 part of p-octylphenyl salicylate, 0.5 part of sorbitan stearate.

[0034] Preparation method of modified light fibrous calcium carbonate: At 80°C, 4 parts of γ-aminopropyltriethoxysilane diluted with 1:1 liquid paraffin oil are evenly sprayed on 100 parts of light fibrous calcium carbonate Calcium, beat with a blender for 30 minutes.

[0035] Fibrous light calcium carbonate preparation method is identical with embodiment 1.

[0036] The preparation method of modified nano-aluminum hydroxide: at 80...

Embodiment 3

[0040] 17 parts of linear low-density polyethylene, melt index MI0.8, 8 parts of hot melt adhesive (ethylene-vinyl acetate copolymer, also known as EVA), melting point of 100 ° C, 75 parts of modified fibrous light calcium carbonate, 2 , 0.4 parts of 5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 3 parts of modified nano aluminum hydroxide, 1.5 parts of bis-2-cyanoethyl phosphate triester, phthalic acid 5 parts of dioctyl esters, 0.6 parts of polyethylene wax, 0.3 parts of triazine-4255, 0.3 parts of dilauryl thiodipropionate, 0.3 parts of p-octylphenyl salicylate, 1.5 parts of sorbitan stearate .

[0041] Preparation method of modified fibrous light calcium carbonate: at 80°C, 5 parts of γ-aminopropyltriethoxysilane diluted with 1:1 liquid paraffin oil are evenly sprayed on 100 parts of light fibrous calcium carbonate Serve, and beat with a high-speed mixer for 30 minutes.

[0042] Fibrous light calcium carbonate preparation method is identical with embodiment 1.

[0043] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com