Annular chemical packer material for water plugging of horizontal well

A packer and horizontal well technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as thixotropy, unsatisfactory process safety, strong gravity, and poor process controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

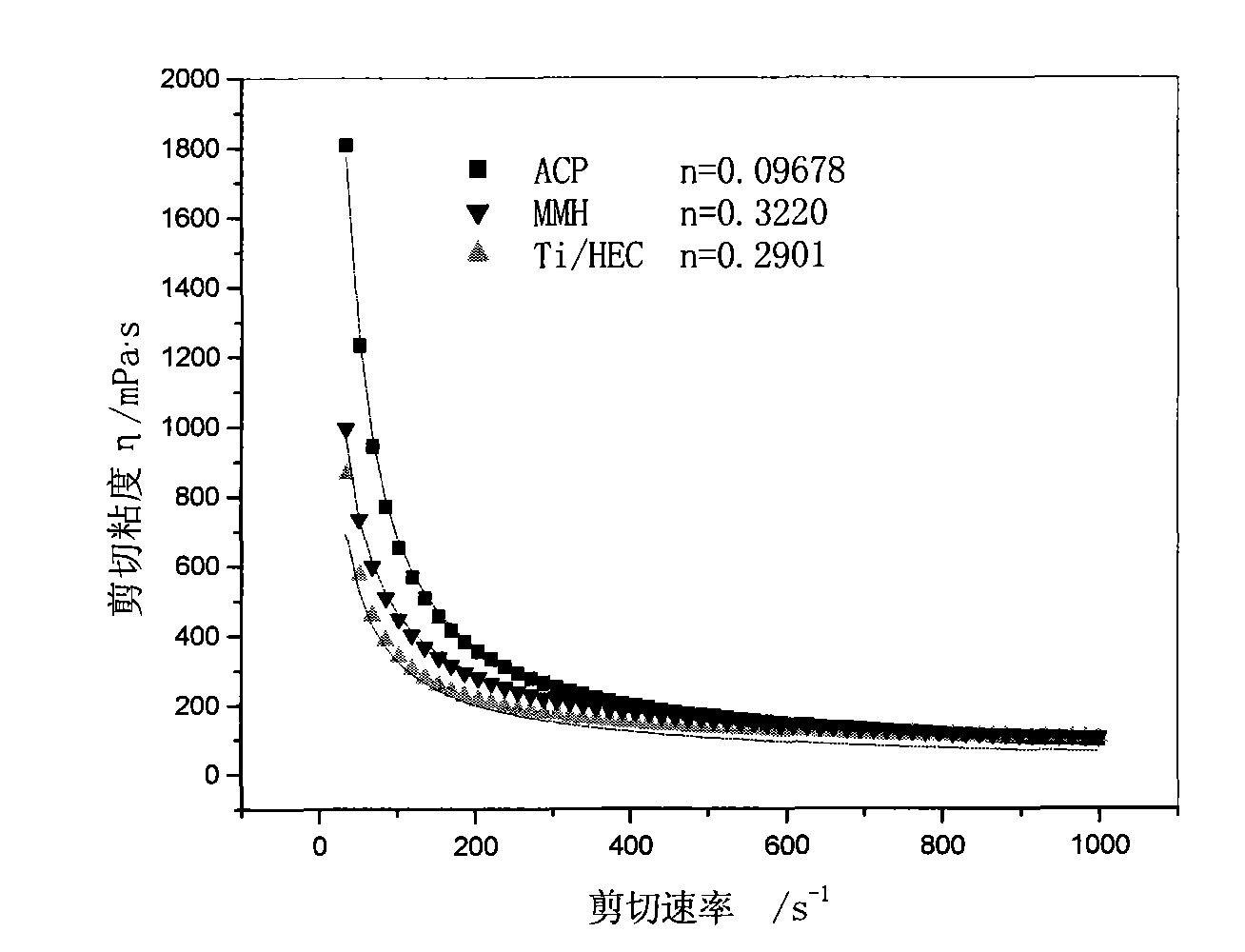

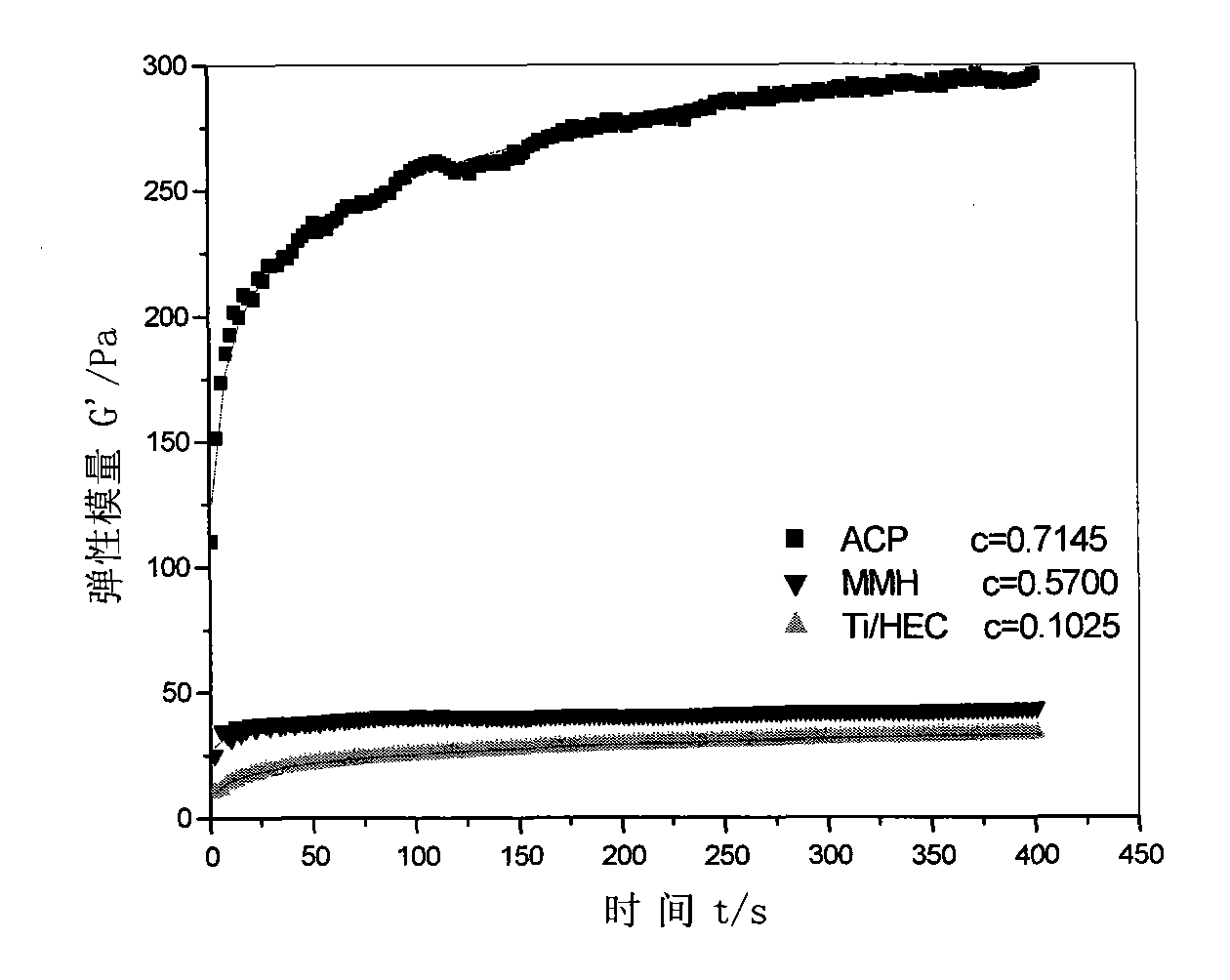

[0039] In parts by weight, add 30 parts of aluminum-iron mixed-layer metal hydroxide and 10 parts of dibromo-bis(dimethyldodecyl)ethylene diammonium to 100 parts of water, stir and dissolve at room temperature, and let it stand still for reaction For 12 hours, synthesize the thixotropic control component; then, add 20 parts of polyacrylamide, N-methylolacrylamide and 0.5 parts of tert-butyl peroxide into the synthesized thixotropic control Components, stir evenly to form ACP material.

[0040] The power law exponent of the ACP material is 0.14, and the final thixotropic structural strength is 0.83Kpa. After shearing, the thixotropic structural strength can be recovered quickly after standing still for about 5 seconds; Become a high-strength viscoelastic solid with a strength of 790.0KPa.

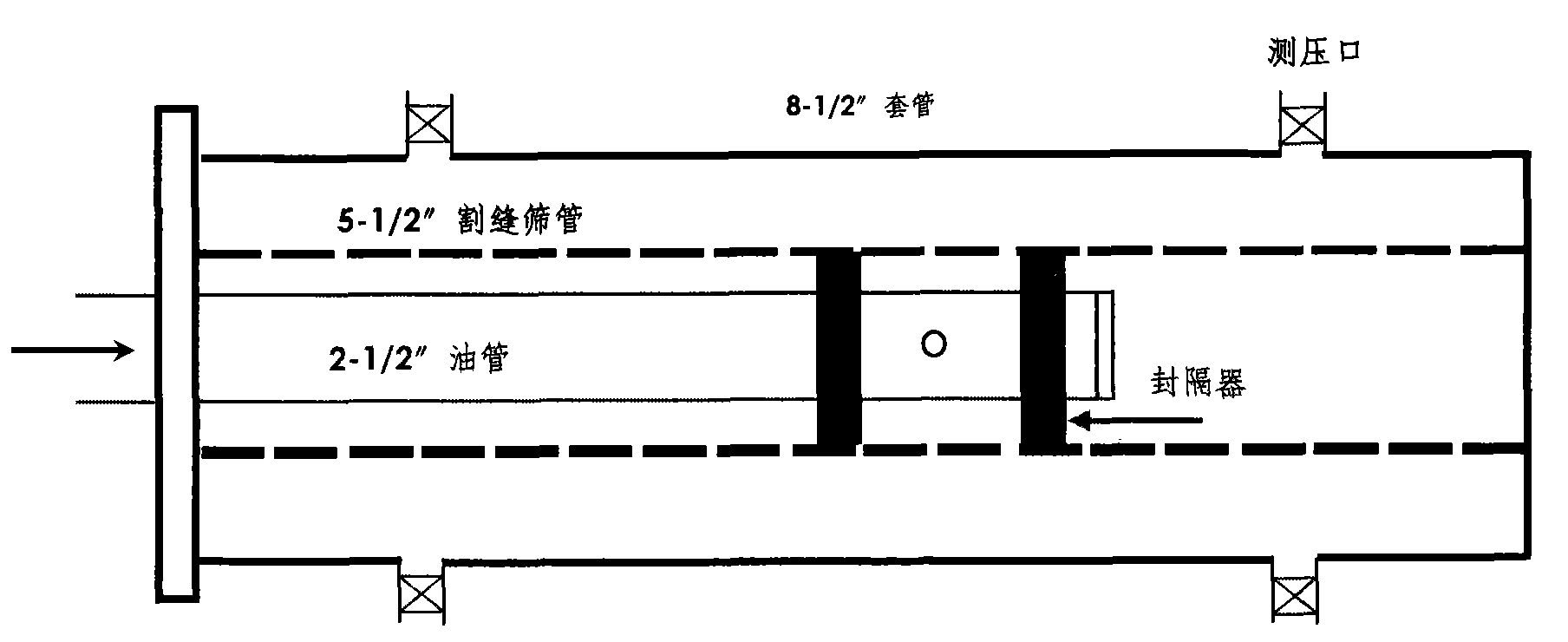

[0041] Prepare a 1-meter-long process model based on the actual wellbore size ( image 3 ). The synthetically prepared ACP material was dyed and injected into the horizontal annulus to ob...

Embodiment 2

[0044]In parts by weight, add 10 parts of aluminum-magnesium mixed-layer metal hydroxide and 1 part of dibromo-bis(dimethyldodecyl)ethylenediammonium to 100 parts of water, stir and dissolve at room temperature, and let it stand still for reaction For 12 hours, synthesize the thixotropic control component; then, add 5 parts of polyoxyethylene ether, N-methylolacrylamide and 0.1 part of tert-butyl peroxide into the synthetic thixotropic In the control component, stir evenly to form ACP material.

[0045] The power law exponent of the ACP material is 0.20, and the final thixotropic structural strength is 0.58Kpa, and the thixotropic structural strength can be recovered rapidly in about 18 seconds after shearing; within 4.5 hours, the thixotropic body with a certain structural strength becomes a high-strength viscous Elastic solid, the strength reaches 207.4KPa.

[0046] Prepare a 1-meter-long process model based on the actual wellbore size ( image 3 ). The synthetically prep...

Embodiment 3

[0049] In parts by weight, add 20 parts of sodium montmorillonite and 5 parts of amide-type gemini quaternary ammonium salt into 100 parts of water, stir and dissolve at room temperature, and leave to stand for reaction for 12 hours to synthesize the thixotropic control component; then, acrylamide 15 parts, 1 part of N-methylolacrylamide and tert-butyl peroxide are added to the synthesized thixotropic control component according to the weight ratio of 1:0.1-5, and stirred evenly to form an ACP material.

[0050] The power law exponent of this ACP material is 0.30, and the final thixotropic structural strength is 0.32Kpa. After shearing, the thixotropic structural strength can be recovered rapidly in about 30 seconds, and the thixotropic body with a certain structural strength will continue to become a high-strength thixotropic substance within 1 hour. Viscoelastic solid, the strength reaches 30.7KPa.

[0051] Prepare a 1-meter-long process model based on the actual wellbore si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com