Additives for Cetane Improvement in Middle Distillate Fuels

a technology of additives and distillates, applied in the direction of fuel additives, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of self-accelerated decomposition, dangerous fire and explosive hazards,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-18

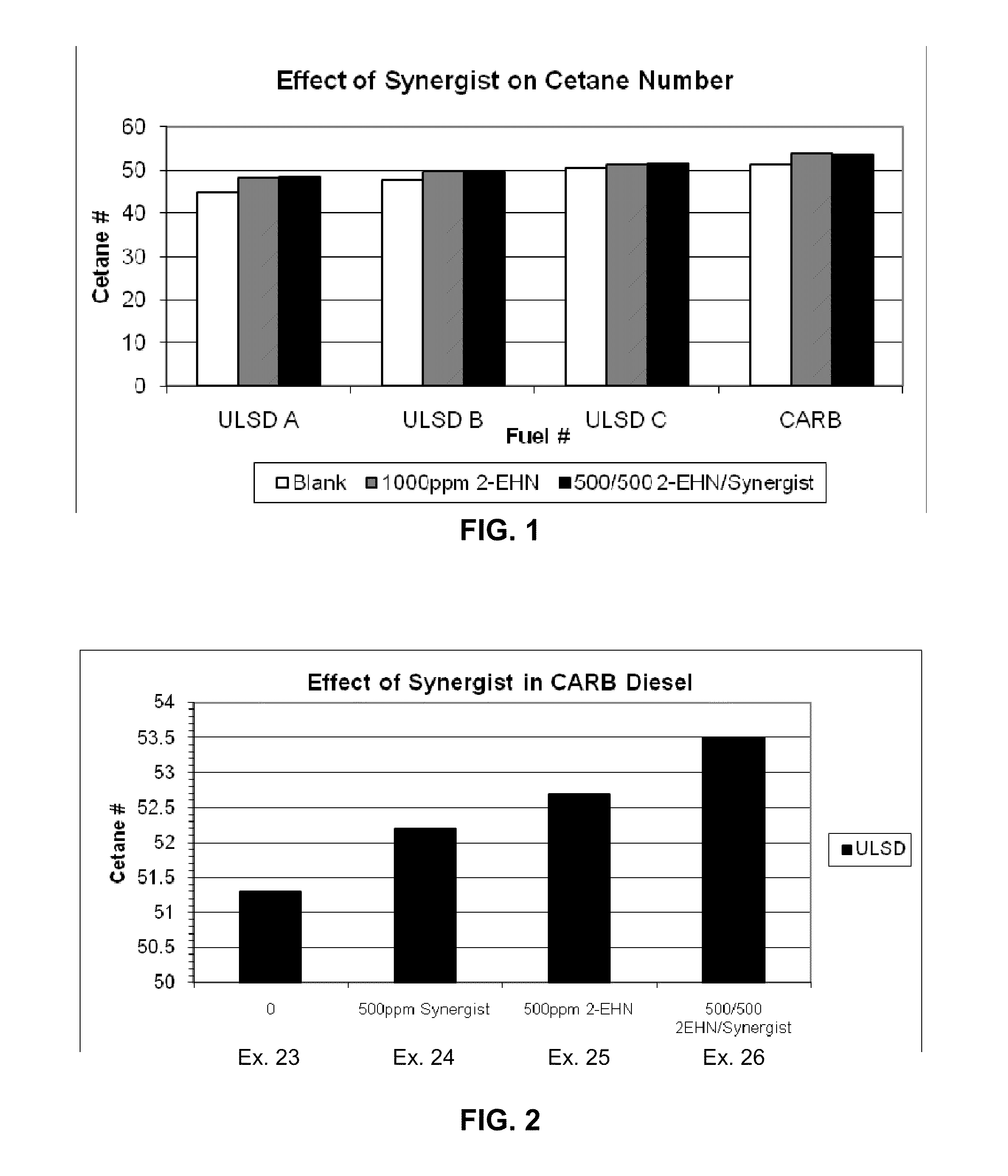

[0025]Tables I through IV are compilations of experimental cetane number test results using the ASTM D613 test methodology in a Midwestern, Eastern, Western and CARB Diesel ultra-low sulfur diesel (ULSD) fuels. All tests were performed at Southwest Research Institute (SwRI) unless otherwise noted. The data show that in these ULSDs, the same level of cetane improvement may be achieved by replacing the relatively more expensive 2-EHN with an additive composition containing 0.2% of an about 2,000,000 Mw PIB homopolymer synergist. The results are plotted in FIG. 1.

TABLE ICetane Synergist Performance SummaryCetane Engine Test Results via ASTM D613 (Midwestern ULSD)Synergist2-EHNCetane NumberEx.Dosage, ppmDosage, ppmCetane #Improvement10044.8—20100048.23.4340060048.43.6450050048.33.5560040048.33.5

TABLE IICetane Synergist Performance SummaryCetane Engine Test Results via ASTM D613 (Eastern ULSD)Synergist2-EHNCetane NumberEx.Dosage, ppmDosage, ppmCetane #Improvement60047.7—70100049.61.98400...

examples 19-26

[0027]Examples 19-26 present the results of testing from the combination of diluted polymer synergist and 2-EHN which worked better than either additive used individually. In these comparisons, the solvent is believed to help improve the cetane number. The synergist was again 2,000,000 Mw PIB homopolymer. The fuels used were a ULSD and CARB Diesel. The results of Table VI are graphed in FIG. 2. FIG. 2 illustrates that with total 1000 ppm of either polymer synergist and solvent, 2-EHN and solvent, or polymer synergist and 2-EHN, the latter combination surprisingly gives the best results. The solvent was butanol.

TABLE VSynergistic Effect of 2-EHN and Cetane SynergistCetane Engine Test Results via ASTM D613 (Valero ULSD)2-EHNSynergistEx.Dosage, ppmDosage, ppmSolventCetane #1900—50.420050050047.121500050049.822500500—51.4

TABLE VISynergistic Effect of 2-EHN and Cetane SynergistCetane Engine Test Results via ASTM D613 (CARB Diesel)2-EHNSynergistEx.Dosage, ppmDosage, ppmSolventCetane #2300...

examples 27-29

[0028]During testing, all high molecular weight polymers ranging from about 900,000 to 2,100,000 only showed marginal performance when used alone for NOx reduction. It was surprisingly discovered that when about 2,000,000 Mw PIB polymer was used with 2-EHN that a clear synergistic effect was shown that gave a 6.2% NOx reduction as compared with only 0.1% reduction when only the 1% PIB mixture was used and only a 3.2% reduction when 2-EHN was used alone. The fuel used was a typical ULSD from a Valero refinery. The 1% PIB mixture was 1 vol % about 2,000,000 Mw PIB homopolymer, 5 vol % butanol and 94% Chevron heavy aromatic distillates. From previous experiments, adding about 5 to about 10% mineral oil may also help lower the NOx emissions. The results are shown in Table VII.

TABLE VIIHigh Molecular Weight PIB Alone, EHN Alone and PIB + EHNEHNEx.Treat RatePIB activeConc.% NOxNo.Sample(ppm)(ppm)(ppm)Red.27BPC91 (0.2% PIB2000400.1mixture)282-EHN50005003.229BPC121 (1% PIB20003.24006.2mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com