Foamed rubber and preparation method thereof

A foaming rubber and foaming agent technology, applied in the field of foaming rubber, can solve the problems of low viscosity of foaming rubber, insufficient foaming pores, uneven foaming pores, etc., and achieve uniform foaming pores and sufficient foaming pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

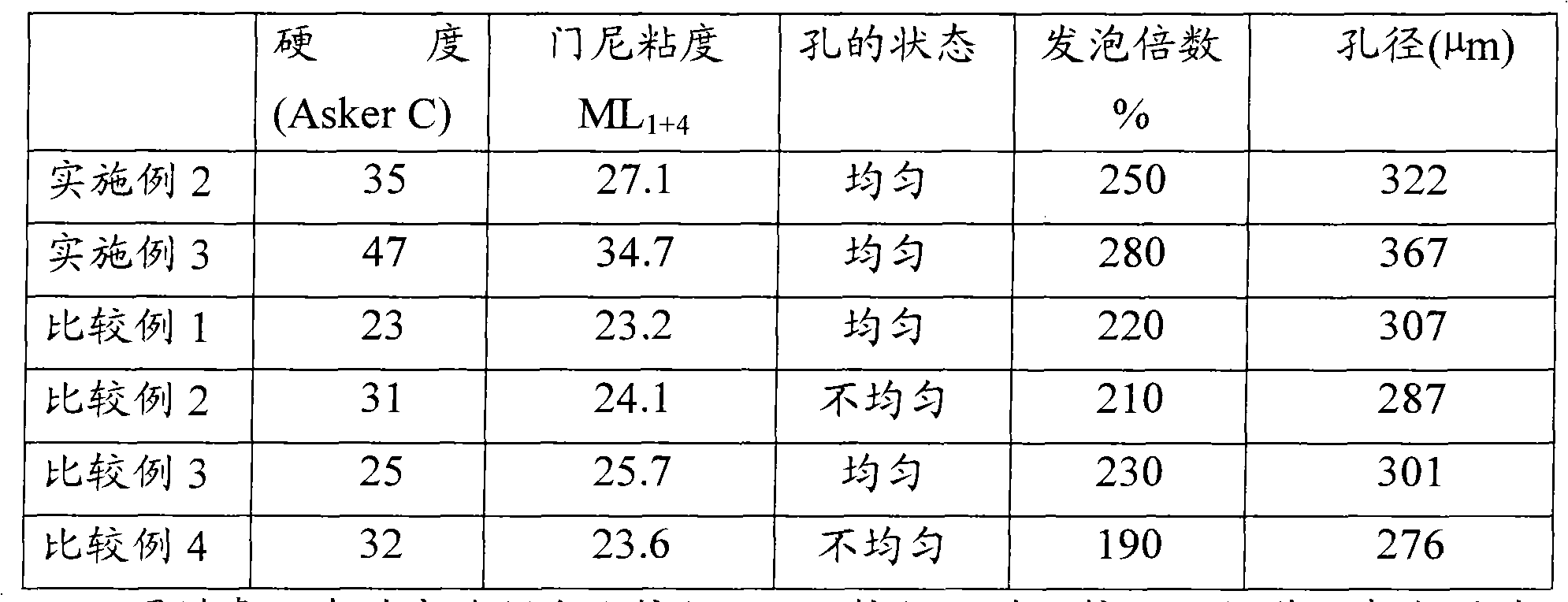

Examples

preparation example Construction

[0061] The present invention also provides the preparation method of above-mentioned foamed rubber, it comprises:

[0062] In the first step, the EPDM rubber, the polyethylene glycol di(meth)acrylate oligomer with the weight average molecular weight of 200-400 and the azobisisobutyronitrile in a torque flow Plasticizing in the variable instrument for 10 minutes to 20 minutes, the plasticizing temperature is 60°C-70°C;

[0063] In the second step, the surface-modified silicon dioxide, the azodicarbonamide, the montmorillonite, the gallic acid foaming agent and the bis(peroxide) tert-butyl) dicumyl vulcanizing agent is added to the torque rheometer, the temperature is raised to 165°C-175°C, banburying is carried out for 20-40 minutes, and then the temperature is lowered and the material is discharged to obtain the foamed rubber .

Embodiment 1

[0071] 5g of octadecyltrimethoxysilane (Shanghai Bowman Biotechnology Co., Ltd.) and 100g of 40nm silicon dioxide (produced by Nalco Chemical Company) were stirred and mixed in 500mL of 1-methoxy-2-propanol solution, Stand still for 12 hours under the condition of 75° C.-90° C., and then dry under the condition of 135° C. to obtain surface-modified silicon dioxide with a particle size of 41.3 nm.

Embodiment 2

[0073] At room temperature, 100g EPDM Mitsui EPT4045 (produced by Japan Mitsui Petrochemical Company), the content of the third monomer ethylidene norbornene in this EPDM rubber is 8%, 10g weight average molecular weight is 330 Polyethylene glycol di(meth)acrylate oligomer (produced by Shanghai Kangliang Chemical Co., Ltd.) and 0.25g described azobisisobutyronitrile (Zibo Chunwangda Chemical Co., Ltd.) in the torque rheometer Plasticating for 15 minutes, the plasticizing temperature is 65°C; the surface-modified silicon dioxide prepared in 0.5g embodiment 1, 4.75g of the azodicarbonamide (produced by Kunming Jinyang Chemical Industry Co., Ltd.), 2g of the Described montmorillonite (produced by Xinyang Jiaxin Bentonite Factory), 0.5g described gallic acid foaming aid and 3g described bis(tert-butyl peroxide) dicumyl vulcanizing agent (produced by Zibo Shengying Chemical Co., Ltd.) Add it into the torque rheometer, increase the temperature to 165°C, banbury for 20 minutes, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com