Composite ceramic connector for tubular solid oxide fuel cell and preparation method thereof

A solid oxide and fuel cell technology, applied in the direction of fuel cells, fuel cell parts, chemical instruments and methods, etc., can solve the problems of complex process and high cost, and achieve the effect of simple process, long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

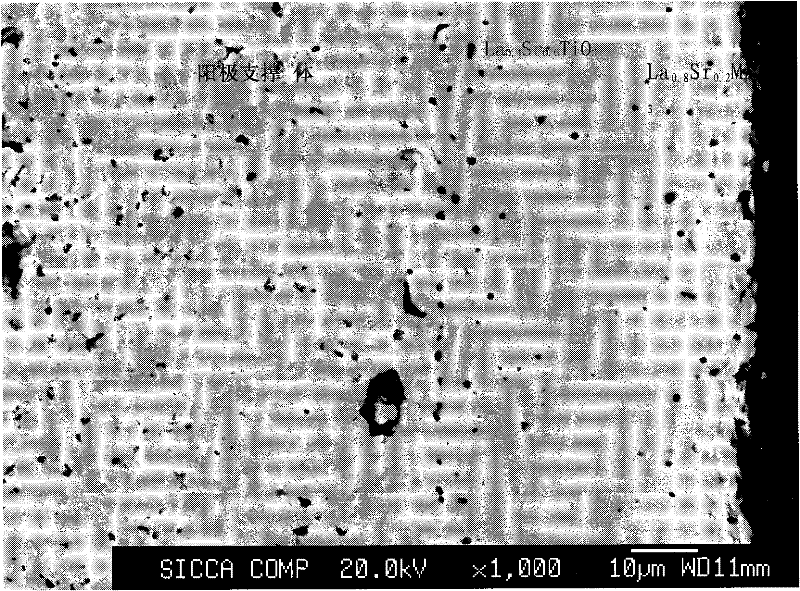

[0034] Example 1: Preparation of tubular SOFC double-layer composite ceramic connector

[0035] The lanthanum-doped strontium titanate powder used in the present invention is synthesized by a solid-state reaction method. As the La doping amount increases from 0.1 to 0.4, the electrical conductivity of the material also increases gradually. But more than 0.4 will appear the second phase. Therefore the preferred embodiment of the present invention is a powder with a La doping amount of 0.4 (La 0.4 Sr 0.6 TiO 3 )As research target. La 0.8 Sr 0.2 MnO 3 The powder is a commercially available powder.

[0036] Lanthanum-doped strontium titanate (La 0.4 Sr 0.6 TiO 3 ) 44 grams of powder, 100 grams of ethanol, 1.5 grams of TEA, add 200 grams of zirconia grinding balls, ball mill on a planetary ball mill for 1 hour, then add 2 grams of PVB to the above slurry, continue ball milling for 2 hours, and then vacuumize After 2-3 minutes, the air in the slurry is removed to obtain ...

Embodiment 2

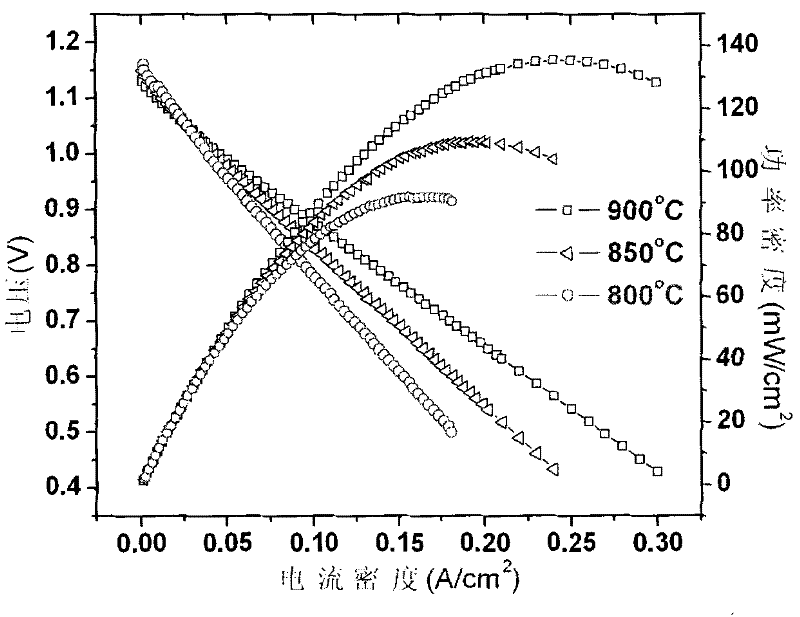

[0040] Example 2: Performance testing of tubular cells and performance characterization of connectors

[0041] According to the tubular single cell prepared in Example 1, the experimental conditions for its power generation performance test are:

[0042] Cathode area: 11cm 2(thickness is about 50-60 microns);

[0043] Connector area: 2.5cm 2 ; Thickness about 35 microns (La 0.4 Sr 0.6 TiO 3 about 20 microns, La 0.8 Sr 0.2 MnO 3 about 15 microns);

[0044] Test gas: H 2 , O 2 , not sealed. h 2 The flow rate is 100ml / min, O 2 The flow rate is 80ml / min.

[0045] Experimental results such as figure 2 shown. Under the condition of 900℃, the maximum power density of the battery can reach 140mW / cm 2 , The total output power of a single battery can reach about 1.5 watts.

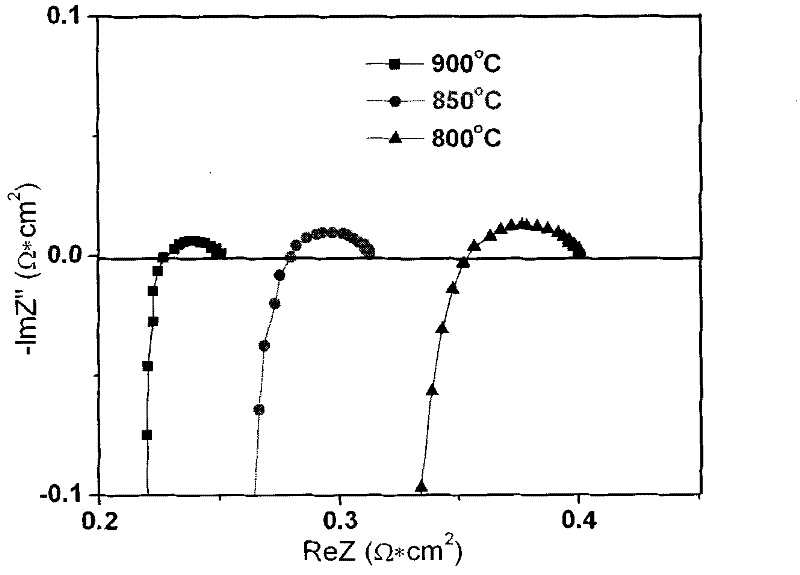

[0046] As an electrical connection material, the connecting body should theoretically have as small a resistance as possible. From image 3 It can be seen that at 900 °C, 850 °C and 800 °C, the ...

Embodiment 3

[0047] Example 3: The influence of the thickness ratio of the composite connector on the performance of the battery

[0048] The linker preparation method is similar to Example 1. The difference is that the lanthanum-doped strontium titanate slurry is applied thinner, and the strontium-lanthanum manganate slurry is applied thicker. The experimental conditions for the power generation performance test are:

[0049] Cathode area: 10.12cm 2 (thickness is about 50-60 microns);

[0050] Connector area: 2.25cm 2 ; Thickness about 35 microns (La 0.4 Sr 0.6 TiO 3 About 15 microns, La 0.8 Sr 0.2 MnO 3 about 20 microns);

[0051] Test gas: H 2 , O 2 , not sealed. h 2 The flow rate is 100ml / min, O 2 The flow rate is 80ml / min.

[0052] Experimental results such as Figure 4 shown. When a single cell operates at 900°C, the maximum power density is about 160mW / cm 2 . Battery performance is relative to embodiment 2 (140mW / cm 2 ) has improved to a certain extent. The rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com