Enameled wire baking hot air circulation method and device

A hot air circulation, enameled wire technology, applied in drying, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of product surface quality decline, short service life, high material requirements, etc., to reduce production costs and Energy consumption, good quality of processed products, good thermal cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

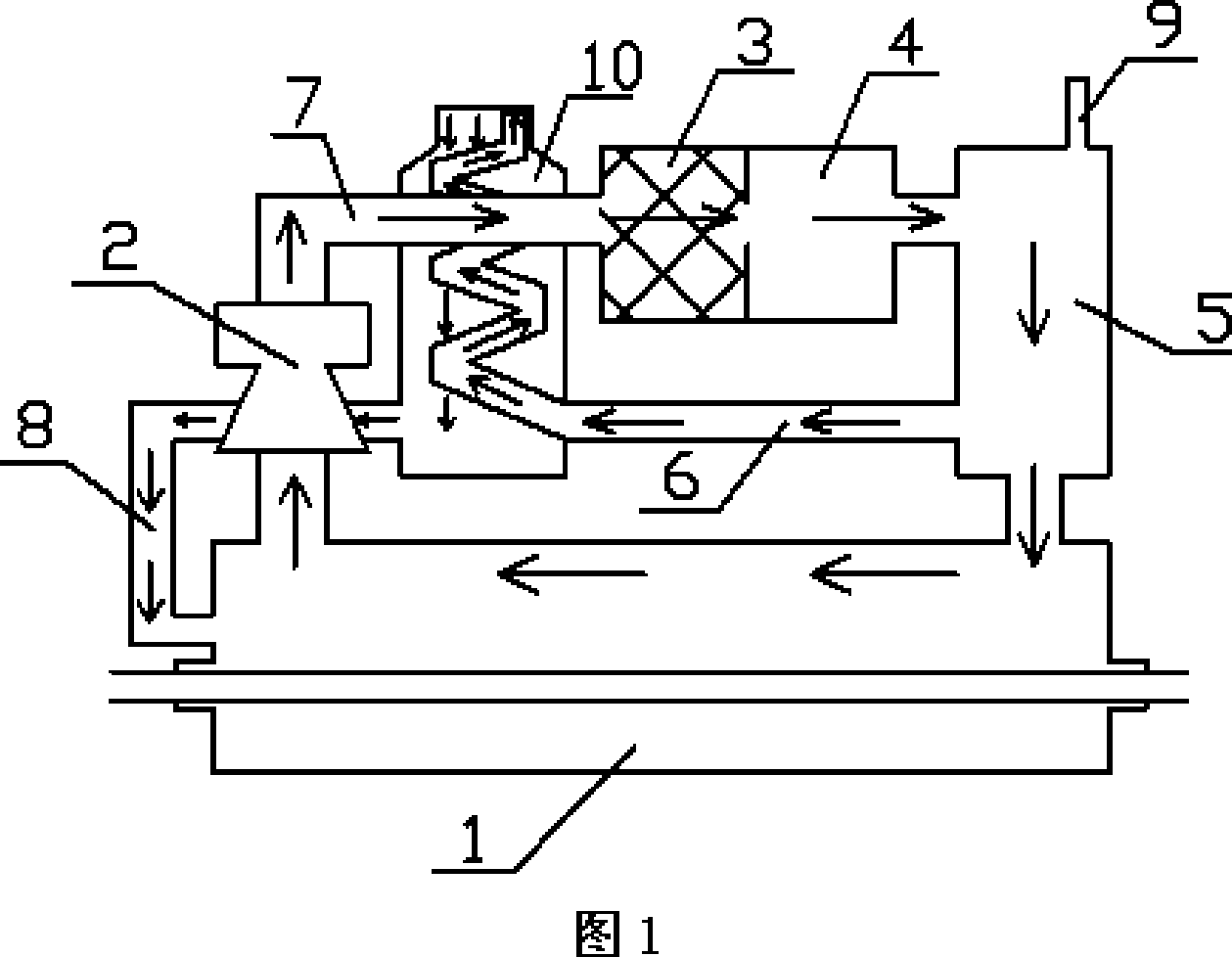

[0012] Embodiment 1: Enameled wire baking hot air circulation method, the hot air in the oven 1 is sucked out by the fan 2 installed in the front of the oven 1, and the fan 2 sends the hot air containing solvent vapor into the catalytic device 3, and passes through the fan 2. The hot air from the catalytic device 3 enters the combustion chamber 4 for heating, and the heated hot air enters the heat storage chamber 5, and the hot air is sent from the rear of the oven 1 through the heat storage chamber 5, and the heat storage chamber 5 The middle part of the hot air enters the heat exchange device 10 and is discharged after heat exchange. The heat exchange device 10 heats the sucked air and sends it to the front end of the oven 1 .

[0013] The hot air circulation device for enameled wire baking as shown in Figure 1 is composed of an oven 1. A fan 2 is provided on the air supply pipe 7 at the front of the oven 1. The fan 2 is connected to the catalytic device 3 through the air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com