Method for designing combined sealing device used in low speed and heavy load conditions of bearing

A low-speed heavy-duty, sealing device technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of insufficient skeleton rigidity of seals, reduce the use effect of seals, and reduce the use effect of seals, etc. Longevity, reduced maintenance, reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

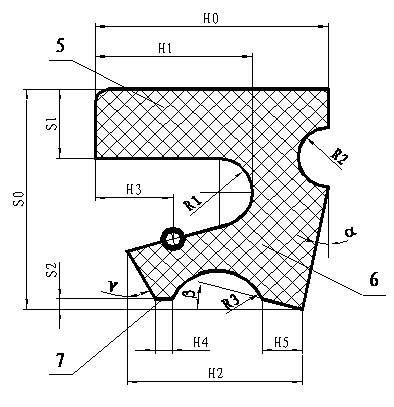

[0031] The present invention is a design method for a combined sealing device used in low-speed and heavy-load working conditions of bearings. The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples, and the purpose of the present invention is disclosed All changes and modifications within the scope of the invention are intended to be protected.

[0032] The specific numerical values listed below are for reference only, and these specific numerical values are not unique, but must comply with and satisfy the present invention.

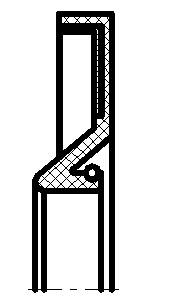

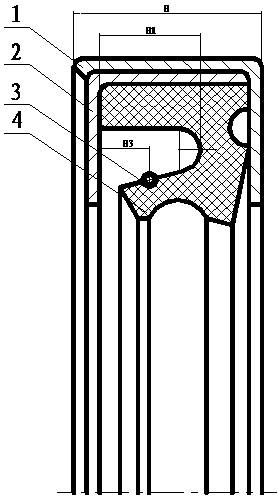

[0033] First, set the width of the shaft shoulder of the bearing outer ring and the inner ring as Hk, set the inner diameter of the shaft shoulder of the outer ring of the bearing as D, and set the outer diameter of the shaft shoulder of the inner ring of the bearing as d, then the combined sealing device design The method includes outer shell 1, inner shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com