ABS composite material for plastic toys and preparation method thereof

A technology of plastic toys and composite materials, which is applied in the field of ABS composite materials for plastic toys and its preparation, which can solve the problems of being easily smashed or worn out, thrown on the ground, on the wall or on the table, etc., so as to reduce friction Effect of contact area, improvement of tensile strength and impact strength, improvement of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

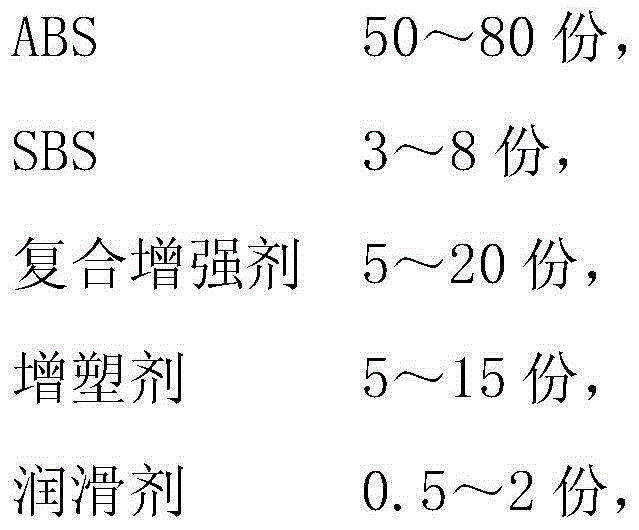

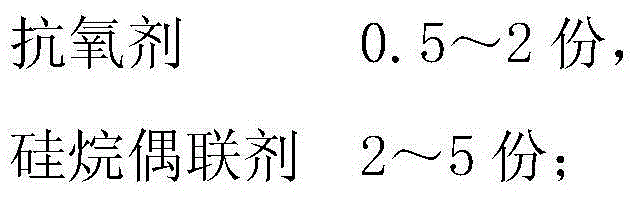

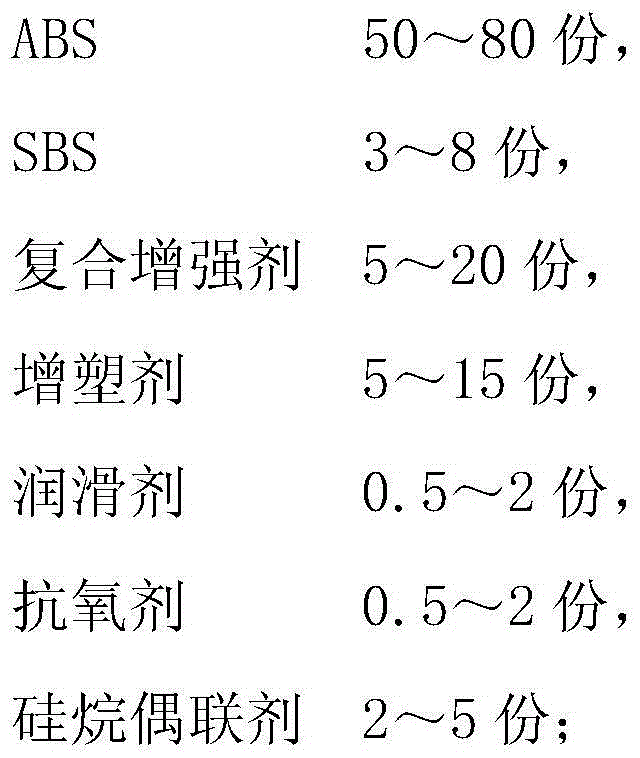

[0023] An ABS composite material for plastic toys, which comprises the following components by weight: 50 parts of ABS, 8 parts of SBS, 18 parts of composite reinforcing agent, 15 parts of DOP, 2 parts of zinc stearate, 10102 parts of antioxidant, KH-5505 Parts; Among them, the composite reinforcing agent is mixed with ceramic microbeads and glass fibers in a weight ratio of 2:1.

[0024] Its preparation method comprises the following steps:

[0025] (1) Dry the composite reinforcing agent at 100°C for 3 hours, dissolve KH-550 in ethanol solution, put the dried composite reinforcing agent into a mixer and stir, add the ethanol solution of KH-550 while stirring, and stir for 1 After 1 hour, place it in an oven and dry at 90°C for 3 hours to obtain a modified composite reinforcing agent;

[0026] (2) Add ABS, SBS, DOP, zinc stearate, antioxidant 1010, and modified composite reinforcing agent into a high-speed mixer and mix for 5 minutes, and obtain a mixture after cooling;

[...

Embodiment 2

[0029] An ABS composite material for plastic toys, which comprises the following components by weight: 80 parts of ABS, 3 parts of SBS, 9 parts of composite reinforcing agent, 5 parts of DBP, 0.5 parts of polyethylene wax, 10760.5 parts of antioxidant, and 2 parts of KH-5602 ; Wherein, the composite reinforcement is mixed with ceramic microbeads and glass fibers in a weight ratio of 2:1.

[0030] Its preparation method comprises the following steps:

[0031] (1) Dry the composite reinforcing agent at 100°C for 3 hours, dissolve KH-560 in ethanol solution, put the dried composite reinforcing agent into a mixer and stir, add the ethanol solution of KH-560 while stirring, and stir for 1 After 1 hour, place it in an oven and dry at 90°C for 3 hours to obtain a modified composite reinforcing agent;

[0032] (2) Add ABS, SBS, DBP, polyethylene wax, antioxidant 1076, and modified composite reinforcing agent into a high-speed mixer and mix for 5 minutes, and obtain a mixture after co...

Embodiment 3

[0035] An ABS composite material for plastic toys, which comprises the following components by weight: 70 parts of ABS, 7 parts of SBS, 5 parts of composite reinforcing agent, 12 parts of DOP, 1 part of polyethylene wax, 10761 parts of antioxidant, 4 parts of KH-5604 ; Wherein, the composite reinforcement is mixed with ceramic microbeads and glass fibers in a weight ratio of 2:1.

[0036] Its preparation method comprises the following steps:

[0037] (1) Dry the composite reinforcing agent at 100°C for 3 hours, dissolve KH-560 in ethanol solution, put the dried composite reinforcing agent into a mixer and stir, add the ethanol solution of KH-560 while stirring, and stir for 1 After 1 hour, place it in an oven and dry at 90°C for 3 hours to obtain a modified composite reinforcing agent;

[0038] (2) Add ABS, SBS, DOP, polyethylene wax, antioxidant 1076, and modified composite reinforcing agent into a high-speed mixer and mix for 5 minutes, and obtain a mixture after cooling; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com