Carbon-fiber-reinforced polyester composite material and preparation method thereof

A polyester composite material and carbon fiber technology, applied in the polymer field, can solve problems such as low utilization rate, and achieve the effects of improving surface polarity, enhancing adhesion, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

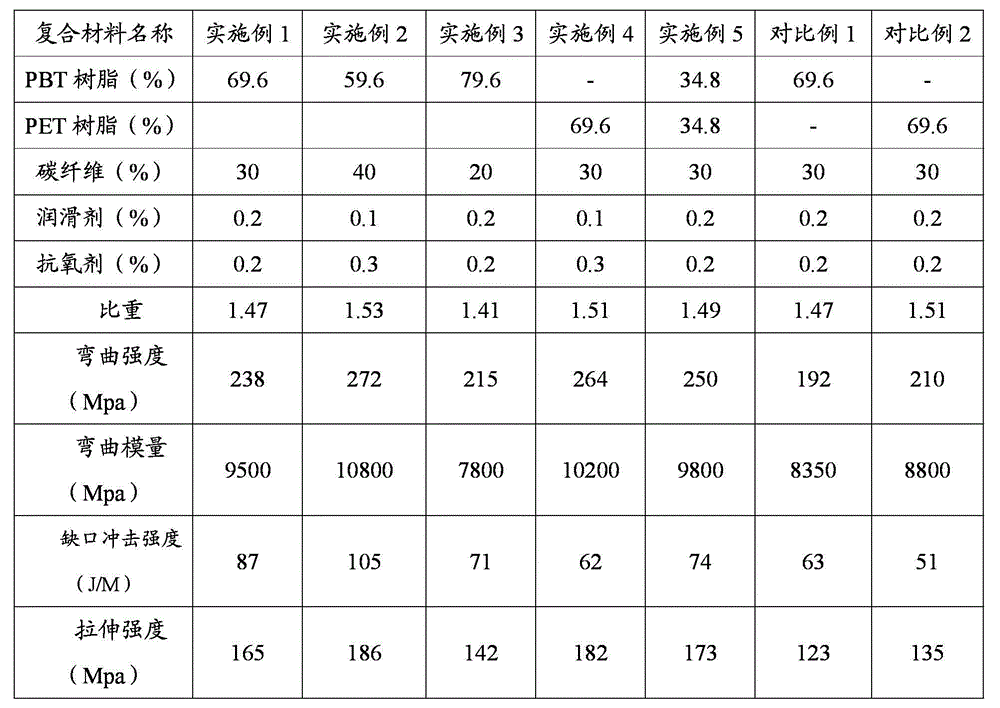

Examples

preparation example Construction

[0025] The invention provides a carbon fiber-reinforced polyester composite material and a preparation method thereof. In the invention, the carbon fiber is subjected to surface treatment, which specifically includes: wherein the carbon fiber surface treatment agent is prepared from the following components according to mass percentage: solvent 0-99% ; Polyacrylonitrile 1-100%.

[0026] The solvent is a polar solvent, including one or more of water, ethanol, methanol, and acetone. The carbon fibers are polyacrylonitrile-based carbon fibers. The polyacrylonitrile is a liquid polyacrylonitrile oligomer with a molecular weight range of 106-10000.

[0027] Carbon fiber surface treatment method, the specific steps include:

[0028] Step 1: mixing polyacrylonitrile and solvent according to the mass percentage and stirring evenly to form a carbon fiber surface treatment agent;

[0029] Step 2: soaking the carbon fiber with the carbon fiber surface treatment agent in step 1;

[00...

Embodiment 1

[0033] The preparation method of the composite material is as follows: the mass ratio of polyethylene terephthalate (PET) is: 69.6%; the mass ratio of lubricant (zinc stearate) is: 0.2%; the antioxidant (phenolic antioxidant Tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionic acid]pentaerythritol ester) mass ratio: 0.2%. Mix for 4 minutes in a high-speed mixer;

[0034] The uniformly mixed components are placed in a twin-screw extruder, melted, mixed, extruded and granulated, and 30% of the carbon fiber is fed into the extruder by side feeding;

[0035] The processing temperature is zone 1 temperature: 210-220℃, zone 2 temperature: 225-230℃, zone 3 temperature: 235-250℃, zone 4 temperature: 240-260℃, zone 5 temperature: 230-250℃, zone 6 Zone temperature: 220-245°C, zone seven temperature: 240-250°C, host speed: 300-350rpm.

[0036] The particles completed by the above method are dried in a blast oven at 100-130°C for 4 hours in advance, and then the dried particle mat...

Embodiment 2

[0038] The preparation method of the composite material is as follows: the mass ratio of polyethylene terephthalate (PET) is 59.6%; the mass ratio of lubricant (zinc stearate) is 0.1%; the antioxidant (phenolic antioxidant Tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionic acid]pentaerythritol ester) mass ratio: 0.3%. Mix for 4 minutes in a high-speed mixer;

[0039] The uniformly mixed components are placed in a twin-screw extruder, melted, mixed, extruded and granulated, and 40% of the carbon fiber is fed into the extruder by side feeding;

[0040] The processing temperature is zone 1 temperature: 210-220℃, zone 2 temperature: 225-230℃, zone 3 temperature: 235-250℃, zone 4 temperature: 240-260℃, zone 5 temperature: 230-250℃, zone 6 Zone temperature: 220-245°C, zone seven temperature: 240-250°C, host speed: 300-350rpm.

[0041] The particles completed by the above method are dried in a blast oven at 100-130°C for 4 hours in advance, and then the dried particle mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com