High-performance uniform-shrinkage-rate PET composite material and preparation method thereof

A technology of composite material and shrinkage rate, which is applied in the field of high-performance PET composite materials with uniform shrinkage rate and its preparation, can solve the problems of uneven shrinkage rate of PET composite materials, and achieve poor impact strength, uniform shrinkage rate, and mechanical strength. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

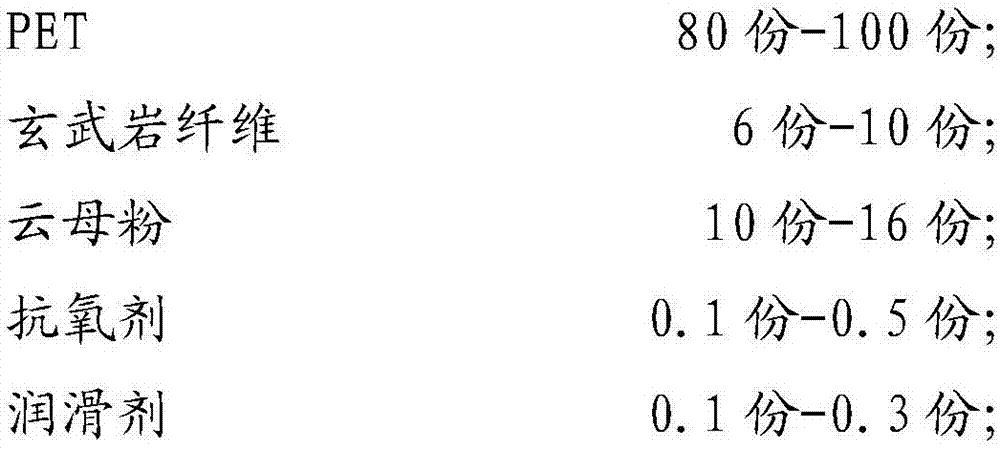

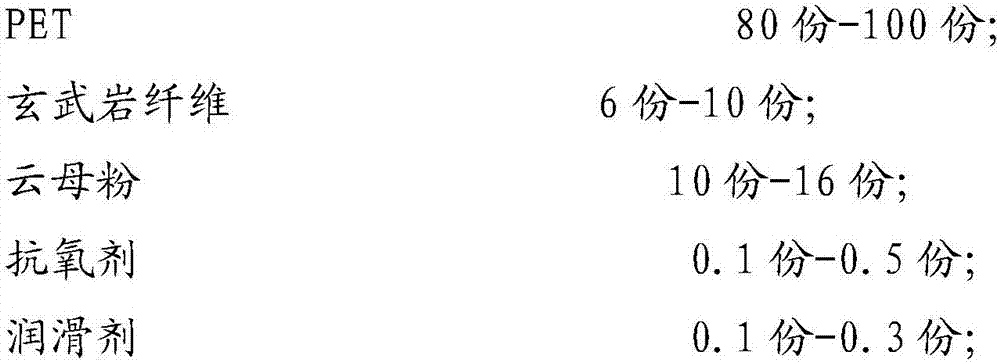

[0039] The preparation method of any one of the above-mentioned high-performance and uniform shrinkage PET composite materials includes the following steps:

[0040] (1) Weigh 80 parts to 100 parts of PBT, 6 parts to 10 parts of basalt fiber, 10 parts to 16 parts of mica powder, 0.1 part to 0.5 part of antioxidant, and 0.1 part to 0.3 part of lubricant to mix and stir evenly, Get the mixture

[0041] (2) Extruding and granulating the mixture obtained in step (1) to obtain a PET composite material.

[0042] The step (2) is specifically:

[0043] Put the mixture obtained in step (1) into the hopper of a twin-screw extruder for extruding and pelletizing, wherein the twin-screw extruder includes six temperature zones arranged in sequence, one zone having a temperature of 240~ 260℃, the second zone temperature is 280~300℃, the third zone temperature is 280~300℃, the fourth zone temperature is 280~300℃, the fifth zone temperature is 280~300℃, the sixth zone temperature is 280~300℃, the mac...

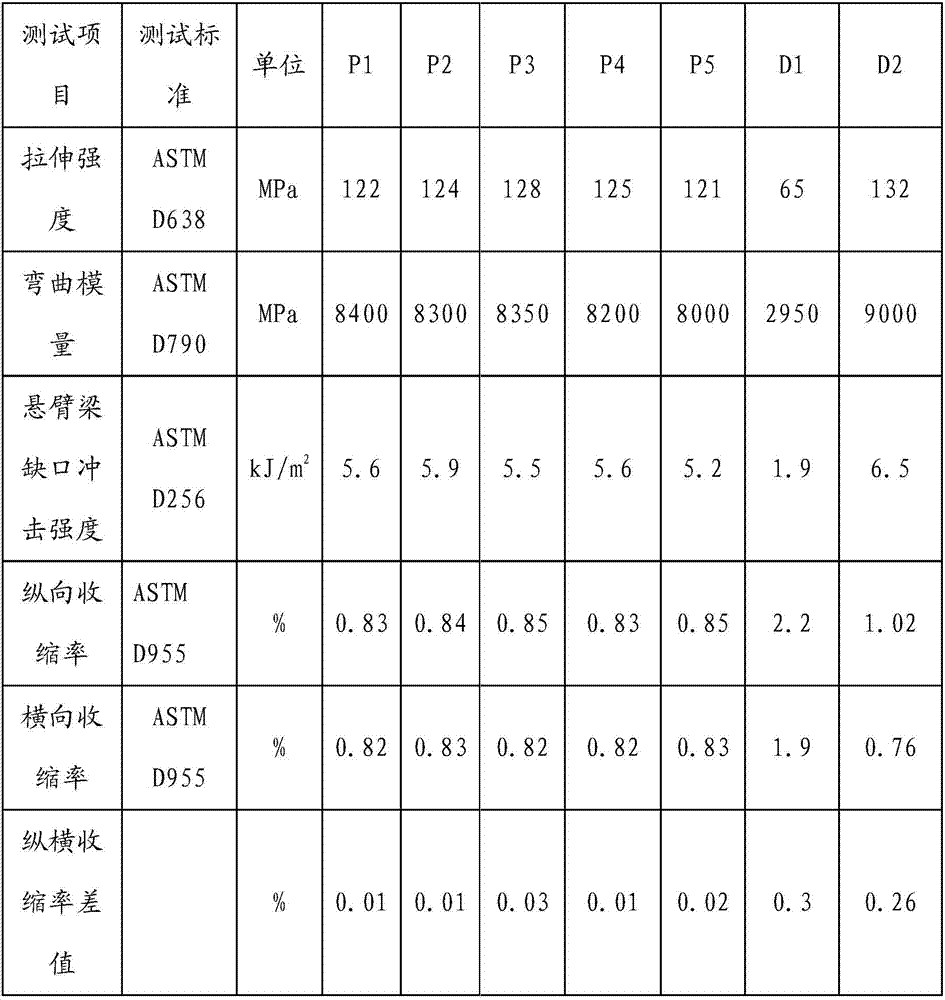

Embodiment 1

[0046] (1) Weigh 80 parts of PET, 6 parts of basalt fiber, 10 parts of mica powder, 0.1 part of Irganox168, and 0.1 part of zinc stearate, mix and stir to obtain a mixture;

[0047] (2) Extruding and granulating the mixture obtained in step (1) to obtain the PET composite material P1.

[0048] Preferably, the step (2) is specifically:

[0049] Put the mixture obtained in step (1) into the hopper of a twin-screw extruder for extrusion and granulation to obtain a PET composite material, wherein the twin-screw extruder includes six temperature zones arranged in sequence , The temperature in the first zone is 240℃, the temperature in the second zone is 280℃, the temperature in the third zone is 280℃, the temperature in the fourth zone is 280℃, the temperature in the fifth zone is 280℃, the temperature in the sixth zone is 280℃, the head temperature is 280℃, and the screw speed is 200r / min.

Embodiment 2

[0051] (1) Weigh 100 parts of PET, 10 parts of basalt fiber, 16 parts of mica powder, 0.1 part of Irganox 168, 0.2 part of Irganox 1010, 0.2 part of Irganox 1330, 0.15 part of potassium stearate, 0.15 part of zinc stearate, mix and stir evenly, Get the mixture

[0052] (2) Extruding and granulating the mixture obtained in step (1) to obtain the PET composite material P2.

[0053] Preferably, the step (2) is specifically:

[0054] The mixture obtained in step (1) is put into the hopper of a twin-screw extruder to be extruded and pelletized to obtain a PET composite material, wherein the twin-screw extruder includes six temperature zones arranged in sequence , Zone 1 temperature is 260℃, Zone 2 temperature is 300℃, Zone 3 temperature is 300℃, Zone 4 temperature is 300℃, Zone 5 temperature is 300℃, Zone 6 temperature is 300℃, head temperature is 300℃, screw speed is 280r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com