Integrated light chain board

A one-piece, lightweight technology, applied in the direction of the chain ring, etc., can solve the problems of large frictional contact area, reduce the flexibility of the chain operation, shorten the service life of the chain, etc., achieve light weight, reduce the frictional contact area, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

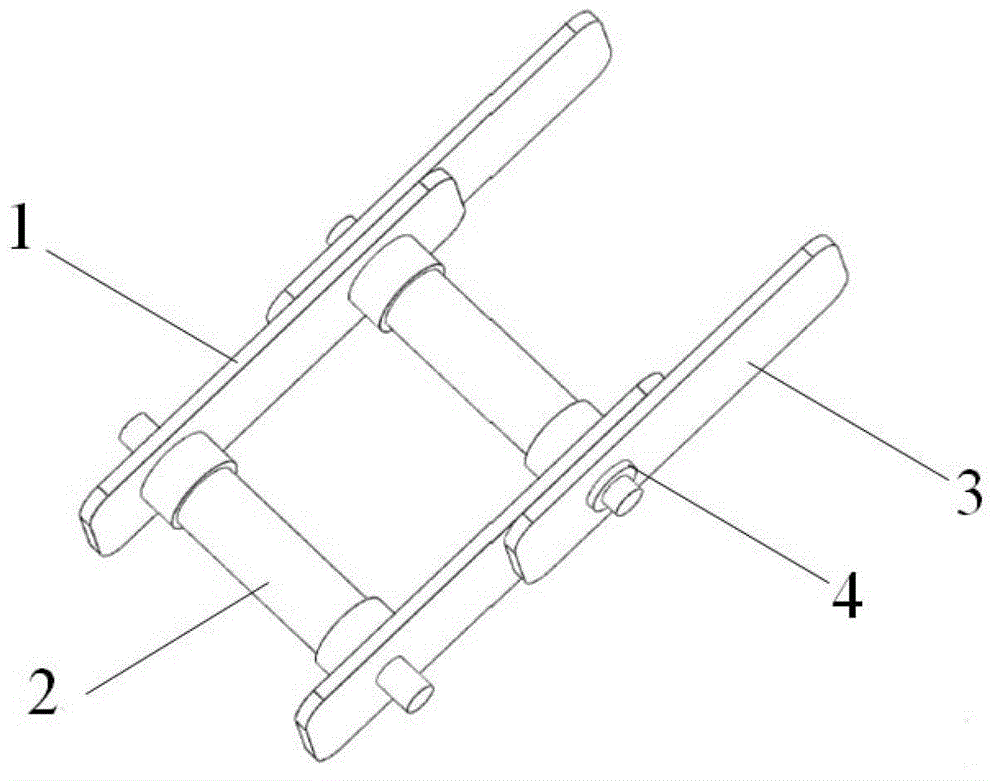

[0010] like figure 1 As shown in the figure, an integrated lightweight chain plate includes an inner chain plate 1 and a chain roller 2. The inner chain plate 1 and the chain roller 2 are integrally thermoplastically molded with high wear-resistant epoxy resin. concave. When in use, the one-piece light chain plate is connected with the outer chain plate 3, and the cap 4 is fixed on the chain roller 2 by means of thermal connection, so as to limit the movement space of the outer chain plate. When the whole chain is connected and installed on the sprocket, the friction area between the chain roller 2 and the sprocket is reduced, and the chain is buffered when running, which effectively protects the chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com