Patents

Literature

44results about How to "Light weight high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

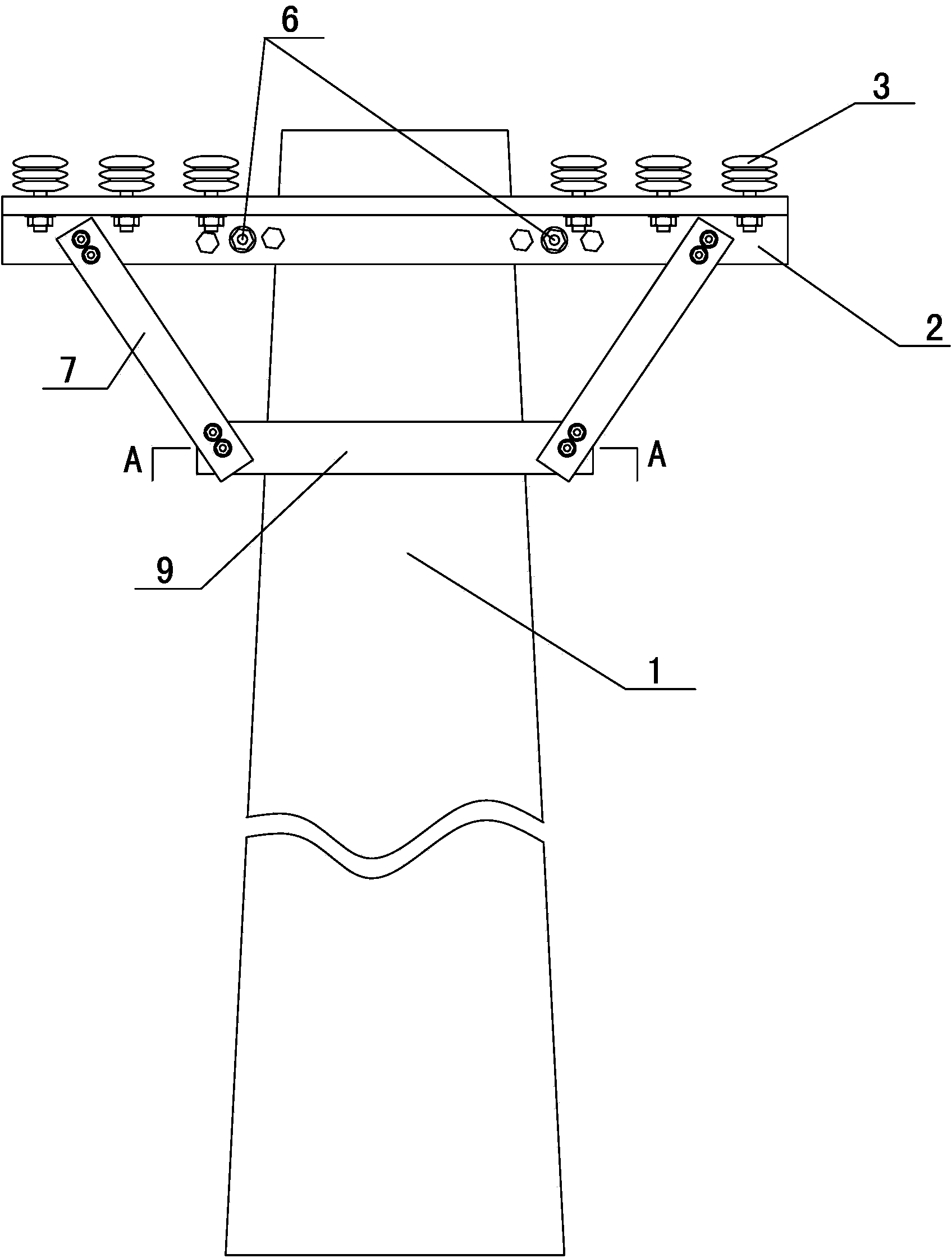

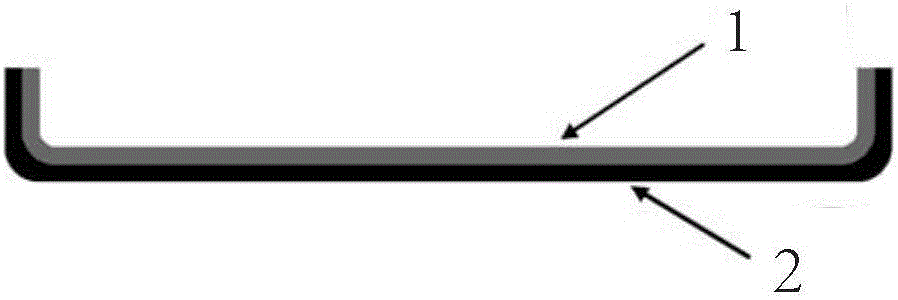

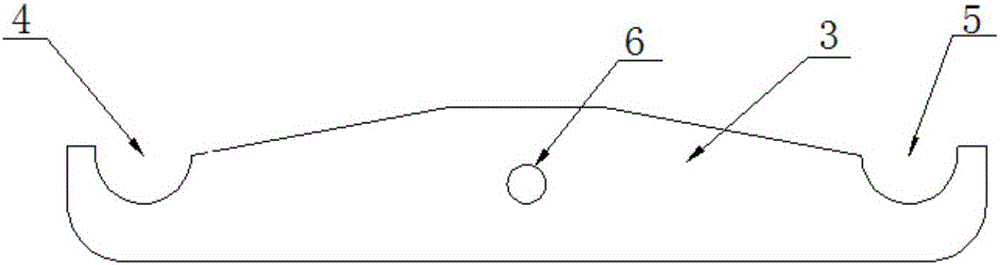

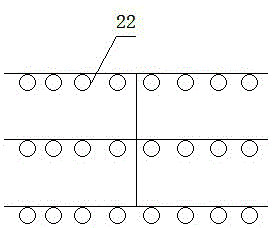

High-voltage line support used on telegraph pole

ActiveCN103944125ALight weight high strengthImprove insulation performanceOverhead installationTowersGlass fiberRepair time

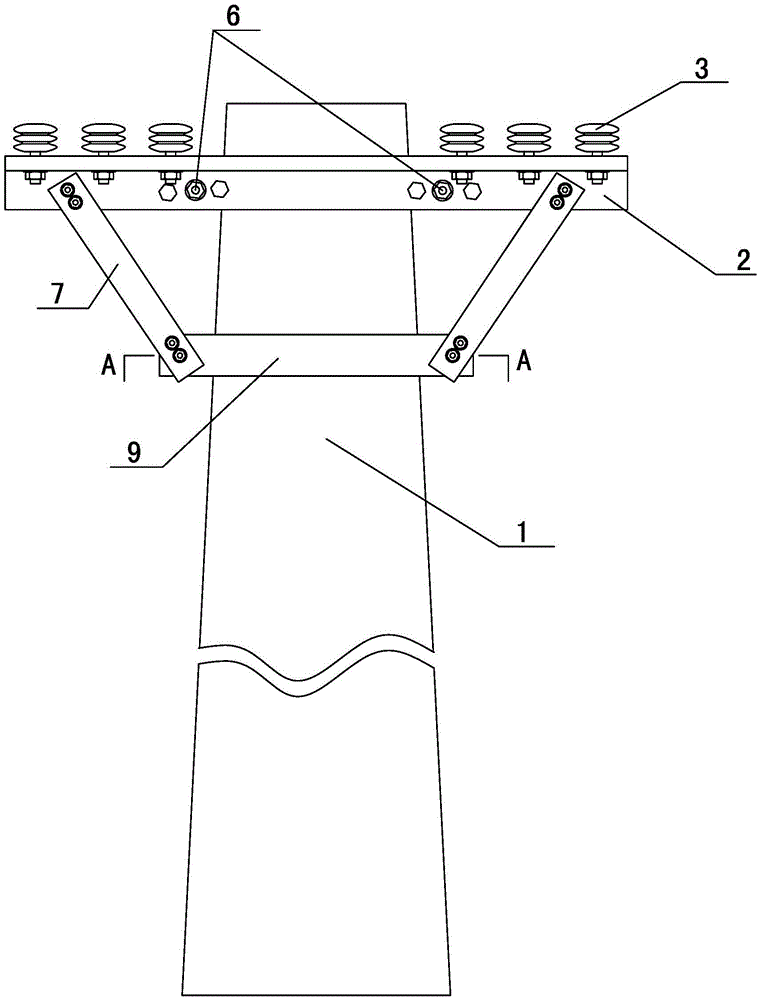

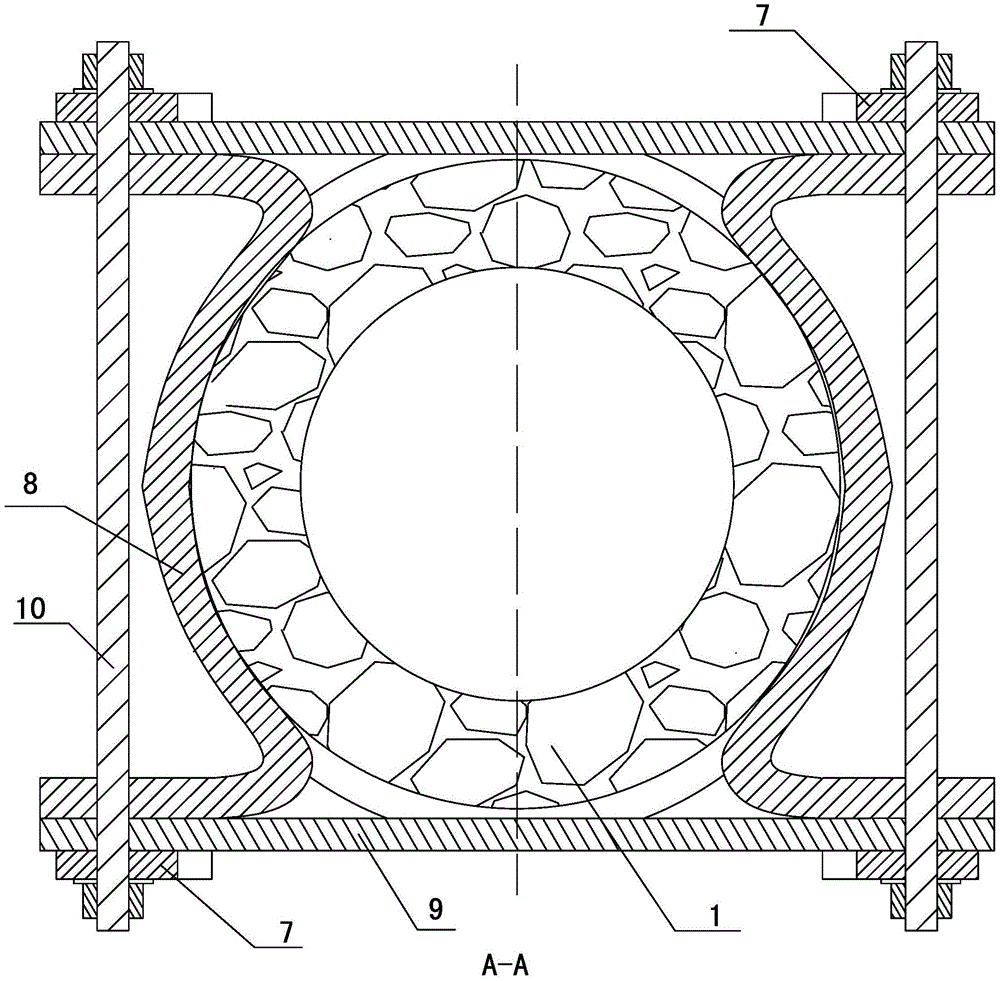

The invention provides a high-voltage line support used on a telegraph pole. The high-voltage line support comprises two parallel cross arms and a plurality of insulators fixed to horizontal plates of the cross arms. Perpendicular plates of the cross arms are fixedly connected with the telegraph pole through first hoops. The high-voltage line support further comprises second hoops fixedly connected with the telegraph pole, the second hoops are arranged below the first hoops, and inclined supporting rods are connected between the ends of the second hoops and the ends of the perpendicular plates of the cross arms. The cross arms are made of glass fiber reinforced plastics, and the insulators are formed by winding glass fibers steeped with vinyl ester resin. The high-voltage line support has the advantages that firstly, the cross arms made of the glass fiber reinforced plastics are adopted, so that the high-voltage line support is low in weight, high in strength, resistant to corrosion, good in insulation performance and long in service life, and the glass fiber insulators made based on the winding technology are not prone to breakage; secondly, the second hoops connected with the two ends of the cross arms through the inclined supporting rods are additionally arranged below the first hoops, the supporting strength is increased, potential safety hazards are reduced, after the first hoops are corroded and damaged, a supporting guarantee still exists, and certain first-aid repair time can be provided.

Owner:NINGHAI COUNTY POWER EQUIP BUILD OR REPAIR FACTORY +1

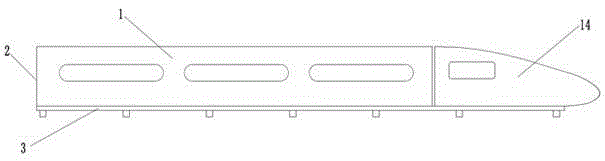

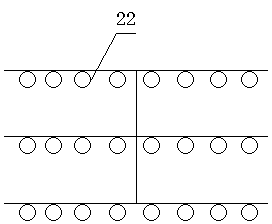

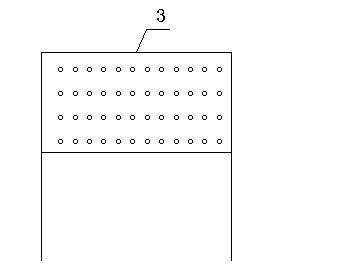

Rail vehicle body and preparation method thereof

ActiveCN105383506AImprove performanceHigh overall performance, good stiffnessRailway transportAxle-box lubricationEngineeringPre treatment

The invention discloses a rail vehicle body which is low in weight and renewable in resource, preserves heat and lowers noise. The rail vehicle body comprises a roof, end walls, a side wall and a bottom frame. The bottom frame comprises a bottom plate and a bearing structure. A vehicle main body is defined by the side wall, the roof and the bottom plate. The side wall and the roof are in fillet transition, the side wall and the bottom plate are in fillet transition, the vehicle main body is integrally formed by winding bamboo skin and resin, the end walls are fixed to the ends of the vehicle main body, and the vehicle main body is fixed to the bearing structure. The invention further discloses a preparation method of the rail vehicle body. The preparation method includes the steps of resin modification, wherein modifier and flame retardant are added to the resin; bamboo skin pretreatment, wherein the bamboo skin is subjected to water removal and antiseptic treatment, and then the bamboo skin is connected into a continuous bamboo skin belt; manufacturing of a mandrel; vehicle main body winding, wherein the bamboo skin belt winds around a mandrel in a transverse, longitudinal and spiral intersecting mode, and the modified resin is poured during winding; manufacturing of the end walls and the bearing structure; fixation of the end walls to the ends of the vehicle main body; fixation of the vehicle main body to the bearing structure.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

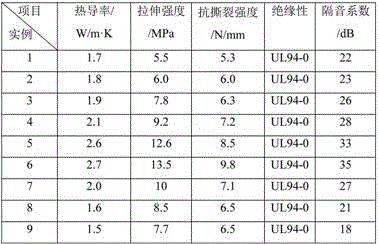

Transformer sound insulation shell material and preparation method thereof

The invention discloses a transformer sound insulation shell material and a preparation method thereof, which belong to the field of materials and solve the problem of poor sound insulation effect of existing materials. The preparation method specifically comprises the following steps of adding bakelite, epoxy resin, glass fibers, chemigum, polyvinyl chloride resin, cenosphere, expanded vermiculite, calcium carbonate, diatomaceous earth, silicone oil and antioxygen into a container, stirring for 15 to 20 minutes at the rotating speed of 1600 to 1900 r / min, uniformly mixing, then adding dichloromethane, continuously stirring for 5 to 10 minutes, adding acetic acid at last, stirring for 5 to 10 minutes at the rotating speed of 2000 to 2200 r / min, pouring raw materials which are uniformly mixed into a mold, solidifying for 60 to 80 minutes at the temperature of 65 to 75 DEG C, cooling and demolding, so as to obtain the transformer sound insulation shell material. The preparation method has the advantages of simplicity, easiness in operation and low production cost and can be widely used for transformer shell and case materials.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

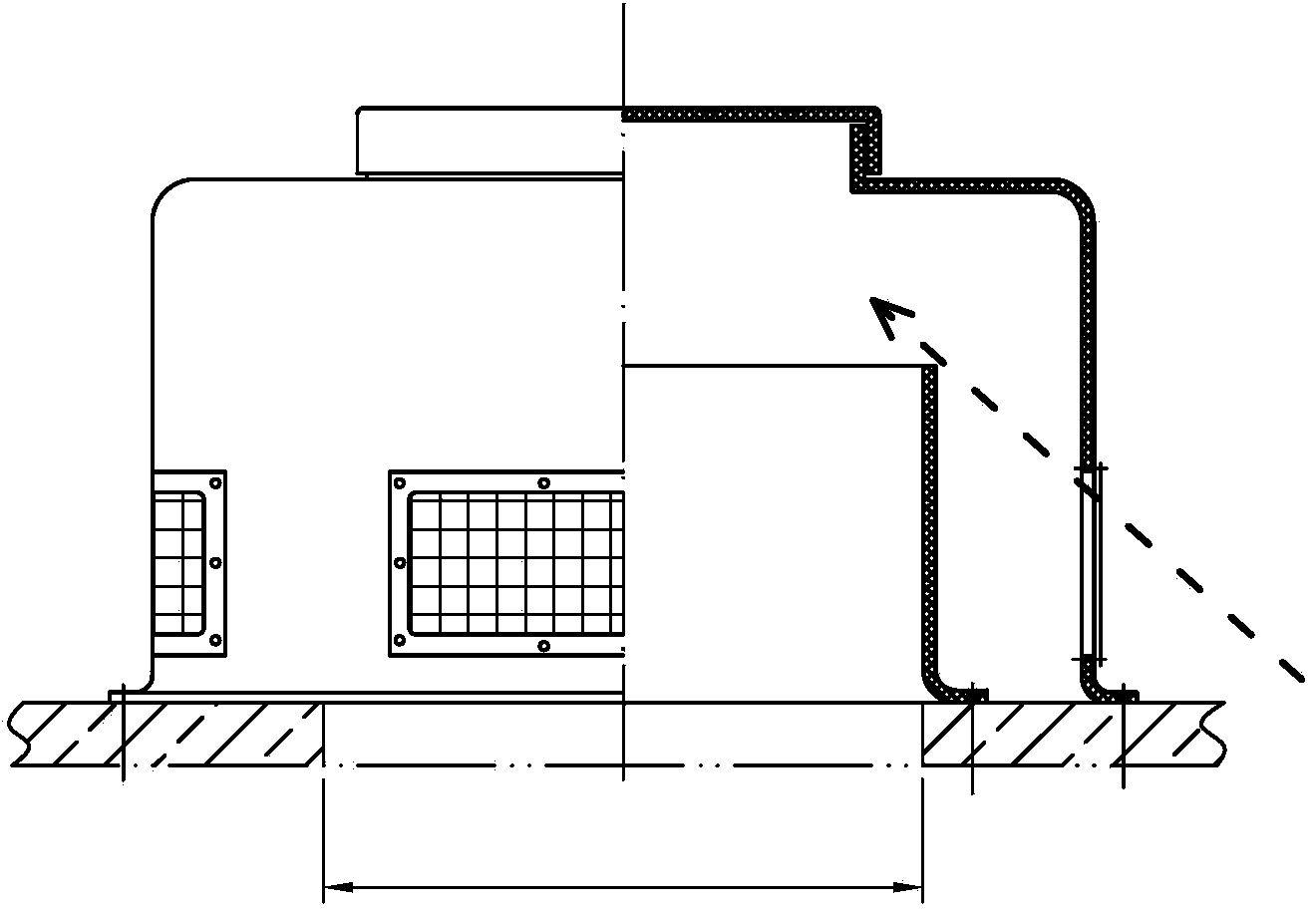

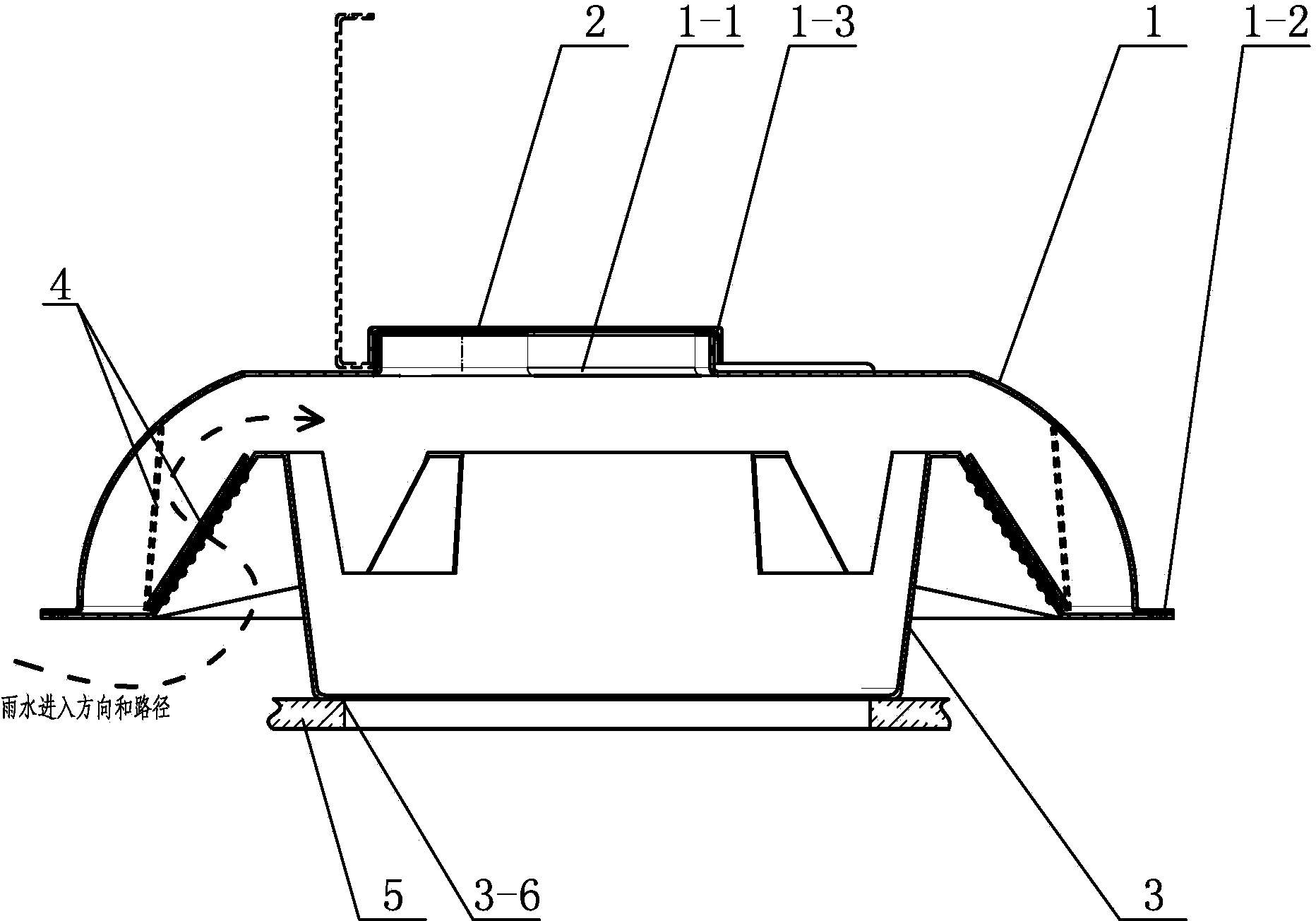

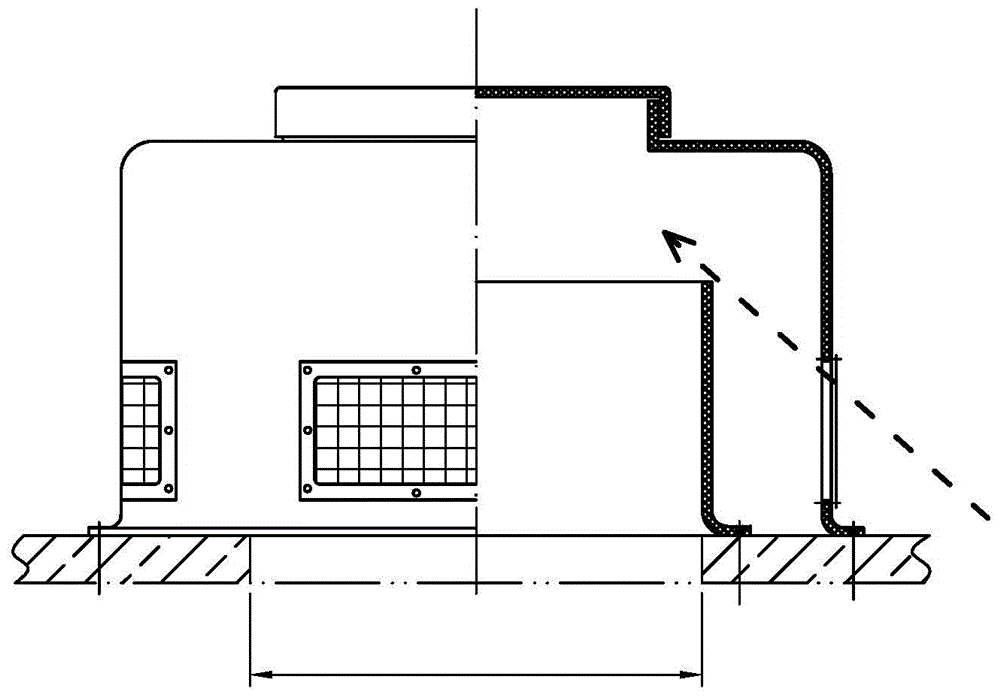

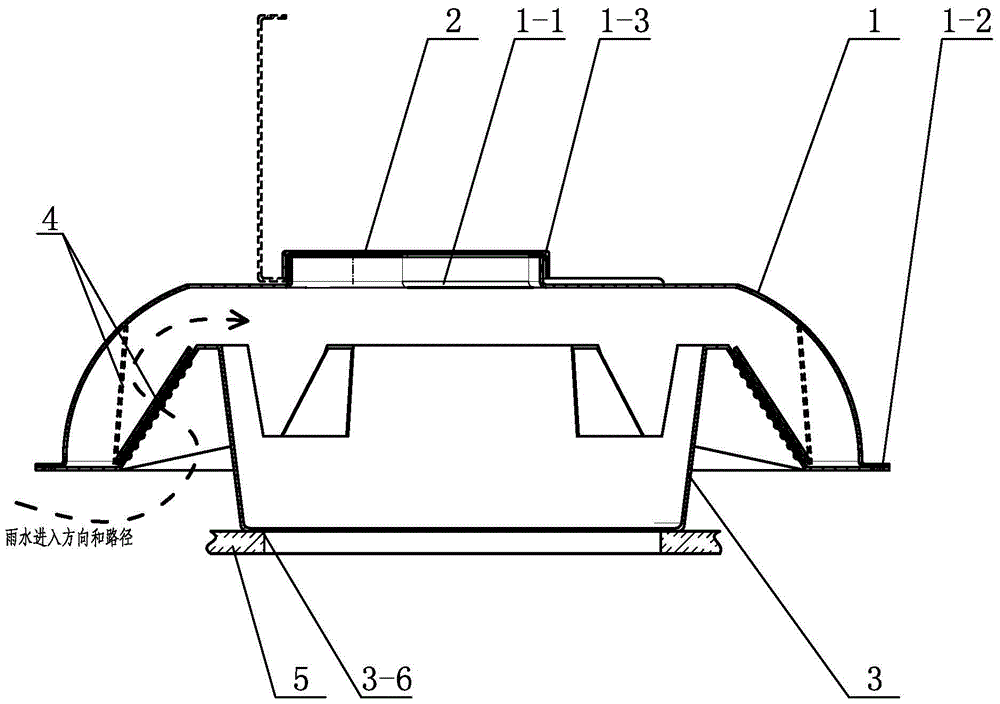

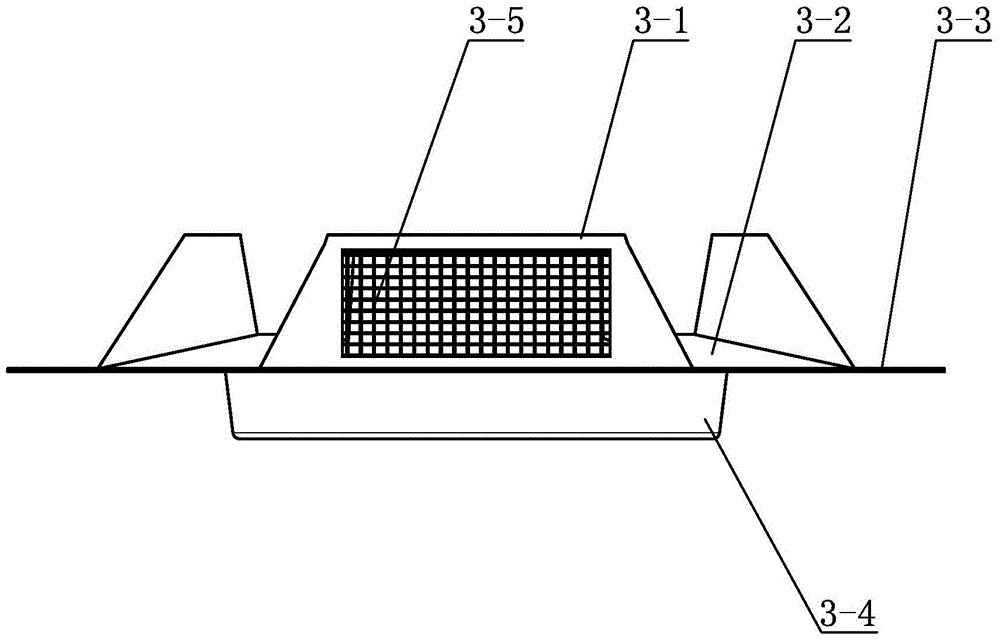

Ventilation device on top of radome

ActiveCN104241846ALight weight high strengthImprove permeabilityRadiating element housingsHollow cylinderMushroom

The invention relates to a ventilation device, in particular to a ventilation device on the top of a radome. The ventilation device on the top of the radome is used for solving the problems that an existing radome ventilation device is low in manufacturing efficiency, low in finished product quality, poor in universality of assembly with various radomes, difficult in later maintenance and poor in natural ventilation effect, rain leakage often happens, and the use performance of a radar antenna is influenced. The ventilation device on the top of the radome comprises a mushroom-shaped upper radome body, a base and turnover plates, wherein the mushroom-shaped upper radome body is buckled to the base, ventilating windows are arranged on the outer side walls of hollowed-out step platforms at the bottom of the base, and the turnover plates are installed on the ventilating windows. A connecting flange extending outwards is arranged on the edge of the mushroom-shaped upper radome body, the mushroom-shaped upper radome body is connected with the annular outer edge through the connecting flange, and a through hole is formed in the bottom surface of a hollow cylinder and provided with a connecting flange extending inwards. The ventilation device on the top of the radome is applicable to the field of wireless communication.

Owner:HARBIN TOPFRP COMPOSITE

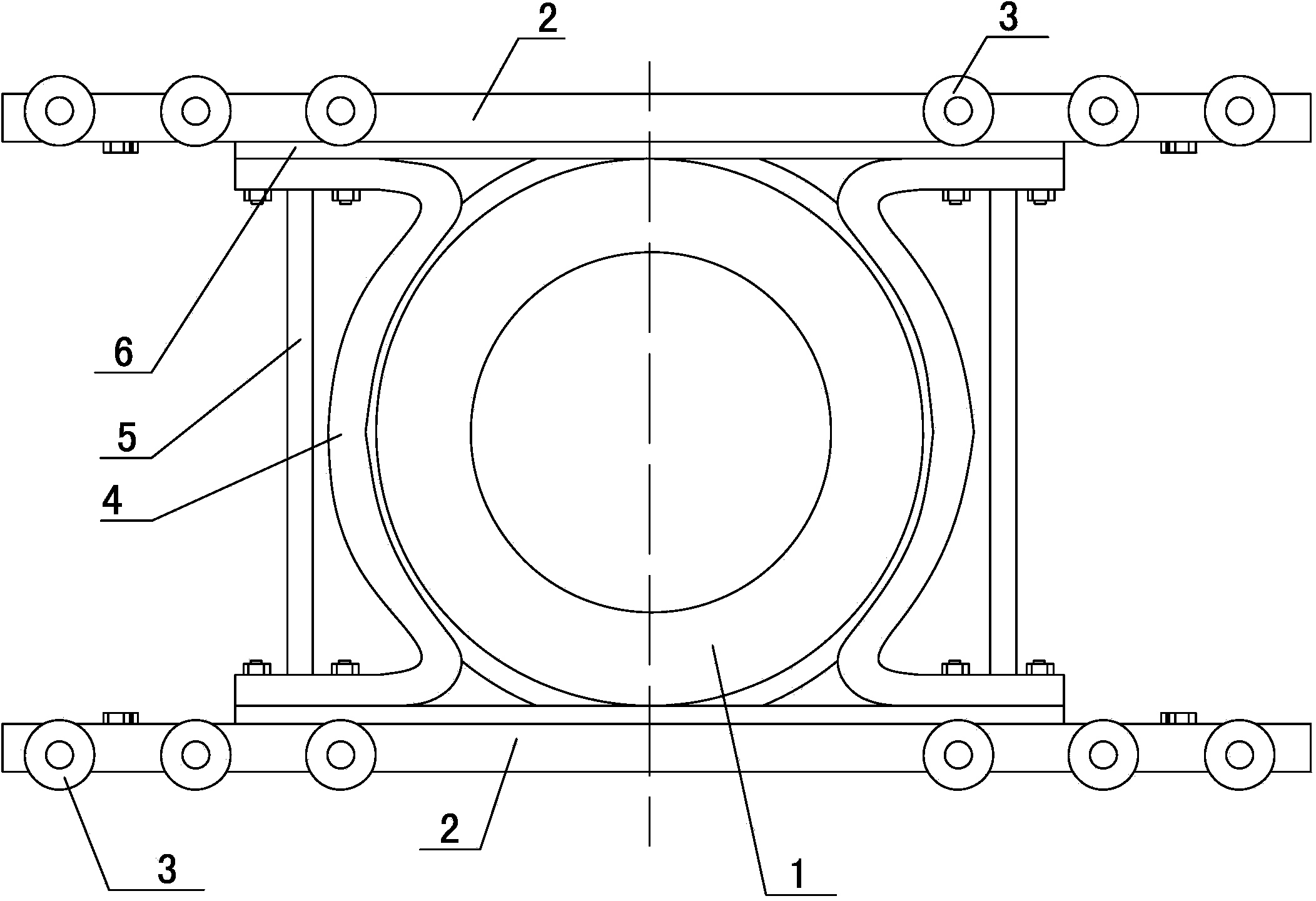

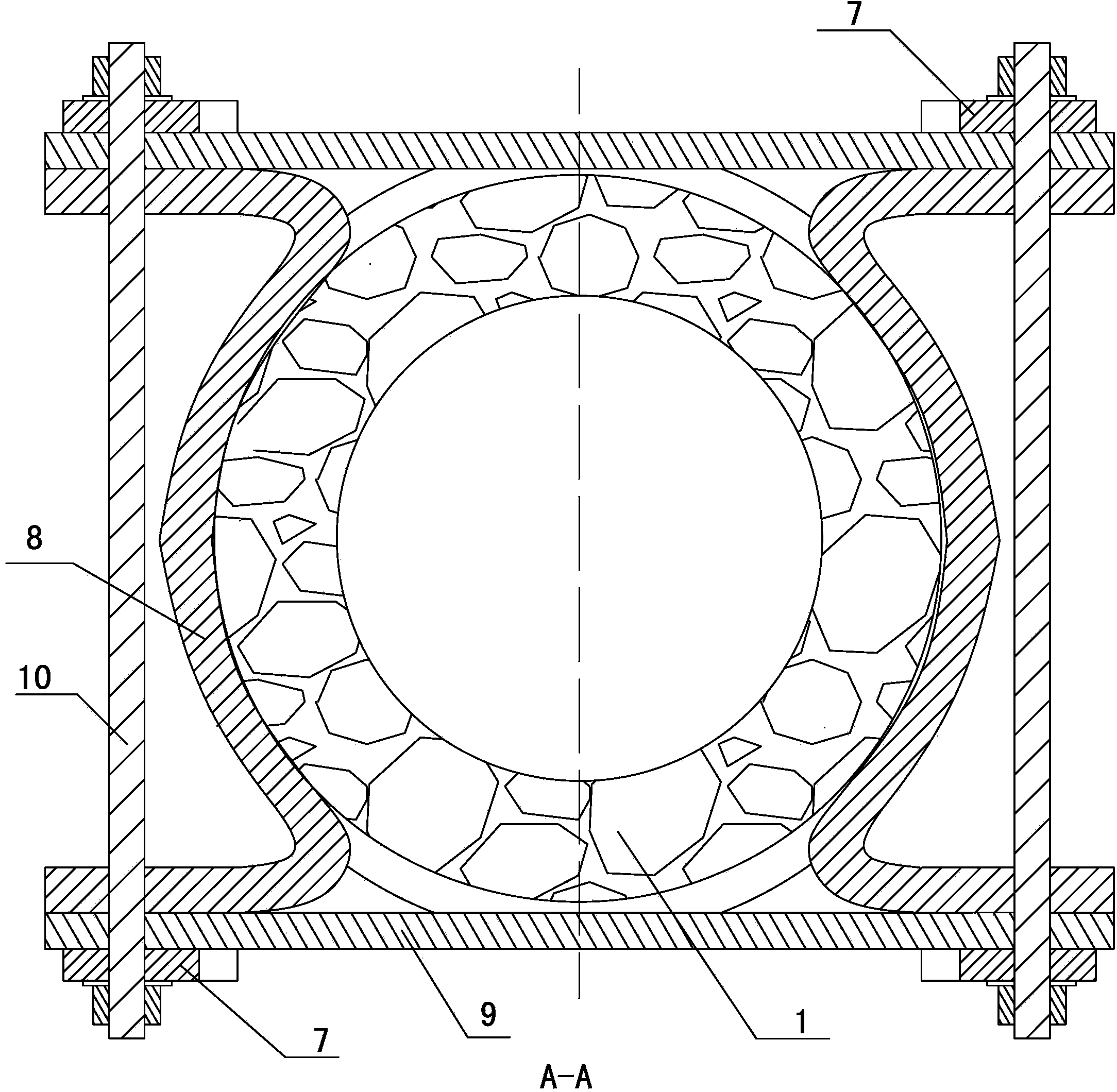

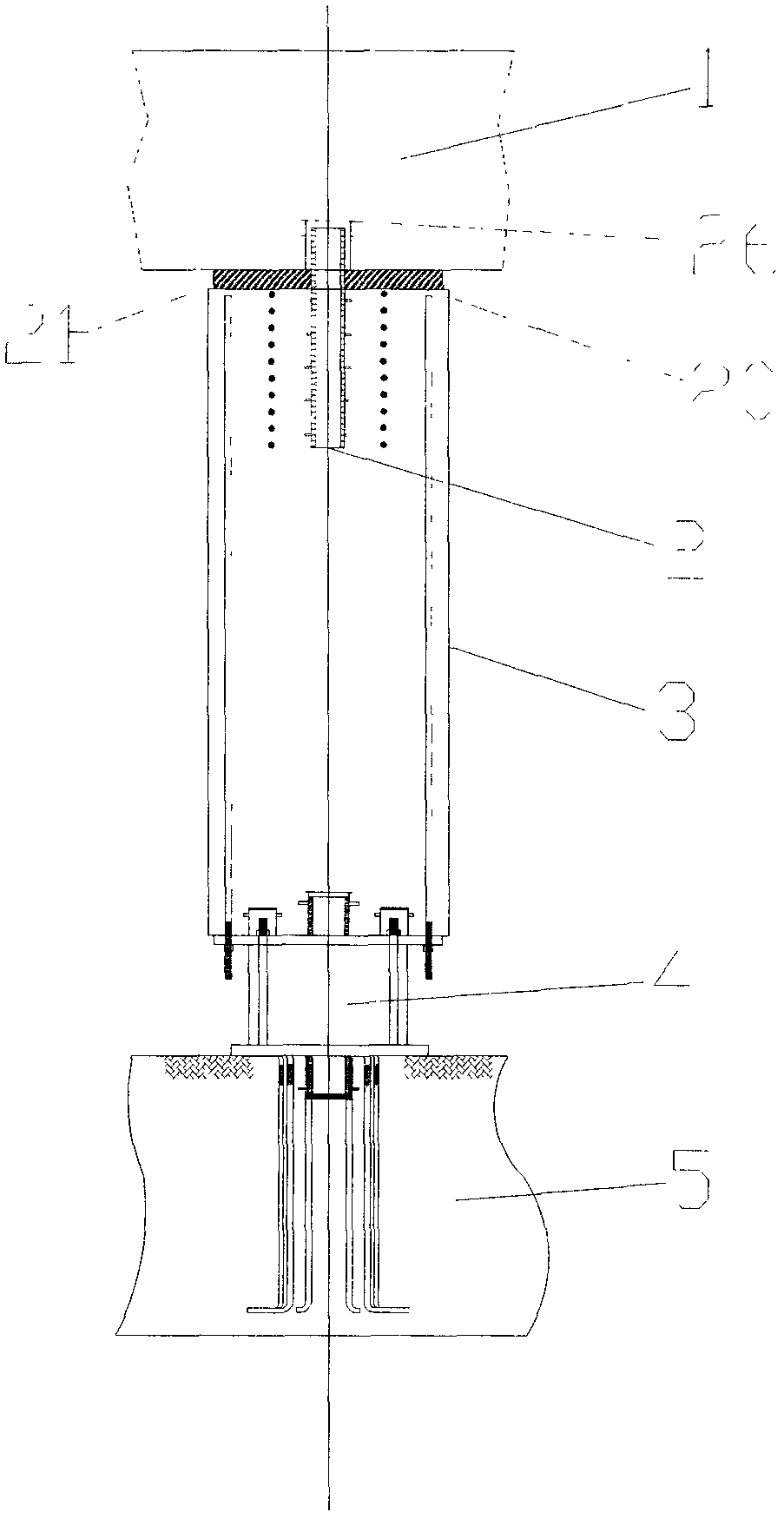

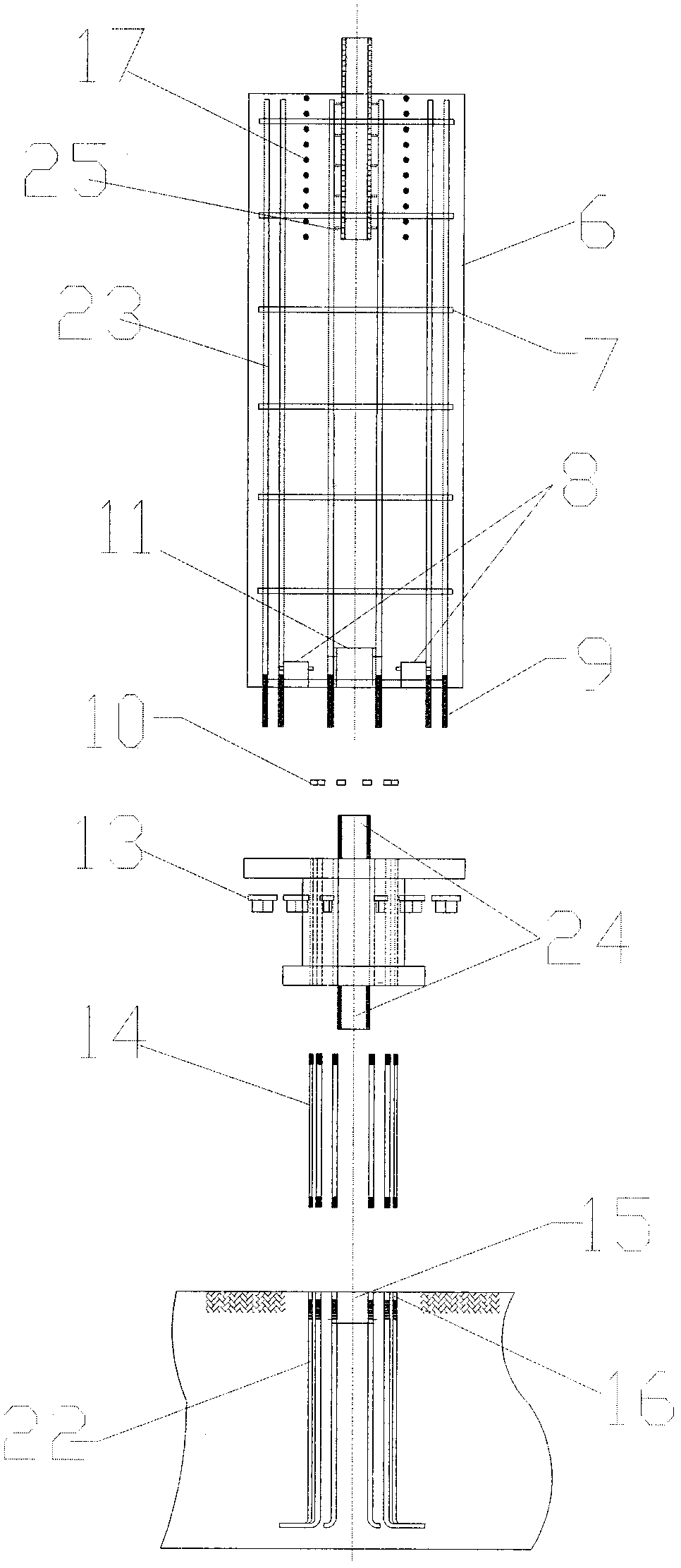

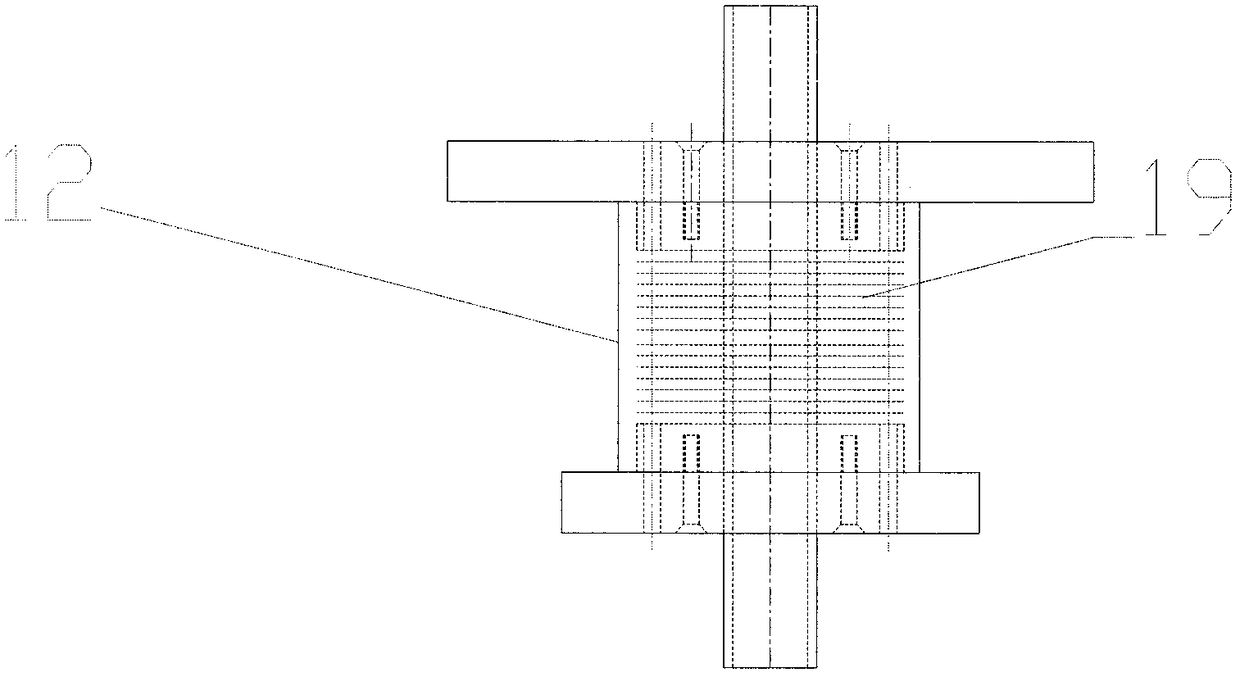

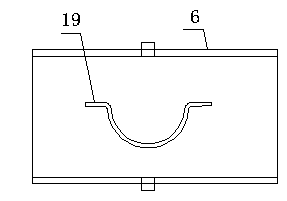

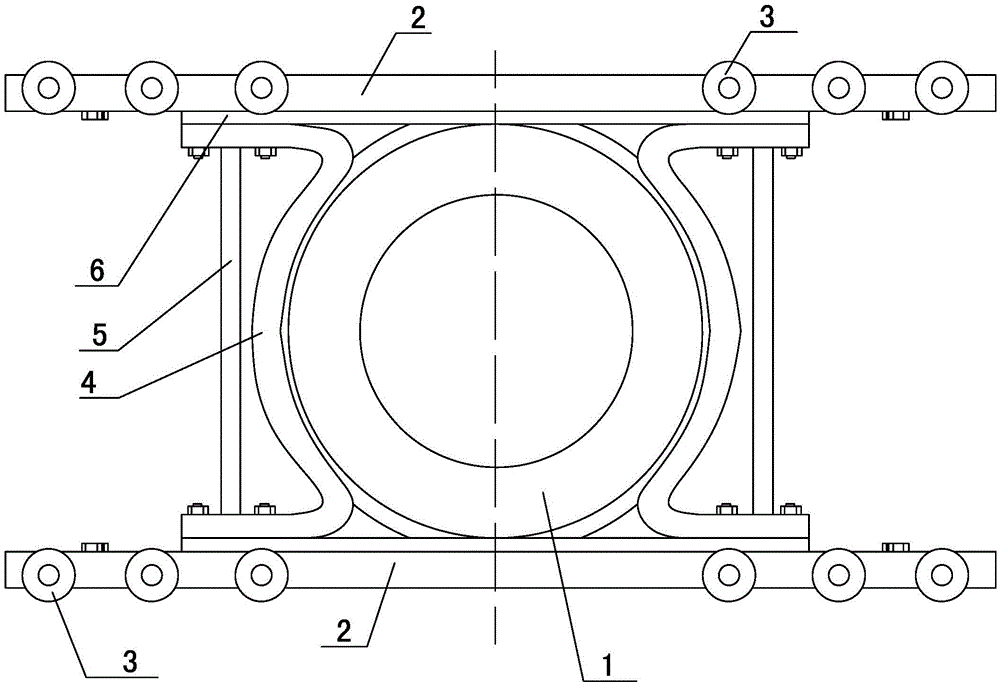

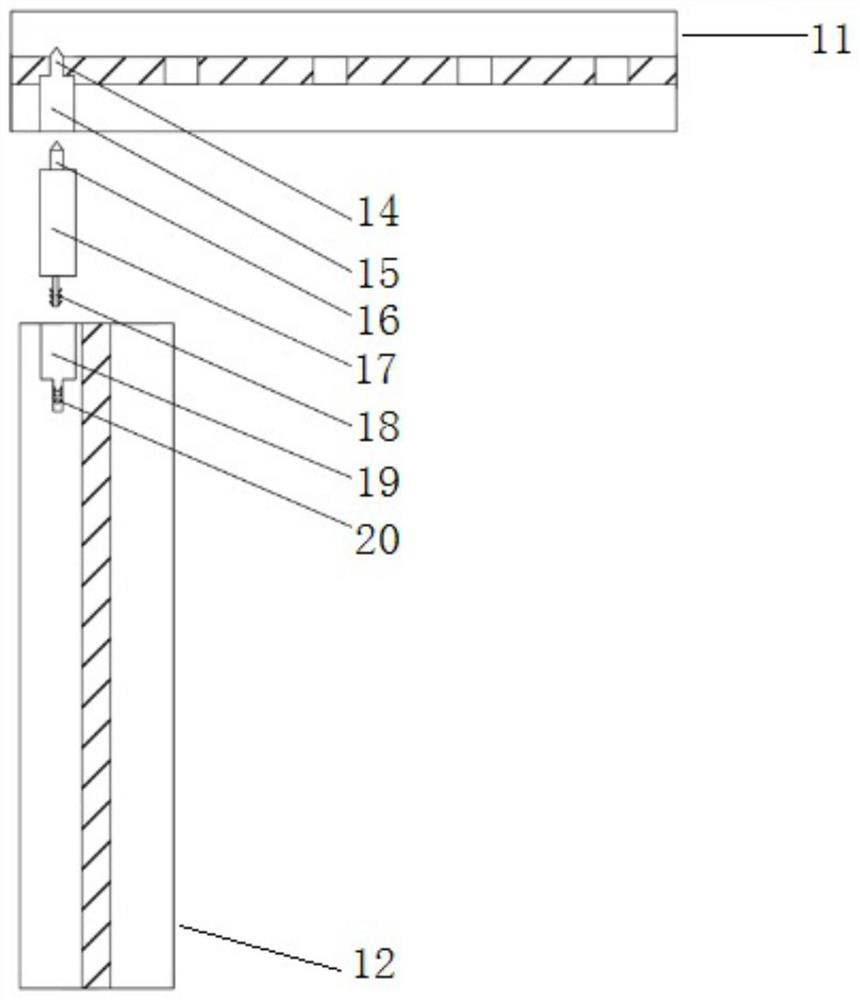

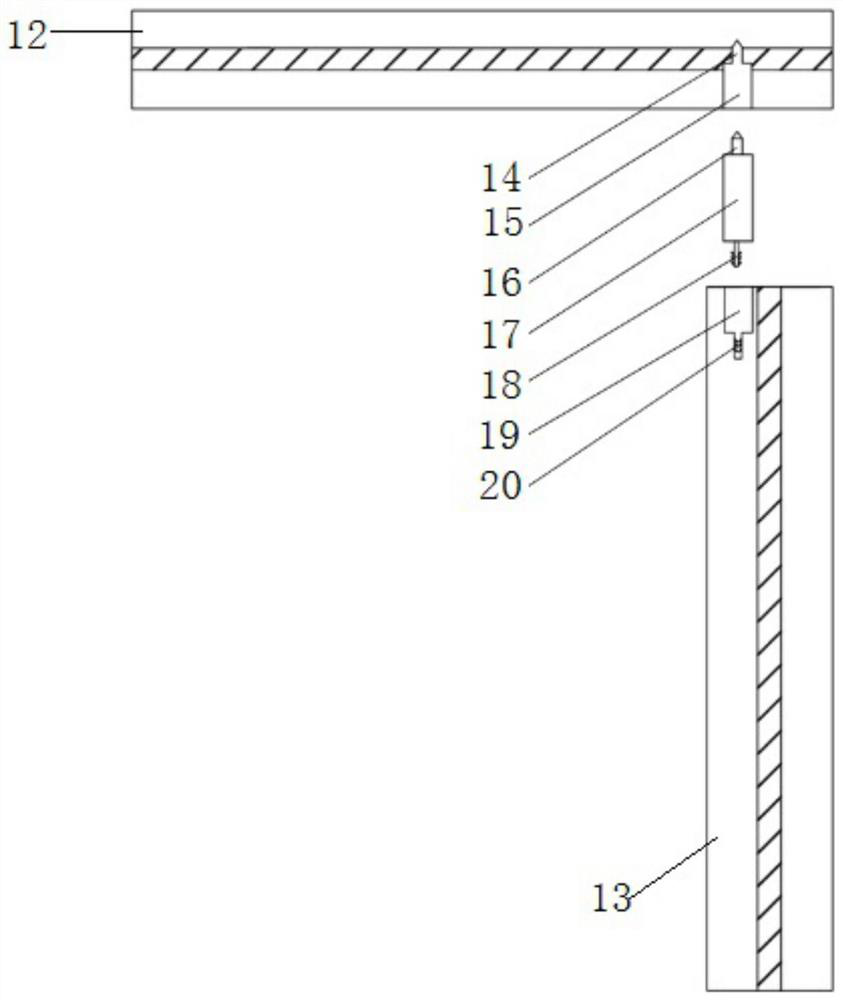

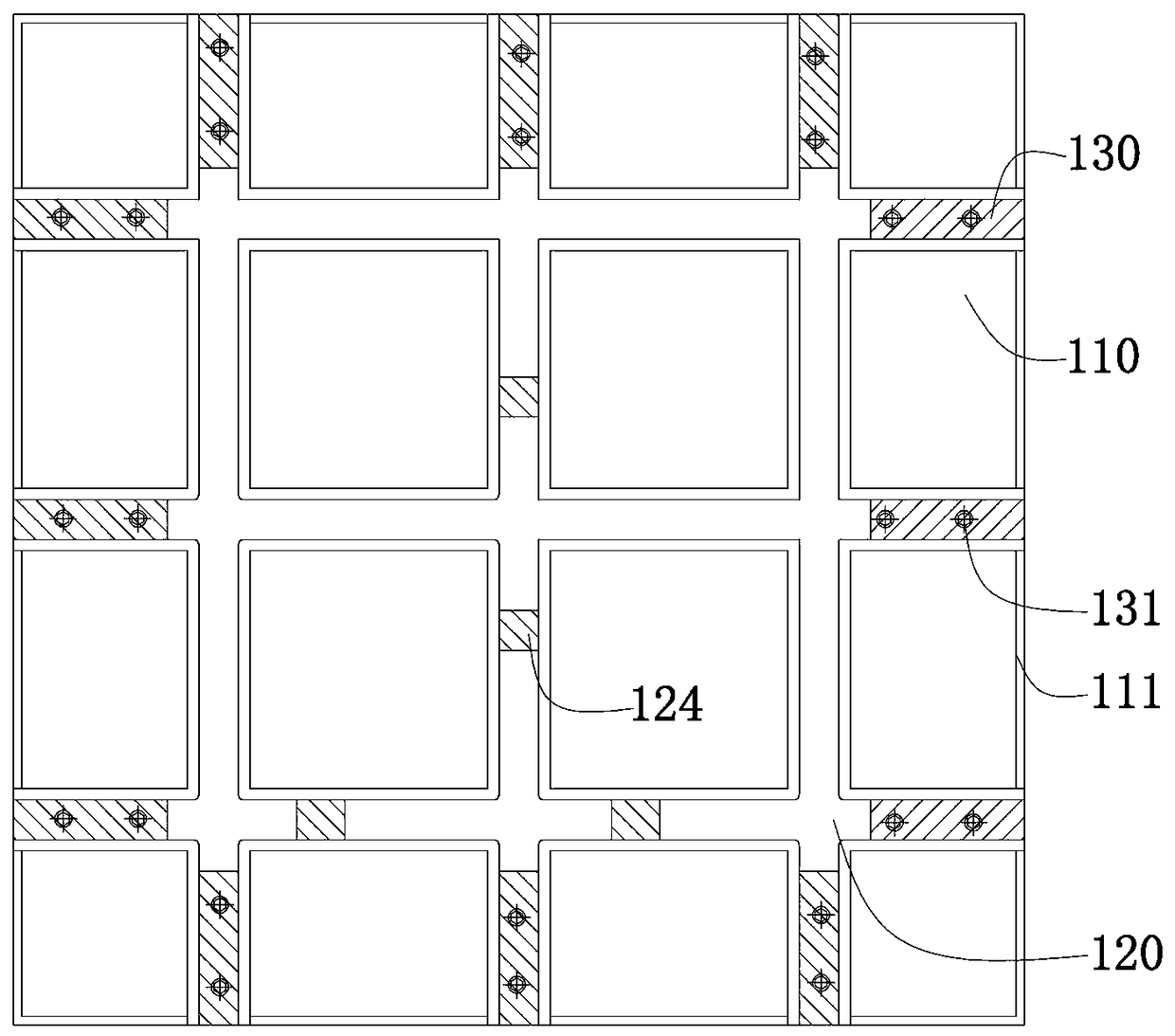

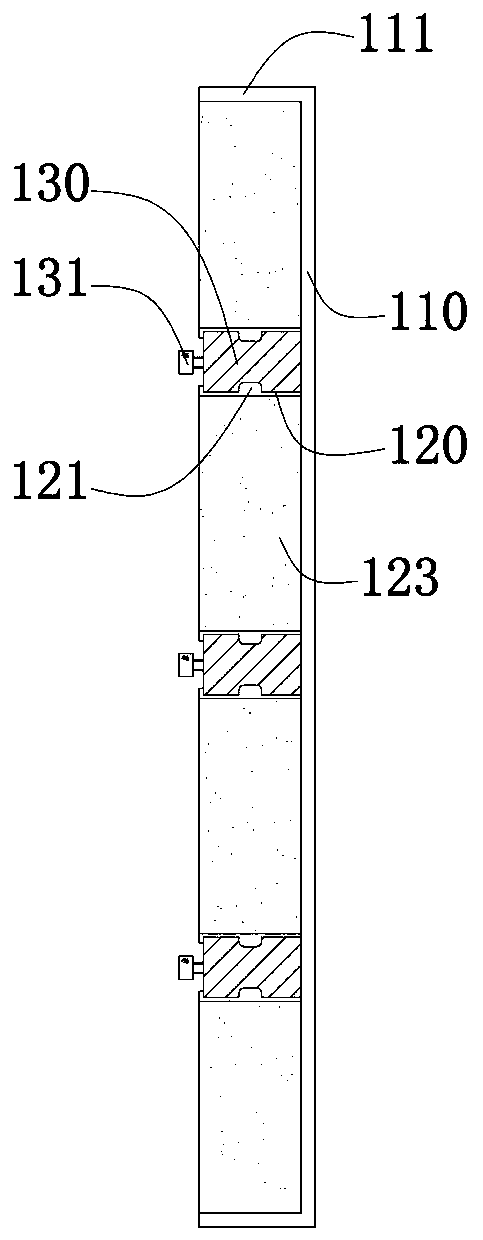

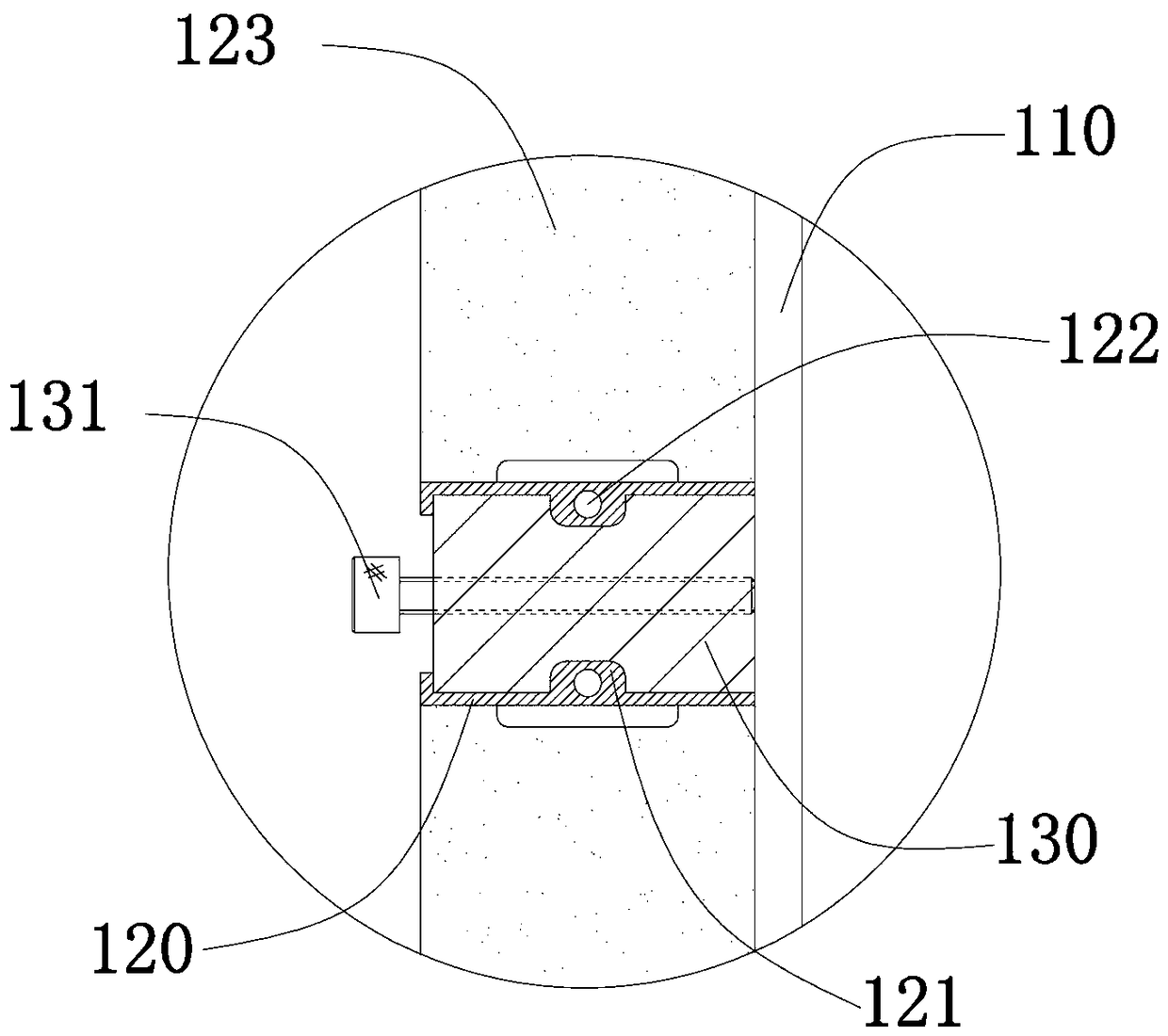

A novel prefabricated detachable and repairable aseismic bridge column structure system and implementation method thereof

InactiveCN109024247AImprove seismic performanceShorten the construction periodBridge structural detailsGreen environmentPlastic hinge

The invention discloses a novel prefabricated detachable and repairable aseismic bridge column structure system and an implementation method, and belongs to the technical field of bridge structure design. The structural system is mainly composed of cover beams, ultra high performance concrete (UHPC) steel pipes, bridge pillars, SMA plastic hinge device sand bearing caps; the bridge column and thebearing cap are connected by the SMA plastic hinge device, The SMA plastic hinge device is composed of an ECC outer layer, a spiral steel ring, an embedded steel pipe and an SMA pipe. The SMA pipe ispierced through a bolt hole reserved in an upper plate and an lower plate of the SMA plastic hinge, and is connected with a bridge column and a bearing cap, which can provide good energy dissipation performance, so that the structural system has good seismic resistance. The invention discloses a novel prefabricated detachable repairable aseismic bridge column structure system can be realized by adopting the prefabricated assembly method, the assembly is simple, the construction period is short, each component can be disassembled, the specific part can be replaced or repaired in the process ofrepairing the bridge, the maintenance cost of the bridge can be greatly reduced, and the generation of construction waste can be greatly reduced, and the green environment protection can be achieved.

Owner:GUANGDONG UNIV OF TECH

Material of noise-reducing and radiating shell of transformer

The invention belongs to the technical field of high polymer material, specifically relates to a material of a noise-reducing and radiating shell of a transformer. The shell material comprises the following raw materials by weight parts: 30-40 parts of polyurethane resin, 15-26 parts of methyl vinyl silicone rubber, 20-35 parts of carbon fiber, 10-20 parts of aluminium oxide,7-12 parts of kieselguhr, 2-8 parts of silicone oil, 0.5-1.5 parts of antioxidant,2-5 parts of 2,5-dimethyl-2,5-dual (tert butyl peroxy)hexane. The noise-reducing and radiating shell material of the transformer provided in the invention has lightweight, high hardness, shock resistance, wearing resistance, ageing resistance and good effects of sound absorption and radiating.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

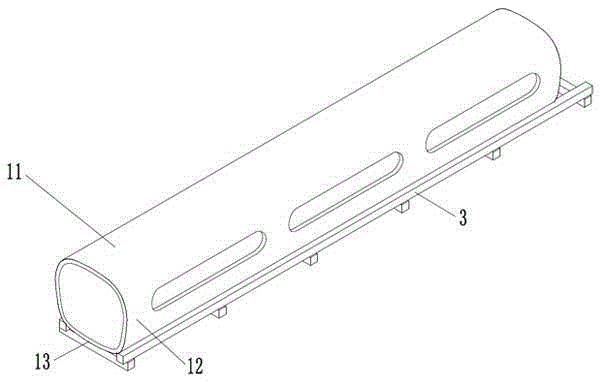

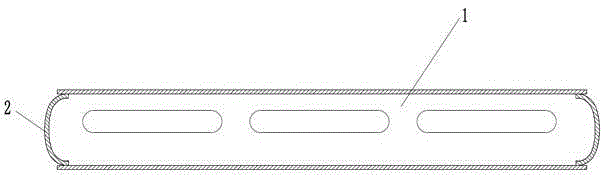

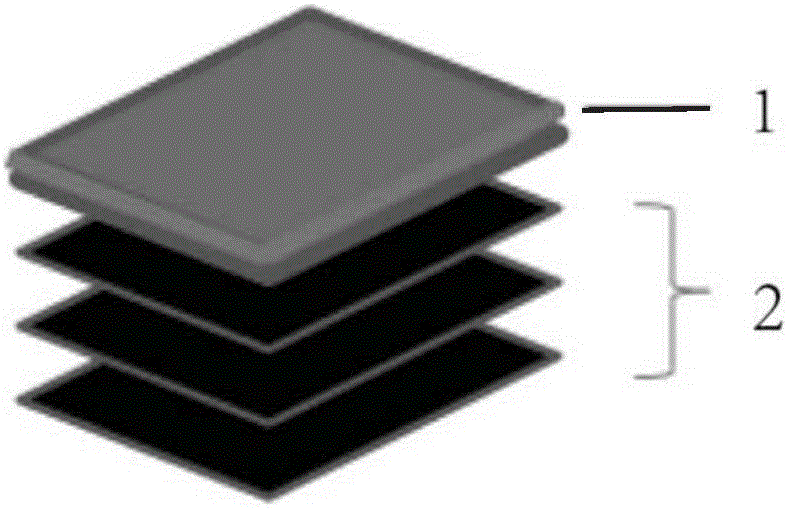

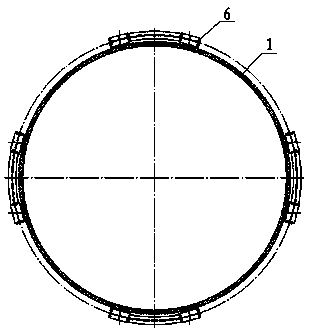

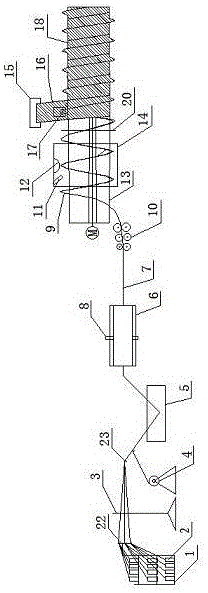

Device and method for processing polyethylene glass fiber reinforced plastic composite molded spiral corrugated tube

InactiveCN103085289ALight weight high strengthCorrosion resistanceCorrugation articlesTubular articlesWinding machineGlass fiber

The invention relates to a device and method for processing a spiral corrugated tube, and in particular relates to a device and method for processing a polyethylene glass fiber reinforced plastic composite molded spiral corrugated tube. The device comprises a drawing and squeezing mold, a roll bending device, a winding machine, a heating adhesive-spraying device and a polyethylene plastic extrusion mold which are arranged in sequence, wherein the drawing and squeezing mold is used for processing glass fibers into glass fiber reinforced plastic strips; the roll bending device is used for bending the glass fiber reinforced plastic strips into glass fiber reinforced plastic spiral rings; the winding machine is used for propelling the glass fiber reinforced plastic spiral rings; the heating adhesive-spraying device is used for spraying an adhesive to the glass fiber reinforced plastic spiral rings; and the polyethylene plastic extrusion mold is used for extruding polyethylene towards inner and outer walls, to which the adhesive is attached, of the glass fiber reinforced plastic spiral rings to ensure that the polyethylene glass fiber reinforced plastic composite molded spiral corrugated tube is formed. By adopting the device and the method, the advantages of corrosion resistance, easiness in processing and molding and recyclability of polyethylene are integrated with the characteristics of high corrosion resistance, high strength, high elastic modulus and easiness in molding of glass fiber reinforced plastics, so that the composite molded tube has the advantages of easiness in processing, corrosion resistance, high strength, low cost, small possibility of deformation, recyclability and the like.

Owner:ANHUI PROVINCE ZHONGYANG PIPE IND

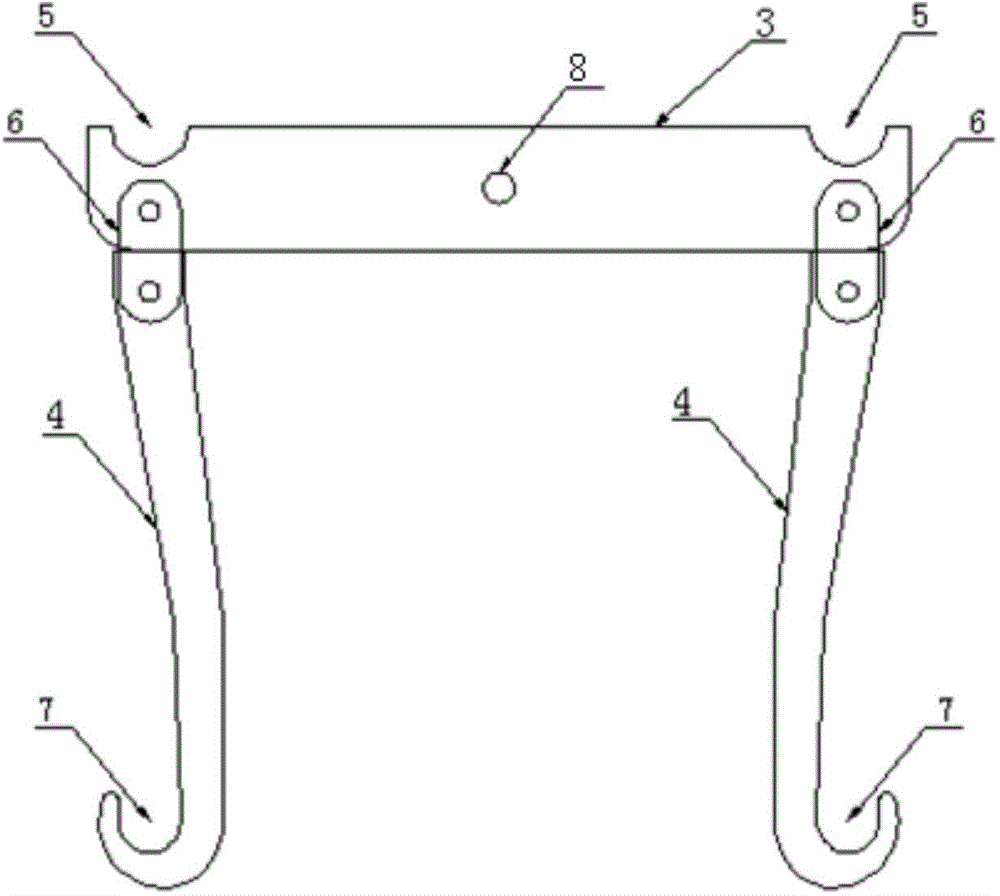

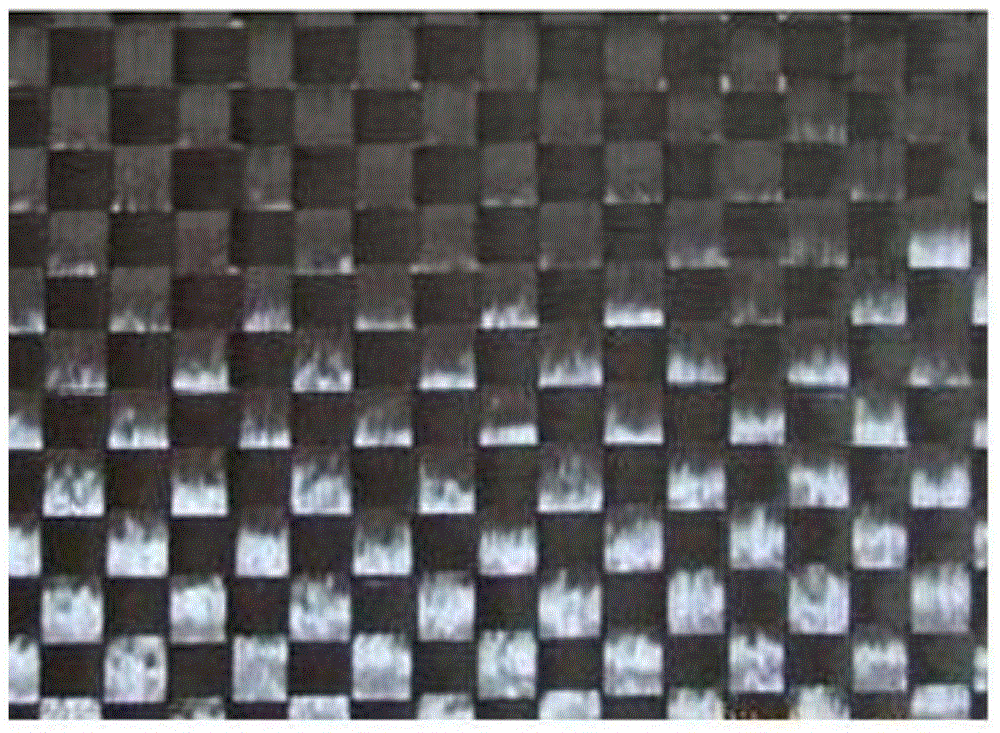

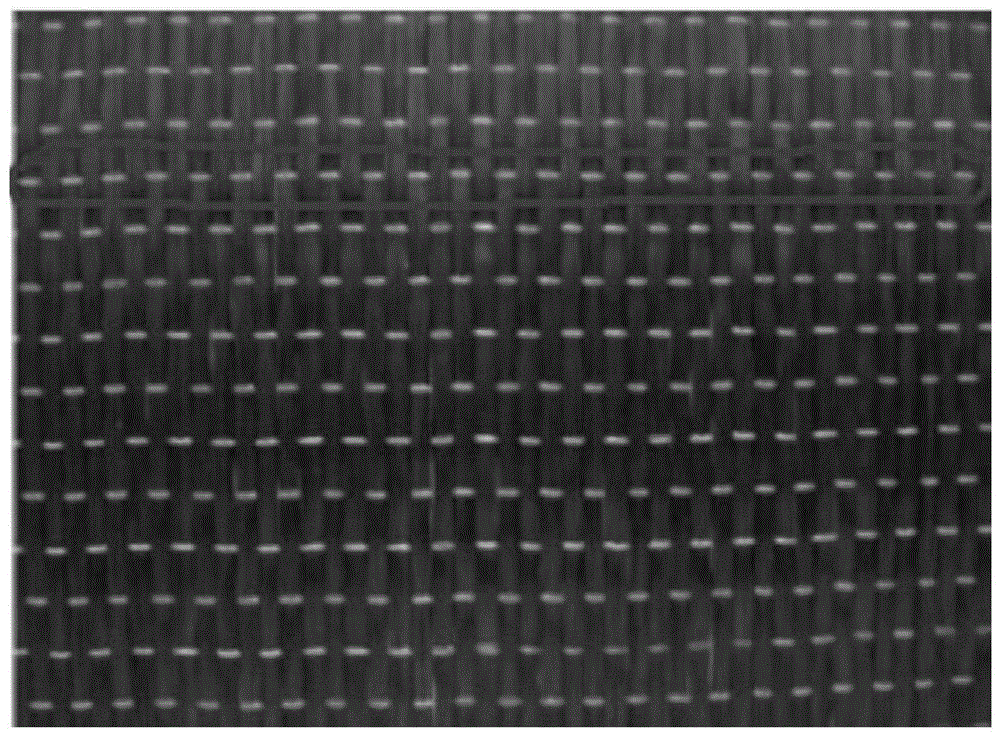

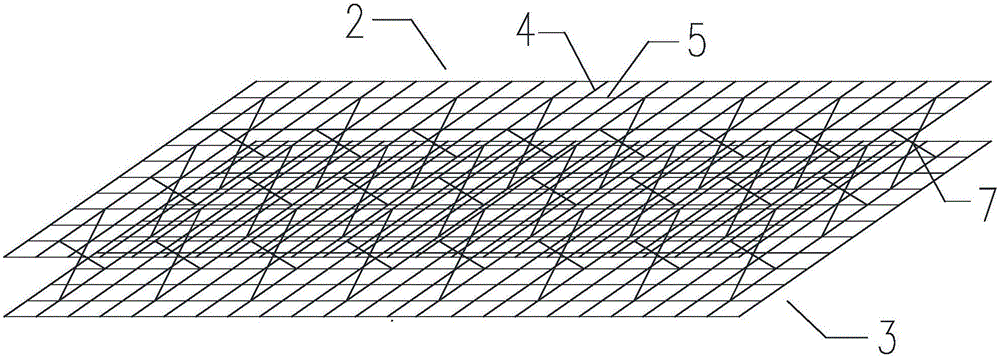

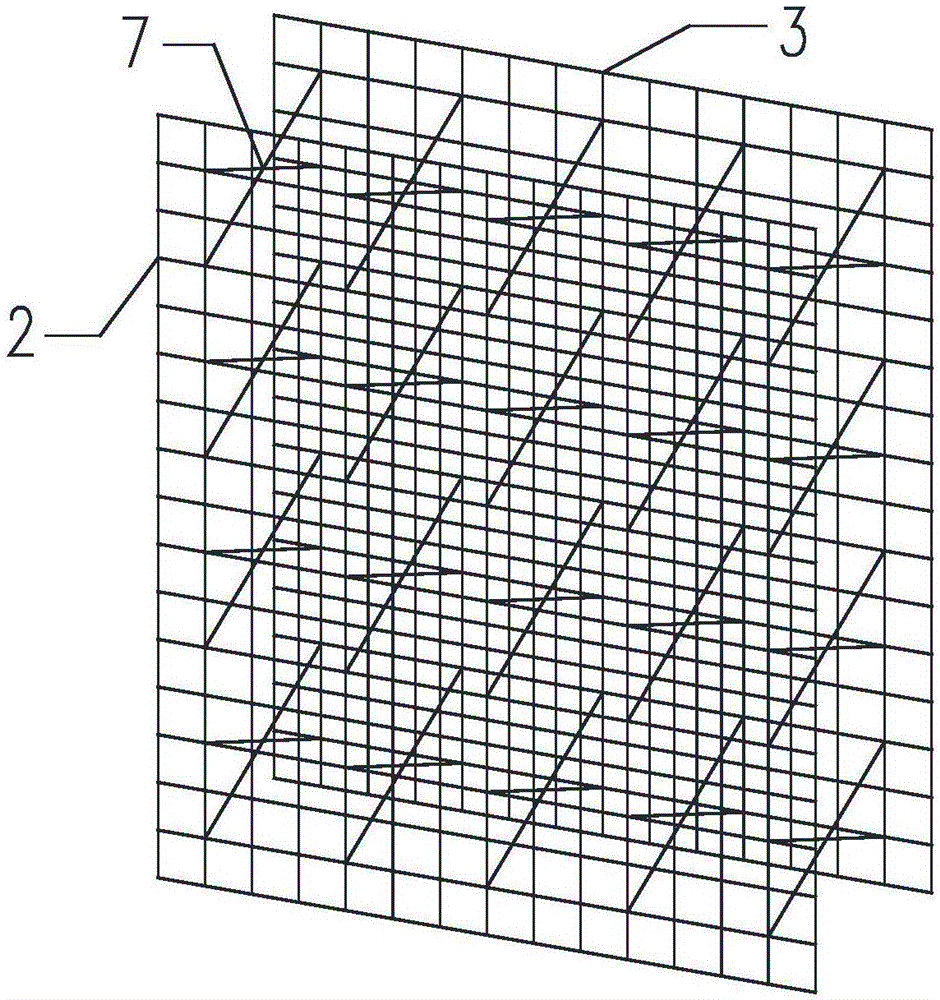

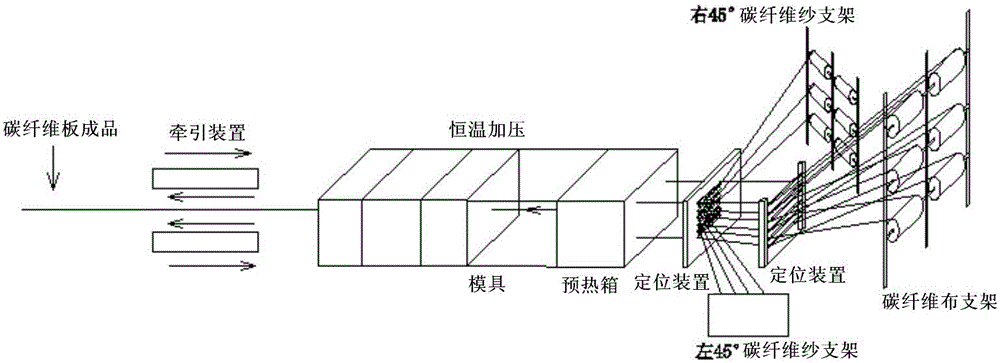

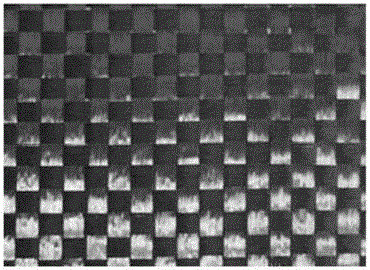

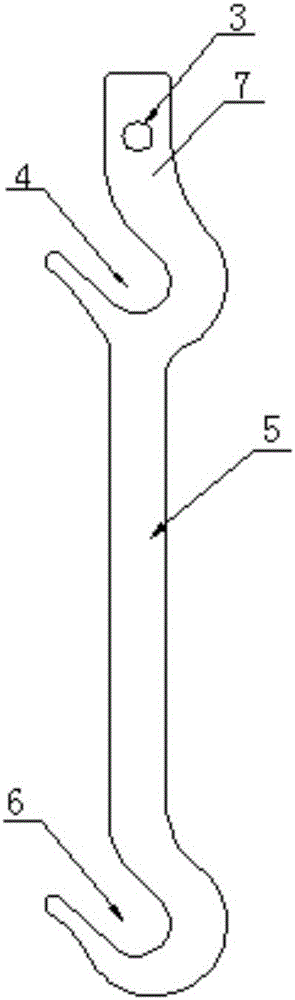

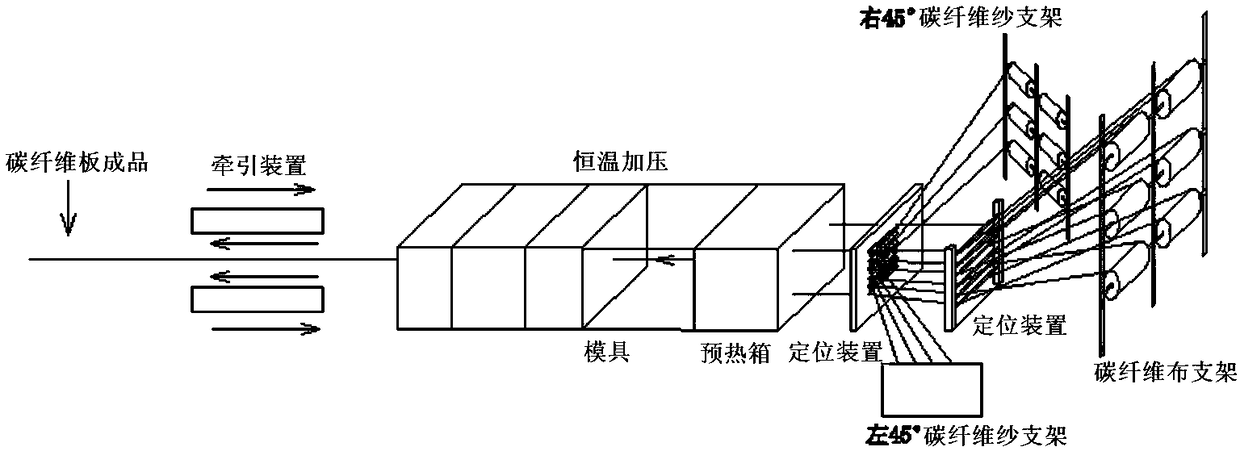

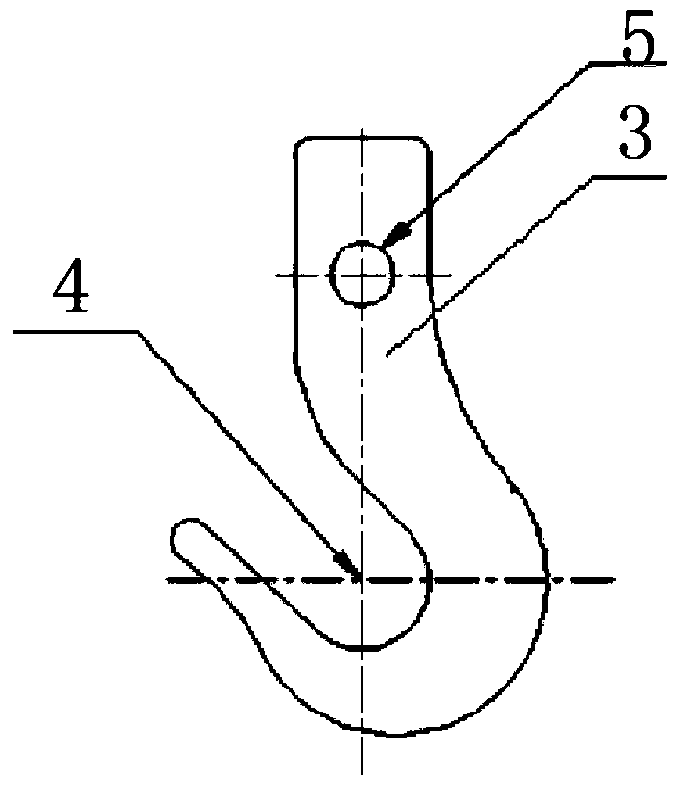

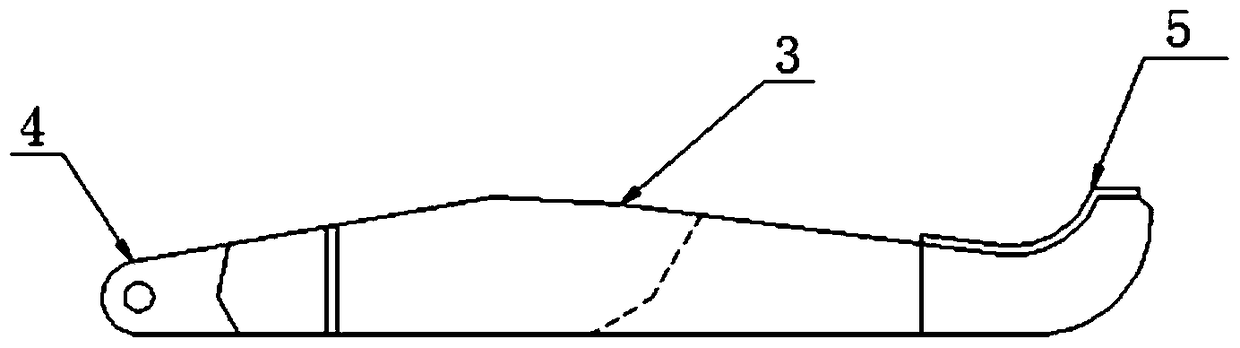

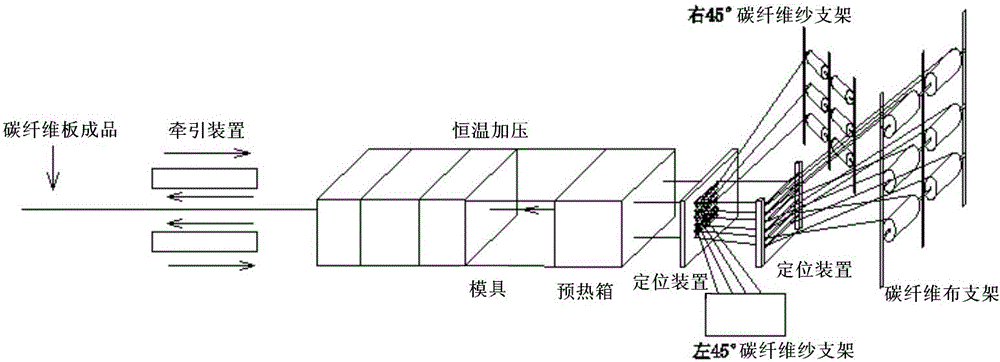

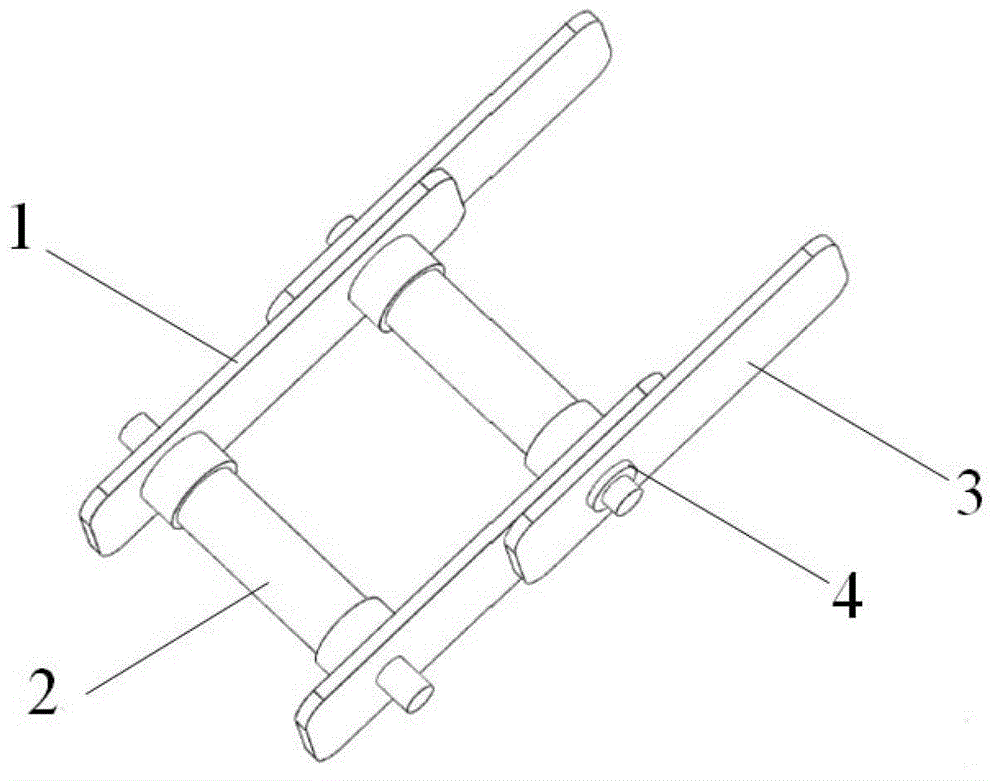

Lifting hook clamp for four-split wires of carbon fiber plates for 500 kV hot-line work

The invention provides a lifting hook clamp for four-split wires of carbon fiber plates for 500 kV hot-line work. The lifting hook clamp comprises a horizontal clamp body, two vertical clamp bodies, a second wire hook and a first wire hook. The horizontal clamp body, the first wire hook, the second wire hook and the vertical clamp bodies are made of carbon fiber plates. Each carbon fiber plate comprises at least two carbon fiber cloth layers and at least one carbon fiber yarn layer, and each carbon fiber yarn layer is located between the every two corresponding carbon fiber cloth layers. Each carbon fiber cloth layer is formed by interweaving longitudinal carbon fiber and transverse carbon fiber in a one-up and one-down mode, and the fiber width of the longitudinal carbon fiber is equal to that of the transverse carbon fiber. Each carbon fiber yarn layer is formed by interweaving carbon fiber in a one-up and one-down two-way mode. The carbon fiber cloth layers and the carbon fiber yarn layers are dipped with adhesive agents. The clamp is high in durability, will not rust, can be used in a high-acid, high-alkali and high-salt environment with atmospheric corrosion and further has the advantages of being high in fatigue resistance, resistant to wear and ageing and the like.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD +1

High voltage wire support for utility poles

ActiveCN103944125BLight weight high strengthImprove insulation performanceOverhead installationTowersGlass fiberHigh tension line

The invention provides a high-voltage line support used on a telegraph pole. The high-voltage line support comprises two parallel cross arms and a plurality of insulators fixed to horizontal plates of the cross arms. Perpendicular plates of the cross arms are fixedly connected with the telegraph pole through first hoops. The high-voltage line support further comprises second hoops fixedly connected with the telegraph pole, the second hoops are arranged below the first hoops, and inclined supporting rods are connected between the ends of the second hoops and the ends of the perpendicular plates of the cross arms. The cross arms are made of glass fiber reinforced plastics, and the insulators are formed by winding glass fibers steeped with vinyl ester resin. The high-voltage line support has the advantages that firstly, the cross arms made of the glass fiber reinforced plastics are adopted, so that the high-voltage line support is low in weight, high in strength, resistant to corrosion, good in insulation performance and long in service life, and the glass fiber insulators made based on the winding technology are not prone to breakage; secondly, the second hoops connected with the two ends of the cross arms through the inclined supporting rods are additionally arranged below the first hoops, the supporting strength is increased, potential safety hazards are reduced, after the first hoops are corroded and damaged, a supporting guarantee still exists, and certain first-aid repair time can be provided.

Owner:NINGHAI COUNTY POWER EQUIP BUILD OR REPAIR FACTORY +1

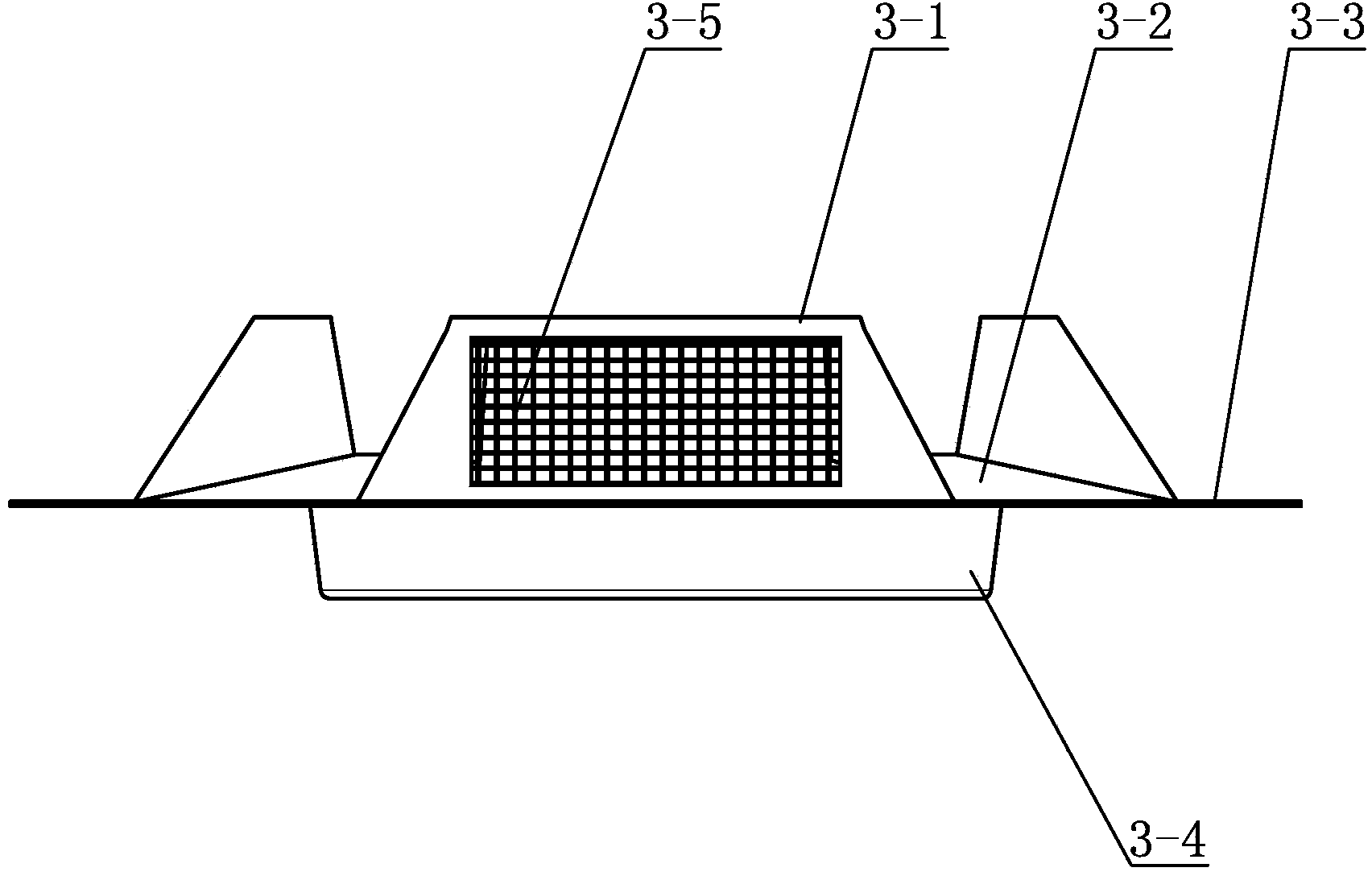

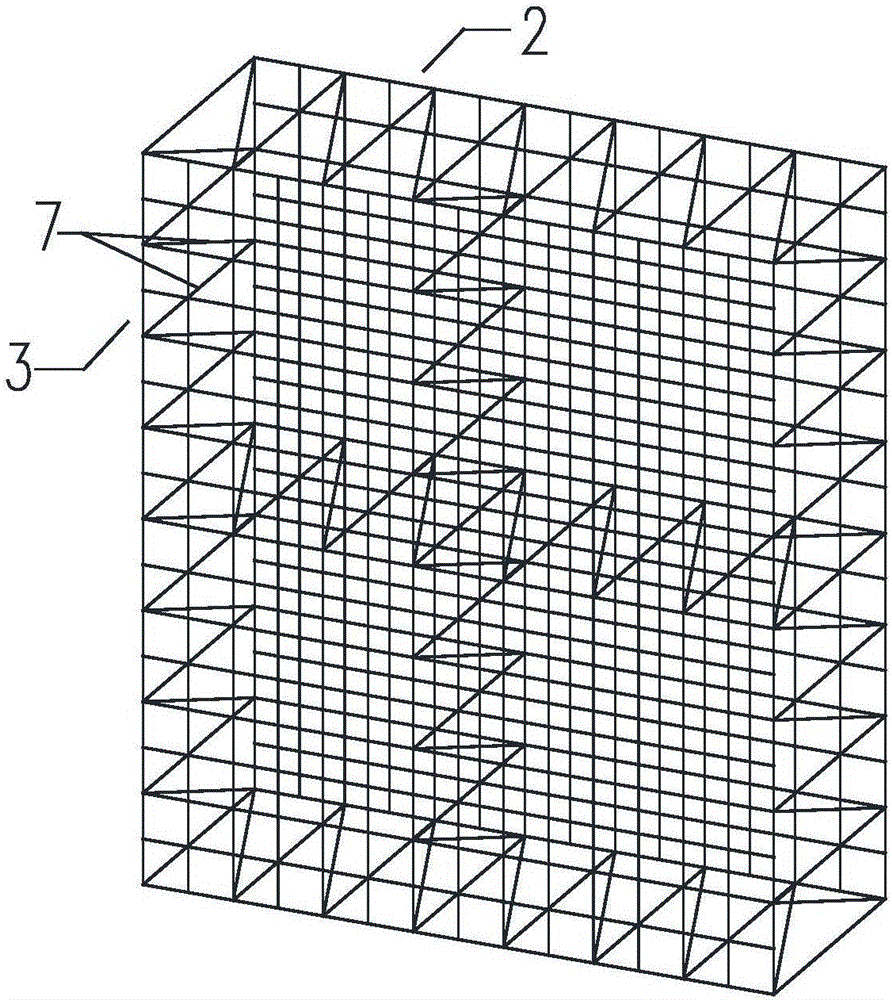

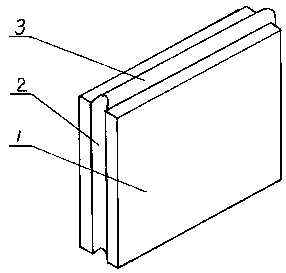

Cement steel mesh frame heat insulation board foamed from magnesian salt gel material

The invention discloses a cement steel mesh frame heat insulation board foamed from a magnesian salt gel material. The heat insulation board comprises a magnesium-based cement foamed board, a first steel wire screen piece and a second steel wire screen piece, the first steel wire screen piece and the second steel wire screen piece are arranged in the magnesium-based cement foamed board and are both of a screen-shaped structure composed of transverse steel wires and longitudinal steel wires, and the transverse steel wires and the longitudinal steel wires are perpendicular to each other. Inclined joint bar sets are arranged between the first steel wire screen piece and the second steel wire screen piece. The prepared cement steel mesh frame heat insulation board foamed from the magnesian salt gel material is simple in preparation line, capable of saving energy, environmentally friendly and capable of using waste, the required raw materials are low in price and easy to obtain, and production cost of the product is low.

Owner:内蒙古绿汇住房产业化技术有限公司 +1

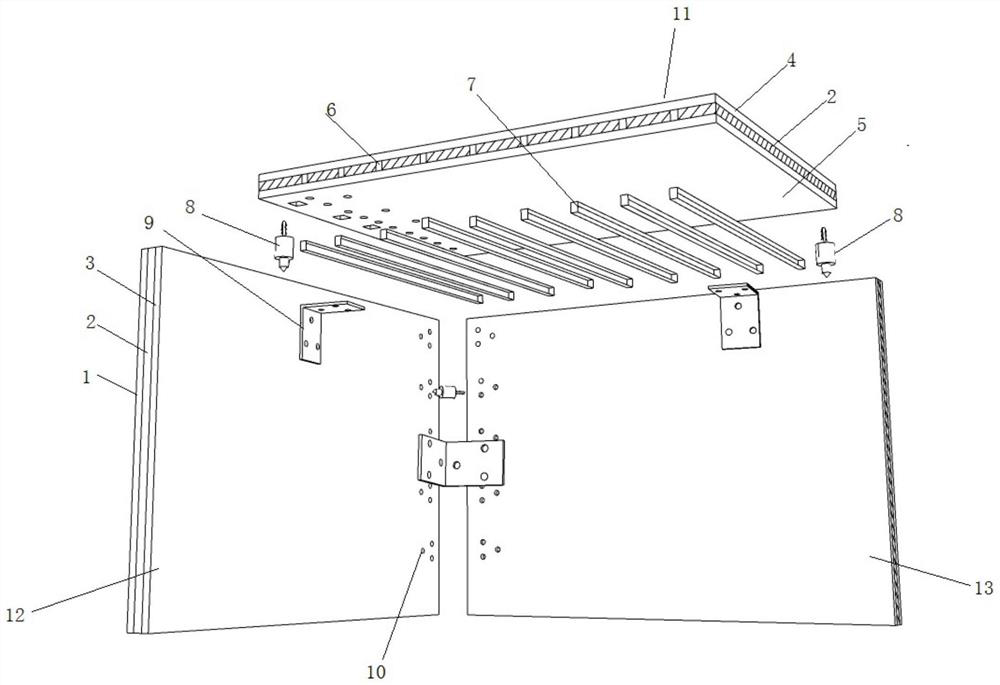

Energy saving integrated engineering bamboo assembly building system with low cost structure

PendingCN111733967AIncrease profitImprove machining accuracyBuilding constructionsArchitectural engineeringWall plate

The invention discloses an energy saving integrated engineering bamboo assembly building system with a low cost structure. The energy saving integrated engineering bamboo assembly building system withthe low cost structure comprises a main wall board, a side wall board and a building roof board; the main wall board and the side wall board are all bonded by inner side engineering bamboo boards, straw boards and outer side engineering bamboo boards in sequence; the building roof board includes an upper side engineering bamboo board, the straw boards, a lower side engineering bamboo board and stiffening ribs; the multiple straw boards are bonded between the upper side engineering bamboo board and the lower side engineering bamboo board, rib slots are formed between the adjacent straw boards,and each rib slot is bonded with the stiffening ribs; and the main wall board and the building roof board are connected through metal connectors and L-shaped angle steel connectors, the side wall board and the building roof board are connected through the metal connectors and the L-shaped angle steel connectors, and the main wall board and the side wall board are connected through the metal connectors and the L-shaped angle steel connectors. The energy saving integrated engineering bamboo assembly building system with the low cost structure simplifies the complex connection mode, the field assembly is simple and fast, the construction efficiency is effectively improved, and the advantages of factory reservation system, stable quality, small space occupation, convenient transportation, lowtransportation cost, environmental protection and the like are realized.

Owner:南京森工生物质材料研究院有限公司

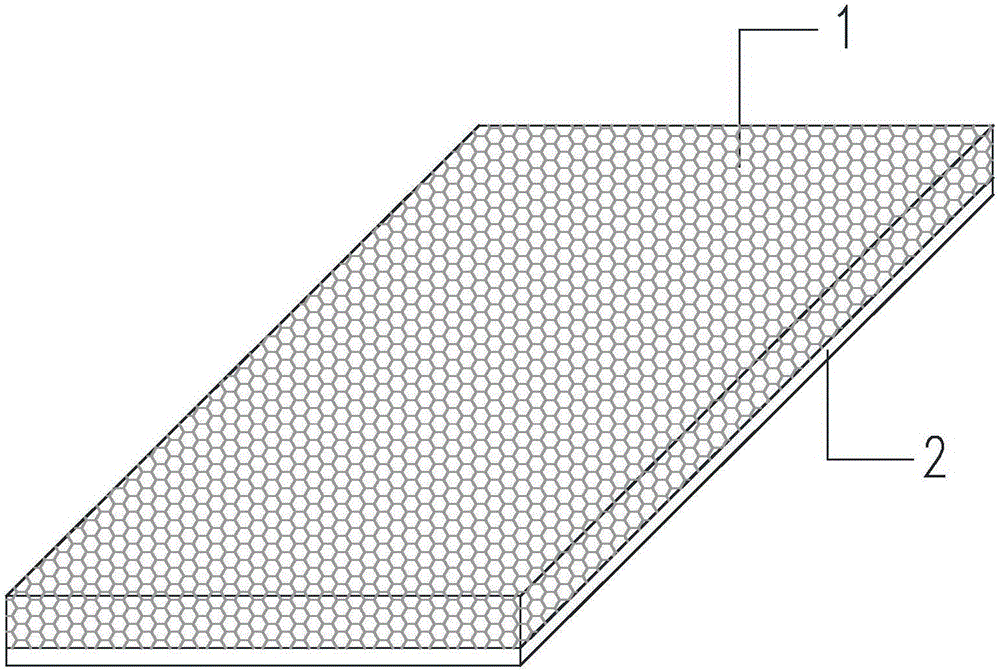

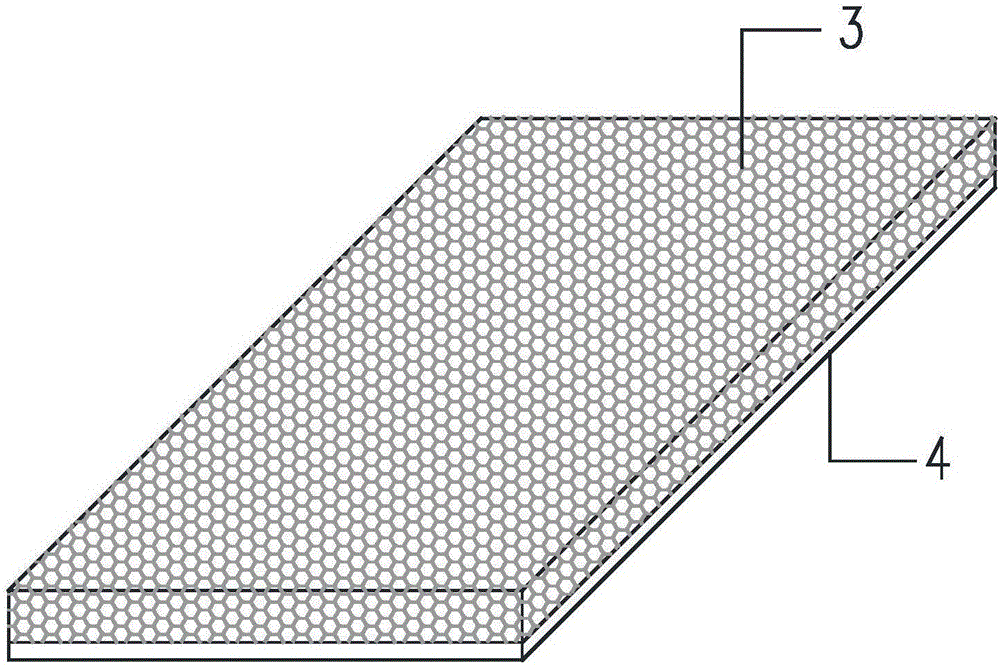

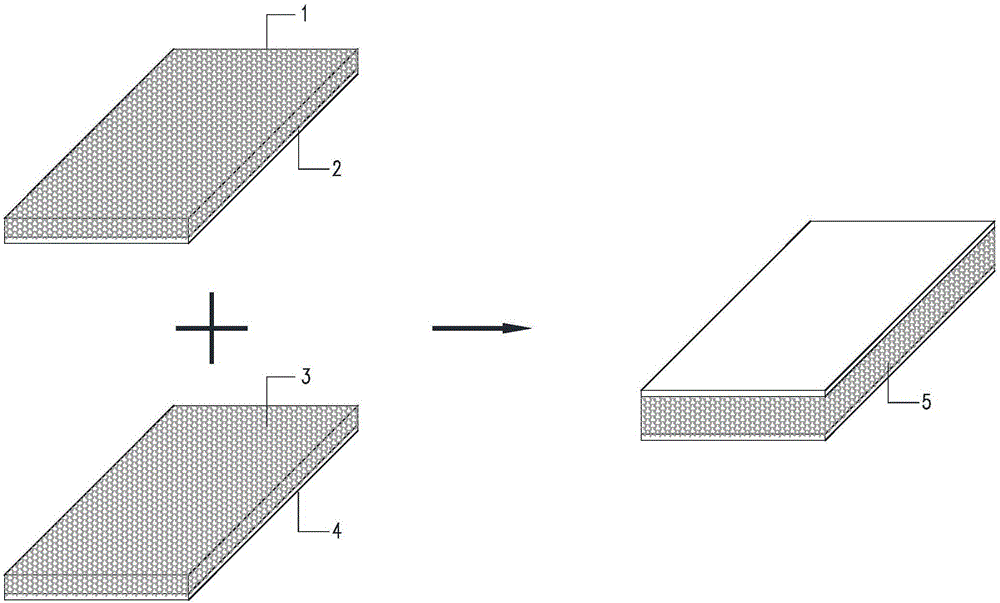

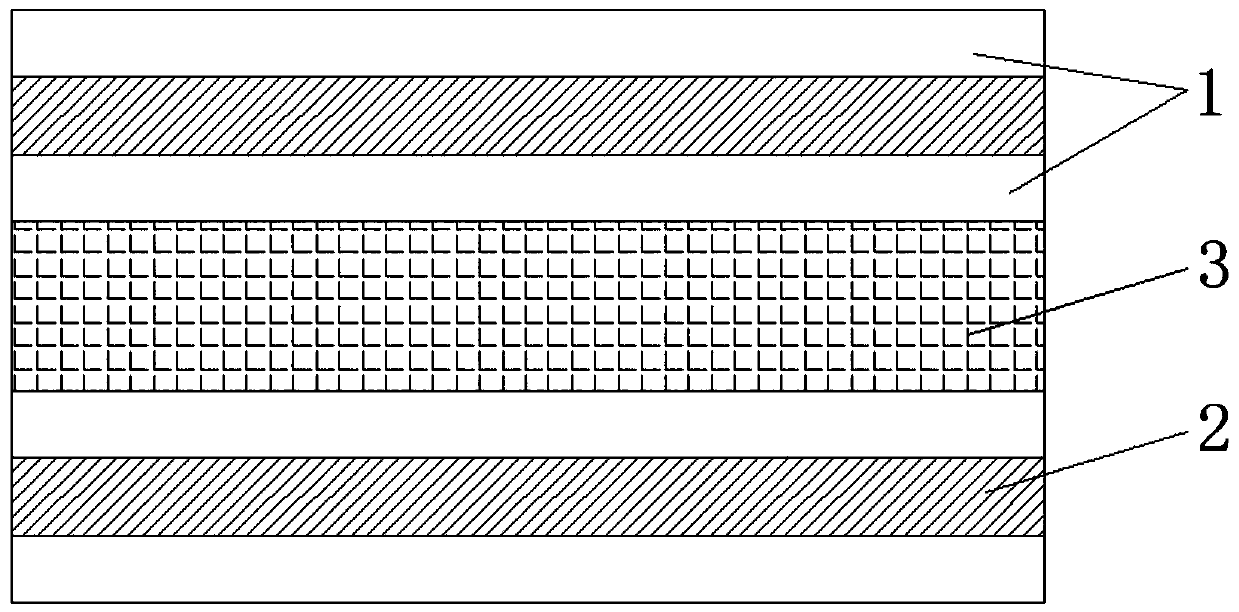

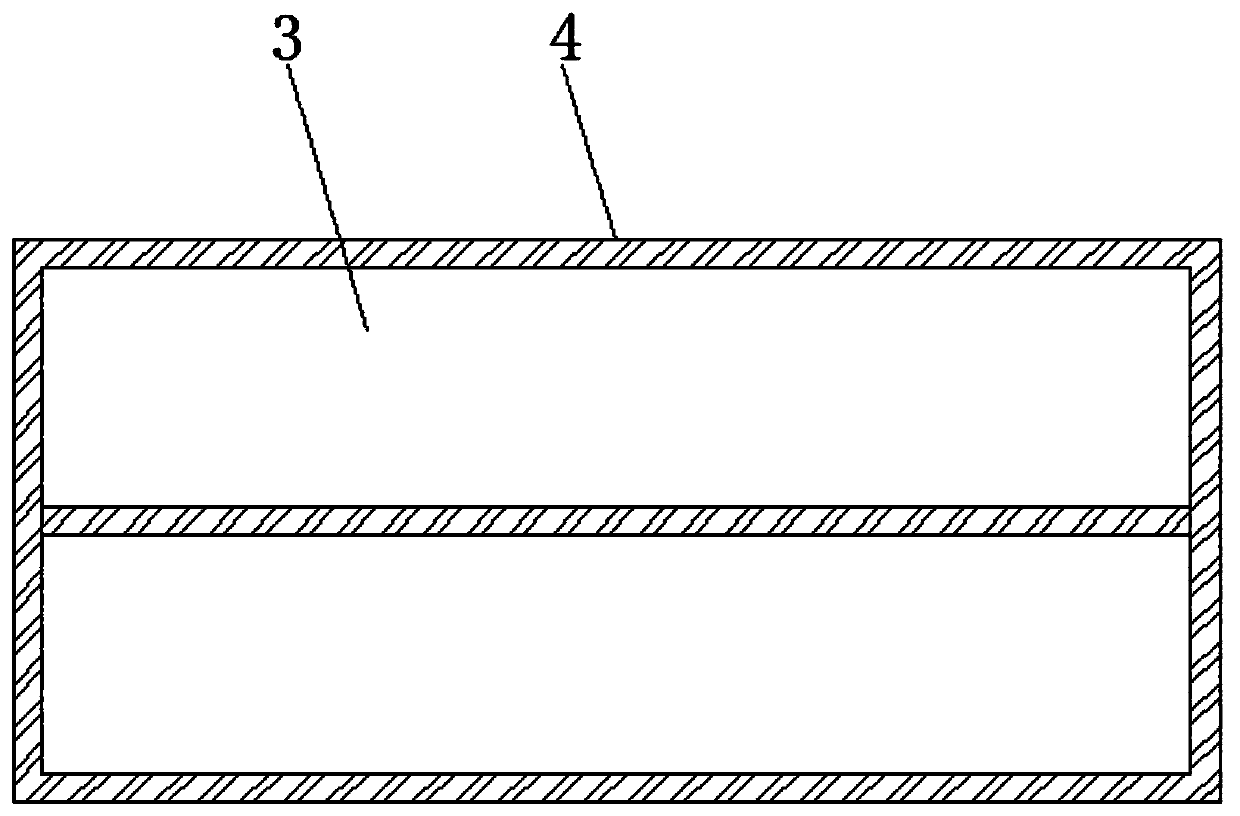

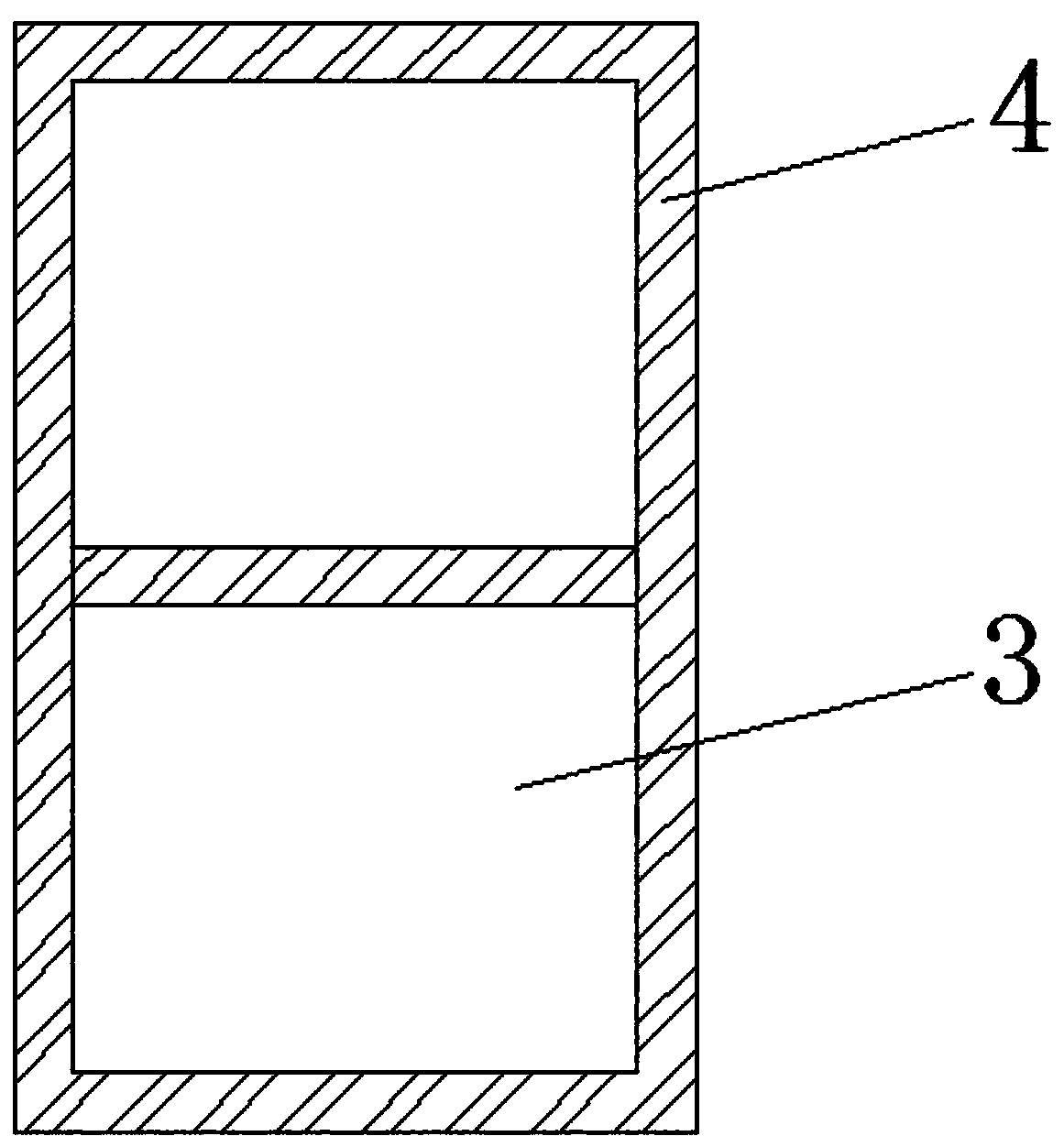

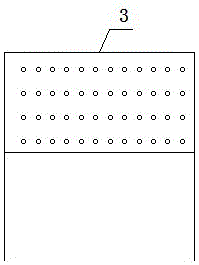

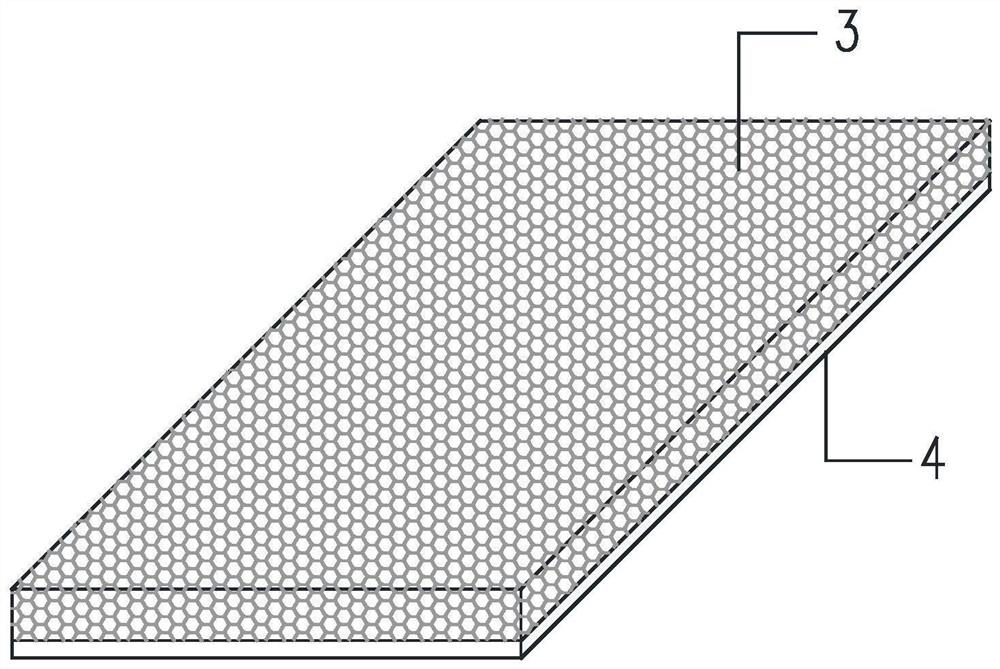

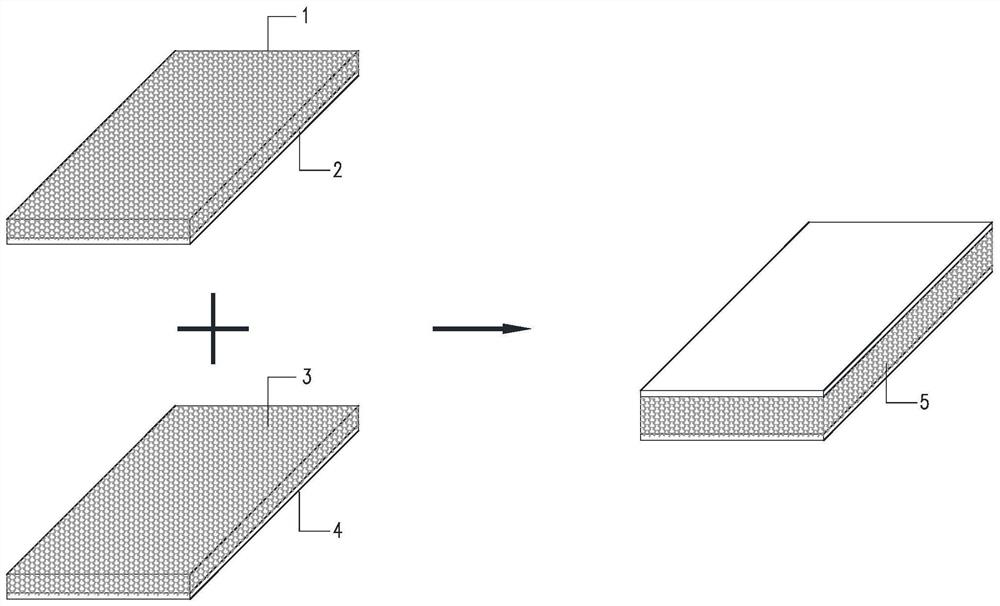

Assembly type magnesium-based cement foaming light board and preparation method thereof

ActiveCN106760149ASimple preparation routeLight weight high strengthConstruction materialSolid waste managementFiberSurface layer

The invention discloses an assembly type magnesium-based cement foaming light board and a preparation method thereof. The assembly type magnesium-based cement foaming light board comprises a first assembly light board body and a second assembly light board body. The first assembly light board body comprises a first magnesium-based cement fiber material surface layer and a first magnesium-based cement foaming layer, and the second assembly light board body comprises a second magnesium-based cement fiber material surface layer and a second magnesium-based cement foaming layer. The preparation method for the assembly type magnesium-based cement foaming light board comprises the following steps of (a) preparation of a magnesium-based cement foaming material; (b) preparation of a magnesium-based cement fiber material; (c) preparation of the first assembly light board body; (d) preparation of the second assembly light board body; and (e) preparation of the assembly type magnesium-based cement foaming light board. The assembly type magnesium-based cement foaming light board prepared through the preparation method is simple in preparation line, energy is saved, the environment is protected, waste is utilized, needed raw materials are cheap and easy to obtain, and the product is low in production cost.

Owner:王常清

Production process of light load-bearing multifunctional plate

The invention discloses a production process of a light load-bearing multifunctional plate. The multifunctional plate is included and comprises a set of composite veneers and heat preservation layers,each composite veneer is arranged to be of a rectangular frame structure, partition plate layers made of the same materials as the rectangular frame structure are arranged in the middles of the rectangular frame structures, the heat preservation layers are arranged at the upper ends and the lower ends of the partition plate layers on the inner sides of the rectangular frame structures of the composite veneers and fixedly connected with the composite veneers in a bonded mode, the composite veneers comprise wood plates arranged in the middle, and adhesives arranged at the upper ends and the lower ends of the wood plates, and the wood plates and the adhesives 1 at the upper ends and the lower ends of the wood plates are bonded and fixed. According to the production process of the light load-bearing multifunctional plate, waste formworks from waste wood, bamboos and construction sites are fully utilized, thus the waste formworks are fully reutilized, cement steel is saved, thus the purposes of de-capacity and environment protection are achieved, the house building speed is high, the plates are industrially produced, and popularization of an integrated house is facilitated.

Owner:王晓明

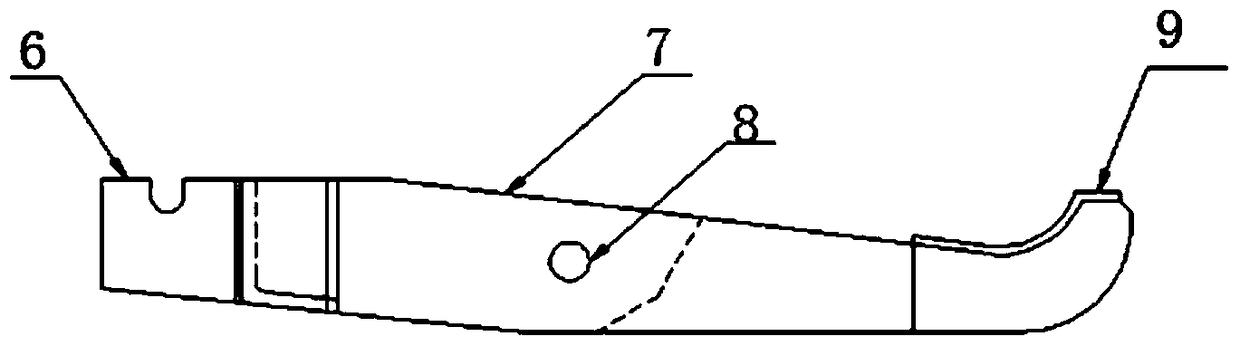

Vertical double-split wire lifting hook clamp used for 220kV hot-line work and made of carbon fiber plate

The invention provides a vertical double-split wire lifting hook clamp used for 220kV hot-line work and made of a carbon fiber plate. The clamp comprises an arm part, an upper wire guide hook, a lower wire guide hook and a connecting section which are integrally designed. The connecting section is used for connecting the upper wire guide hook with the lower wire guide hook. The clamp is made of the carbon fiber plate which comprises at least two carbon fiber cloth layers and at least one carbon fiber yarn layer. The carbon fiber yarn layers are located between every two carbon fiber cloth layers. The carbon fiber cloth layers are formed by interweaving longitudinal carbon fibers and transverse carbon fibers in a one-up and one-down mode. The longitudinal carbon fibers and the transverse carbon fibers are the same in fiber width. The carbon fiber yarn layers are formed by interweaving carbon fibers in a one-up and one-down bi-directional mode. The carbon fiber cloth layers and the carbon fiber layers are steeped with cementing agents. The clamp is high in durability and capable of being used in an environment with strong acid, alkali, salt and atmospheric corrosion, does not rust, and has the advantages of being high in fatigue resistance, resistant to wear and aging and the like.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

Preparation method of high-temperature-resistant and fire-proof carbon fiber cloth

InactiveCN107385888ALight weight high strengthImprove ductilityCarbon fibresHeat resistant fibresFiberCarbon fibers

The invention discloses a preparation method of high-temperature-resistant and fire-proof carbon fiber cloth. The preparation method is characterized by comprising the steps as follows: (1) blending: all fiber materials are blended and woven into carbon fiber cloth; (2) cleaning and drying: the carbon fiber cloth is immersed in a cleaning fluid for heated cleaning, taken out and dried until the moisture content is 7%-10%; (3) surface reduction: the carbon fiber cloth is subjected to a reduction reaction in a reaction kettle by use of CO gas; (4) impregnation treatment: the reduced carbon fiber cloth is immersed in an impregnation liquid for impregnation treatment; (5) plasma treatment: the carbon fiber cloth is placed in a plasma treatment machine for plasma treatment and subjected to secondary impregnation; (6) oxidation treatment: ozone is introduced into the reaction kettle and oxidation treatment of the carbon fiber cloth is carried out. The prepared carbon fiber cloth has good fire resistance, has better shielding effects on ultraviolet and sunlight and has a deodorization function.

Owner:JIESHOU SHUANGXIN TEXTILE

Lightweight composite wall panel

InactiveCN109267691AAccurate specificationsSmooth surfaceConstruction materialGypsumBuilding material

The invention relates to a lightweight composite wall panel and belongs to the field of building materials. Not only is a novel building material developed, but also a new field is opened up for urbansludge treatment. The wall panel is a square thick plate, grooves or ridges are processed at four side faces of the wall panel respectively. The grooves and the ridges are oppositely disposed, that is, a groove is processed at one side face, and the ridge is processed on the other corresponding side face. The wall panel is prepared from, by weight ratio, 65-75% of sludge ceramsite, 12.5-17.5% ofcement and 12.5-17.5% of gypsum. Water accounts for 72-78% the weight of the cement and the gypsum. The weight ratios of the weights of additives to the weight of the cement and the gypsum are high iron powder 0.8-1.2%., cellulose 0.08-0.12%., alkali inhibitor 1.8-2.2%., and water reducing agent 1.8-2.2%.. The lightweight composite wall panel has the advantages of high precision, small size, lightweight, good sound insulation and heat insulation effect, energy saving and environmental protection, simple and convenient construction and high efficiency, and can be widely used in the construction of interior walls and exterior walls of buildings.

Owner:北京千华新材科技有限公司

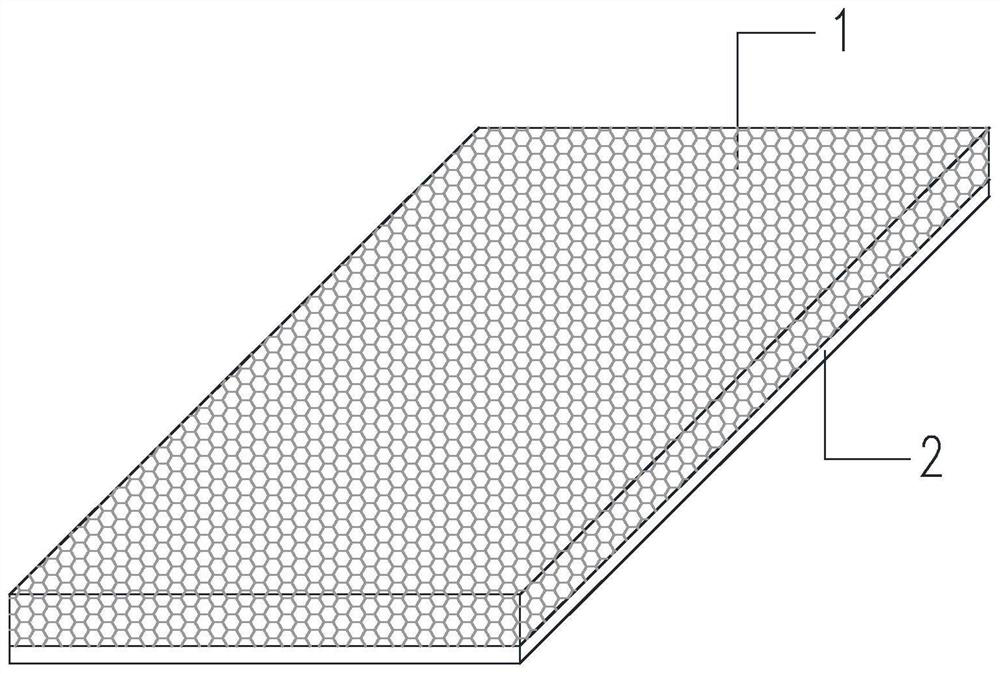

Electronic product shell and manufacture method thereof

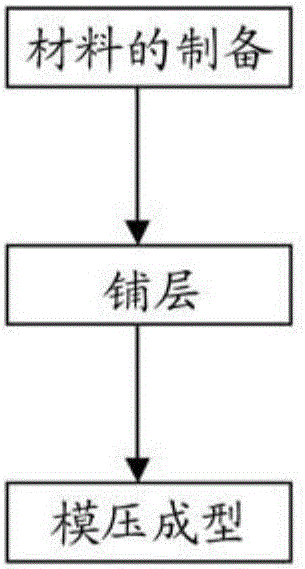

InactiveCN106827711AQuality improvementImprove liquiditySynthetic resin layered productsLaminationCompression moldingEngineering

The invention relates to an electronic product shell. The shell is manufactured by combining and curing a continuous prepreg sheet material and a short-cut prepreg sheet material by adopting a compression molding method. The invention further relates to a method for manufacturing the electronic product shell.

Owner:LENOVO (BEIJING) CO LTD

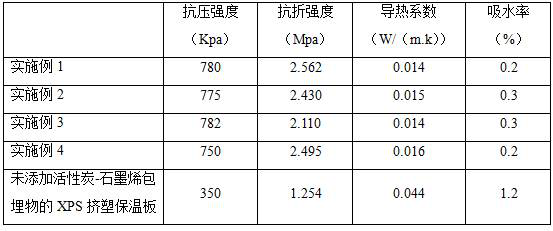

Preparation method of high-strength XPS (extruded polystyrene) thermal insulation board

The invention discloses a preparation method of a high-strength XPS (extruded polystyrene) thermal insulation board, and belongs to the technical field of preparation of XPS thermal insulation boards. According to the specific scheme, raw materials for preparing the thermal insulation board comprise an activated carbon-graphene embedded material. A preparation method of the embedded material comprises the steps: making tungsten carbide and graphene powder jointly subjected to ball milling, then adding activated carbon for continuous ball milling, adding water into a ball-milled mixture, adjusting the pH to be 8-8.5, carrying out ultrasonic treatment in the stirring state, and centrifugally filtering the solution subjected to ultrasonic treatment to obtain a precipitate; carrying out high-temperature treatment on the precipitate at 350 to 550 DEG C for 20 to 30 minutes to obtain activated carbon-graphene powder; and embedding the activated carbon-graphene powder with melamine resin to obtain an activated carbon-graphene embedded material. The prepared XPS thermal insulation board is higher in overall waterproof performance, light in weight and high in strength.

Owner:山西利源中天保温防腐工程有限公司

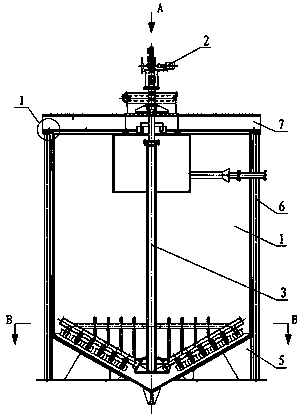

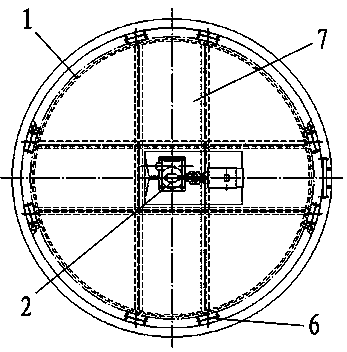

Anti-corrosion sedimentation tank and building method thereof

InactiveCN102462981BLight weight high strengthHigh strengthSedimentation settling tanksElectrolysisStructural engineering

The invention discloses an anti-corrosion sedimentation tank and a building method thereof. A tank body is made of glass fiber reinforced plastics, so the anti-corrosion problem is solved; and a support frame, a support tank body, a raking machine arranged in the tank body and a driving device driving the raking machine to operate are made of carbon steel, so the problem that the tank body has poor rigidity and can not support the raking machine to normally work is solved. The raking machine is a carbon steel welding element, in addition, ethylene-chlorotrifluoroethylene copolymer (ECTFE) anti-corrosion coatings with the thickness not less than 1.5mm are integrally sprayed and coated on the surface of the raking machine, the intensity requirement of the raking machine is met, and the anti-corrosion problem of the raking machine is also solved. A scraping plate is covered by more than 8.5mm of glass fiber wires or cloth, and the coatings on the scraping plate are prevented from being damaged when the scraping plate is used for scraping materials settled at the bottom of the tank body. The anti-corrosion problem of the sedimentation tank is perfectly solved, simultaneously, the work stability of the sedimentation tank is also ensured, and the production requirement of the electrolysis industry is met. The anti-corrosion sedimentation tank has the advantages that the structure is compact, the operation is stable, the sedimentation effect is good, economy and practicability are realized, and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

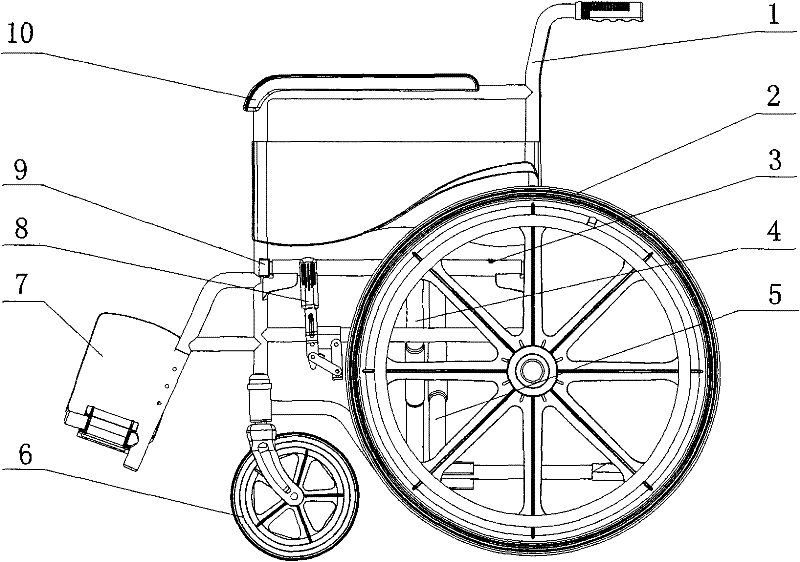

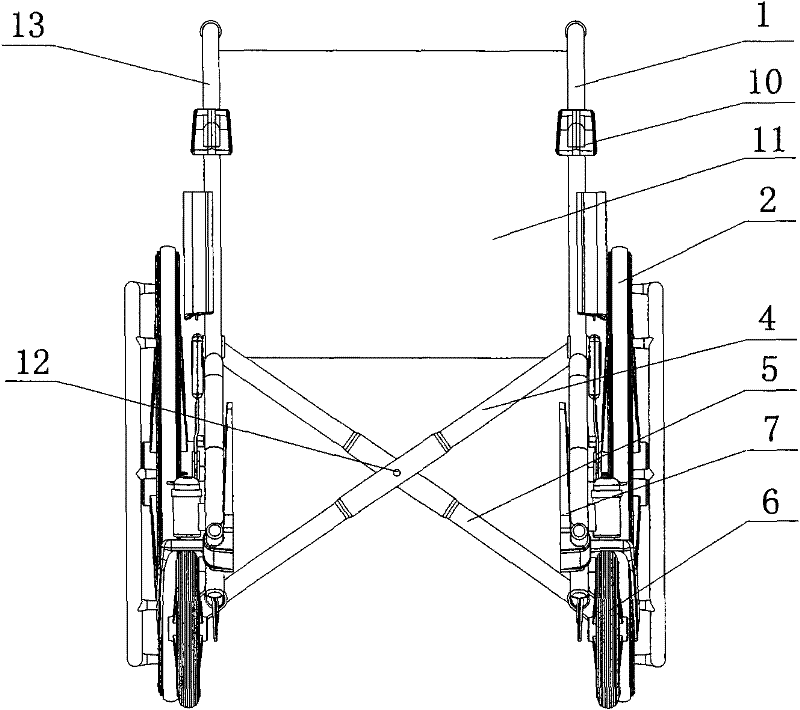

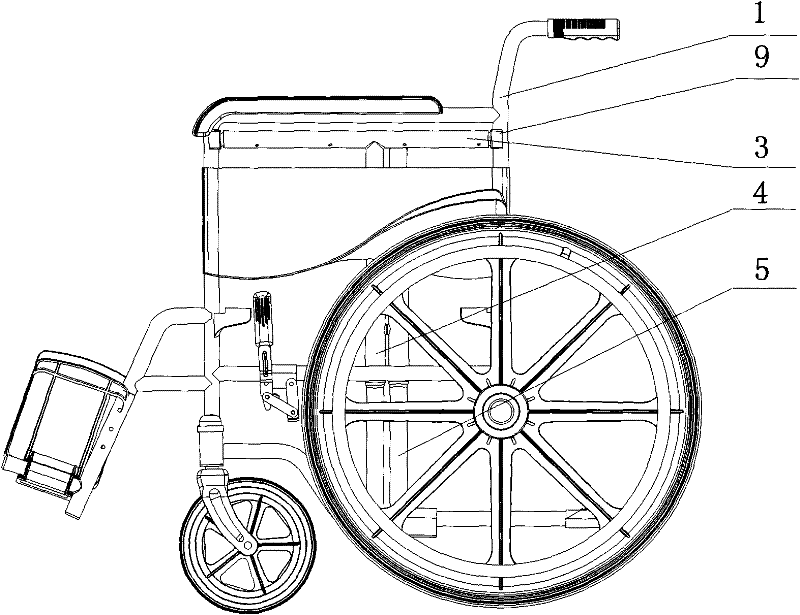

Alloy plastic wheelchair

InactiveCN101606876BSimple structureEasy to assembleWheelchairs/patient conveyanceWheelchairVehicle frame

The invention discloses an alloy plastic wheelchair consisting of a wheelchair assembly connected with an armrest, a chair back, a chair pad, front wheels, wheels, a pedal and a brake, wherein, the wheelchair assembly is composed of a whole formed by connecting a left frame and a right frame by folding pieces; the folding pieces are connected into a rotatable whole by a left support pipe and a right support pipe along a pin shaft; bent clamps at vertical ends of the left support pipe and the right support pipe and sliders at two transversal ends are respectively matched with the left frame and the right frame, and the left frame, the right frame, the left support pipe and the right support pipe are manufactured into a hollow pipe frame using alloy plastic with the method of injection molding by one time. The wheelchair has simple structure, does not need joints and accessories and uses few components. The wheelchair can be simply assembled without welding, electroplating and subsequent processing and has the advantages of short production period, high production efficiency, low price and zero environmental pollution; moreover, the wheelchair is made of material with favorable intensity and toughness; the wheel chair is beautiful, light and bright in color and can compare favourably with a metal wheel chair. The alloy plastic wheelchair can be directly recycled after being damaged for a long time of usage, thus having low energy consumption and environment protection.

Owner:NINGBO LE COUNT DAILY COMMODITIES

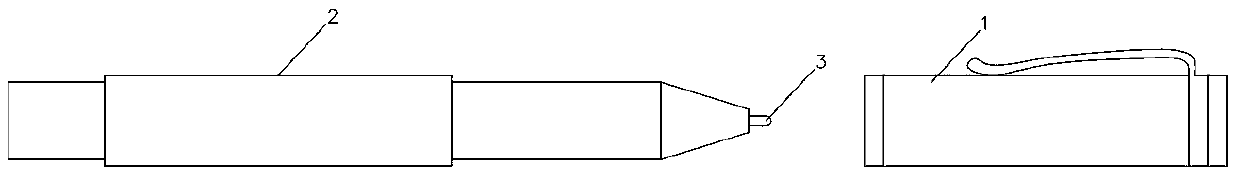

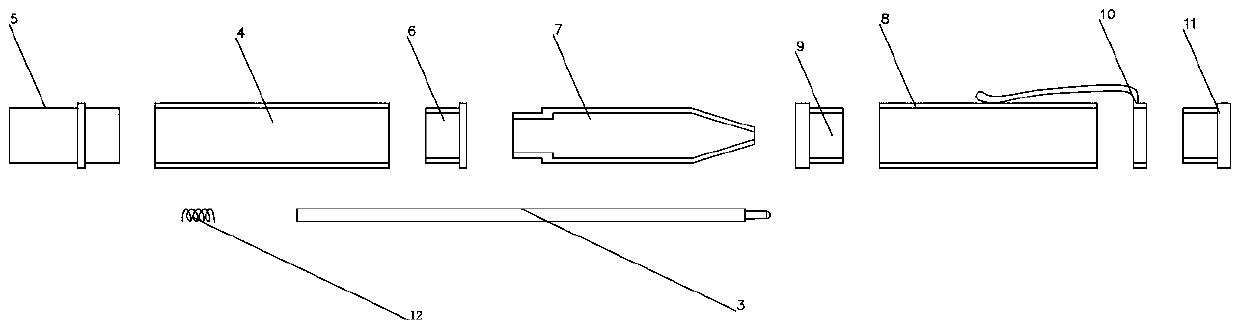

Carbon fiber decorative ballpoint pen and manufacturing method thereof

The invention discloses a carbon fiber decorative ballpoint pen and a manufacturing method thereof. The pen comprises a pen sleeve, a refill and a pen body, and is characterized in that cylindrical sleeves, molded by carbon fiber reinforced epoxy resin winding pipes, sleeve the pen body and / or the pen sleeve. The sleeves are manufactured by special materials and processes. The ballpoint pen has the following effects: (1) the weight is low; and the strength is high; (2) the decorative effect is good; the product grade is high; as carbon fibers have the characteristics of low weight, good thermal conductivity, good epoxy resin transparency and good skin feel, the cylinders are contacted with human skin to achieve the advantages of lubrication and good holding force; and (3) the practicability is better; carbon fiber reinforced composite materials have the advantages of heat resistance and aging resistance, so that the cylinders achieve better practicability and adaptability; the specifications of the cylinders are freely changed; and even if the sizes of the cylinders are increased, the practicability cannot be influenced.

Owner:江门市瑞祥复合材料研究院有限公司

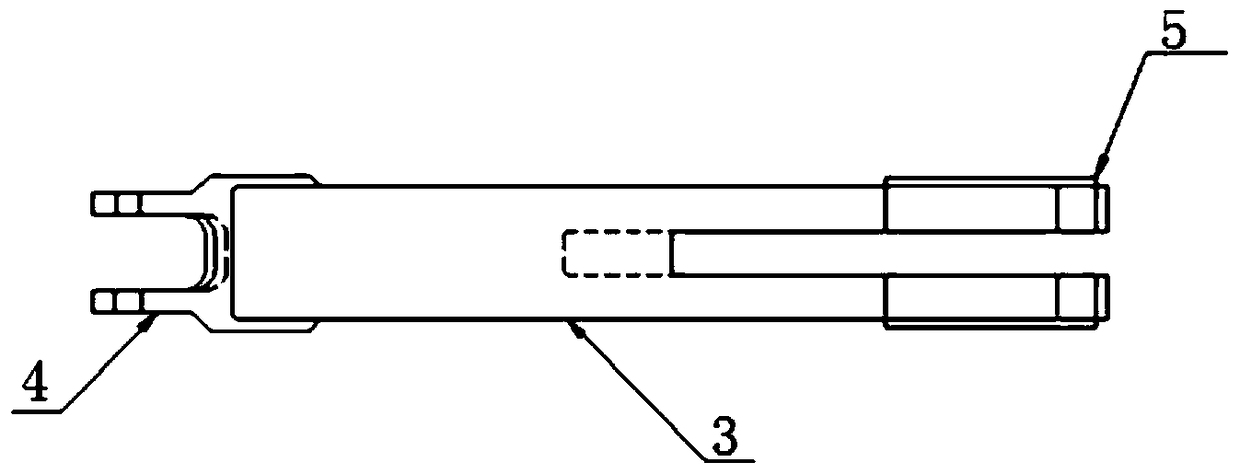

110kv live work with carbon fiber plate single wire hook fixture

ActiveCN105024302BIncreased durabilityStainlessApparatus for overhead lines/cablesFiberCarbon fibers

The invention provides a carbon fiber plate single-conductive-wire hooking clamping tool for 110kV live-wire work. The carbon fiber plate single-conductive-wire hooking clamping tool comprises an arm portion and a hook portion integrally designed. The arm portion and the hook portion are made of carbon fiber sheet materials. The carbon fiber sheet materials include at least two carbon fiber cloth layers and at least one carbon fiber filament layer. The carbon fiber filament layer is positioned between the two carbon fiber cloth layers. Each carbon fiber cloth layer is made of vertical carbon fibers and transverse carbon fibers which are interlaced in an upper-and-lower mode. The fiber widths of the vertical carbon fibers and the transverse carbon fibers are the same. The carbon fiber filament layer is made of carbon fibers which are in bidirectional interlacing in an upper-and-lower mode. The carbon fiber cloth layers and the carbon fiber filament layer are impregnated with cementing agents. The carbon fiber plate single-conductive-wire hooking clamping tool of the invention is strong in endurance and free from rusting. The carbon fiber plate single-conductive-wire hooking clamping tool can be used in environments with peracid, high alkali, high-salt and atmosphere corrosion. The carbon fiber plate single-conductive-wire hooking clamping tool of the invention is advantaged by being high in anti-fatigue strength, being wear resistant, being anti-aging, etc.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

220kv live work with carbon fiber board big knife card fixture

The invention provides a 220kV live work with a carbon fiber plate big knife clamp, including a front clamp, a rear clamp, an insulating pull rod and a wire tensioner, the insulation pull rod is connected with the wire tightener, and the first clamp body and the second clamp body use carbon fiber The carbon fiber sheet includes at least two carbon fiber cloth layers and at least one carbon fiber filament layer, the carbon fiber filament layer is located between the two carbon fiber cloth layers, and the carbon fiber cloth layer is one layer of longitudinal carbon fiber and transverse carbon fiber. The vertical carbon fiber and the horizontal carbon fiber have the same fiber width, and the carbon fiber layer is bidirectionally interwoven with carbon fiber, and the carbon fiber cloth layer and the carbon fiber layer are impregnated with a binder. Strong durability, no rust, can be used in high acid, alkali, salt and atmospheric corrosion environment, also has the advantages of high fatigue resistance, wear resistance, anti-aging and so on.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

Ventilation device at the top of a radome

ActiveCN104241846BLight weight high strengthImprove permeabilityRadiating element housingsNatural ventilationRadar

The invention relates to a ventilation device, in particular to a ventilation device on the top of a radome. The ventilation device on the top of the radome is used for solving the problems that an existing radome ventilation device is low in manufacturing efficiency, low in finished product quality, poor in universality of assembly with various radomes, difficult in later maintenance and poor in natural ventilation effect, rain leakage often happens, and the use performance of a radar antenna is influenced. The ventilation device on the top of the radome comprises a mushroom-shaped upper radome body, a base and turnover plates, wherein the mushroom-shaped upper radome body is buckled to the base, ventilating windows are arranged on the outer side walls of hollowed-out step platforms at the bottom of the base, and the turnover plates are installed on the ventilating windows. A connecting flange extending outwards is arranged on the edge of the mushroom-shaped upper radome body, the mushroom-shaped upper radome body is connected with the annular outer edge through the connecting flange, and a through hole is formed in the bottom surface of a hollow cylinder and provided with a connecting flange extending inwards. The ventilation device on the top of the radome is applicable to the field of wireless communication.

Owner:HARBIN TOPFRP COMPOSITE

Carbon fiber plate horizontal double-fission wire lifting hook clamp for 220 kV hot-line work

InactiveCN105016192AIncreased durabilityStainlessLayered productsLoad-engaging elementsFiberCarbon fibers

A carbon fiber plate horizontal double-fission wire lifting hook clamp for 220 kV hot-line work comprises a clamp body. A left wire hook is arranged at one end of the clamp body. A right wire hook is arranged at the other end of the clamp body. The clamp body, the left wire hook and the right wire hook are integrally designed. The carbon fiber plate horizontal double-fission wire lifting hook clamp for 220 kV hot-line work is characterized in that the clamp body, the left wire hook and the right wire hook are made from a carbon fiber plate; the carbon fiber plate comprises at least two carbon fiber cloth layers and at least one carbon fiber silk layer; the carbon fiber silk layer is located between the two carbon fiber cloth layers; the carbon fiber cloth layers are formed by interweaving longitudinal carbon fibers and transverse carbon fibers in an up-and-down manner; the width of the longitudinal carbon fibers is equal to that of the transverse carbon fibers; the carbon fiber silk layer formed by interweaving carbon fibers in an up-and-down manner; and the carbon fiber cloth layers and the carbon fiber silk layer are provided with grouting agents in a dipping mode. The clamp is durable, will not get rusty and can be used in a high-acid, high-alkali, high-salt and high-atmosphere-corrosion environment and further has the beneficial effects of being high in strength, resistant to abrasion, resistant to aging and the like.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD +1

Quick-dismantling building formwork and light-weight cast-in-place wall body construction method

PendingCN108331332AReasonable structural designReduce weightForms/shuttering/falseworksSurface plateUltimate tensile strength

Owner:常华北

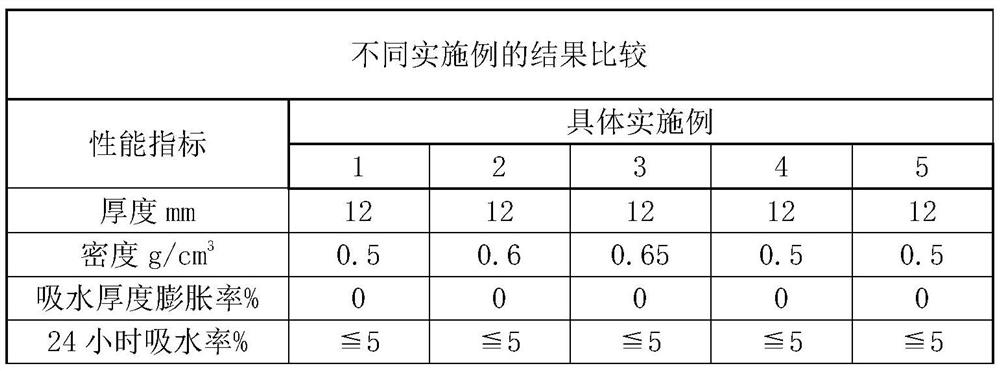

Manufacturing method of full-core reinforced composite template

The invention discloses a manufacturing method of a full-core reinforced composite template. The method comprises the following steps of 1, mixing materials, specifically, fully stirring and uniformly mixing phenolic resin, epoxy resin, melamine resin, benzoxazine resin, a curing agent, a release agent, a foaming agent and a diluent according to a formula; 2, infiltrating, specifically, fully infiltrating fiber reinforced materials with different varieties, specifications and gram weights through a glue dipping line tank, conducting heating and pre-curing through a drying tunnel to achieve the needed feeding amount and residual volatile matter, conducting cutting and stacking, and preparing intermediate prepregs with different varieties, specifications and gram weights; 3, conducting blank assembling, specifically, conducting blank assembling according to the density, thickness, size specification and strength requirements of the target product; and 4, conducting thickness limiting, heating, foaming, curing and molding through a hot press, inspecting, cutting, packaging and warehousing to obtain a full-core reinforced composite template product. The full-core reinforced composite template prepared by the method is light in weight, high in strength, flame-retardant, corrosion-resistant, homogeneous inside and outside, and free of structural defects. The manufacturing method is feasible and low in cost.

Owner:江苏美龙新材料有限公司

Processing device and processing method of polyethylene glass fiber reinforced plastic composite molding spiral corrugated pipe

InactiveCN103085289BLight weight high strengthCorrosion resistanceCorrugation articlesTubular articlesGlass fiberWinding machine

The invention relates to a device and method for processing a spiral corrugated tube, and in particular relates to a device and method for processing a polyethylene glass fiber reinforced plastic composite molded spiral corrugated tube. The device comprises a drawing and squeezing mold, a roll bending device, a winding machine, a heating adhesive-spraying device and a polyethylene plastic extrusion mold which are arranged in sequence, wherein the drawing and squeezing mold is used for processing glass fibers into glass fiber reinforced plastic strips; the roll bending device is used for bending the glass fiber reinforced plastic strips into glass fiber reinforced plastic spiral rings; the winding machine is used for propelling the glass fiber reinforced plastic spiral rings; the heating adhesive-spraying device is used for spraying an adhesive to the glass fiber reinforced plastic spiral rings; and the polyethylene plastic extrusion mold is used for extruding polyethylene towards inner and outer walls, to which the adhesive is attached, of the glass fiber reinforced plastic spiral rings to ensure that the polyethylene glass fiber reinforced plastic composite molded spiral corrugated tube is formed. By adopting the device and the method, the advantages of corrosion resistance, easiness in processing and molding and recyclability of polyethylene are integrated with the characteristics of high corrosion resistance, high strength, high elastic modulus and easiness in molding of glass fiber reinforced plastics, so that the composite molded tube has the advantages of easiness in processing, corrosion resistance, high strength, low cost, small possibility of deformation, recyclability and the like.

Owner:ANHUI PROVINCE ZHONGYANG PIPE IND

Integrated light chain board

The invention relates to the technical field of transmission parts, in particular to an integrated light chain board. The integrated light chain board comprises an inner chain board and a chain roller. The inner chain board and the chain roller are integrally formed in a thermoplastic mode with high-wear-resisting epoxy resin. Reinforcing particles adopted in the high-wear-resisting epoxy resin is nano-SiC. The diameter of the nano-Sic ranges from 50 nanometers to 80 nanometers. Polyacrylamide is added into the epoxy resin. The two sides of the chain roller are in a concave shape. A chain assembled by the chain board is simple in structure, convenient to use, low in mass and high in strength; due to the concave design in the middle of the chain roller, the frictional contact area between the chain roller and a chain wheel is reduced, flexibility of the chain during operation is improved, and the service life of the chain is prolonged.

Owner:TIANJIN KAIRUI METAL PROD

A prefabricated magnesium-based cement foamed lightweight board and its preparation method

ActiveCN106760149BSimple preparation routeLight weight high strengthConstruction materialSolid waste managementFiberProcess engineering

The invention discloses an assembled magnesium-based cement foamed lightweight board and a preparation method thereof. The assembled magnesium-based cement foamed lightweight board includes a first assembled lightweight board and a second assembled lightweight board; the first assembled The lightweight board includes a first magnesium-based cement fiber material surface layer and a first magnesium-based cement foam layer; the second assembled lightweight board includes a second magnesium-based cement fiber material surface layer and a second magnesium-based cement foam layer ; A method for preparing a prefabricated magnesium-based cement foamed lightweight board, comprising the following steps: (a) preparing magnesium-based cement foam; (b) preparing a magnesium-based cement fiber material; (c) preparing the first prefabricated lightweight board (d) preparing the second prefabricated lightweight board; (e) preparing a prefabricated magnesium-based cement foamed lightweight board. The preparation route of the fabricated magnesium-based cement foamed lightweight board prepared by the invention is simple, energy-saving, environmentally friendly and waste-efficient, the required raw materials are cheap and easy to obtain, and the product has relatively low production cost.

Owner:王常清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com