A prefabricated magnesium-based cement foamed lightweight board and its preparation method

A technology of cement foaming and cement foaming layer is applied in the field of preparation of assembled magnesium-based cement foamed lightweight board, which can solve the problems of low strength and insufficient hydration, and achieve good impact resistance and thermal insulation. Good thermal insulation effect and large heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

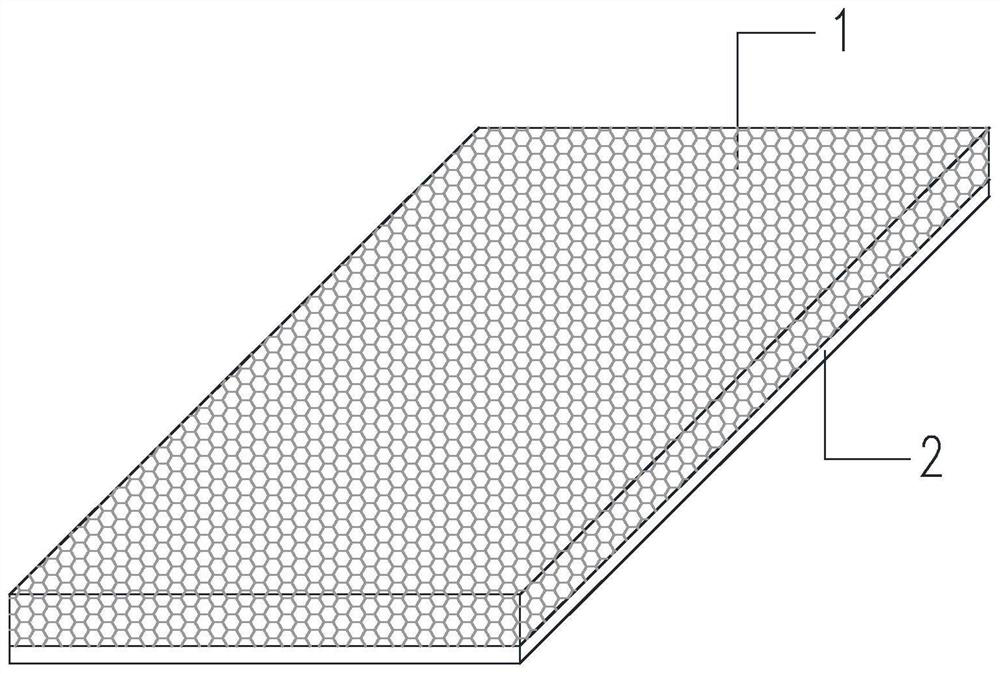

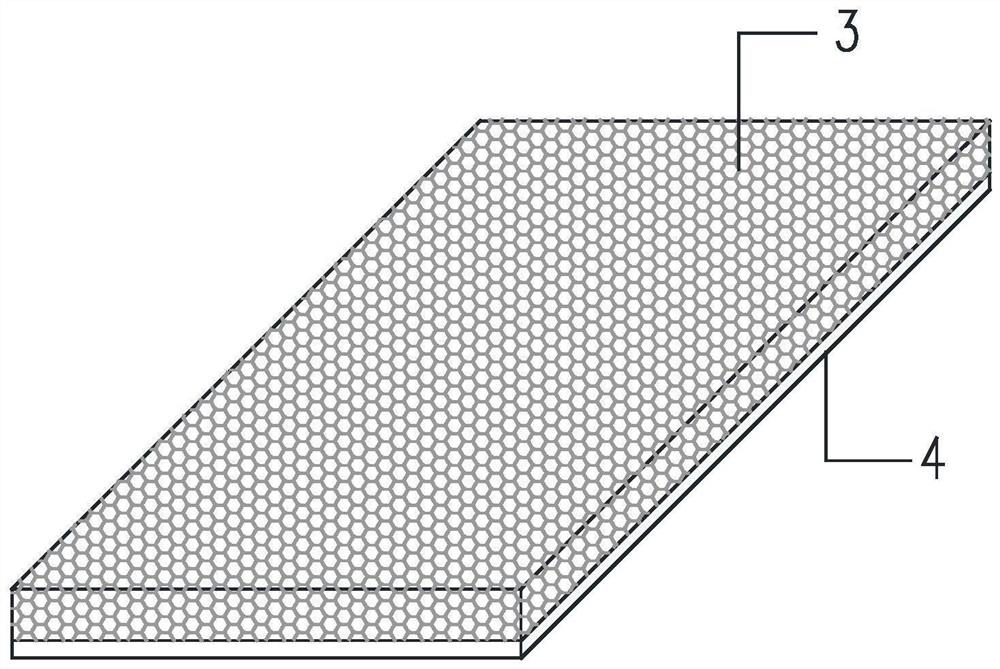

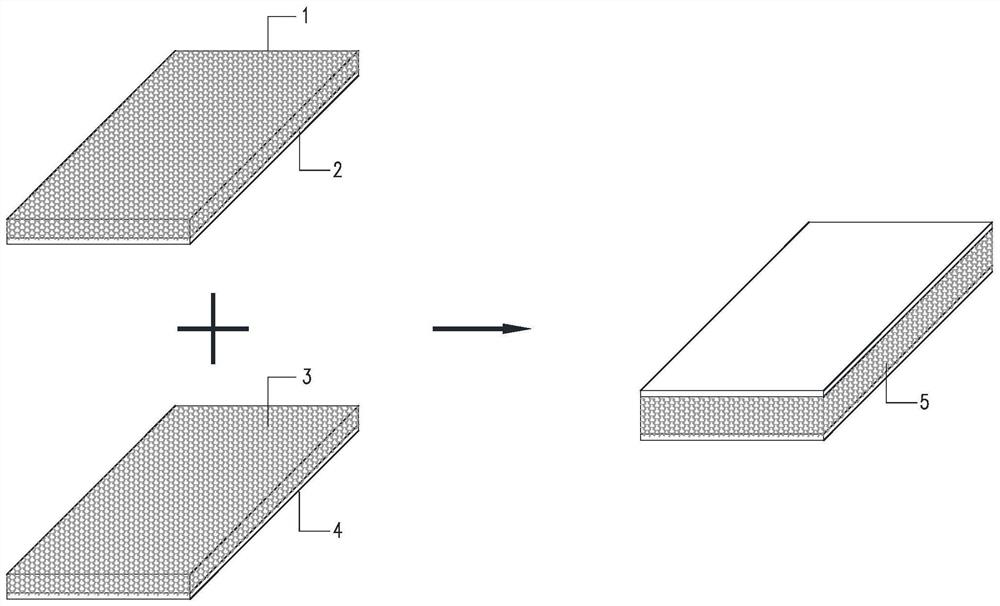

[0035] Preparation method of assembled magnesium-based cement foamed lightweight plate, the method specifically comprises the following steps:

[0036] (a) Preparation of magnesium-based foamed cement

[0037] Magnesium salt cement 65 kg, foam stabilizer 3 kg and foaming agent 5 kg, according to the water ash ratio of 0.45 add water, stirred to make magnesium cement foaming slurry. The foam stabilizer is silicone amide; the blowing agent is sodium dodecyl sulfate.

[0038] The preparation method of the magnesium salt cement is as follows: 100-200 mesh MgO, 100-200 mesh MgSO 4 and H 2 O The three are mixed according to the ratio of the amount of the substance to 9:1:25, and then the inducer is added, and the amount of inducer is MgO and MgSO 4 and H 2O 1wt of the total mass of the three, stirred for more than 24 hours, dried, ground, after 200 mesh sieve to obtain magnesium salt cement.

[0039] The preparation method of the inducer is as follows: 200-400 mesh talc powder is added ...

Embodiment 2

[0049] The difference between the present embodiment and Example 1 is:

[0050]The inducer consists of component A and component B, the preparation method of component A is as follows: 200-400 mesh talc powder is added to the vinegar propylene emulsion, the mass ratio of talc powder to acetic propylene emulsion is 8:27, stirred, heated to 60 ° C and maintained for 4 hours, filtered and dried; the resulting solid product is added to the aqueous tannic acid solution, the mass fraction of tannic acid in the aqueous tannic acid solution is 10wt, the mass ratio of the solid product to the aqueous solution of tannic acid is 1:30, heated to 100 ° C and maintained for 5 hours, Filter drying and crushing, after 100 mesh sieve to obtain A component; the preparation method of B component is as follows: the 200-400 mesh fly ash is added to the aqueous solution of triethanolamine, the mass fraction of the aqueous solution of triethanolamine is 5wt%, the mass ratio of fly ash and triethanolamin...

Embodiment 3

[0053] The difference between the present embodiment and Example 2 is:

[0054] (a) Preparation of magnesium-based foamed cement

[0055] Magnesium salt cement 65 kg, pretreated fly ash, foam stabilizer 3 kg and foaming agent 5 kg, according to the water ash ratio of 0.45 add water, stirred to make magnesium cement foam slurry. The amount of fly ash added after pretreatment is 10wt% of the mgO mass used in the preparation of magnesium salt cement.

[0056] The preparation method of fly ash after pretreatment is as follows: the 200-400 mesh fly ash is added to the aqueous solution of triethanolamine, the mass fraction of the aqueous solution of triethanolamine is 3wt%, the mass ratio of fly ash and triethanolamine aqueous solution is 1:12, stirred, heated to 70 ° C and maintained for 12 hours, filtered and dried; the resulting solid product is added to the silane coupling agent solution, and the mass ratio of the solid product to the silane coupling agent solution is 1:16, The mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com