Patents

Literature

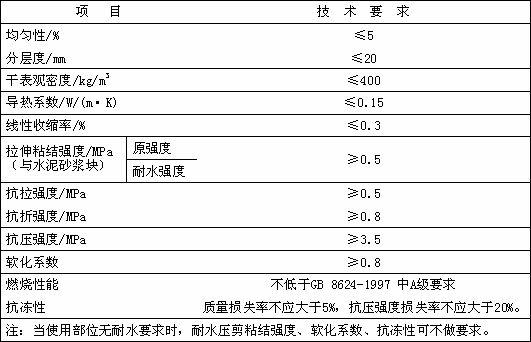

152results about How to "High softening coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

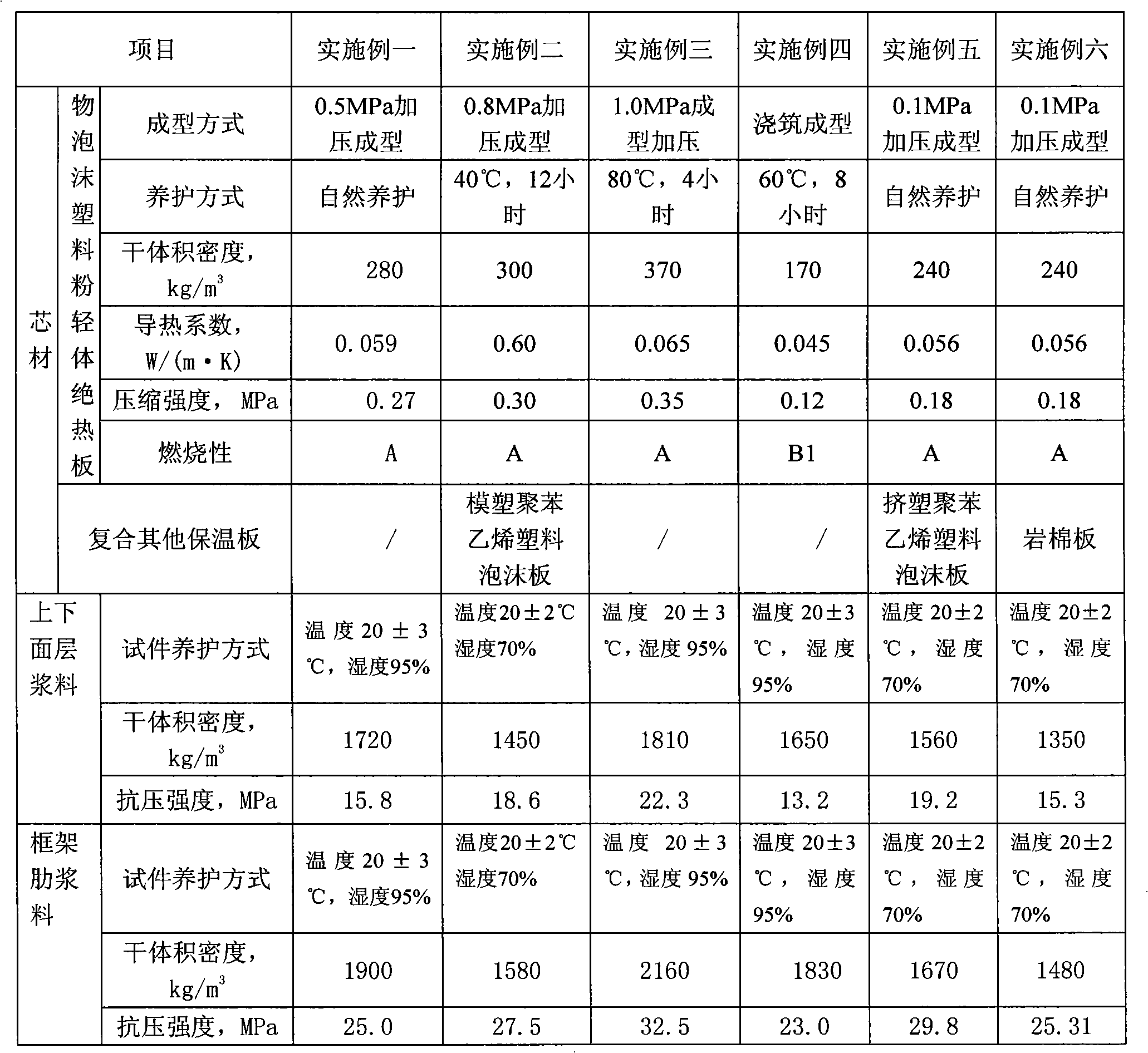

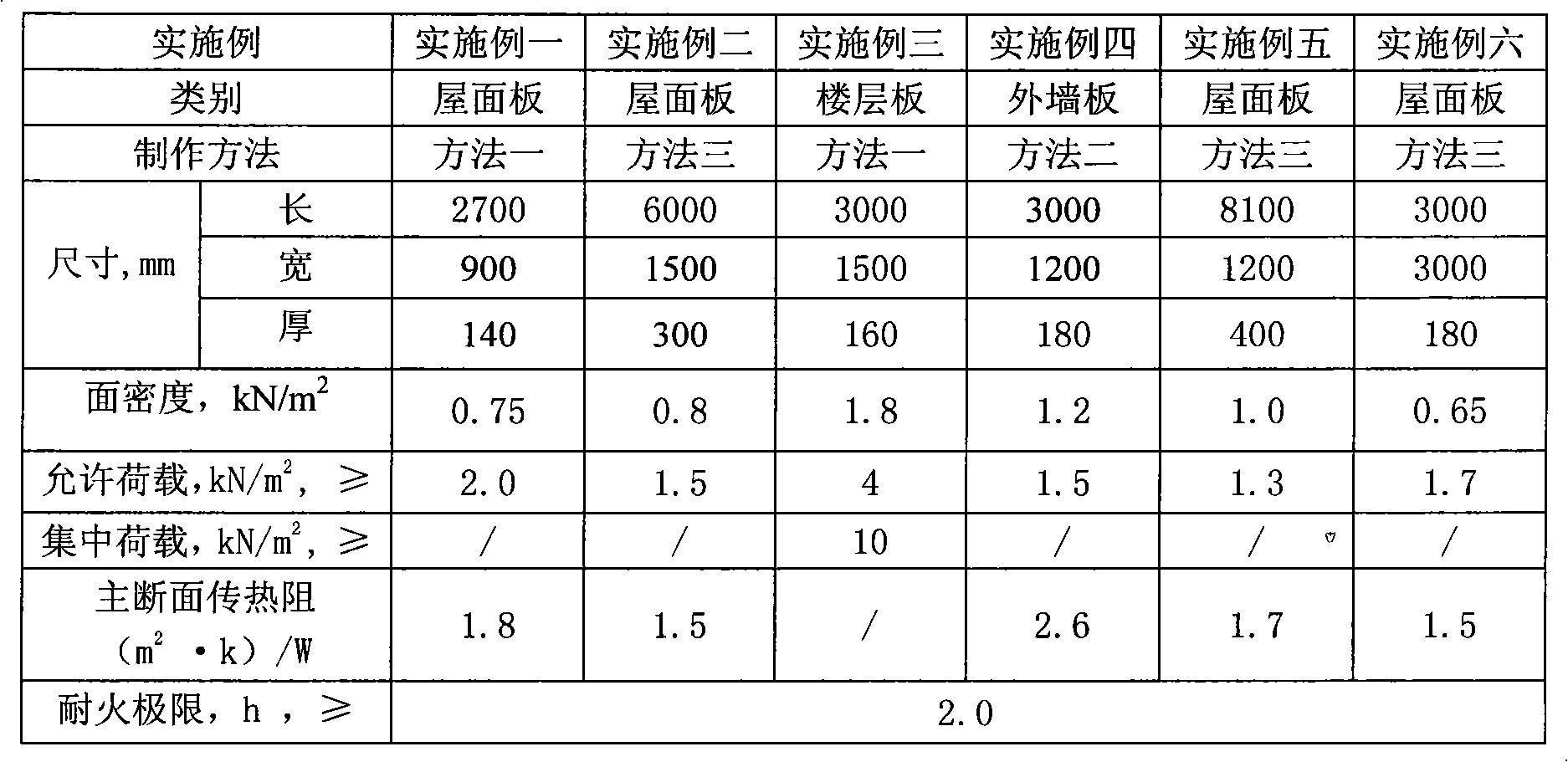

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

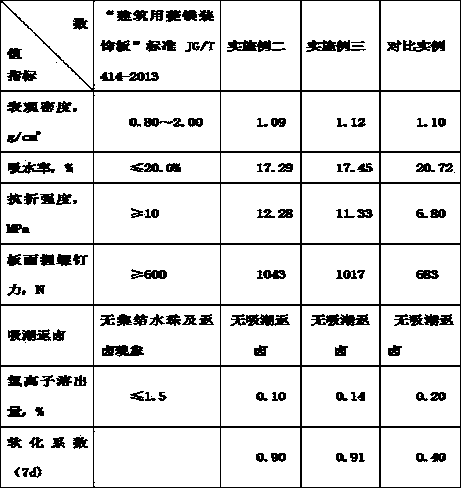

Water-resistant magnesium oxysulfate fire-proof plate and manufacturing method thereof

InactiveCN103979920AAddress water resistanceSolve the problem of moisture absorption and brine returnGlass fiberSlurry

The invention discloses a water-resistant magnesium oxysulfate fire-proof plate and a manufacturing method thereof and belongs to the field of fire-proof plate production. The fire-proof plate is prepared by adding active filler into slurry, mixing, hardening under a certain condition and demoulding, wherein modified magnesium oxysulfate is taken as a base material and medium-alkali glass fiber and non-woven fabrics and other materials are taken as a skeleton. Compared with the prior art, the fire-proof door core plate disclosed by the invention has no moisture absorption, higher durability than a conventional glass magnesium plate and smooth and beautiful appearance. The fire-proof plate can be applied to the field of building fire protection, especially fire protection engineering under a humid environment and has a good popularization and application value.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Paraffin phase changed thermal mortar powder and preparing method thereof

A mortar powder containing paraffin wax for phase-change insulating is prepared from cement, light aggregate, fibres and paraffin wax through fusing paraffin wax or preparing the microcrystal powder of paraffin wax, and proportionally mixing it with others. Its advantages are low hydroscopicity and high water-proof performance and softening coefficient.

Owner:北京振利高新技术有限公司

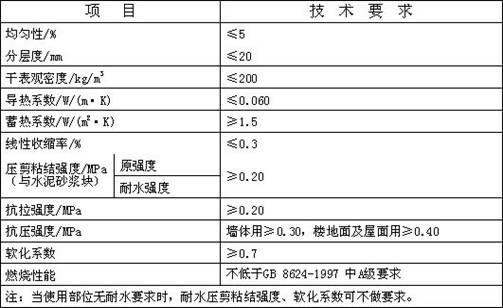

Inorganic thermal insulation light mortar and construction method thereof

InactiveCN102372476AReduce loadImprove integrityBuilding material handlingMass ratioThermal insulation

The invention discloses an inorganic thermal insulation light mortar, the mortar is mainly composed of a raw material and water in the following percentage by mass: the raw material is composed of 45-55% of lightweight aggregate, 15-20% of hydraulic material, 12-18% of air-setting material, 7-10% of active stuffing and 5-8% of additives; and the mass ratio of the water to the raw material is 0.15-0.25. The mortar in the invention is selected based on a principle of combining a hydraulic cementing material with an air-setting cementing material to satisfy material strength development and application quality demand and effect under a wall body environment condition; a non-gravity gasification suspension stirring technique is applied for achieving an expected stirring effect of generating no damage on a light thermal insulation material; and a one-time continuous jetting construction technique is utilized for not only solving the air bubbling and cracking problems of a wall body, but also greatly improving the construction quality, thermal insulation effect and construction efficiency.

Owner:MINGYUAN NEW MATERIALS TECH DEV CO LTD

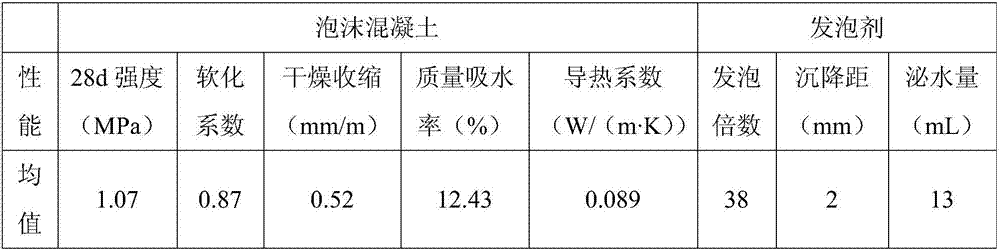

Foaming concrete for foam agent

The invention discloses a foaming agent for foam concrete. The foaming agent is prepared by uniformly mixing and stirring the following raw materials at room temperature, by weight : 5-10 parts of sodium dodecyl benzene sulfonate, 2-4 parts of sodium alcohol ether sulphate, 1-2 parts of sodium lauroyl sarcosinate, 1-2 parts of cocamidopropyl betaine, 0.2-0.6 part of polyethylene glycol (120) methyl glucoside dioleate, 0.3-0.5 part of triethanolamine, 0.5-1 part of polyacrylamide, 1-2 parts of hydroxyethyl cellulose, and 60-70 parts of water. The invention has advantages of easily available raw materials, low cost and simple preparation process; and the produced foaming agent has advantages of good stability, no deterioration, easiness for long-term preservation, prolonged shelf-life, good foaming power, good peaceability with various foam concrete substrates, no defoaming and unrestricted range of usage.

Owner:安徽艾柯泡塑股份有限公司

Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

ActiveCN105060830AHigh strengthImprove waterproof performanceSolid waste managementCement boardPhase change

The invention discloses a waterproof type phase-change heat storing plaster wallboard formed by reinforcing straw fibers. The plaster wallboard is compounded from the following raw materials in percentage by weight: 20-60% of plaster gelate materials, 10-25% of phase-change heat storing microcapsules, 1-7% of a composite water repellent, 25-55% of mineral micro powder, 0.1-0.6% of straw fibers, 0.8-1.5% of a binder, 1-5% of an exciting agent and 0.2-1.5% of a water reducing agent. The preparation method comprises the following steps of: 1) firstly, adding the plaster gelate materials, the mineral micro powder, the straw fibers and the exciting agent into a reaction kettle, adding water, and uniformly stirring the plaster gelate materials, the mineral micro powder, the straw fibers, the exciting agent and the water so as to obtain a material A; 2) sequentially adding the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent into the reaction kettle, and stirring the material A, the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent once again so as to obtain a material B; and 3) directly pouring the material B in the reaction kettle into a mold through a grouting pump so as to obtain the phase-change heat storing plaster wallboard, wherein a fiber cement board is arranged on the inner surface of the mold. The waterproof type phase-change heat storing plaster wallboard disclosed by the invention has the advantages of being suitable for operation under humid environment, simple in production technology and environment-friendly.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and preparation method thereof

ActiveCN103711211APrevent sinkingDoes not increase stirring mixing resistanceHeat proofingFire proofingThermal insulationAdhesive

The invention discloses a modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and a preparation method thereof. The modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board is prepared by using modified melamine formaldehyde as binder and polystyrene foaming particles as foaming thermal insulating materials under certain process conditions. The flame retardant thermal insulating board has the advantages that the combustion performance of the flame retardant thermal insulating board can reach level A, combustion, collapse and dripping can be prevented when the board is grilled by open fire, and the potential fire hazard of outer wall outer thermal insulation is eliminated; the board has excellent thermal insulation performance and mechanical strength; the board can be fixed on the outer building envelope structure by means of adhesives, fixing anchor bolts, hot galvanizing zinc wire mesh, and the like to perform thermal insulation.

Owner:SUZHOU INST OF BUILDING SCI GRP CO LTD

Waterproof crack-resistant foam concrete and manufacture method

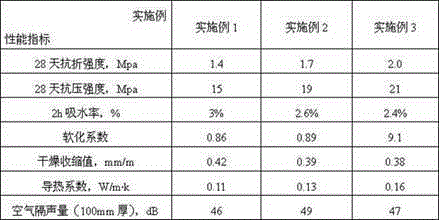

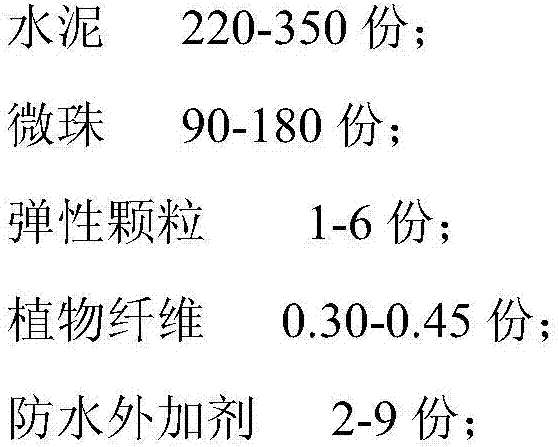

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Method for preparing baking-free bricks from high soil content construction waste

The invention belongs to the technical fields of environmental engineering and building materials, and in particular relates to a method for preparing baking-free bricks from high soil content construction waste. The method comprises the following steps of: uniformly mixing the construction waste, a mixture of one or more solid industrial solid wastes, a mixture of gypsum powder and lime powder, a mixture of one or more water-soluble solid alkali metal salt powders or aqueous solution thereof, and silicate-sintered clinker in a certain ratio, adding water to stir the materials, and putting the materials into a mold for vibrating molding compaction or pressurized molding compaction; and demolding after adobe maintenance or directly demolding. The method has the advantages of low content of cementing materials and flexible molding method, can fully utilize the construction waste, greatly reduces the cost, and has good economic benefits and social benefits.

Owner:广东新立晟环保科技股份有限公司

Inorganic efficient waterproof adiabatic building material and use thereof

The invention relates to an inorganic efficient waterproof adiabatic building material and use thereof. The building material comprises the following raw materials in percentage by weight: 20-60% of a binder, 0.1-5% of an auxiliary reinforcing material, 0.5-10% of a composite heat-insulating material, 1-10% of an anti-cracking heat-insulating material, 0.5-10% of a radiant heat-insulating material and 1-35% of inorganic mineral or oxides. The prepared inorganic efficient waterproof adiabatic building material has the advantages of low heat conductivity coefficient, tensile strength being not less than 400kpa, high compressive strength, Level A fireproof property, no combustion, high softening coefficient, strong weather resistance and waterproof and water-repellent functions and is applicable to heat-preservation, adiabatic, waterproof coating projects of building walls, basements and roof and the coating is used directly after being mixed with water.

Owner:张泽荣

Special powder water-proofing agent for gypsum

ActiveCN103922639AHigh softening coefficientImprove softening coefficient, with added amountMethyl palmoxirateMineralogy

The invention provides a special powder water-proofing agent for gypsum, which can obviously improve the hydrophobic property of a gypsum base material and is suitable for dry-mixed mortar. The powder water-proofing agent comprises the following components by weight percent: 15-30% of organic silicon polymer, 20-30% of kieselguhr, 30-50% of white carbon black and 5-10% of kaolin; the organic silicon polymer is one or few of methyl silicate, organic silane or organic siloxane, and the kieselguhr contains more than 90% of SiO2. According to the special powder water-proofing agent for gypsum, the organic silicon polymer is adsorbed by a porous high-purity silicon material, on the premise that the activity of the organic silicon polymer is guaranteed, the organic silicon polymer can be well dispersed and stored; the water-proofing agent has a simple formula, has wide source of feed, needs no complicated preparation technologies, can obviously improve the hydrophobicity of the gypsum material and the softening coefficient of the gypsum, has the advantages of small using amount and good water resistance, and is particularly suitable for the dry-mixed mortar of the gypsum base material.

Owner:广东龙湖科技股份有限公司

Active fracturing reagent for softening coal rock

ActiveCN101781553AHigh softening coefficientPrevent spontaneous combustionDrilling compositionSpontaneous combustionCoal dust

The invention discloses an active fracturing reagent for softening coal rock, which is a series of special active fracturing reagents for softening coal rock through mixing a new compound surfactant, and is formed by mixing anionic surfactant (alkylbenzene sulfonate), nonionic surfactant (alkylphenol ethoxylates or fatty alcohol polyoxyethylene ether), adducts (aliphatic alcohol and ethylene oxide condensate) of nonionic surfactant to form a novel compounded surfactant, and then mixing with potassium chloride, sodium sulphate and water in a definite ratio. The reagent provided by the invention can be applied to improving water-supplying efficiency, preventing the top-board coal layer striking, reducing coal layer hardness coefficient to a large extent, strengthening coal layer caving ability, improving resource mining rate, lowering coal dust, and preventing the spontaneous combustion of machine and the coal layer, etc.

Owner:XIAN UNIV OF SCI & TECH

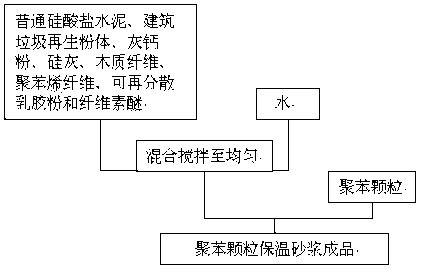

Polyphenylene granular thermal-insulation mortar

InactiveCN103242014ALow thermal conductivityStable heat retentionSolid waste managementFiberFreeze thawing

The invention discloses a polyphenylene granular thermal-insulation mortar. Construction waste regenerated powder is added as an inert filler into common thermal-insulation mortar. The polyphenylene granular thermal-insulation mortar comprises ordinary Portland cement, construction waste regenerated powder, sierozem powder, silica fume, polyphenylene granule, wood fiber, polystyrene fiber, redispersible latex powder and cellulose ether. The thermal-insulation mortar has the advantages of low heat conductivity coefficient, stable thermal-insulation properties, high softening coefficient, freeze-thawing resistance and aging resistance, and is suitable for thermal insulation of various walls.

Owner:北京建筑工程学院

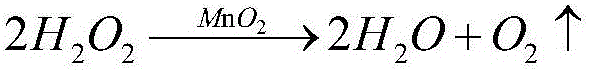

Hydrogen peroxide foamed phosphogypsum lightweight building block and preparation method thereof

InactiveCN105819888AEfficient use ofLightweight insulationSolid waste managementCeramicwareFiberPolymer science

The invention relates to a hydrogen peroxide foamed phosphogypsum lightweight building block and a preparation method thereof. The building block comprises the following components in parts by weight: 60 to 80 parts of high strength phosphogypsum, 10 to 30 parts of fly ash, 1 to 5 parts of quicklime, 1 to 5 parts of hydrogen peroxide, 2 to 8 parts of light aggregate, 2 to 8 parts of fiber, 0.5 to 2 parts of calcium stearate, 0.1 to 0.5 part of activator, 0.05 to 0.25 part of retarder, and 0.05 to 0.15 part of water-retaining agent. The building block and preparation method have the following advantages: (1) the building block is light and has a thermal insulation property, the dry density is 300-600 kg / m3, and the thermal conductivity is 0.1 W / (m.K); (2) the setting time is short, the early strength is high, the initial setting time is less than 100 minutes, and the compressive strength can reach at least 80% within 2 hours; (3) the softening coefficient is high and can reach 0.7 or more; (4) the preparation technology is simple, the industrial wastes are effectively utilized, and thus the preparation method is green and environment-friendly.

Owner:WUHAN UNIV OF TECH

Fireproofing, humid conserving boards for building, and preparation method

This invention relates to a method for preparing fireproof and heat-insulating board for architectures. The fireproof and heat-insulating board comprises aggregate and gel material at a weight ratio of (100-150):(100-250). The gel material comprises: light-burned MgO 46-56 wt.%, industrial MgCl2 20-26 wt.%, H2O2 1.5-3.5 wt.%, H3PO4 0.2-0.3 wt.%, HBO3 0.2-0.3 wt.%, and water 20-26 wt.%. The method comprises: (1) screening foam glass (particle sizes are 15-35 mm, and density is 160-180 kg / m3), and placing in a mold; (2) adding industrial MgCl2 and water; (3) adding H3PO4 and HBO3, and stirring uniformly; (4) adding light-burned MgO, stirring uniformly, and adding H2O2 during stirring to obtain a gel material; (5) pouring the gel material into a mold; (6) covering the lid, and curing naturally; (7) demolding, and maintaining. The fireproof and heat-insulating board has such advantages as low weight, high strength, high impact resistance, no deformation, good heat, sound, fire and water resistance, and good processability.

Owner:上海永丽节能墙体材料有限公司

Autoclaved aerated concrete plate repairing agent

InactiveCN104926258AIncrease late strengthRealize comprehensive utilizationSolid waste managementFiberBuilding product

The invention discloses an autoclaved aerated concrete plate repairing agent and belongs to the technical field of building materials. The autoclaved aerated concrete plate repairing agent is composed of, by mass, 40-60% of coal ash, 10-30% of gypsum, 5-15% of cement, 10-30% of sand, 0.01-2.0% of fiber, 0.01-1.05 of water retaining agent and 0.01-1.5% of setting retarder. The coal ash is coal ash for silicate building products meeting JC / T, the gypsum is semi-hydrated gypsum, and the cement is universal silicate cement meeting GB. By the autoclaved aerated concrete plate repairing agent, the problem that an existing repairing agent and an autoclaved aerated concrete plate have chromatic aberration and are low in binding strength and long in setting time.

Owner:SHANDONG TIANYU WALL MATERIAL

Concrete foaming agent and preparation method thereof

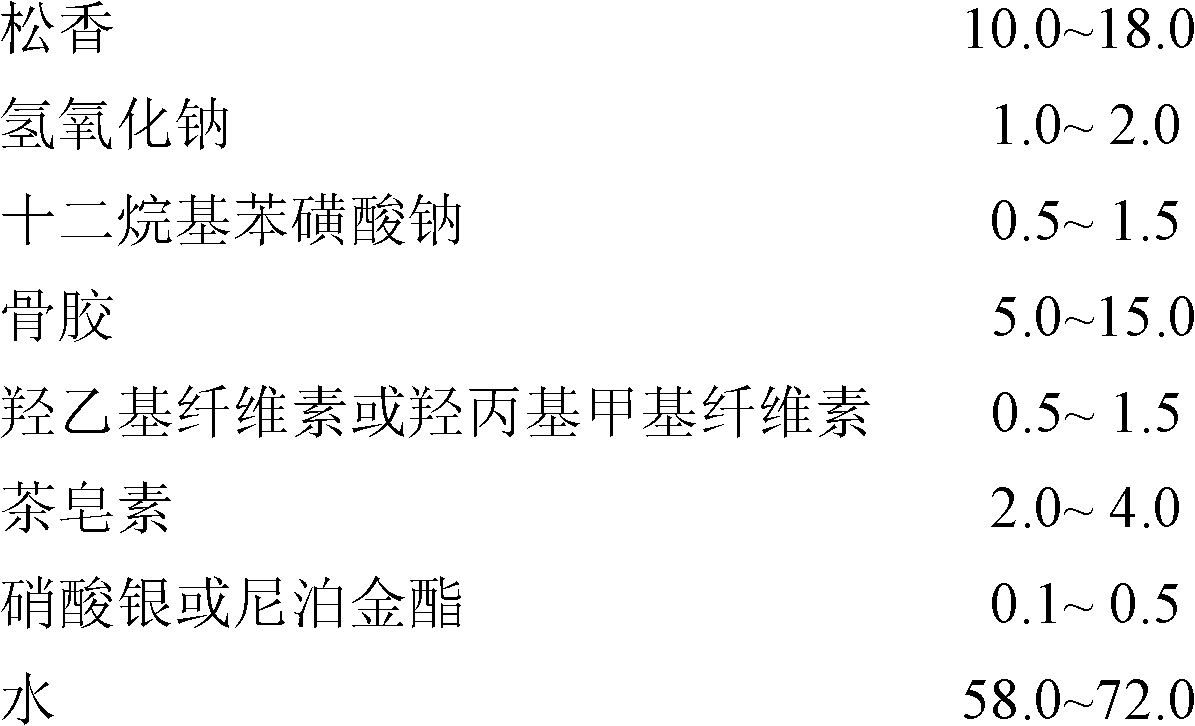

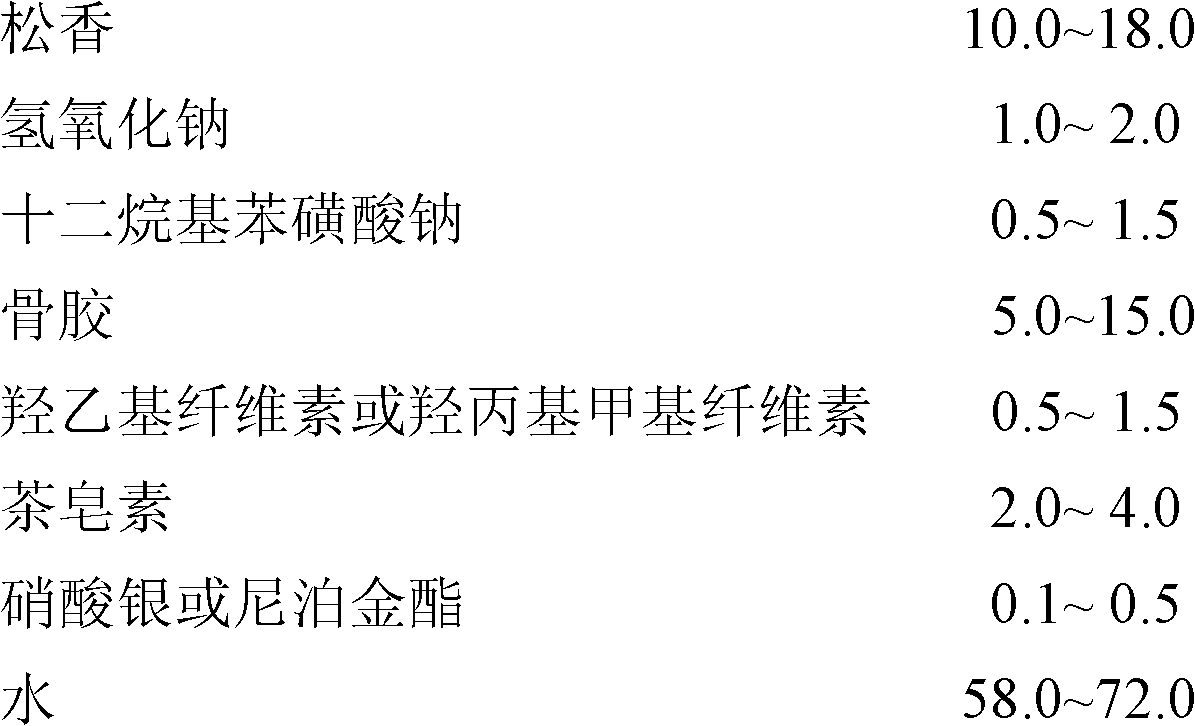

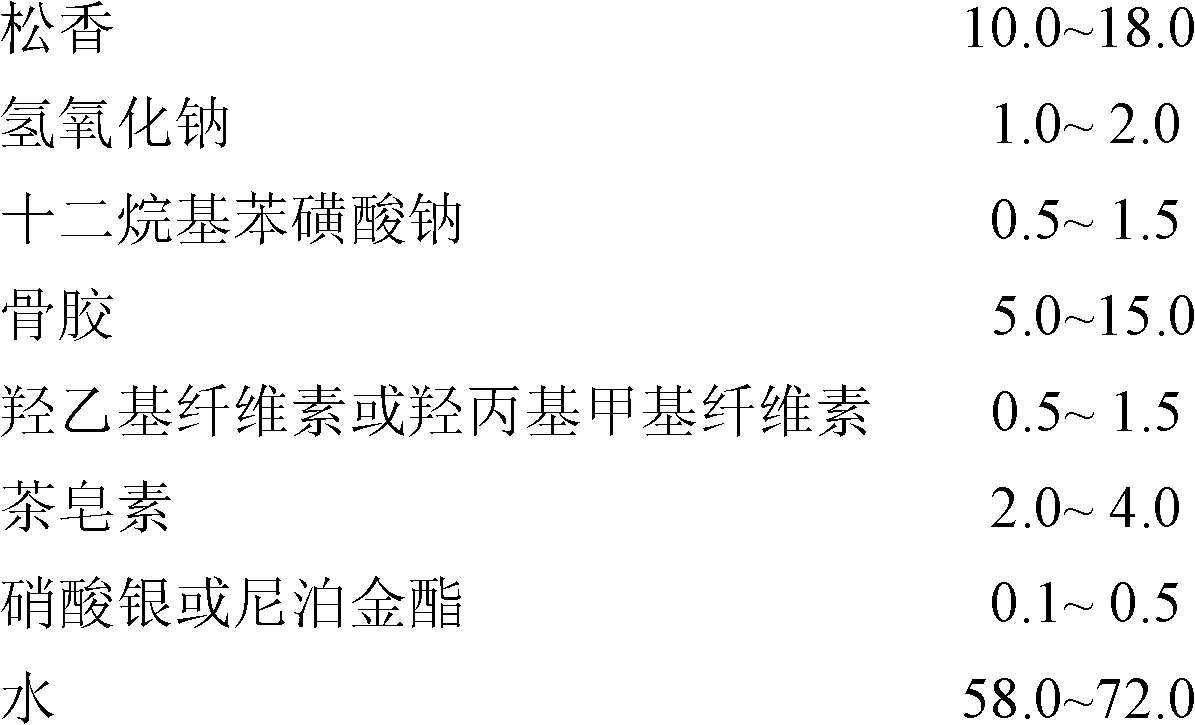

The invention relates to a concrete foaming agent and a preparation method thereof. The concrete foaming agent comprises raw materials in mix proportion by mass: 10.0-18.0 of colophony, 1.0-2.0 of sodium hydroxide, 0.5-1.5 of sodium dodecyl benzene sulfonate, 5.0-15.0 of bone glue, 0.5-1.5 of ethoxyl or hydroxypropyl methylcellulose, 2.0-4.0 of tea saponin, 0.1-0.5 silver nitrate or paraben and 58.0-72.0 of water. During preparation, the preparation method comprises the steps of: soaking the bone glue in water for 24-48h; adding the colophony and the sodium hydroxide while stirring; hydrolyzing for 3-5h under the temperature of 80-100 DEG C; standing for 10min; filtering, wherein the ethoxyl or hydroxypropyl methylcellulose, the tea saponin, the silver nitrate or the paraben are added in a filtrate under the temperature of 80-100 DEG C; and completing after dissolving and cooling down. The concrete foaming agent and the preparation method thereof have the advantages of simple process,low cost, good placeability with various foamed concrete-based materials, no defoaming and unlimited application range.

Owner:梁材

Non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste with high water resistance

The invention discloses a non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste with high water resistance. 100 parts of the non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste comprise, by weight, 65 to 70 parts of cement, 2 to 10 parts of fly ash, 8 to 10 parts of a high activity mineral admixture, 5 to 10 parts of an alkali activator, 3 to 5 parts of a sulfate activator, 2 to 4 parts of a redispersible latex powder, 0.5 to 1 part of modified cellulose ether, 0.3 to 0.7 part of a high efficiency water reducing agent, 0.02 to 0.05 part of an accessory ingredient with drop resistance, 0.3 to 0.5 part of fiber, 0.3 to 0.5 part of a stearate water repellent, 0.5 to 1 part of a silylation water repellent, 0.01 to 0.02 part of an air entraining agent, and 4.5 to 5 parts of a B1-grade native-level polyphenyl granule. The non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste is low in heat conductivity coefficient, high in thermal insulation performance, high in compression strength, low in volume water absorption rate, high in softening coefficient, and high in fire-protection rating.

Owner:BEIJING YUEZHU XINTIAN ENERGY SAVING TECH

Fireproof heat-insulated board with inorganic light aggregates and preparation method thereof

ActiveCN102731050AImprove hydrophobicityHigh softening coefficientConstruction aggregateExterior insulation finishing system

The invention discloses a fireproof heat-insulated board with inorganic light aggregates and a preparation method thereof. The fireproof heat-insulated board is prepared by mixing 100 parts of the inorganic light aggregates, 5-15 parts of modified inorganic polymer powder, 0.1-0.3 parts of organic silicon water repellent, 0.5-1 part of a curing agent and 80-120 parts of water, and carrying out compression moulding and curing on a mixture. The fireproof heat-insulated board provided by the invention reaches the need of the incombustible-type (Grade A) uniform fireproof heat-insulated material, wherein the thermal conductivity of the fireproof heat-insulated board is smaller than or equal to 0.07W / m.k; the stability of the fireproof heat-insulated board is lasting; the mechanical strength and hydrophobicity of the fireproof heat-insulated board are excellent; the softening coefficient of the fireproof heat-insulated board is high; the workability of the fireproof heat-insulated board is good; and, the toughness of the fireproof heat-insulated board is good. The fireproof heat-insulated board can be prepared into large-sized board materials and can be also convenient to anchor without cracks, and has remarkable advantages in the toughness and durability compared with the similar inorganic heat-insulated boards. The preparation process provided by the invention is simple; the moulded board is cured only at a low temperature between 150 DEG C and 220 DEG C without the high-temperature thermal treatment or sintering; and, the comprehensive cost performance is high. The outer wall heat-insulated system made of the fireproof heat-insulated boards is convenient to construct, is stable in quality, saves energy and is fireproof, and the service life of the outer wall heat-insulated system is as long as the buildings. The application prospects of the fireproof heat-insulated board and the preparation method provided by the method are wide.

Owner:ZHENGZHOU UNIV

Paraffin phase changed thermal mortar powder and preparing method thereof

A mortar powder containing paraffin wax for phase-change insulating is prepared from cement, light aggregate, fibres and paraffin wax through fusing paraffin wax or preparing the microcrystal powder of paraffin wax, and proportionally mixing it with others. Its advantages are low hydroscopicity and high water-proof performance and softening coefficient.

Owner:北京振利高新技术有限公司

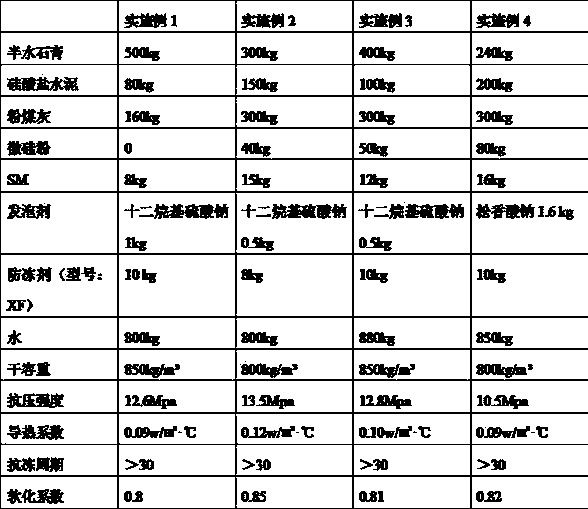

Composite-based self-heat-insulation building block and preparation method thereof

InactiveCN103553532AReduce intensityHigh strengthSolid waste managementCeramicwareFoaming agentCompressive strength

The invention relates to a composite-based self-heat-insulation building block. The composite-based self-heat-insulation building block comprises the following components in parts by weight: 240 to 500 parts of semi-hydrated gypsum, 80 to 200 parts of silicate cement, 160 to 300 parts of coal ash, 8 to 16 parts of a high-efficiency water reducing agent SM, and 0.5 to 1.6 parts of foaming agent. The composite-base self-heat-insulation building block is prepared by adding the high-efficiency water reducing agent SM and the foaming agent into 800 to 880 parts of water to obtain a mixture; adding the semi-hydrated gypsum, the silicate cement and the coal ash into the mixture; stirring the mixture, casting and molding to harden the mixture; drying or naturally curing to obtain the composite-based self-heat-insulation building block. The prepared composite-based self-heat-insulation building block has light weight, high compressive strength, a good heat insulation effect, high water resistance and a high softening coefficient, and is an excellent material for an energy-saving wall body of a building.

Owner:CHANGSHA YUKANG BUILDING MATERIAL TECH

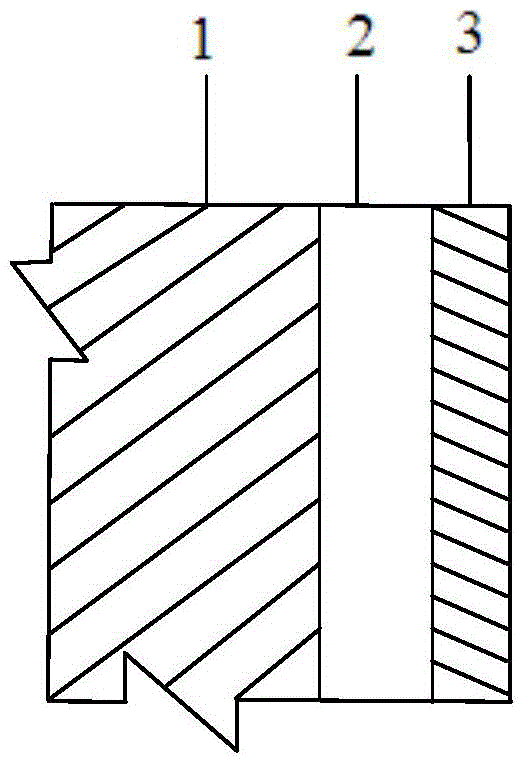

Environmental-friendly light partition board produced by waste ardealite

The invention relates to an environmental-friendly light partition board produced by waste ardealite and belongs to the techniques of building materials. The partition board comprises an inner interlayer and two outer layers, wherein the inner interlayer is made of polystyrene heat-insulation heat-preservation board, the two outer layers are arranged outside the two surfaces of the inner interlayer, non-woven fabrics are arranged between the outer layers and the inner layer, and the outer layers are made from the following raw materials according to parts by weight: 90 parts of ardealite, 10 parts of magnesium oxide, 35-40 parts of magnesium chloride, 30-35 parts of industrial coal ash, 20-25 parts of crushed crude pearlite, 14-20 parts of kieselguhr, 14-20 parts of saw timber powder and 20-25 parts of magnesite binding materials. The ardealite is waste generated in production process of phosphatic fertilizer enterprises. According to the environmental-friendly light partition board produced by the waste ardealite, the light partition board is free of toxin, odor and radioactivity, and has the characteristics of shock resistance, large compressive strength, heat insulation, fire protection, good sound insulation effect, water resistance, damp proof, and convenience in construction; the light partition board is mounted by plates or in a combined manner, has the characteristics of capabilities in nailing, sawing, digging, adhering, pasting and the like and is flat and unnecessary to be plastered, and the puttying can be directly carried out.

Owner:KUNMING SHANJIE BUILDING MATERIAL MFG

Method for improving performance of gypsum powder

A method for improving the performance of gypsum powder belongs to the field of gypsum powder application, and comprises the following steps: 1, selecting a coating agent capable of tightly combiningwith gypsum crystal; 2, adding a liquid coating agent to the gypsum powder; and 3, sending the gypsum powder into which the liquid coating agent is added to a coating device for coating. The method has the characteristics of greatly improving the strength, water resistance and the like of the gypsum powder.

Owner:ZHENGZHOU SUNDY BUILDING TECH

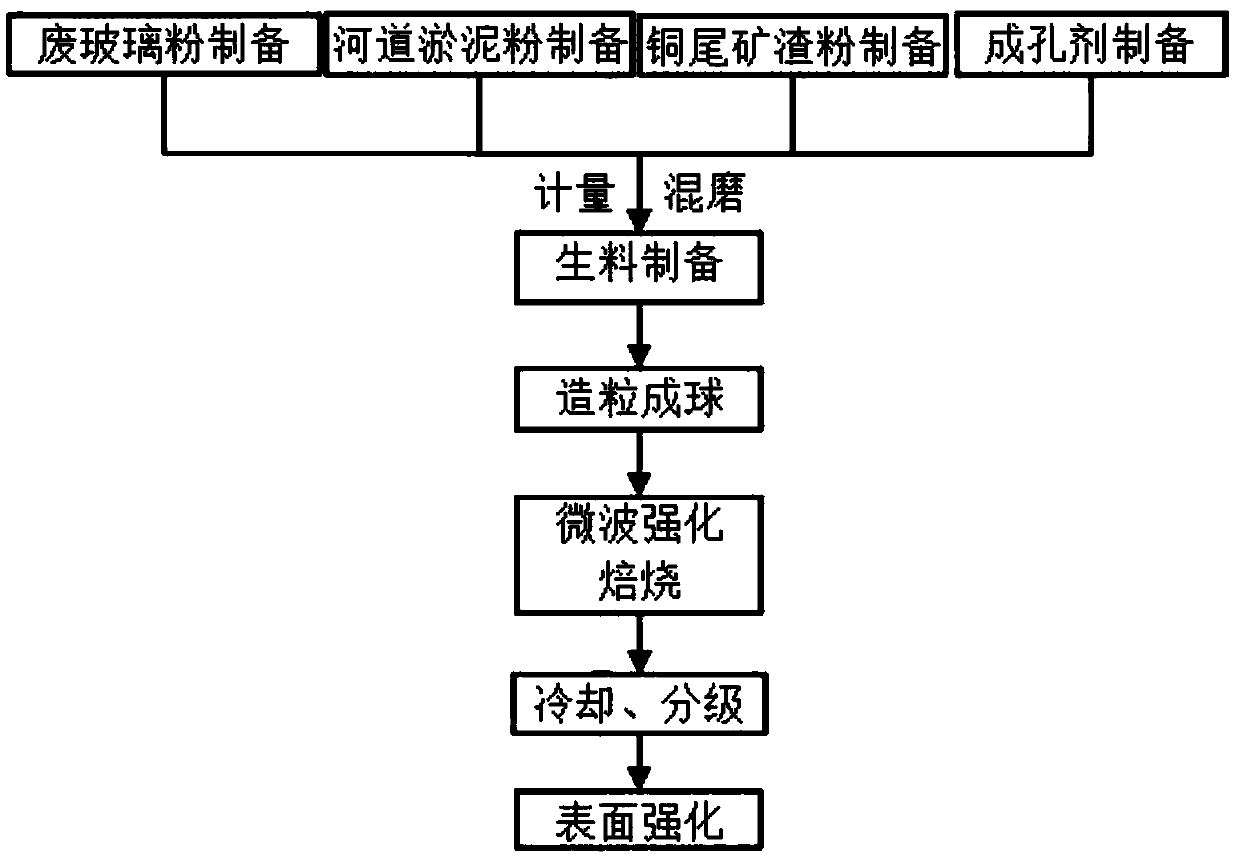

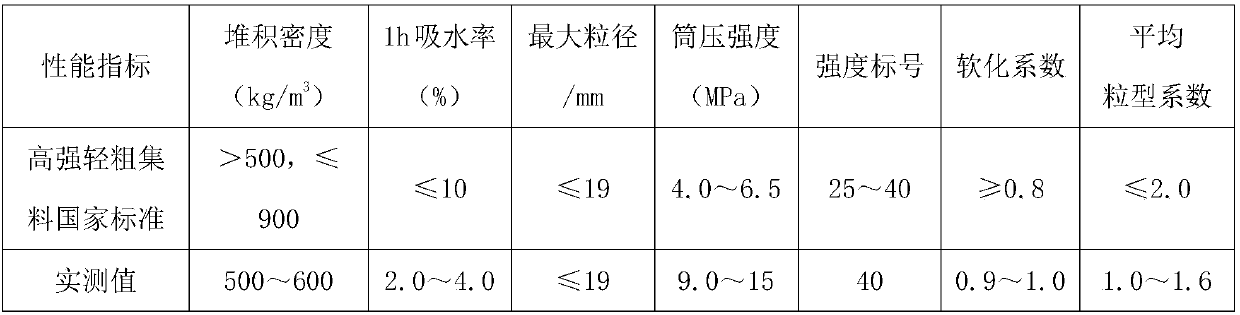

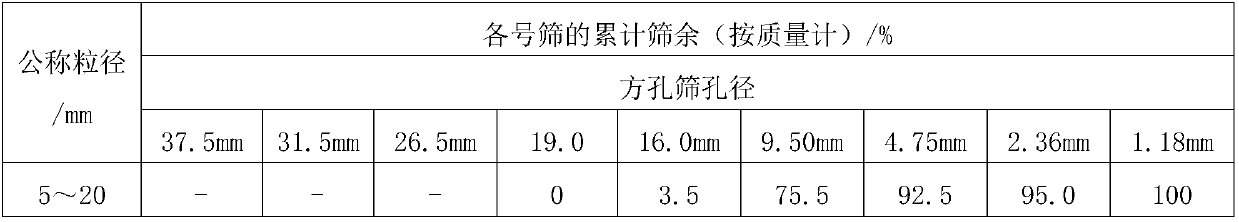

Light-weight high-intensity waste glass ceramsite and preparation method thereof

The invention provides light-weight high-intensity waste glass ceramsite and a preparation method thereof. The light-weight high-intensity waste glass ceramsite is characterized by being prepared fromthe following raw material ingredients in parts by weight: 70 to 80 parts of waste glass powder, 15 to 25 parts of riverway silt powder, 4 to 6 parts of copper tailing powder and 1 to 2 parts of pore-forming agents. The preparation method comprises the following steps of (1) raw material preparation; (2) granulation balling; (3) microwave reinforced roasting; (4) surface reinforcing. Waste such as waste glass is used as main raw materials; the raw materials are subjected to mixing, pelleting, roasting and surface reinforcement; finally, the ceramsite with light weight and high intensity is prepared; the porosity is high; the weight is light; the tube pressure intensity is high; the softening coefficient is great; high water resistance, low water absorption rate and good particle shape arerealized; the prepared light aggregate concrete has good durability. The problem that the waste glass and the like are difficult to dispose can be effectively solved; waste materials are changed intovaluable materials; the ecological environment can be protected; in addition, the raw material resources are rich; the cost is low; the process is simple.

Owner:EAST CHINA JIAOTONG UNIVERSITY

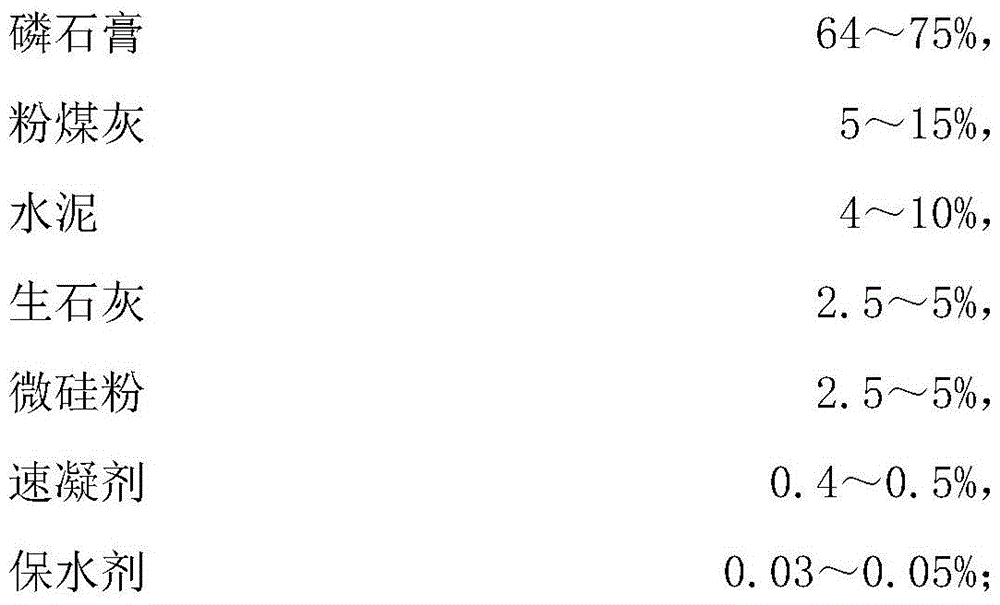

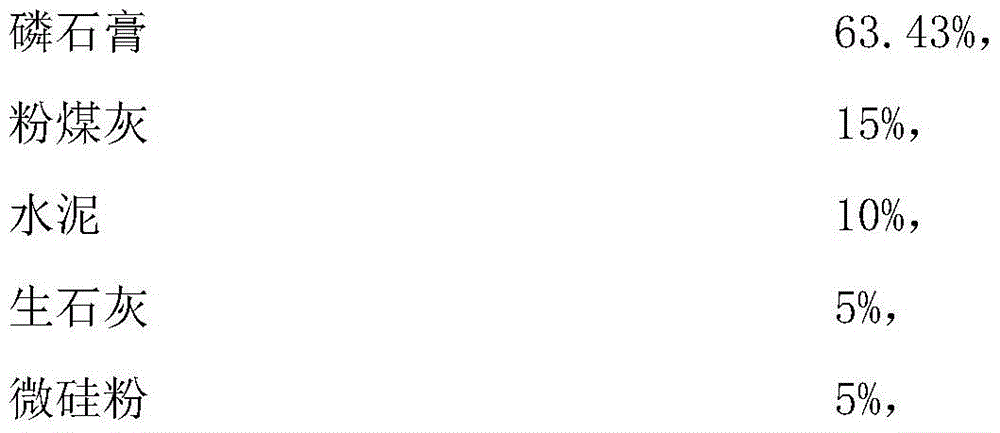

Phosphogypsum-based grouting material for filling solution cavity of mine

The invention discloses a phosphogypsum-based grouting material for filling a solution cavity of a mine. The grouting material is prepared from a powder material and a liquid material, wherein, calculated by the total weight, in percentage by weight, of the grouting material, the powder material is prepared from 65 to 75 percent of phosphogypsum, 5 to 15 percent of pulverized fuel ash, 4 to 10 percent of cement, 2.5 to 5 percent of unslaked lime, 2.5 to 5 percent of micro silica fume, 0.4 to 0.5 percent of setting accelerator sodium aluminate and 0.03 to 0.05 percent of water-retaining agent methyl cellulose ether, and the liquid material is prepared from 0.8 to 1.1 percent of polycarboxylate superplasticizer and 0.03 to 0.05 percent of early strength agent triethanolamine. The phosphogypsum-based grouting material for filling the solution cavity of the mine can be directly used for filing and grouting a solution cavity of an abandoned mine shaft, and has the characteristics of high fluidity, good workability, acid resistance, erosion resistance, higher later strength and the like.

Owner:五矿二十三冶建设集团有限公司

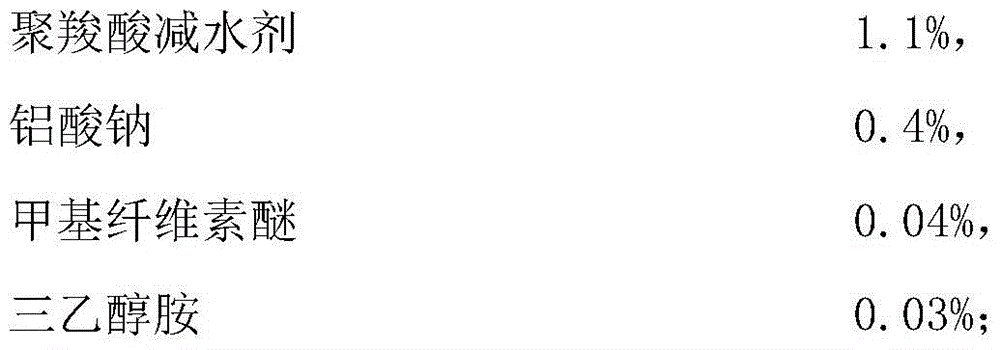

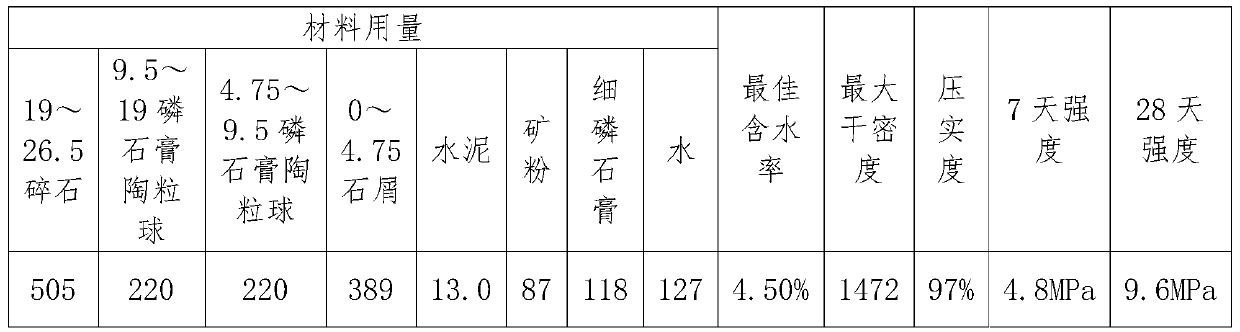

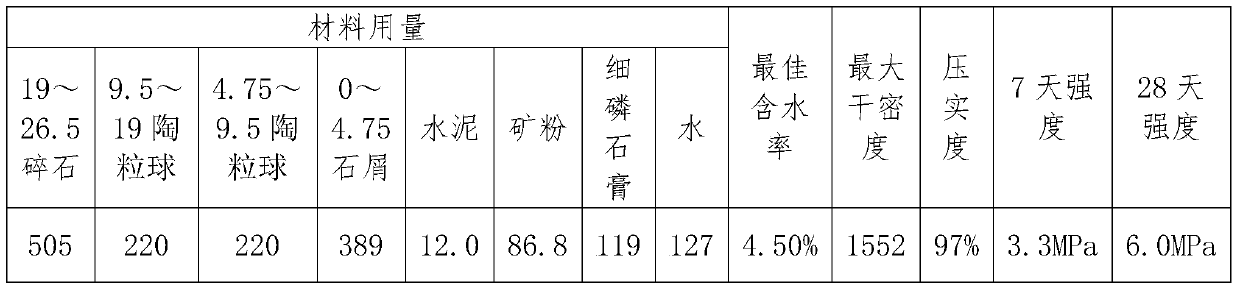

Phosphogypsum ceramsite ball and spherical and gravel type phosphogypsum ceramsite ball light aggregate water stable layer

The invention provides a phosphogypsum ceramsite ball. The phosphogypsum ceramsite ball comprises a phosphogypsum core, an oversulfated phosphogypsum layer wrapping the phosphogypsum core, and a cement layer wrapping the oversulfated phosphogypsum layer. The phosphogypsum core is formed by granulating original phosphogypsum, calcium oxide, cement clinker, mineral powder and residual slurry of theelectric pole, and the over-sulfur phosphogypsum layer is formed by mixing fine phosphogypsum, slag and cement clinker. Meanwhile, the invention further provides two kinds of water stable layers obtained by applying the phosphogypsum ceramsite ball, the 7-day unconfined compressive strength can reach 3-4.8 MPa, and the phosphogypsum ceramsite ball can be used for base structures of heavy traffic in expressways and first-grade highways.

Owner:HUBEI CHANG YAOXIN MATERIALS LIMITED BY SHARE

Nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes and processing method thereof

InactiveCN103113074AFix instabilitySolve the problem of high f-CaO content in itSolid waste managementBrickSlag

The invention provides a nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes and a processing method thereof. The problems that a lot of the conventional steel slag is stacked, lots of lands are occupied and the environment is polluted are solved. The nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes comprises the following components in parts by weight: 40-60 parts of converter slag, 20-30 parts of mill tailings powder, 5-10 parts of coal ash and 10-20 parts of inorganic gelatinization material. The method is used for manufacturing the nonbearing concrete hollow brick by utilizing industrial solid wastes.

Owner:南京梅山海强新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com