Concrete foaming agent and preparation method thereof

A technology of foaming agent and concrete, which is applied in the field of building materials, can solve the problems of easy deterioration during long-term storage and transportation, the deterioration of protein foaming agent can not be used, the easy softening of protein material pH value and other problems, so as to reduce the investment in fixed assets , The scope of use is not limited, the effect of improving strength and softening coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

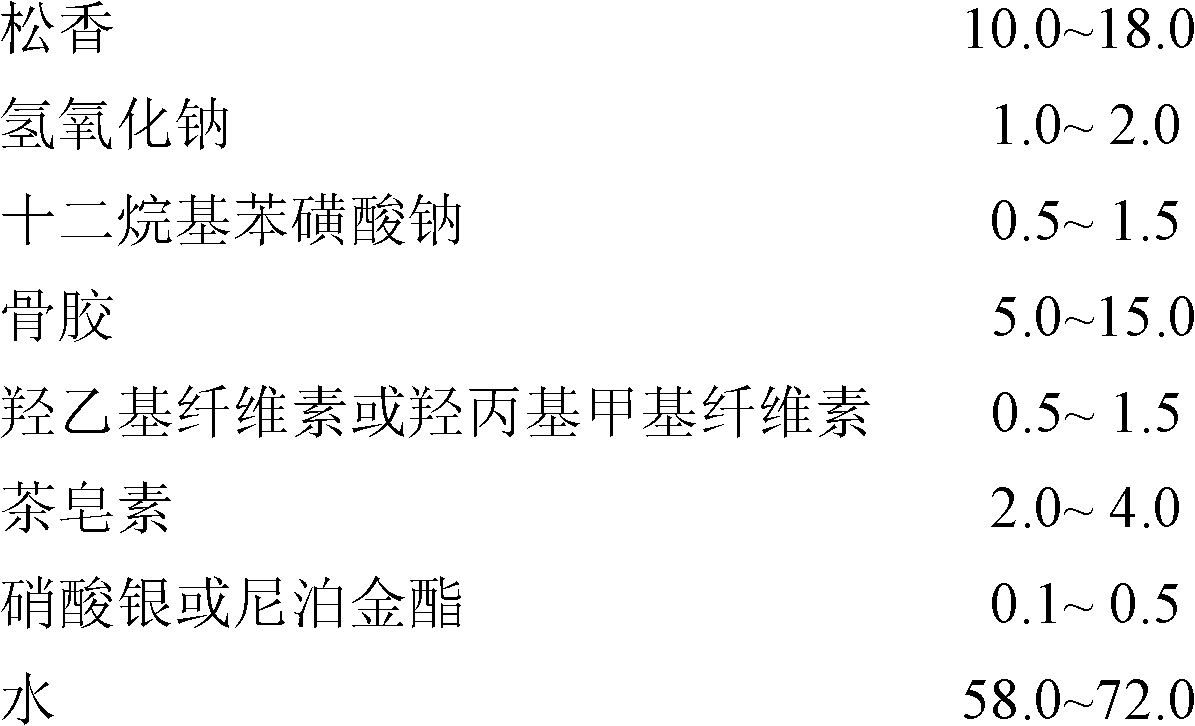

[0018] Raw material mass ratio (Kg): rosin 10.0, sodium hydroxide 1.2, sodium dodecylbenzene sulfonate 0.5, bone glue 5.0, hydroxyethyl cellulose 1.3, tea saponin 2.0, silver nitrate 0.1, water 50.

[0019] First add bone glue to water and soak for 24 hours, add rosin and sodium hydroxide in turn under stirring, heat at 80-100°C for 3 hours, stop heating, let stand for 10 minutes, filter the hydrolyzed solution, and continue heating the filtrate to 80-100°C , while stirring continuously, add hydroxyethyl cellulose (HEC), tea saponin, and silver nitrate sequentially, and cool down after dissolution to obtain a brown liquid product with a density of 1.1-1.2Kg / L. The product and water can be mixed in any proportion, and it will not delaminate or deteriorate after being stored for half a year.

Embodiment 2

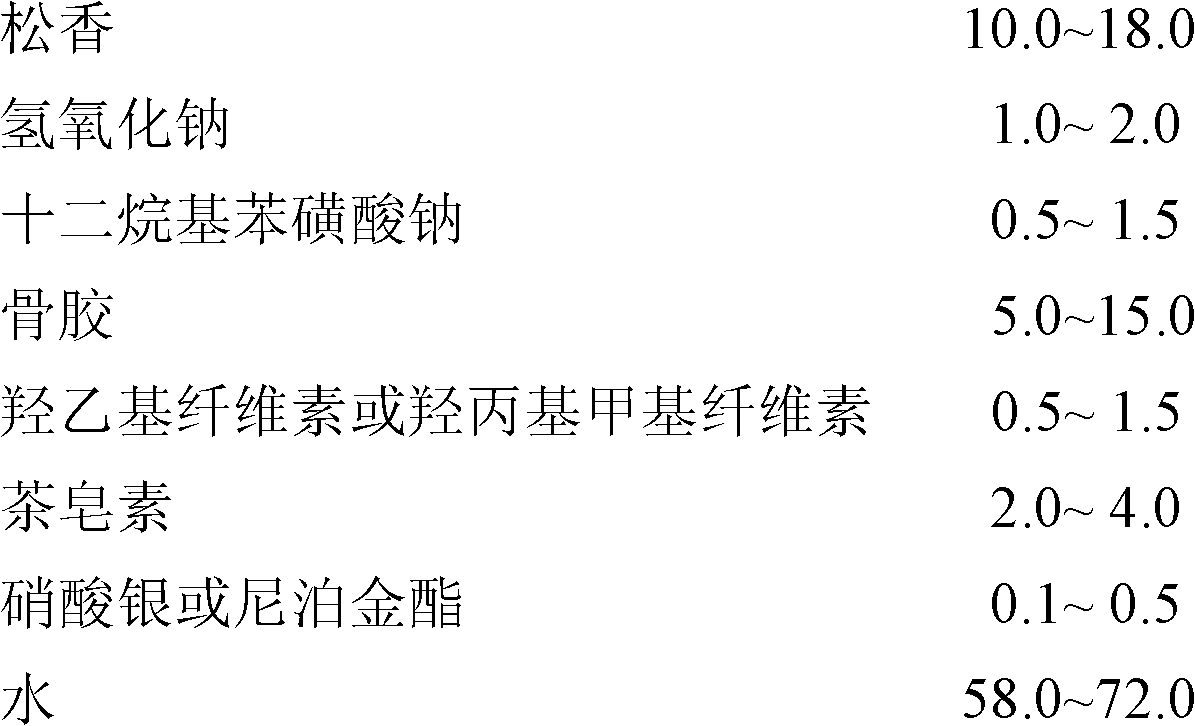

[0021] Raw material mass ratio (Kg): rosin 12.0, sodium hydroxide 1.4, sodium dodecylbenzenesulfonate 0.7, bone glue 7.0, hydroxyethyl cellulose 1.1, tea saponin 2.5, ethylparaben 0.1, water 55.0 .

[0022] First add bone glue to water and soak for 24 hours, then add rosin and sodium hydroxide in sequence under stirring, heat at 80-100°C for 5 hours, stop heating, let stand for 10 minutes, filter the hydrolyzed solution, and continue heating the filtrate to 80-100°C , and then add hydroxyethyl cellulose (HEC), tea saponin, silver nitrate or butylparaben in turn under the condition of constant stirring, after dissolving, cool down to get a brown liquid product, density: 1.2-1.3Kg / L . The product and water can be mixed in any proportion and stored for three months without stratification or deterioration.

Embodiment 3

[0024] Raw material mass ratio (Kg): rosin 15.0, sodium hydroxide 1.7, sodium dodecylbenzene sulfonate 1.0, bone glue 10.0, hydroxypropyl methylcellulose 1.0, tea saponin 3.0, propylparaben 0.3, Water 62.0.

[0025] First add bone glue to water and soak for 24 hours, add rosin and sodium hydroxide in turn under stirring, heat at 80-100°C for 4 hours, stop heating, let stand for 10 minutes, filter the hydrolyzed solution, and continue heating the filtrate to 80-100°C , while stirring continuously, add hydroxypropyl methylcellulose (HPMC), tea saponin, and propylparaben sequentially. After dissolving, cool down to obtain a brown liquid product with a density of 1.3-1.4Kg / L. The product and water can be mixed in any proportion and stored for 8 months without delamination or deterioration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com