Inorganic thermal insulation light mortar and construction method thereof

A technology of inorganic heat preservation and construction method, which is applied in the direction of construction, building structure, and building material processing, etc., to achieve good waterproof performance, low water absorption, and avoid environmental pollution and fire hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

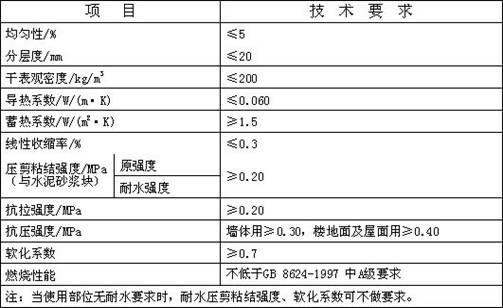

[0027] Embodiment 1 thermal insulation type mortar

[0028] The raw material composition of mortar is:

[0029] 1. Density 80kg / m 3 Grade closed-cell expanded perlite 55%;

[0030] 2. CSA special gelling material (mixed with hydraulic materials and active fillers) 20%

[0031] 3. 80 mesh burnt gypsum (air hardening material): 12%;

[0032]4. 60 mesh (L / D28) acicular wollastonite powder: 8%;

[0033] 5. The total amount of admixture: 5.0%;

[0034] in:

[0035] Hydroxyethyl methylcellulose (HEMC): 0.8%;

[0036] Redispersible rubber powder: 1.3%;

[0037] Magnesium stearate waterproofing agent: 1.7%;

[0038] NNO air-entraining agent (sodium methylene bis-tetrasulfonate): 1.2%

[0039] Among them, the preparation method of CSA special cementitious material is: CAS clinker = 18% and gypsum = 6% (both belong to hydraulic materials); active filling material triple powder (copper ore powder 1: gold ore powder 1: sea Ash discharge 1) = 76%; co-grinding until the specific s...

Embodiment 2

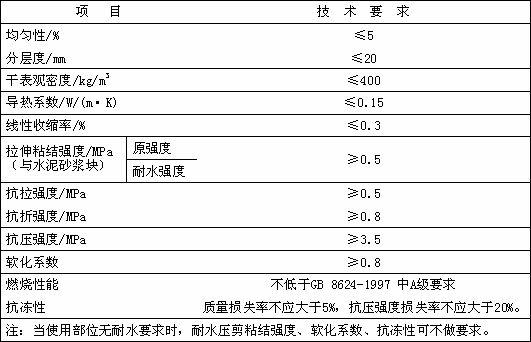

[0044] Example 2 Anti-crack decorative type

[0045] The raw material composition of mortar is:

[0046] 1. Density 100kg / m 3 Grade closed-cell expanded perlite: 45%;

[0047] 2. CSA special gelling material (mixed with hydraulic materials and active fillers) 15%;

[0048] 3. 80 mesh burnt gypsum (air hardening material): 12%;

[0049] 4. 60 mesh (L / D28) acicular wollastonite powder: 8%;

[0050] 5. Color mineral powder 12%;

[0051] 6. The total amount of admixture: 8%;

[0052] in:

[0053] Hydroxyethyl methylcellulose (HEMC): 1.3%;

[0054] Redispersible rubber powder 1.8%;

[0055] Silane composite waterproofing agent 2.2%;

[0056] EE44 epoxy emulsion (adhesive) 2.7%.

[0057] Performance index of anti-crack decorative mortar

[0058]

[0059] The construction method of anti-crack decorative mortar is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com