Hydrogen peroxide foamed phosphogypsum lightweight building block and preparation method thereof

A technology of hydrogen peroxide and phosphogypsum, which is applied in the field of building materials, can solve the problems of complex preparation process, high foaming cost, and low strength, and achieve the effects of simple preparation process, fast setting time and high softening coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A hydrogen peroxide foamed phosphogypsum lightweight building block and a preparation method thereof, the components and parts by weight of which include:

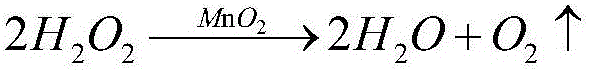

[0028] 70 parts of high-strength phosphorus gypsum, 20 parts of primary fly ash, 2 parts of quicklime, 2 parts of hydrogen peroxide, 4 parts of vitrified microspheres, 4 parts of polypropylene fiber, 0.5 parts of calcium stearate, MnO 2 0.2 parts, 0.25 parts of sodium citrate, and 0.1 parts of carboxymethyl cellulose ether.

[0029] The preparation method is as follows: (1) Weighing, dry mixing, weighing phosphorus high-strength gypsum, first-grade fly ash, quicklime, vitrified microbeads, polypropylene fiber, calcium stearate, MnO 2 , sodium citrate, hydroxypropyl methyl cellulose ether, dry mix in a mixer for 25s to disperse the materials evenly; (2) add water and stir, add water according to the water-cement ratio 0.37, stir quickly for 2min, slowly stir for 1min, and let stand for 25s (3) Foaming with hydrogen ...

Embodiment 2

[0032] A hydrogen peroxide foamed phosphogypsum lightweight building block and a preparation method thereof, the components and parts by weight of which include:

[0033] 68 parts of phosphorus high-strength gypsum, 20 parts of secondary fly ash, 2 parts of quicklime, 3 parts of hydrogen peroxide, 5 parts of vitrified microspheres, 5 parts of polypropylene fiber, 1.0 parts of calcium stearate, MnO 2 0.35 parts, 0.1 parts of citric acid, 0.15 parts of sodium citrate, and 0.05 parts of hydroxypropyl methylcellulose ether.

[0034]The preparation method is as follows: (1) Weighing and dry mixing, weighing high-strength phosphorus gypsum, 20 parts of secondary fly ash, quicklime, vitrified beads, polypropylene fiber, MnO 2 , calcium stearate, citric acid, sodium citrate, hydroxypropyl methyl cellulose ether, dry mix in a mixer for 35s to disperse the material evenly; (2) add water and stir, add water according to the water-cement ratio 0.38, and stir quickly for 2 minutes , stirr...

Embodiment 3

[0036] A hydrogen peroxide foamed phosphogypsum lightweight building block and a preparation method thereof, the components and parts by weight of which include:

[0037] 75 parts of high-strength phosphorus gypsum, 5 parts of primary fly ash, 9 parts of secondary fly ash, 3 parts of quicklime, 4 parts of hydrogen peroxide, 4 parts of vitrified microbeads, 4 parts of polypropylene fiber, 1.0 part of calcium stearate, MnO 2 0.45 parts, SC retarder 0.1 part, hydroxypropyl methylcellulose ether 0.1 part

[0038] The preparation method is: (1) Weighing, dry mixing, weighing phosphorus high-strength gypsum, first-grade fly ash, second-grade fly ash, quicklime, vitrified microbeads, polypropylene fiber, MnO 2 , calcium stearate, SC retarder, hydroxypropyl methyl cellulose ether, dry mix in a mixer for 30s to disperse the material evenly; (2) add water and stir, add water according to the water-cement ratio 0.37, stir quickly for 2min, slowly Stir for 1 min and let stand for 30 s; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com