Phosphogypsum-based grouting material for filling solution cavity of mine

A grouting material and phosphogypsum technology, applied in the field of grouting material and mine karst cave filling grouting material, can solve the problems of reducing efficiency, increasing the economic cost of phosphogypsum-based grouting material, restricting the use range of phosphogypsum, and achieving high mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

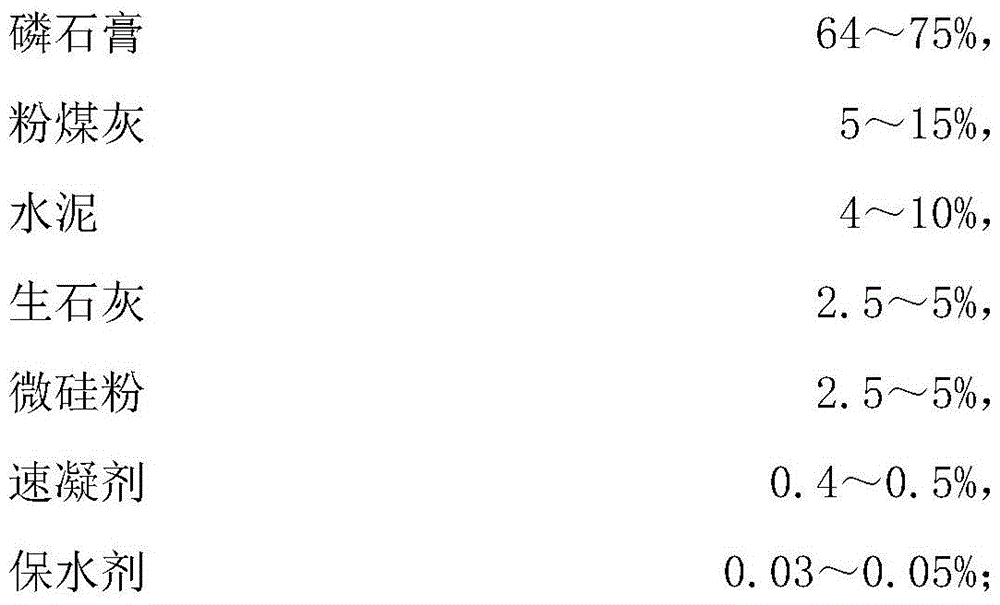

[0028] Each component and weight percentage thereof are in the present embodiment:

[0029]

[0030]

[0031] Phosphogypsum, fly ash, Portland cement, quicklime, microsilica, sodium aluminate, and methyl cellulose ether in the above components are prepared according to the aforementioned process to obtain grouting material powder. Add tap water of 0.20% powder quality, and add the early strength agent (triethanolamine) and water reducer (polycarboxylate water reducer) of the above ratio into the water, and stir for 3 minutes to obtain a flowable slurry. Its initial fluidity reaches 320mm, and it reaches final setting in 200 minutes. Its 7d strength is 14MPa, 14d strength is 18MPa, 28d strength is 21MPa, and the softening coefficient is 0.71.

Embodiment 2

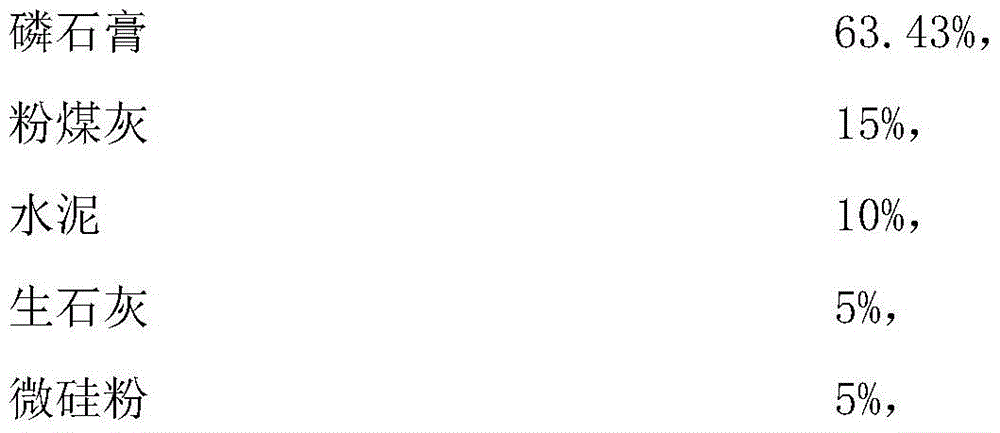

[0033] Each component and weight percentage thereof are in the present embodiment:

[0034]

[0035] Phosphogypsum, fly ash, Portland cement, quicklime, microsilica, sodium aluminate, and methyl cellulose ether in the above components are prepared according to the aforementioned process to obtain grouting material powder. Add tap water of 0.22% powder quality, and add the early strengthening agent (triethanolamine) and water reducer (polycarboxylate water reducer) of the above ratio into the water, and stir for 3 minutes to obtain a flowable slurry. Its initial fluidity reaches 280mm, and it reaches final setting in 180 minutes. Its 7d strength is 10MPa, 14d strength is 13MPa, 28d strength is 17MPa, and the softening coefficient is 0.70.

Embodiment 3

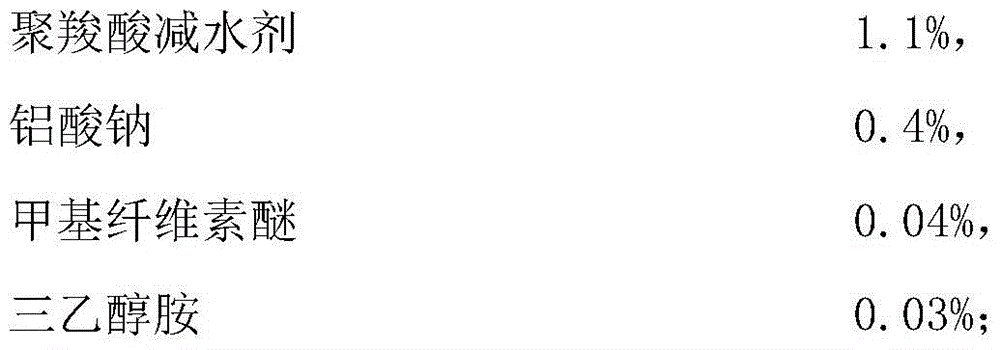

[0037] Each component and weight percentage thereof are in the present embodiment:

[0038]

[0039]

[0040] Phosphogypsum, fly ash, Portland cement, quicklime, microsilica, sodium aluminate, and methyl cellulose ether in the above components are prepared according to the aforementioned process to obtain grouting material powder. Add tap water of 0.21% powder mass, and add the above-mentioned ratio of early strengthening agent (triethanolamine) and water reducer (polycarboxylate water reducer) into the water, and stir for 2 minutes to obtain a flowable slurry. Its initial fluidity reaches 300mm, the final setting time is 160min, its strength at 7d is 11MPa, its strength at 14d is 14MPa, its strength at 28d is 20MPa, and its softening coefficient is 0.74.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com