Light-weight high-intensity waste glass ceramsite and preparation method thereof

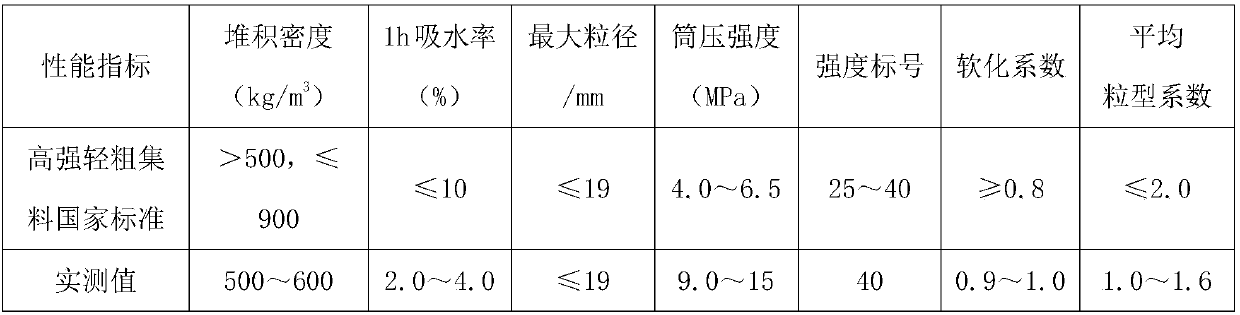

A technology of waste glass and waste glass powder, which is applied in the field of building materials, can solve the problems of low strength, high firing temperature, and poor water resistance of ceramsite, and achieve the effects of large softening coefficient, high cylinder compressive strength, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

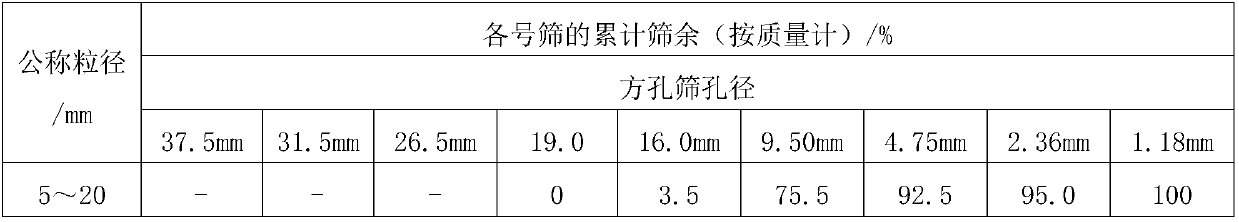

Examples

preparation example Construction

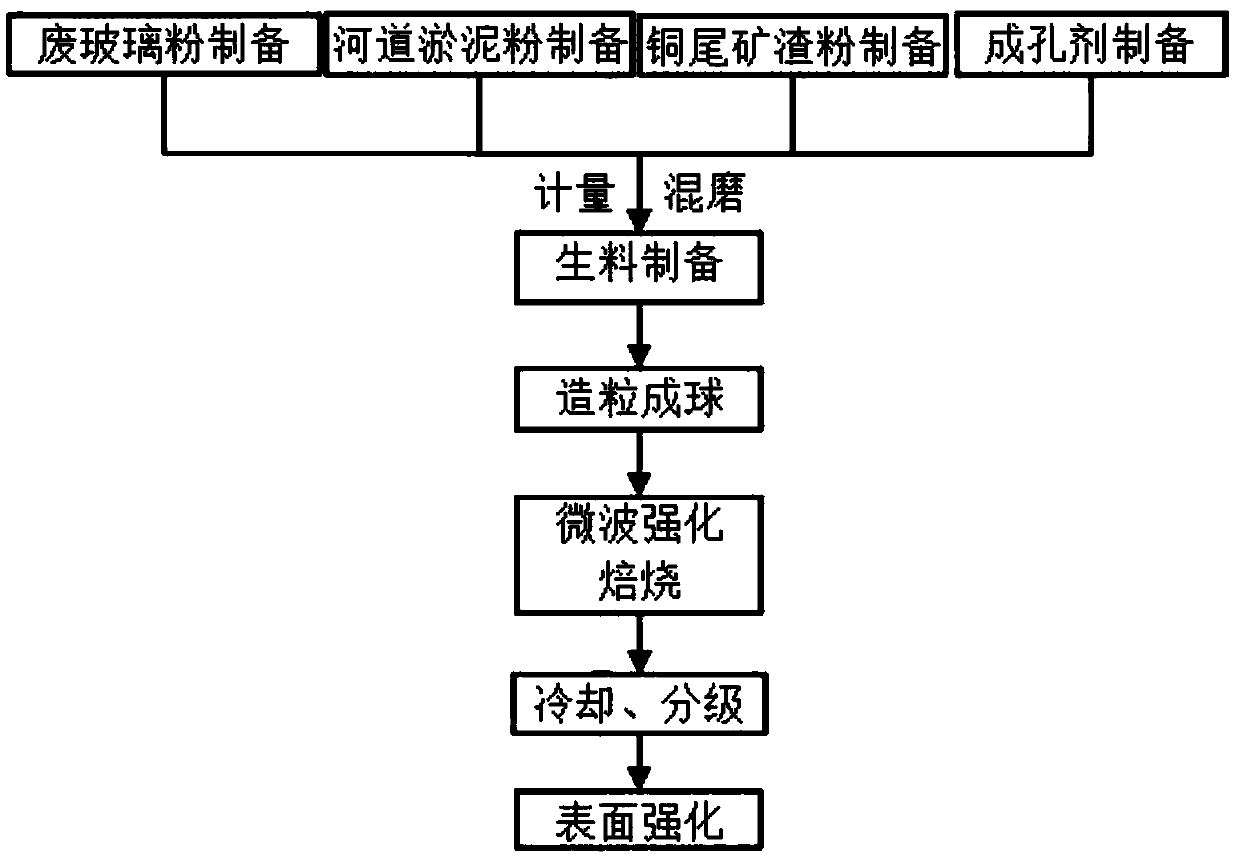

[0047] In addition, the present invention also provides a method for preparing light-weight and high-strength waste glass ceramsite, the preparation method comprising the following steps:

[0048] (1) Preparation of raw meal:

[0049] A. Preparation of waste glass powder: process waste glass powder and glass containers according to the preparation procedures of sorting, impurity removal, cleaning, drying, crushing, magnetic separation, and ball milling to obtain waste glass powder for future use;

[0050] Further preferably, the waste glass powder is prepared by processing the discarded architectural glass and glass containers in construction and daily life according to the preparation procedures of sorting, impurity removal, cleaning, drying, crushing, magnetic separation, and ball milling, and the mud content is less than 1 %, the content of metal flakes, paper flakes and wood chips is less than 1%, the moisture content is less than 1%, and the fineness is 300-320m 2 / kg, g...

Embodiment 1

[0076] Such as figure 1 As shown, the preparation method of the lightweight high-strength waste glass ceramsite of the embodiment of the present invention specifically comprises the following steps:

[0077] (1) Preparation of raw meal

[0078] A. Preparation of waste glass powder: The flat glass discarded by the building is processed according to the preparation procedures of sorting, impurity removal, cleaning, drying, crushing, magnetic separation, and ball milling. The mud content is 0.2%, and metal sheets, paper sheets, The sawdust content is 0.1%, the moisture content is 0.1%, and the fineness is 320m 2 / kg, get waste glass powder, standby;

[0079] B, preparation of river silt powder: with the river silt processed through biodegradation, dehydration, natural air-drying, the content of its illite mineral is 45%, the loss on ignition is 1.5%, and the moisture content is 0.2%, grinds with electric ball mill to 330m 2 / kg, get river silt powder, spare;

[0080] C. Prep...

Embodiment 2

[0106] Such as figure 1 As shown, the preparation method of the lightweight high-strength waste glass ceramsite of the embodiment of the present invention specifically comprises the following steps:

[0107] (1) Preparation of raw meal

[0108] A. Preparation of waste glass powder: The glass beer bottles discarded in daily life are processed according to the preparation procedures of sorting, impurity removal, cleaning, drying, crushing, magnetic separation, and ball milling. The mud content is 0.1%, and the metal flakes, The content of paper and sawdust is 0.1%, the moisture content is 0.1%, and the fineness is 315m 2 / kg, get waste glass powder, standby;

[0109] B, preparation of river silt powder: the river silt through biodegradation, dehydration, natural air-drying process, its illite mineral content is 50%, loss on ignition is 1.8%, and water content is 0.2%, pulverizes with electric ball mill to 335m 2 / kg, get river silt powder, spare;

[0110] C. Preparation of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com