Patents

Literature

47results about How to "Stable heat retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

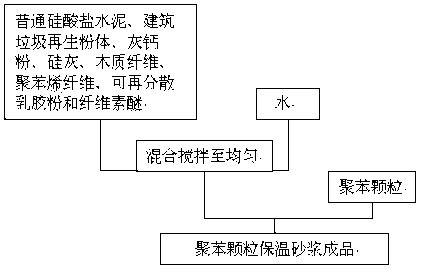

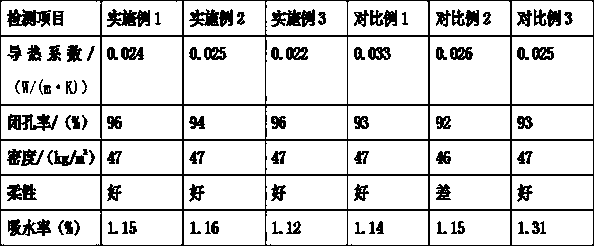

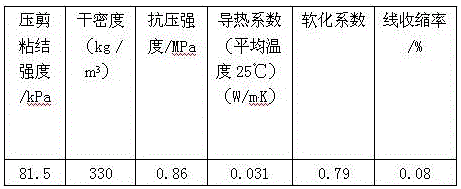

Polyphenylene granular thermal-insulation mortar

InactiveCN103242014ALow thermal conductivityStable heat retentionSolid waste managementFiberFreeze thawing

The invention discloses a polyphenylene granular thermal-insulation mortar. Construction waste regenerated powder is added as an inert filler into common thermal-insulation mortar. The polyphenylene granular thermal-insulation mortar comprises ordinary Portland cement, construction waste regenerated powder, sierozem powder, silica fume, polyphenylene granule, wood fiber, polystyrene fiber, redispersible latex powder and cellulose ether. The thermal-insulation mortar has the advantages of low heat conductivity coefficient, stable thermal-insulation properties, high softening coefficient, freeze-thawing resistance and aging resistance, and is suitable for thermal insulation of various walls.

Owner:北京建筑工程学院

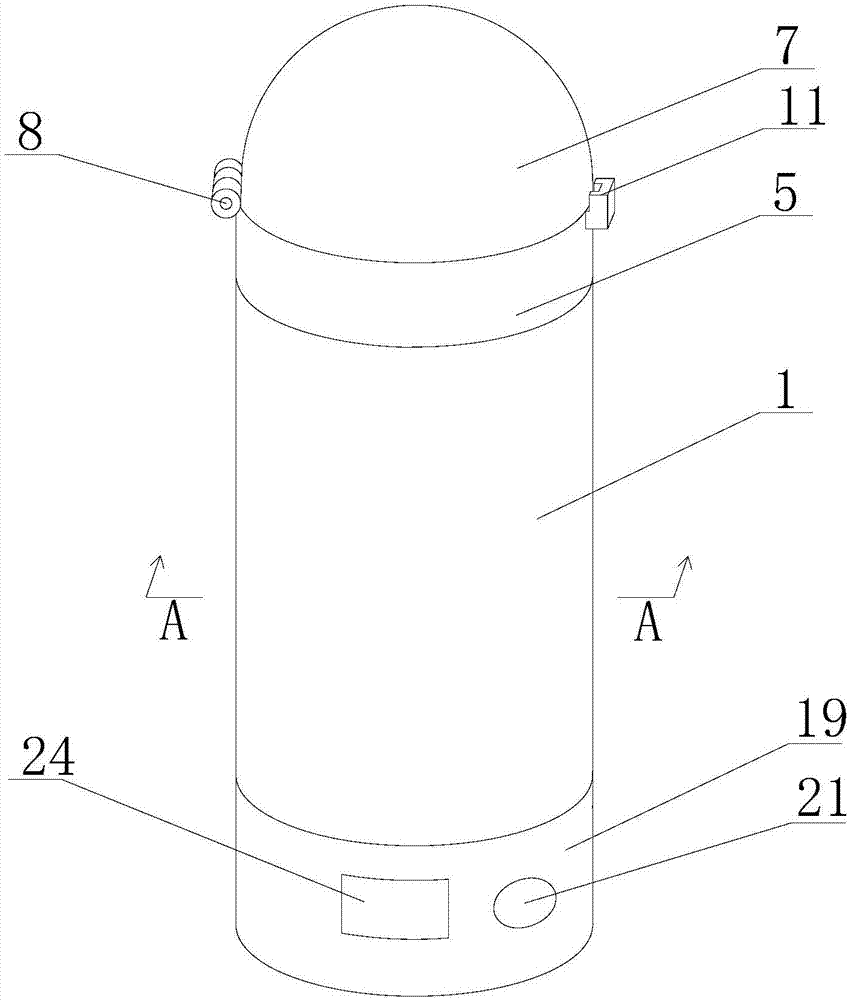

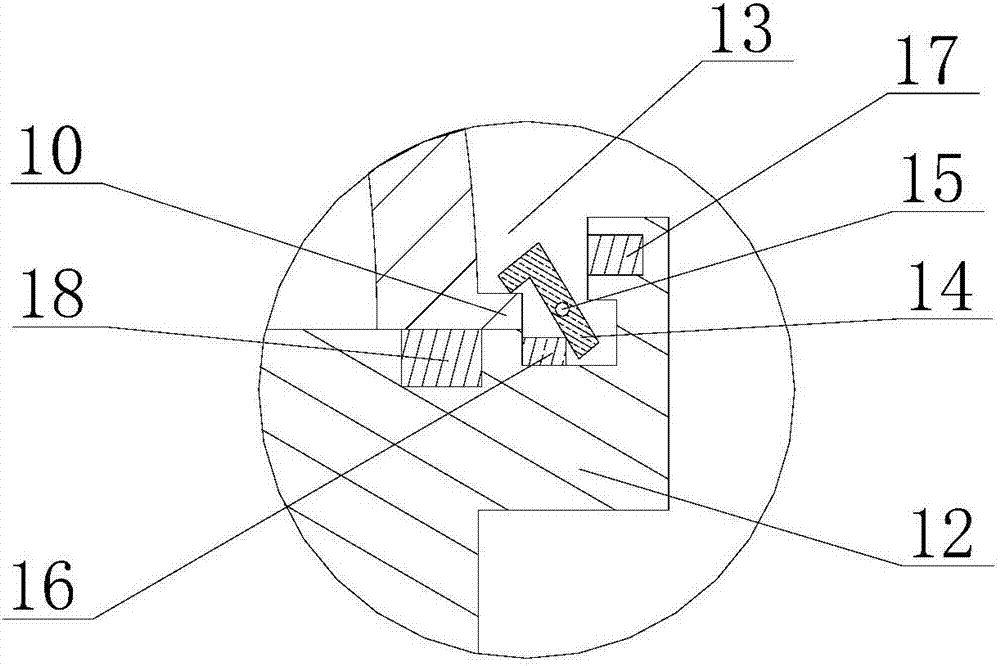

Portable thermal-insulation cup

ActiveCN107468016AAvoid pollutionAvoid automatic openingTravelling sacksDrinking vesselsThermal insulationEngineering

The invention discloses a portable thermal-insulation cup, and belongs to the technical field of articles of daily use. The portable thermal-insulation cup comprises a cup body, an inner cup lid, an outer cup lid, a locking device, a detection device, a base, an infrared sensing switch and a controller; the cup body is internally provided with an inner cavity, the inner cup lid is arranged at the upper portion of the cup body, and the outer cup lid is hinged to the upper portion of the inner cup lid, and is provided with a first lug which is matched with the locking device to lock the outer cup lid; the locking device comprises a second lug, a pressing rod, an electromagnet, an elastic part and a second overturn shaft; the detection device is inset at the upper edge of the inner cup lid; the base is arranged at the bottom of the cup body, and is provided with an electric appliance mounting cavity; the infrared sensing switch is arranged at the outer circumference surface of the base; the controller is arranged in the electric appliance mounting cavity. According to the portable thermal-insulation cup, automatic opening and locking of the outer cup lid are achieved, and the problem that the cup opening is easily contaminated when a lid of a traditional thermal-insulation cup needs to be unscrewed with hands is solved.

Owner:南丹县产品质量检验所

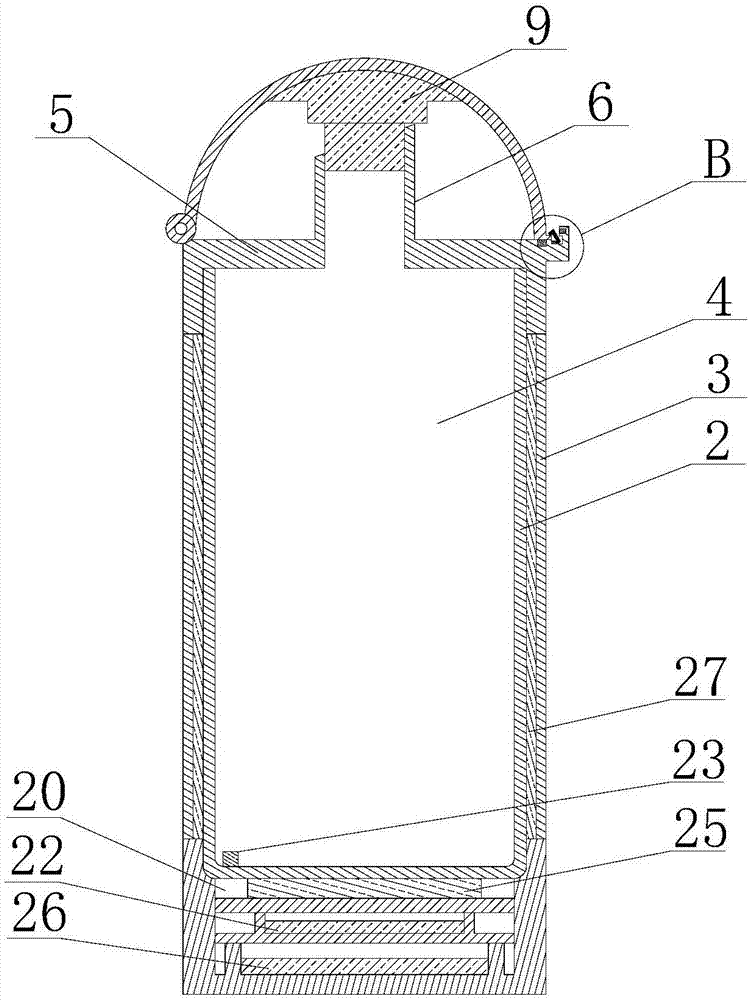

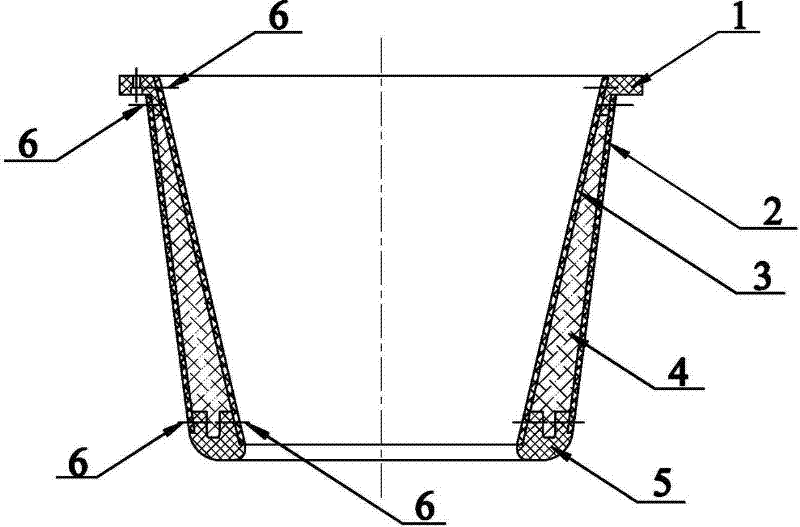

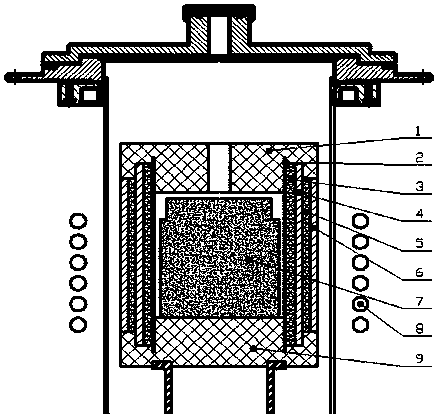

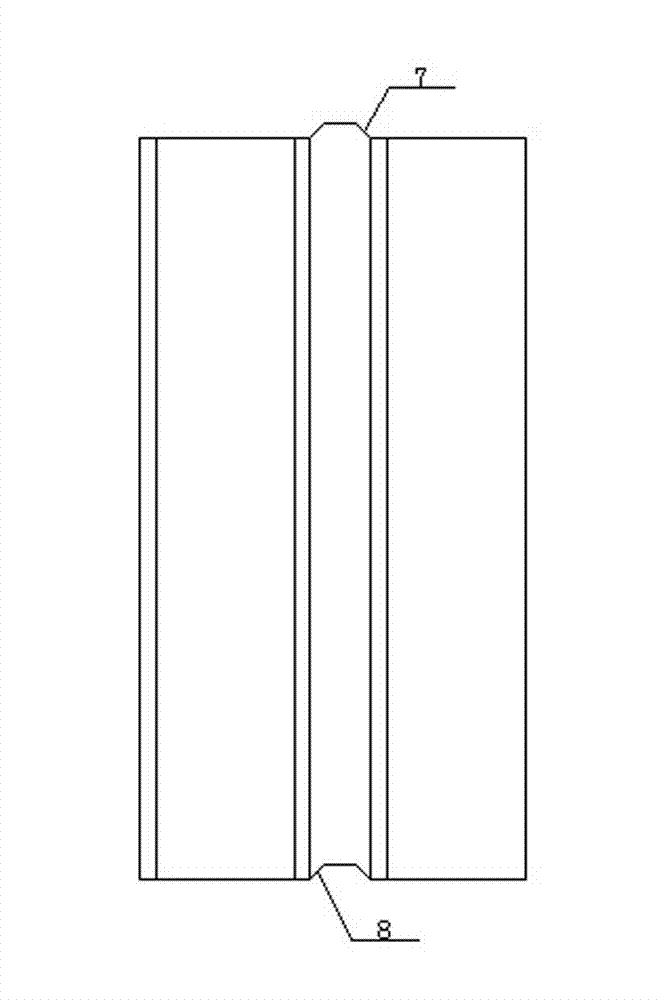

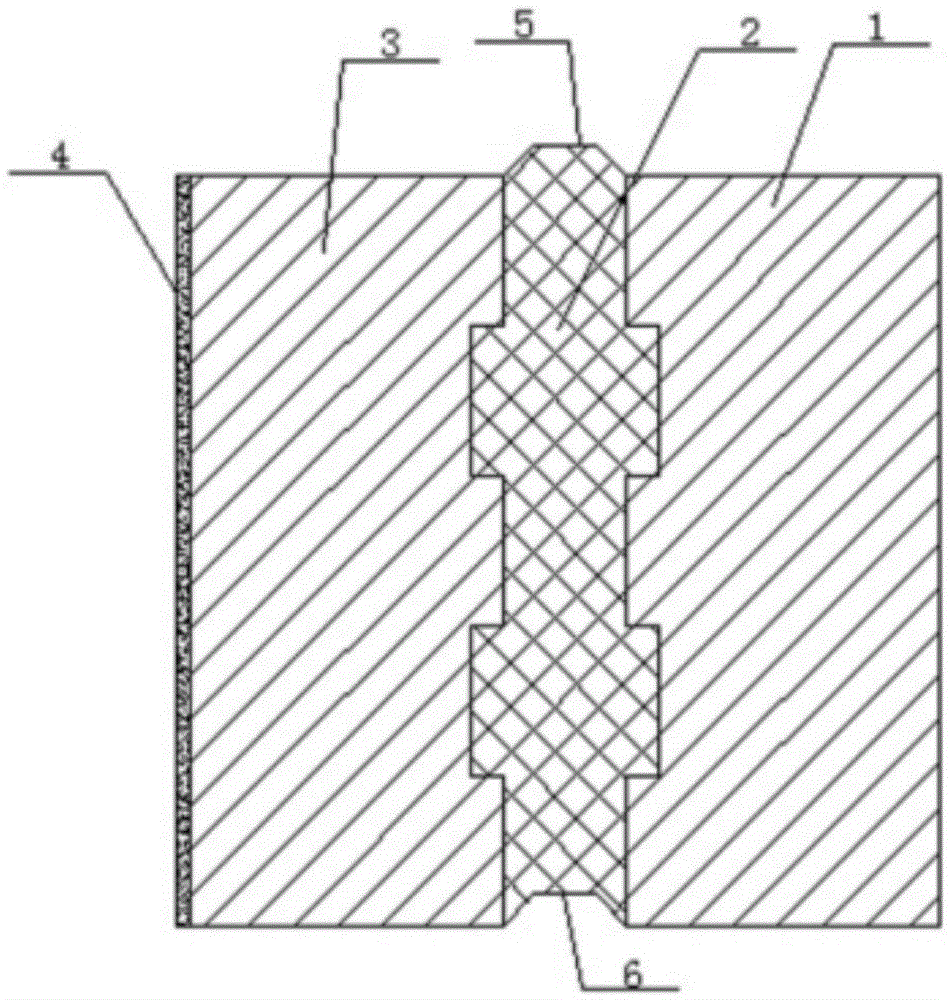

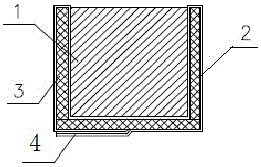

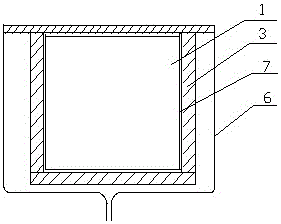

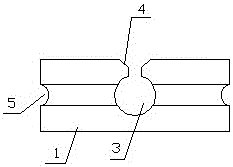

Guide shell made from carbon/carbon composite material and production method

ActiveCN102296355AStable heat retentionStrong mechanical propertiesBy pulling from meltChemical vapor deposition coatingCarbon compositesSlag

The invention discloses a guide shell which is simple to produce, has a good insulation effect and is made from a high-strength carbon / carbon composite material. The guide shell provided by the invention comprises a cylindrical shell and is characterized in that the cylindrical shell comprises an outer cylinder (2) and an inner cylinder (3); one end of the outer cylinder (2) and that of the inner cylinder (3) are connected by a flange (1); the other ends are connected by a connecting ring (5) to form an integral body; carbon felt (4) is disposed between the outer cylinder (2) and the inner cylinder (3); the outer cylinder (2), the inner cylinder (3), the flange (1) and the connecting ring (5) are all prepared by the carbon / carbon composite material with the density being 1.0g / cm<3>-1.4g / cm<3>; and the density of the carbon felt (4) is 0.1g / cm<3>-0.2g / cm<3>. A production method of the guide shell comprises the following steps of: (1) processing for molding; (2) assembling of the cylindrical shell; and (3) purifying step. The production method is simple and easy to operate; in addition, by the adoption of the production method, the prepared guide shell provided by the invention has stronger thermal insulation performance and mechanical properties than graphite guide shells, the scour resistance and corrosion resistance of the guide shell surface is improved, and the slag-and-block dropping phenomenon on the surface of the guide shell is prevented.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

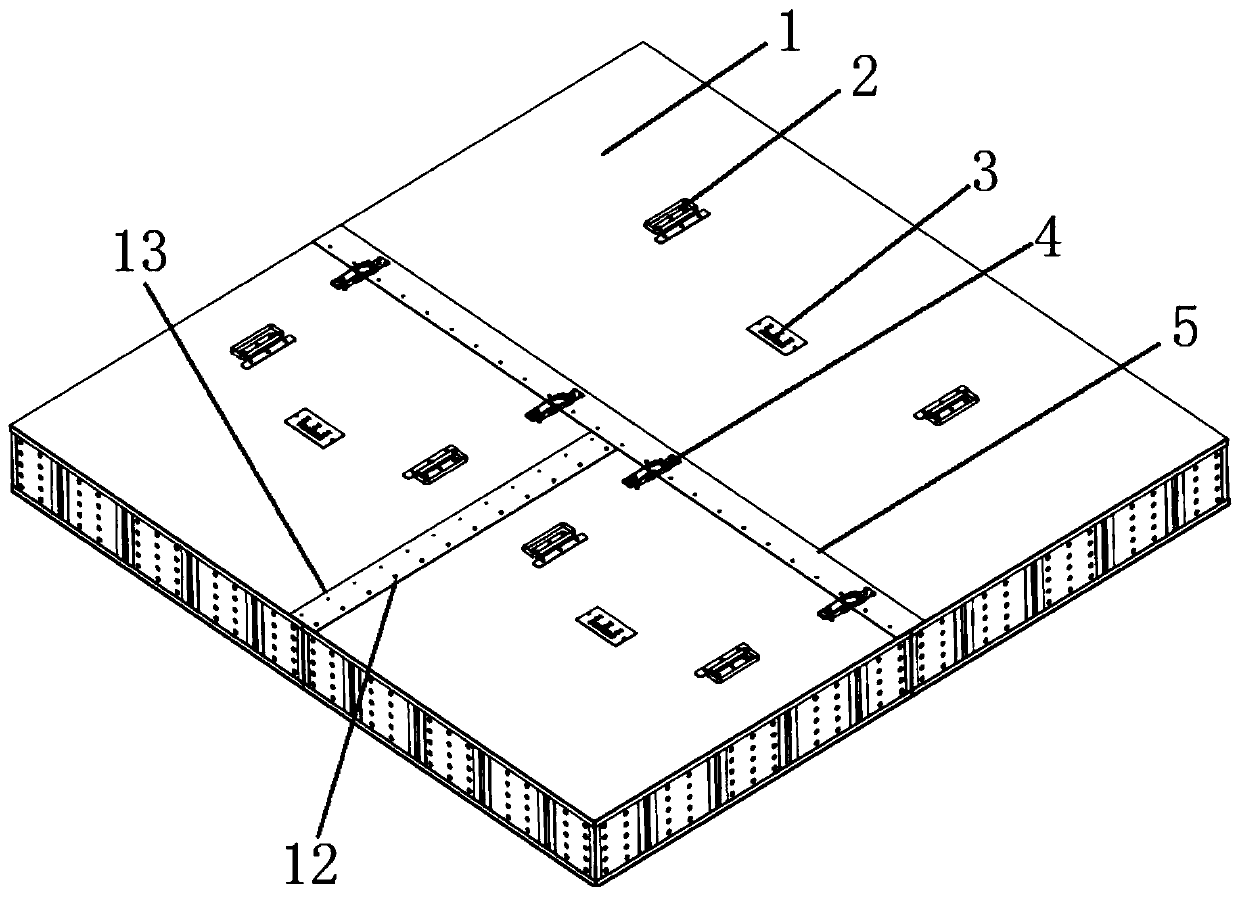

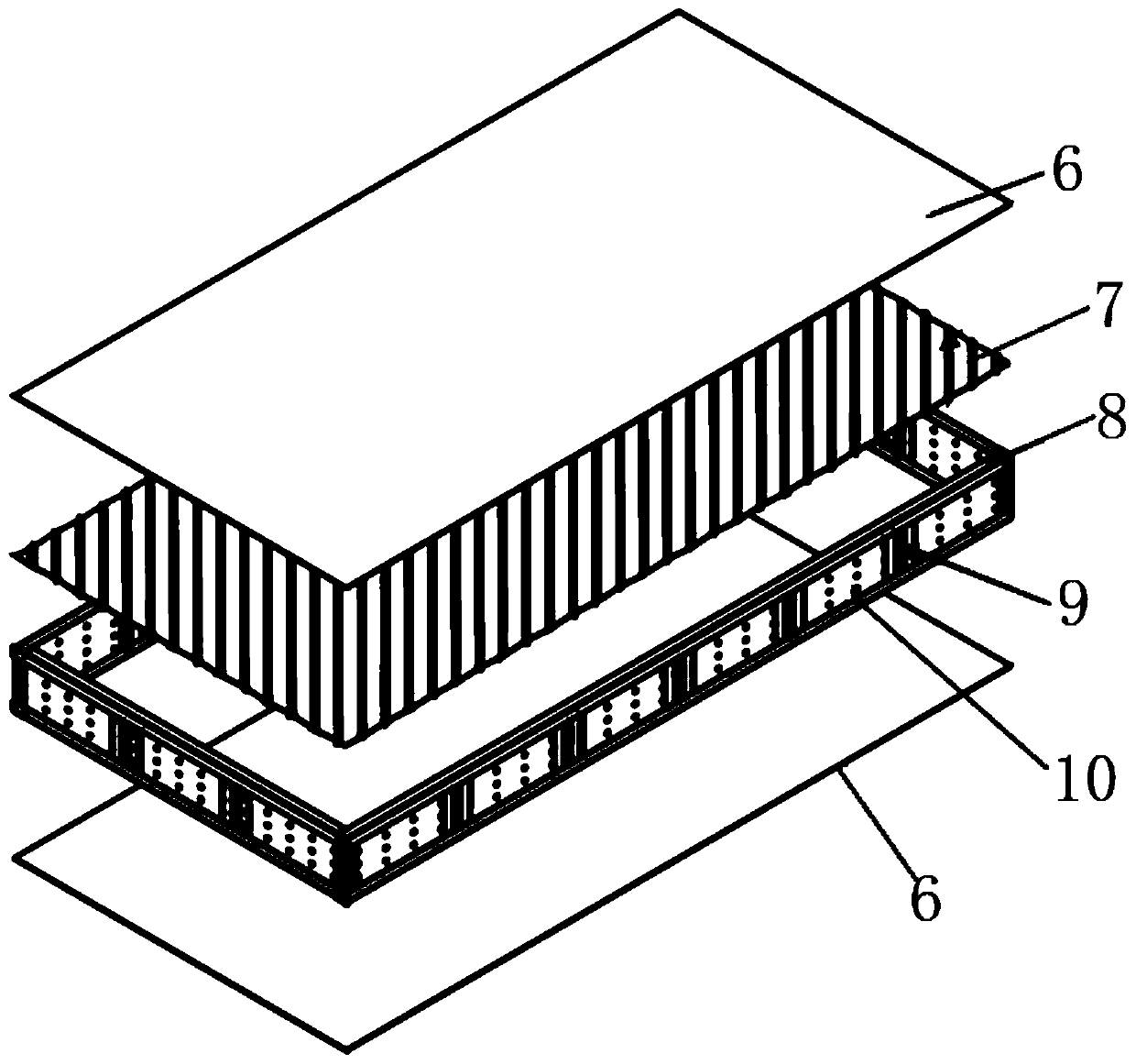

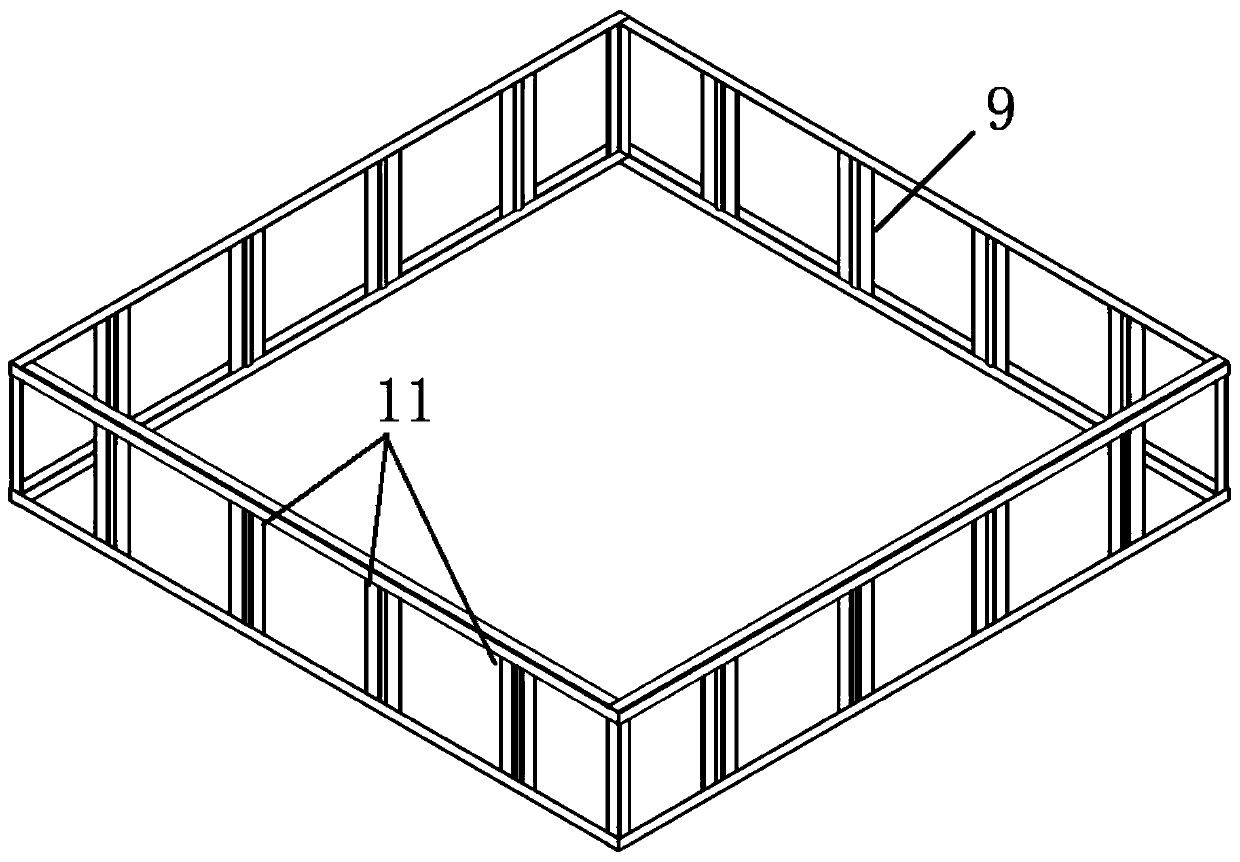

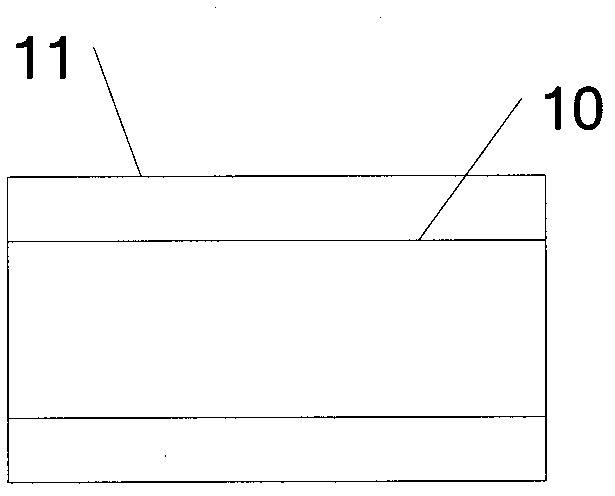

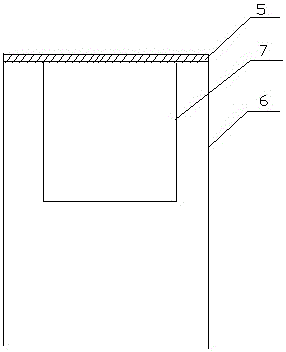

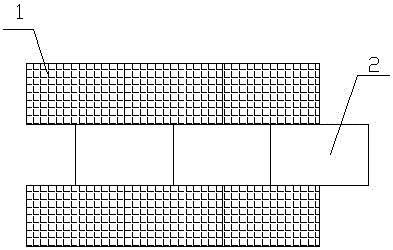

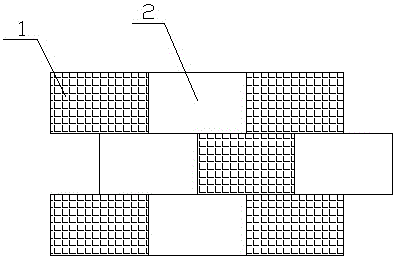

Cast-in-site rigid bone self-heat-preservation wall body, building blocks and wall building method

InactiveCN104047392AEasy to smoothGuaranteed smoothConstruction materialWallsArchitectural engineeringBuilding construction

Owner:SHANDONG CHUNTIAN BUILDING MATERIAL SCI & TECH

Thermal insulation system with long service life for silicon carbide crystal growth furnace

InactiveCN107779955AReduced thermal and chemical corrosion ratesExtend your lifePolycrystalline material growthFrom condensed vaporsThermal insulationMechanical property

The invention relates to a thermal insulation system with long service life for a silicon carbide crystal growth furnace. On the basis of composite thermal insulation of soft / hard felts, a C / C composite material is innovatively selected as an innermost layer thermal insulating material, excellent characteristics that the mechanical properties are increased with temperature raised, the linear expansion coefficient is small, the ablative resistance is excellent, the damage tolerance is high, and adhesion does not occur under a high temperatures are utilized, a cylinder with a thickness of 0.5mmis adopted, the upper and lower ends are cut, two fractures exist per round, the fracture width is 1-1.5mm, so that formation of a closed circuit is avoided, because the C / C composite material has anextremely small linear expansion coefficient, the fractures are not closed under a high temperature, and a low obstruction to alternating magnetic field penetration is realized; and damage on thermalinsulation of each layer at an outer side caused by thermal corrosion, thermal shock, chemical corrosion and the like is fully reduced, the overall service life and stability of the thermal insulationsystem are improved, the stability period of a thermal insulation system can be increased from previous 800h to 1500h or more, and people only need to replace an innermost layer thermal insulating soft felt to restore a stable state, and the overall service life is extended by 1 time or more.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

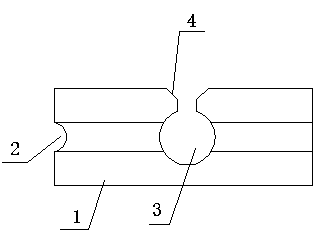

Novel composite wall brick

InactiveCN102966213ASimplify on-site construction workloadSave manpower and material resourcesConstruction materialFoam concreteBrick

The invention relates to the technical field of a building construction wall brick, and particularly relates to a novel composite wall brick. The novel composite wall brick comprises a first foam concrete layer, a foam polyurethane layer, a second foaming concrete layer and a surface plastic spraying layer; the first foaming concrete layer, the foam polyurethane layer, the second foaming concrete layer and the surface plastic spraying layer are sequentially compactly arranged from inside to outside; and the inner surfaces of the contact face of the first foaming concrete layer and the second foaming concrete layer, and the foam polyurethane layer are in the shape of a tooth-shaped groove. With the adoption of the structural manner, the wall brick, a thermal insulating layer and an outer wall waterproof decoration can be organically combined to be a compound whole body, so that the working amount of the field construction can be simplified, the labor and the materials can be saved, the labor productivity can be improved, the knock-off operation is rapider and safer, and the thermal-insulating property is stable.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

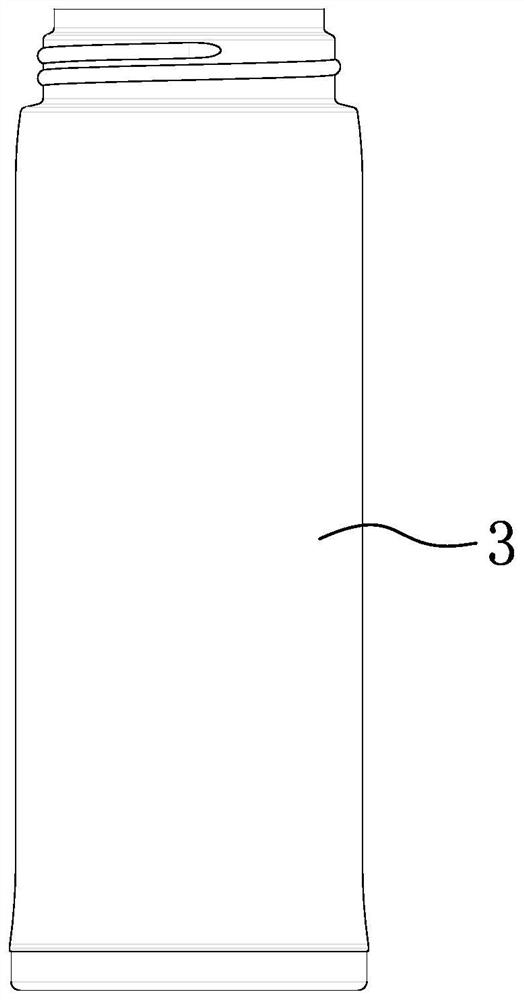

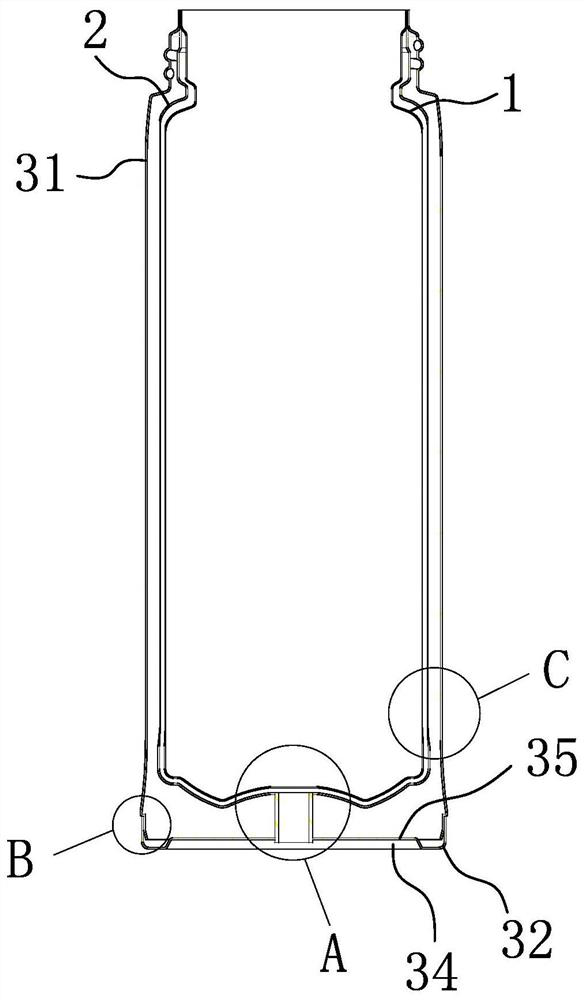

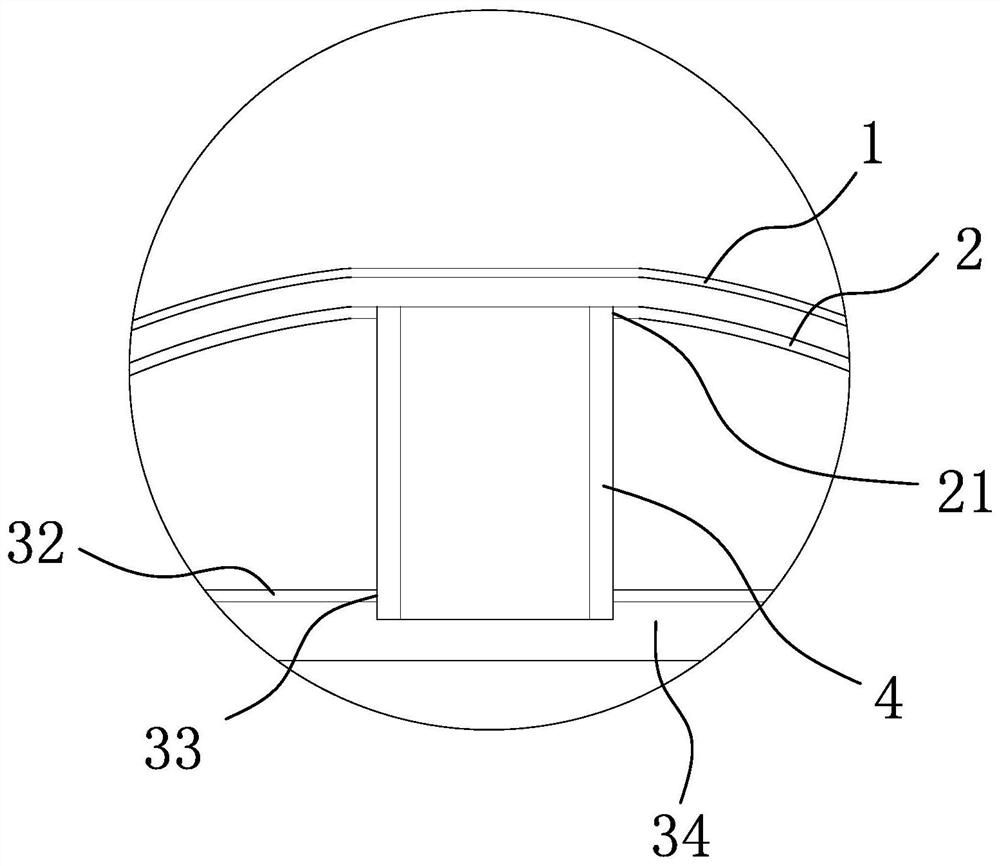

Vacuum cup and processing method thereof

InactiveCN111713939AAvoid deformationMeet production and processing requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSS - Stainless steel

The invention belongs to the technical field of heat preservation, and particularly relates to a vacuum cup and a processing method thereof. The technical problem that an existing titanium vacuum cupis not easy to machine and manufacture is solved. The vacuum cup comprises a titanium layer, a middle stainless steel layer and an outer stainless steel layer which are sequentially arranged from inside to outside, the vacuum cup is characterized in that the upper end of the titanium layer is welded with the upper end of the middle stainless steel layer; a closed space is formed between the titanium layer and the middle stainless steel layer; the upper end of the middle stainless steel layer and the upper end of the outer stainless steel layer are connected in a welded mode, a vacuum cavity isformed between the middle stainless steel layer and the outer stainless steel layer through vacuumizing, and a pressure pipe penetrating through the vacuum cavity and enabling the closed space to becommunicated with the outside is connected between the bottom of the middle stainless steel layer and the bottom of the outer stainless steel layer. The processing method has the advantage that the production and processing efficiency is improved.

Owner:蒋文柏

Organic fireproof foaming composite of water tank of solar water heater

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to an organic fireproof foaming material applied to thermal insulation of a water tank of a solar water heater. The material adopts the technical scheme that the material is formed by mixing and foaming isocyanate and a polyether composite, and the polyether composite contains main raw materials such as composite polyether, dimethyl ether, chitosan, an organic flame retardant and expanded perlite. The polyurethane hard foaming thermal insulation material overcomes the defect of great shrinkage after foaming forming, prevents the water tank from deformation, bulking, barring and even cracking, and ensures the thermal insulation property and the flame retardancy of the water tank of the water heater.

Owner:SHANDONG HEZE TONGYANG AMPEREX TECH

HCM glue powder polyphenyl particle external wall thermal insulation system

InactiveCN101100892AGood weather resistanceLow thermal conductivityCovering/liningsWallsGlass fiberThermal insulation

An outer wall heat preservation system is composed by the outer wall, HCM layer, HCM gel with polybenzene granular, protection layer and face layer. Process steps includes: base wall treatment; coating HCM to the treated base wall; coating HCM gel with polybenzene granular and standing for dry; coating HCM cement and sand slurry and press on HCM glass fiber texture; coating a secondary layer of HCM cement and sand slurry to form a protection layer; coating HCM and water proof putty.

Owner:上海康马建材有限公司

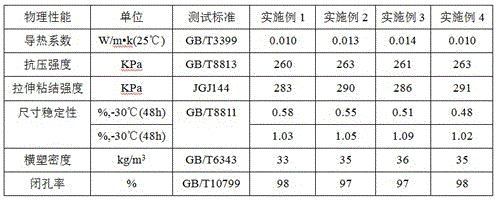

Polyurethane hard foam thermal-insulation material

The invention relates to a thermal-insulation material, and discloses a polyurethane hard foam thermal-insulation material. The thermal-insulation material is prepared by mixing and foaming the following raw materials in parts by weight: 70-100 parts of dimer acid diisocyanate, 40-80 parts of polyether glycol I, 10-30 parts of polyether glycol II, 3-6 parts of expanded vermiculite, 5-8 parts of nano silicon dioxide, 10-20 parts of monofluorodichlorohexane, 1-5 parts of catalyst and 1-5 parts of foam stabilizer. The polyether glycol I is lignin polyether glycol, and the polyether glycol II is polyether glycol formed by carrying out polymerization on a polymerizable monomer epoxypropane by using modified soybean oil as an initiator. The thermal-insulation material has higher compression strength, tensile strength and impact strength, and avoids the phenomena of deformation, bulging, edging and even cracking of the water tank.

Owner:GUANGXI JISHUN ENERGY TECH

Solar-energy water tank polyurethane heat insulating material

The invention relates to a solar-energy water tank polyurethane heat insulating material. The solar-energy water tank polyurethane heat insulating material is composed of isocyanate, epoxy resin, a foaming agent, polyether polyol, alkali-resistant glass fibers, diatomite, fatty alcohol-polyoxyethylene ether and deionized water. The solar-energy water tank polyurethane heat insulating material has uniformly distributed and fine bubble holes, the heat insulating material is difficult to deform, heat insulating property is stable, heat conductivity coefficient is low, the alkali-resistant glass fibers are added in a white material, the diatomite enables the prepared heating insulating material to be good in flame retardant effect and have fireproof effect, a production method that materials are mixed and poured into a solar-energy water heater water tank heat insulating material layer is adopted, simplicity and easiness are realized, production cost is reduced, integrity and closeness of the whole insulating layer are guaranteed, heat loss can be reduced, and service life of the heat insulating material is prolonged and safety performance of the heat insulating material is also improved.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

Organic polyurethane fireproof and heat insulating material for solar water tank

The invention relates to an organic polyurethane fireproof and heat insulating material for a solar water tank. The material is mainly prepared from a component A and a component B through mixing, wherein the component A comprises isocyanate, polyvinyl alcohol and a foaming agent; the component B comprises polyether glycol, gelatin powder, activated aluminum oxide, calcium carbide, tributyl phosphate and deionized water. According to the organic polyurethane fireproof and heat insulating material for the solar water tank, uniformly distributed and fine pores are formed, and the material is stable in heat insulating property, high in foaming speed and convenient to use; sepiolite is added to a white material, calcium powder enables the prepared heat insulating material to have a good flameretardant effect and a fireproof function; a proper amount of gelatin powder is added to the white material, the problem of poor flexibility of the heat insulating material can be effectively solved,and the prepared heat insulating material is convenient to use; a proper amount of tributyl phosphate is added to the white material, the problem of higher water absorbency of the heat insulating material can be effectively solved, and the prepared heat insulating material is low in water absorption.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

Internal wall thermal insulating mortar

The invention discloses internal wall thermal insulating mortar which is prepared from the following raw materials in parts by weight: 45-55 parts of slag cement, 3-6 parts of citric acid residue, 15-25 parts of quick lime, 10-15 parts of volcanic rock, 2-4 parts of asbestos fiber, 20-30 parts of hollow microsphere, 10-15 parts of calcined zeolite, 3-5 parts of soybean protein powder, 2-3 parts of sodium hexametaphosphate, 4-6 parts of guar gum powder, 2-3 parts of polyoxyethylene, 1-2 parts of sodium acetate, 2-3 parts of sugar calcium and 3-6 parts of composite packing. Compared with conventional thermal insulating mortar, the thermal insulating mortar disclosed by the invention has the characteristics of low volume-weight, high strength, stable thermal insulation property, freeze-thawing resistance, aging resistance, anti-cracking property, good anti-mold effect and the like, is green and environment-friendly, safe and reliable, simple and convenient to construct, low in cost, and can be widely applied to internal wall heat preservation systems.

Owner:ANHUI FUYANG SIKEDA SCI & TECH BUILDINGMATERIAL

Solar polyurethane thermal insulation material

The invention relates to a thermal insulation material and discloses a solar polyurethane thermal insulation material. The thermal insulation material is prepared by mixing and foaming the following raw materials in parts by weight: 70-100 parts of diphenylmethane diisocyanate, 40-80 parts of polyether polyol I, 10-30 parts of polyether polyol II, 3-6 parts of expanded vermiculite, 5-8 parts of nano silicon dioxide, 10-20 parts of dichlorofluoroethane, 1-5 parts of catalyst and 1-5 parts of foam stabilizer, wherein the polyether polyol I is lignin polyether polyol; and the polyether polyol II is polyether polyol polymerized by taking modified olive oil as an initiator and epoxy propane as a polymerization monomer. The thermal insulation material has better compressive strength, tensile strength and impact strength while the phenomena of water tank deformation, bulking, ridging and even cracking are avoided.

Owner:GUANGXI JISHUN ENERGY TECH

Novel composite wall brick

InactiveCN105544842ASimplify construction workloadSave manpower and material resourcesConstruction materialThermal insulationMaterials science

The invention relates to the technical field of wall bricks for construction, and specifically relates to a novel composite wall brick. The novel composite wall brick comprises a first foamed concrete layer, a foamed polyurethane layer, a second foamed concrete layer, and a surface sprayed plastic layer; the first foamed concrete layer, the foamed polyurethane layer, the second foamed concrete layer, and the surface sprayed plastic layer are tightly arranged from inner to outer; and the contact surface between the first foamed concrete layer / second foamed concrete layer and the foamed polyurethane layer has a tooth liked groove shape. Through the structure mentioned above, the wall brick, thermal insulation layer, and outer wall waterproof decoration are organically combined to form a composite whole body, which can replace the conventional wall materials. Moreover, the procedure of on-site construction is simplified, a large amount of resources and labor is saved, the work efficiency is improved, the construction becomes more convenient and safer, and the thermal insulation property of the wall brick is stable.

Owner:CHONGQING SHENGYU NEW MATERIAL CO LTD

High-performance metal reflecting type heat preservation layer

InactiveCN109812646AShorten maintenance timeReduce replacement timeThermal insulationNuclear energy generationThermal insulationShock resistance

The invention discloses a high-performance metal reflecting type heat preservation layer, and belongs to high-performance heat preservation equipment. The problems that for a non-metal heat preservation material, the degradation phenomenon exists, the pit filter screen blocking risk is prone to occurring, and dust can be generated to harm health of construction personnel are solved. The high-performance metal reflecting type heat preservation layer is formed by assembling and connecting high-performance metal reflecting type heat preservation blocks, and connectors have two modes of detachableconnection and non-detachable connection and have the better high temperature resistance, corrosion resistance and thermal insulation resistance; the containment circulation pit filter screen blocking risk is effectively reduced; the nuclear power plant maintenance and replacement time is shortened; the mechanical strength is high, and the anti-seismic property and the shock resistance are good;the service life is long, and the heat preservation performance is stable in the service life; no dust is generated, no pollutant diffusion occurs, and harm of radioactive substances to operation andmaintenance personnel can be avoided or reduced; and no corrosivity is generated to the equipment or pipelines.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

Synthetic leather pulp with functions of environment protection, heat insulation and heat preservation, and preparation method thereof

InactiveCN104389189ASimple recipeImprove insulation effectFibre treatmentDiethylene glycol monobutyl etherThermal insulation

The invention discloses synthetic leather pulp with functions of environment protection, heat insulation and heat preservation, and a preparation method thereof. The synthetic leather pulp comprises the following raw materials in parts by weight: 85-90 parts of polyphenylene thioether, 2-3 parts of metaphenylene diamine, 0.8-1.0 part of ethylene distearamide, 25-30 parts of nanoscale silicon dioxide, 2-3 parts of aluminium-magnesium-silicate, 10-15 parts of peanut leaves, 1.1-1.2 parts of stearic acid, 0.1-0.2 part of calcium ricinoleate, 28-35 parts of light calcium carbonate, 4-4.5 parts of dicumyl peroxide, and 50-55 parts of diethylene glycol monobutyl ether. The pulp disclosed by the invention is simple in a formula, and a paint made from the pulp can effectively realize reflective insulation, and has the advantages of being good in heat preservation effect, stable in heat-insulation property, good in corrosion resistance, long in service life, environment-friendly, and free of pollution. The technical problem that traditional heat-insulation and heat-preservation pulp is nonwaterproof is solved; the peanut leaves are modified, so that the stickiness of the peanut leaves can be improved, the stickiness of the pulp can be enhanced, and the performance stability of the pulp is improved.

Owner:HEFEI ANSHAN COATING FABRICS

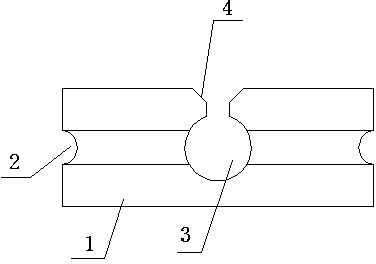

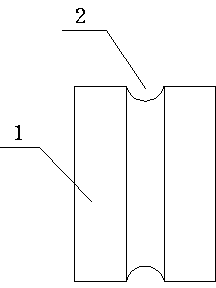

Enamel heat-insulation tube

InactiveCN102900899ALow priceStable heat retentionThermal insulationPipe protection by thermal insulationEngineering

The invention provides an enamel heat-insulation tube which comprises an inner-layer tube and an outer-layer tube. The inner-layer tube is made of metal materials, and the outer-layer tube is made of enamel materials. The enamel heat-insulation tube is low in cost and stable in heat-insulation performance, and is not easy to deform.

Owner:YIKEBO ENERGY TECH SHANGHAI

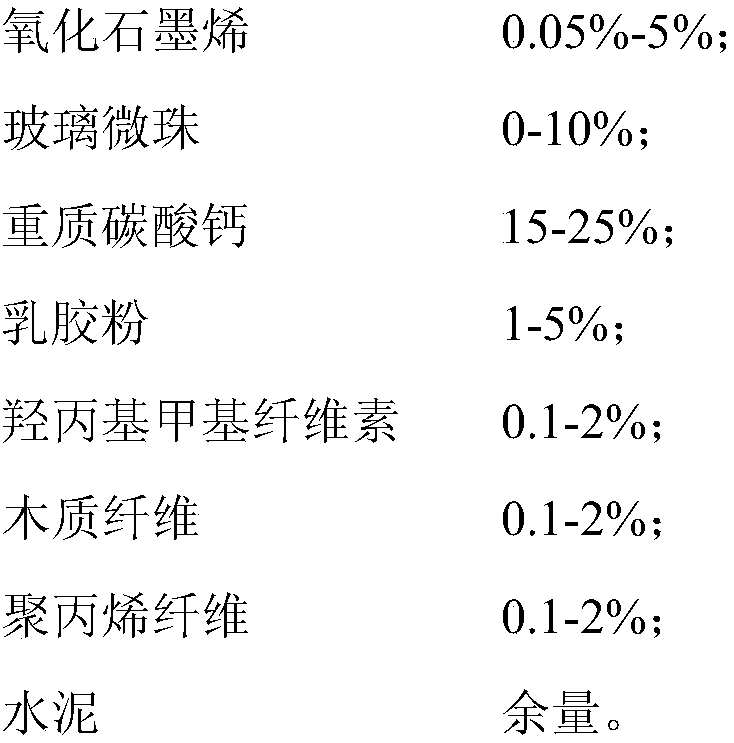

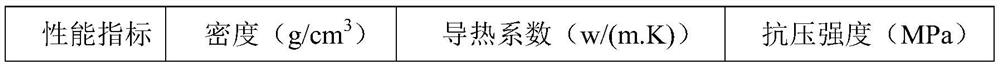

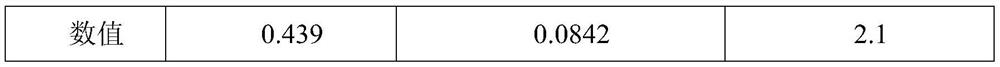

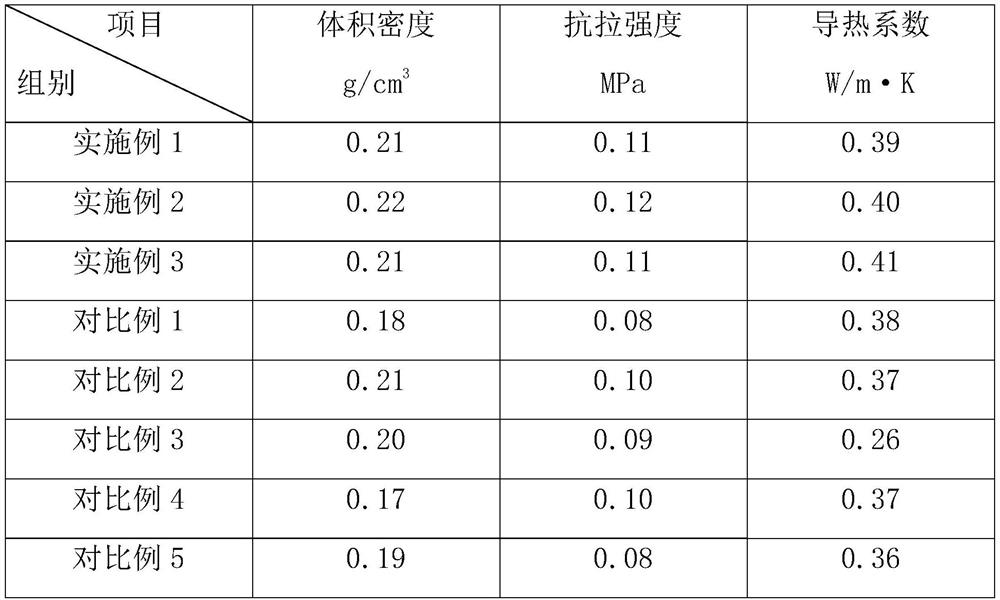

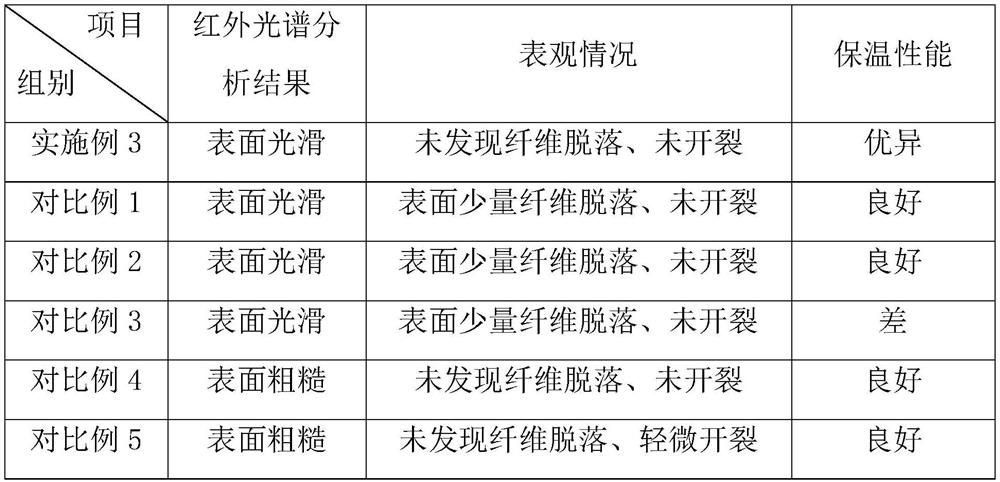

Graphene oxide-based insulating mortar and preparation method thereof

InactiveCN107935479AGood mechanical properties and durabilityImprove performanceHydroxypropylmethyl celluloseCvd graphene

The invention provides graphene oxide-based insulating mortar which is prepared from the following raw materials and water: the raw materials include graphene oxide, glass beads, cement, ground calcium carbonate, latex powder, hydroxypropyl methyl cellulose, wood fibers and polypropylene fibers. The invention also provides a preparation method of the graphene oxide-based insulating mortar. The preparation method comprises the following steps: dispersing graphene oxide in water; then adding mixed dry powder of glass beads, cement, ground calcium carbonate, latex powder, hydroxypropyl methyl cellulose, wood fibers and polypropylene fibers into the graphene oxide dispersion liquid; and uniformly stirring the mixture for 5-10min at a uniform speed to obtain the graphene oxide-based insulatingmortar. As the glass beads are replaced fully or massively by a small doping amount of graphene oxide, the inorganic insulating mortar has relatively good mechanical property and durability while ensures the insulating effect, so that the performance of the insulating mortar is integrally improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Insulation board, preparation method and application thereof

PendingCN111647211ALight weightImprove insulation effectClimate change adaptationHeat proofingThermal insulationEngineering

The invention discloses an insulation board, which is prepared from the following components by mass percentage: 20-30% of straw fragments, 20-25% of inorganic thermal insulation particles and 45-60%of waste plastic. The preparation method of the insulation board is specifically limited. The invention also discloses the preparation method and application of the insulation board. According to theinvention, the straw fragments, inorganic thermal insulation particles and waste plastic are prepared into the insulation board according to a specific ratio and a preparation process; the insulationboard only needs the three raw materials, the straw fragments and the inorganic thermal insulation particles are used for filling and thermal insulation, and the waste plastic is used as a gelatinizing agent besides the thermal insulation effect, and the prepared insulation board has the advantages of light weight, good thermal insulation performance, high structural strength and the like.

Owner:YANGZHOU POLYTECHNIC COLLEGE

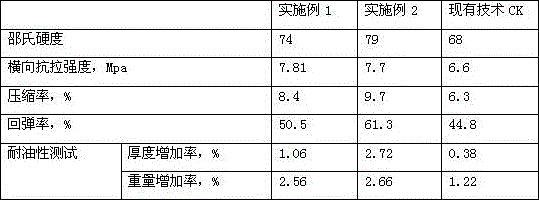

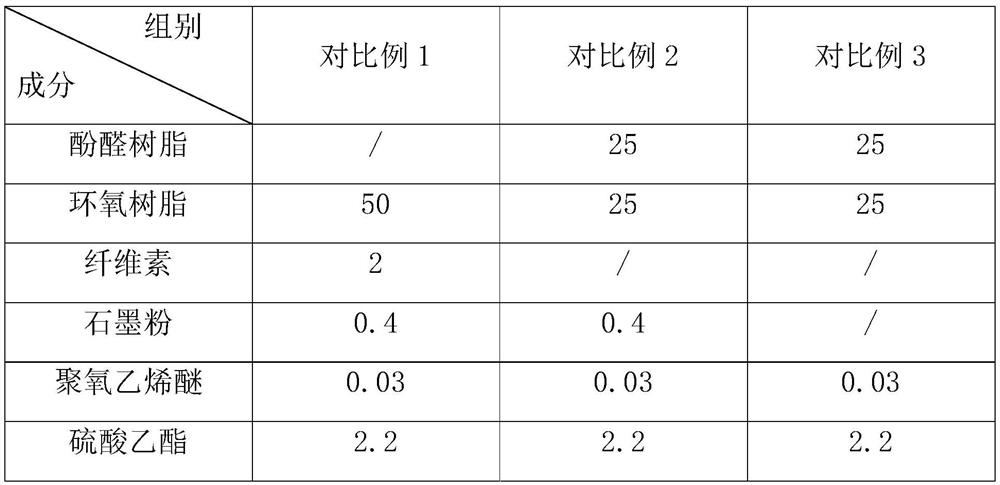

Oil-resistant and wear-resistant modified PVC resin nanometer environment-friendly construction material and preparation method

The invention discloses an oil-resistant and wear-resistant modified PVC resin nanometer environment-friendly construction materials and a preparation method. The construction material comprises organic silicon resin, organic solvent, vitrified micro-beads, titanium dioxide, quartz sand, silicon carbide micropowder, nanometer cerium oxide, ethanedioic polyester, light calcium carbonate, water-retaining resin polyvinyl alcohol, dispersant, thickener, brightener, zinc sulfide, foamed aluminum, hydroxy propyl methyl cellulose, nanosilicone dioxide, adhesive, cobalt naphthenate, molybdenum, nickel, propylene glycol, and chromium. The construction material is used for exterior walls of buildings specially, all performances of the exterior walls are effectively improved, nitrile rubber modifled bakelite, is mixed with the raw material and cured after being heated, melted resin turns into unmelted body structure rapidly from the linear structure. Mechanical performance is improved, and performance of high temperature resistance and low expansion is achieved. With pitch-based carbon fibers, mechanical performance of the material is enhanced, harmful gas and dust in the tail gas can be greatly absorbed and removed.

Owner:常熟市瑞思知识产权服务有限公司

Inorganic vitrification-modified nano environment-friendly rubber material and preparation method thereof

The invention discloses an inorganic vitrification-modified nano environment-friendly rubber material and a preparation method thereof. The inorganic vitrification-modified nano environment-friendly rubber material is prepared from epichlorohydrin rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene-butadiene rubber, regenerated rubber, light calcium carbonate, high-water-retentivity resin polyvinyl alcohol, a dispersing agent, a thickener, a whitener, zinc sulfide, foamed aluminum, hydroxypropyl methylcellulose, nano silicon dioxide, an adhesive, cobalt naphthenate, molybdenum, nickel, propanediol and chromium. The inorganic vitrification-modified nano environment-friendly rubber material is specially used for building external walls, and effectively enhances various properties of the building external wall. The combination of the butadiene-acrylonitrile rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene-butadiene rubber and regenerated rubber used as main materials greatly enhances the toughness of the inorganic vitrification-modified nano environment-friendly rubber material and effectively solves the problem of high cracking rupture tendency of the conveyer belt. The inorganic vitrification-modified nano environment-friendly rubber material can not generate harmful gases to the human body, has a perfect combination of high temperature resistance, tear resistance and other properties, and thus, is applicable to various severe working conditions. The asphalt-base carbon fibers are adopted to enhance the mechanical properties of the material, and can greatly adsorb and remove harmful gases and dust substances in the tail gas.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Heat preservation and decoration integrated construction process for passive heat-bridge-free pitched roof with thickness of 300 mm

InactiveCN112695959AImprove energy efficiencyGood impetusBuild-up roofsRoof toolsPhysicsHeat conservation

The invention discloses a heat preservation and decoration integrated construction process for a passive heat-bridge-free pitched roof with the thickness of 300 mm. The heat preservation and decoration integrated construction process comprises the following steps of (1) acceptance and cleaning of a base layer; (2) arrangement of a waterproof vapor-proof layer; (3) arrangement of a heat preservation layer; (4) arrangement of a fine aggregate concrete protection layer; and (5) laying of roof tiles. By applying the heat preservation and decoration integrated construction process, energy loss in an operation stage is reduced, thermal insulation performance is stable, waterproofness is good, various experimental results meet the design requirements, good economic benefits and social benefits are obtained, the building energy-saving efficiency can be greatly improved, and a national energy-saving strategy is greatly promoted.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

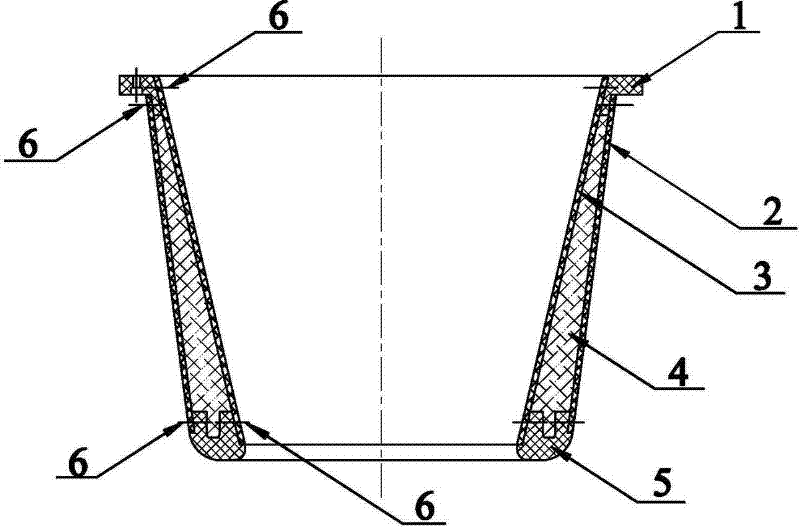

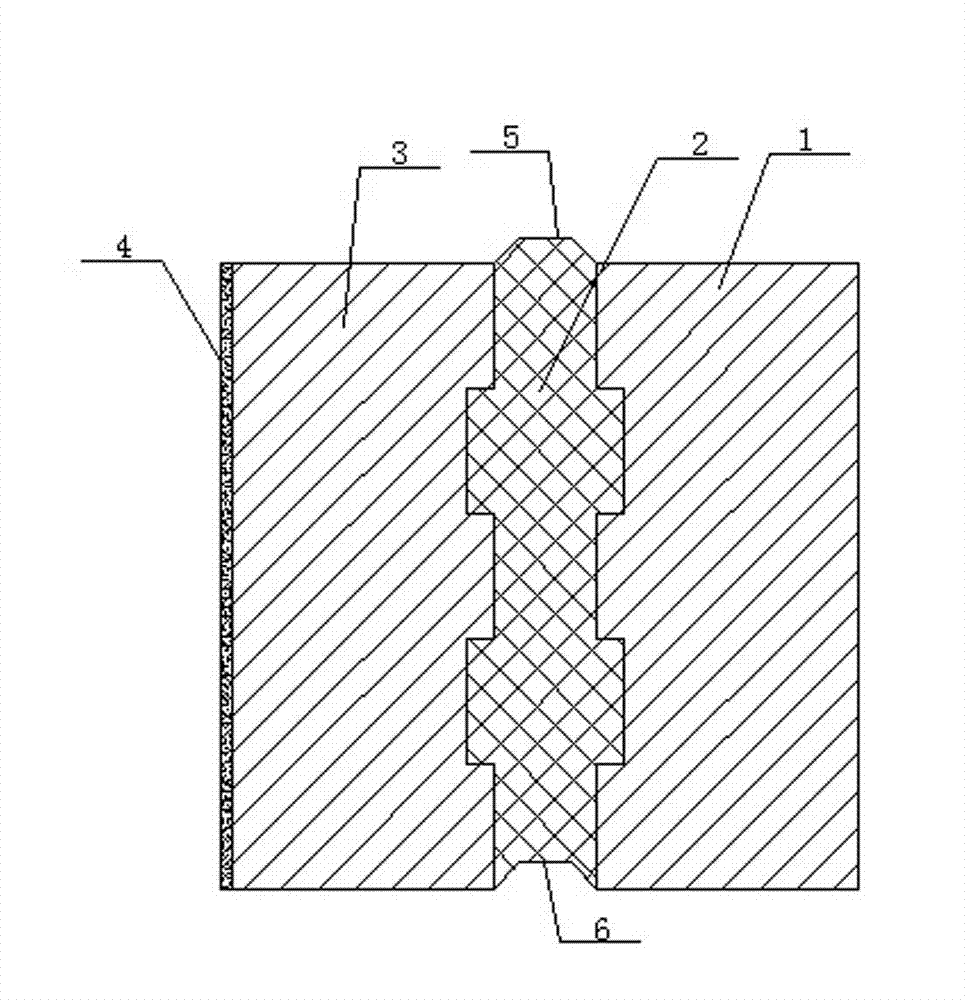

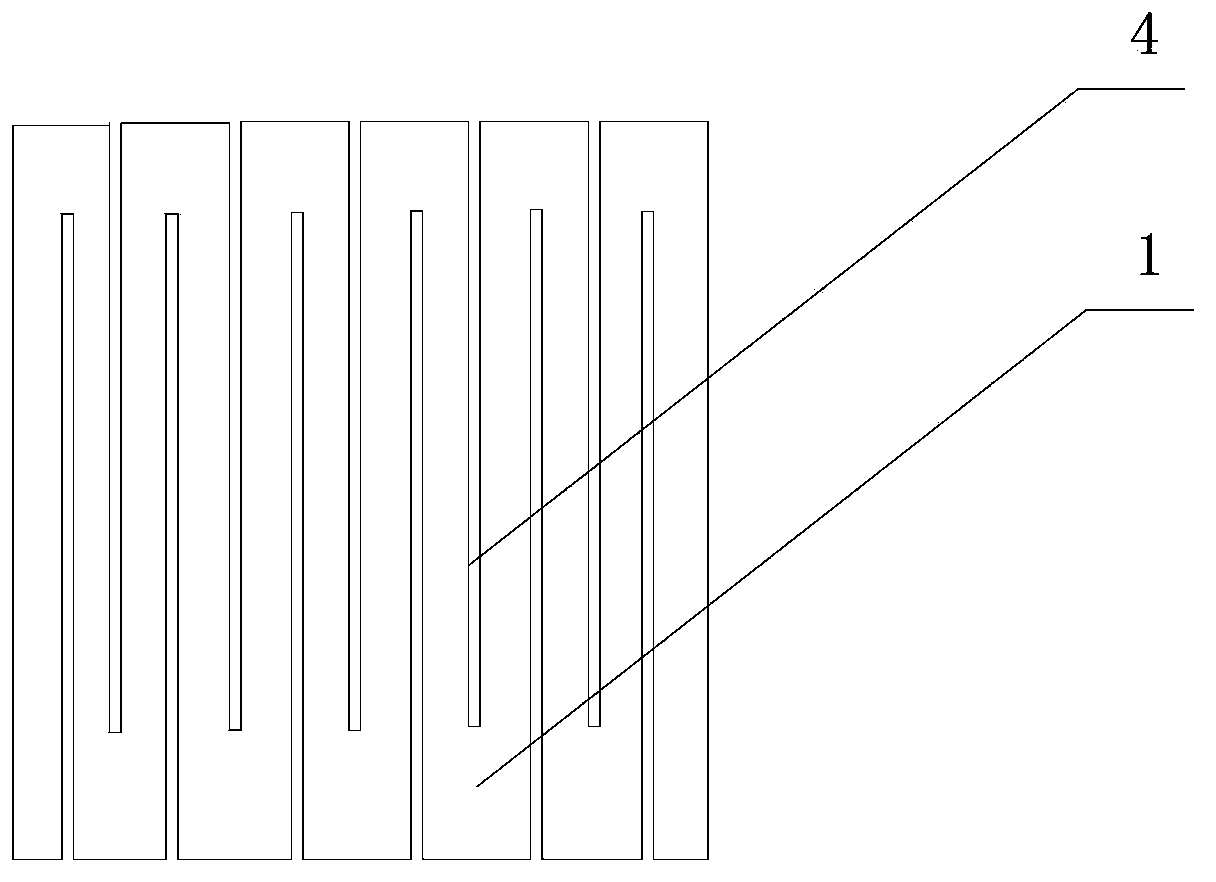

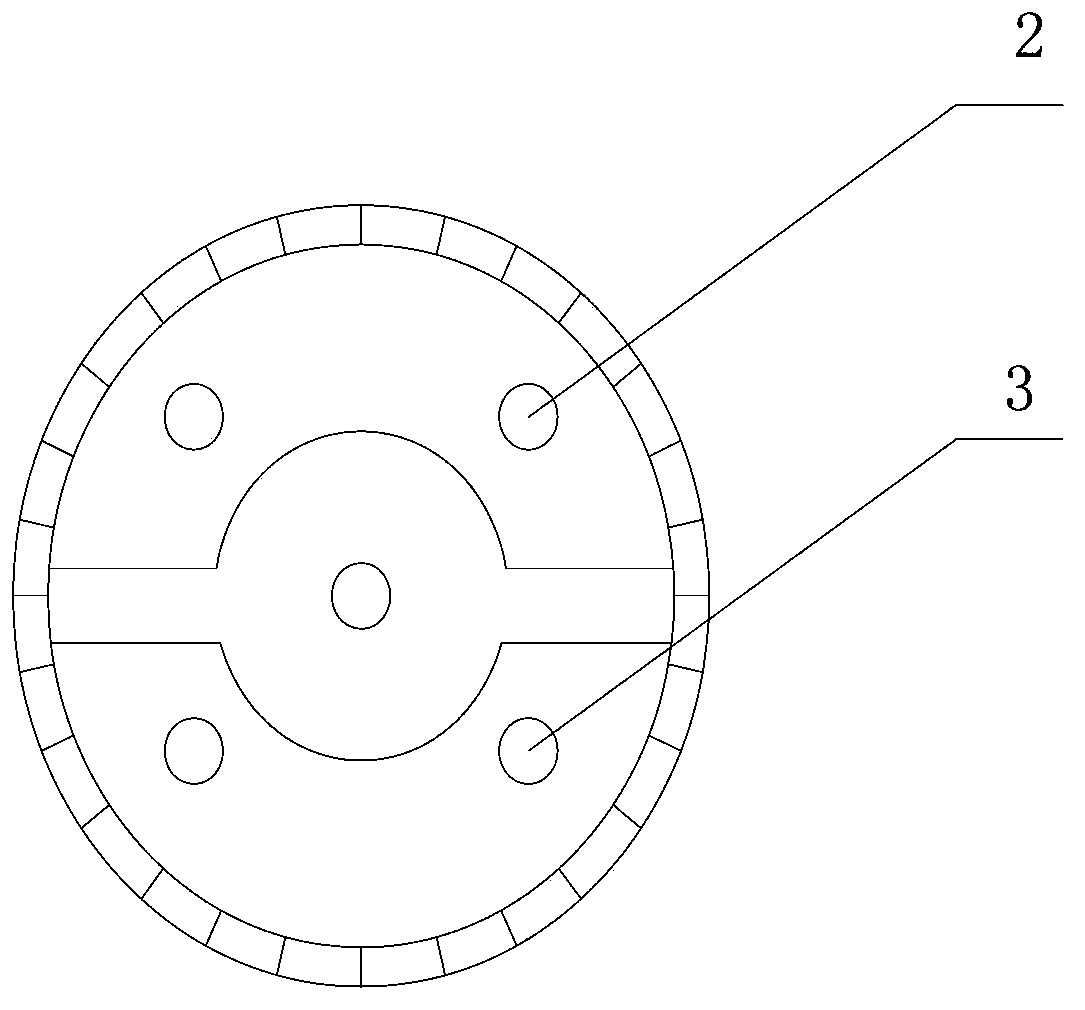

Graphite heater

InactiveCN103687112ASimple structureReasonable designFurnace heating elementsThermal insulationAnode

The invention relates to a graphite heater. The graphite heater is provided with a cylindrical graphite heating cylinder body (1) as well as anode fixing holes (2) and cathode fixing holes (3) formed at the top of the graphite heating cylinder body (1); through grooves (4) are formed in the heating cylinder body; and the heating cylinder body is evenly segmented into 28 parts through the through grooves. The graphite heater of the invention has the advantages of simple structure, reasonable design, stable thermal insulation performance and excellent heating performance.

Owner:CHANGZHOU LIXIN GRAPHITE

Preparation method of thermal insulation hard felt for silicon carbide single crystal growth furnace

The invention provides a preparation method of a thermal insulation hard felt for a silicon carbide single crystal growth furnace, which comprises the following steps: carrying out first pretreatment on a carbon fiber felt matrix, and carrying out first carbonization treatment in a carbonization furnace to obtain a carbonized felt; preparing a treatment solution, and carrying out second pretreatment on the treatment solution to obtain a pretreatment solution; and cutting the carbonized felt, fixing a mold, spraying a pretreatment solution, and carrying out curing treatment, secondary carbonization treatment and machining to obtain the heat-preservation hard felt for the silicon carbide single crystal growth furnace. By optimizing the formula of the treating fluid and optimizing the process steps and the process parameters, the obtained heat preservation hard felt for the silicon carbide single crystal growth furnace has the advantages of stable heat preservation performance, excellent heat insulation performance and long service life.

Owner:佛山市石金科技有限公司

Anti-cracking water resistant heat insulation material and preparation method thereof

InactiveCN105753402AGood crack resistance and water resistanceNo crackSolid waste managementEpoxyCellulose

The invention discloses an anti-cracking water resistant heat insulation material and a preparation method thereof. The anti-cracking water resistant heat insulation material is prepared from the following major raw materials in parts by weight: 30 to 46 parts of glazed hollow beads, 12 to 18 parts of zeolite, 11 to 15 parts of coke, 6 to 12 parts of dog bone, 4 to 8 parts of saw dust, 4 to 9 parts of epoxy resin, 3 to 7 parts of magnesium powder, 4 to 9 parts of hydroxyethyl ether cellulose, 13 to 17 parts of portland cement and 1.1 to 1.8 parts of compound penetrating agents. The obtained anti-cracking water resistant heat insulation material has the advantages that the anti-cracking and water resistant performance is good; the plastering surface has no crack; no hollowing falling exists; the tensile degree is high; the construction is easy; freezing resistance is realized; safe, fireproof and environment-friendly effects are achieved; the excellent performance of heat insulation, heat isolation and the like is realized; the heat insulation performance is stable; the integral performance is good; the wear-resistant, corrosion-resistant and radiation protection performance is obvious; a good flame retardant effect is achieved.

Owner:任甜甜

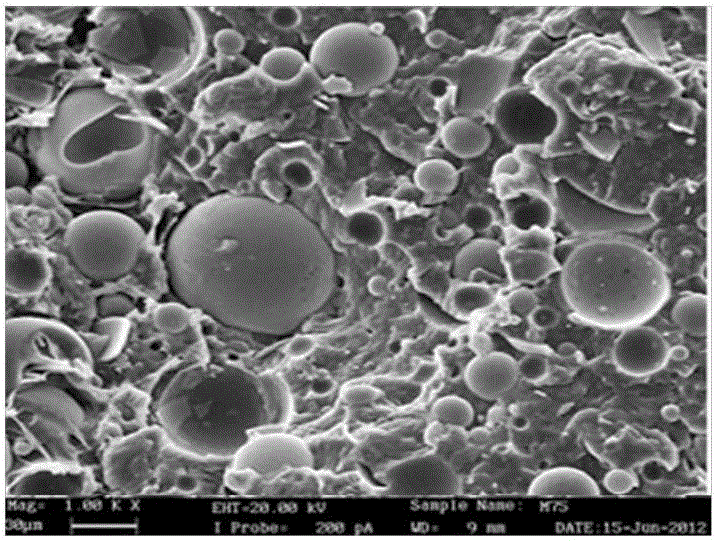

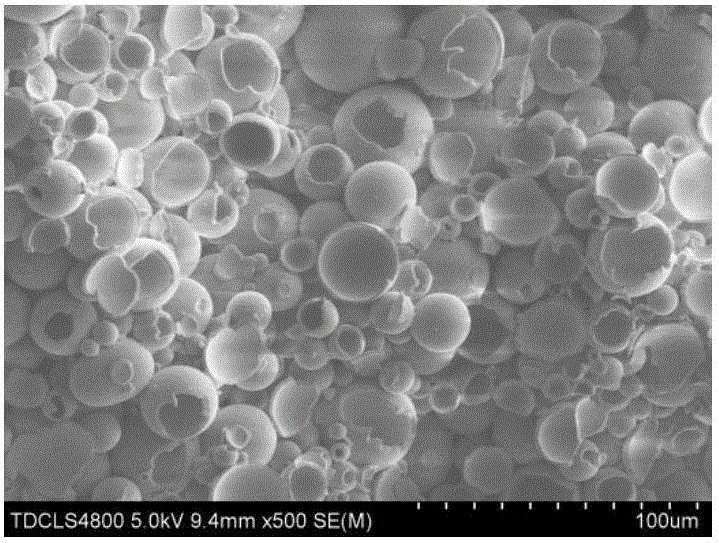

Preparation method of silicon dioxide-boron trioxide low melting point glass combined with hollow glass microsphere insulation material

InactiveCN103601358BLow densityLow thermal conductivityGlass reforming apparatusPorosityBoron trioxide

The invention relates to a preparation method of silicon dioxide-diboron trioxide (SiO2-B2O3) low-melting-point glass combined hollow glass bead heat-insulating material. The method comprises the following steps: using TEOS ( tetraethoxysilane ) as precursor of SiO2 and ethanol as solvent, adding deionized water to promote the hydrolysis of the TEOS and dissolving boric acid serving as the precursor of the B2O3 in ethanol; uniformly mixing the above two solutions according to a mole ratio of B2O3 to SiO2 being (0.56-1.68): 1 and stirring; sealing and standing at room temperature for 48 hours to obtain required sol solution; stirring, then putting in a grinding tool, and pressing into a green body; gelling, drying and sintering to prepare heat-insulating material formed in which beads are directly combined. The hollow material beads are used as main material to prepare the heat-insulating material which is a lightweight high-strength structure material in which beads are directly combined. The apparent porosity reaches 30-60%, the volume density is 0.30-0.50g / cm<3>, and the highest compressive strength can reach 14MPa.

Owner:TIANJIN UNIV

A method of manufacturing an integral vacuum insulation box

InactiveCN104326173BAvoid the disadvantages of decreased insulation performanceAvoid breakingDomestic cooling apparatusLighting and heating apparatusVacuum pumpingEngineering

The invention discloses an integral vacuum heat insulation box and a manufacturing method of the integral vacuum heat insulation box. Blocking films cover the inside and the outside of a box body in a vacuum state, the inside of the blocking films is filled with heat insulation core materials, and the outer side of the box body is provided with a vacuum pumping opening. The integral vacuum heat insulation box and the manufacturing method adopt a major principle that the box body is covered by blocking materials, core materials of each surface and each corner part of the box body are respectively in the same vacuum state, the defect of heat insulation performance reduction generated at the box body splicing part when other methods such as splicing, foam fixation and gluewater fixation are adopted is effectively avoided, the three methods can respectively reach the requirements, a bag does not need to turn in a large amplitude according to the first method, the excessive deformation of the blocking bag is reduced, the fracture and the breaking of the blocking bag are avoided, and the breaking rate of a product is reduced by more than 80 percent. The integral vacuum heat insulation box manufactured by adopting the manufacturing method provided by the invention has the advantages that the heat insulation performance is stable, and the use effect is good.

Owner:浙江赛尔达真空新材料有限公司

Cast-in-place rigid concrete self-insulation wall composed of openings and opening and closing blocks and wall-building method

ActiveCN104047377BEasy to smoothGuaranteed smoothConstruction materialWallsReinforced concretePolystyrene

Owner:SHANDONG CHUNTIAN BUILDING MATERIAL SCI & TECH

The manufacture method of water-based imitation granite colorful environmental protection thermal insulation paint

ActiveCN103756494BImprove insulation effectStable heat retentionReflecting/signal paintsMulticolor effect coatingsWater basedThermal insulation

The invention provides a manufacturing method for a water-based simulated granite colorful environment-friendly heat-insulating coating. The manufacturing method comprises the following steps: I. preparing base gum pre-solution; II. preparing the basic sizing agent of the coating; III. preparing colorful wrapped sizing master batch; IV. preparing the water-based simulated granite colorful environment-friendly heat-insulating coating. The prepared coating can effectively reflect heat insulation, and is good in heat-insulating effect, stable in heat-insulating property, corrosion-resistant, long in service life, and environment-friendly and pollution-free.

Owner:JIAXING BEIDA HUAFENG NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com