Novel composite wall brick

A composite wall, a new type of technology, applied in building materials and other directions, can solve the problems of high construction cost, high safety risk, and heavy construction workload of personnel, and achieve the effect of saving manpower and material resources, stable thermal insulation performance, and faster and safer work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present embodiment will be further described in detail below in conjunction with the accompanying drawings.

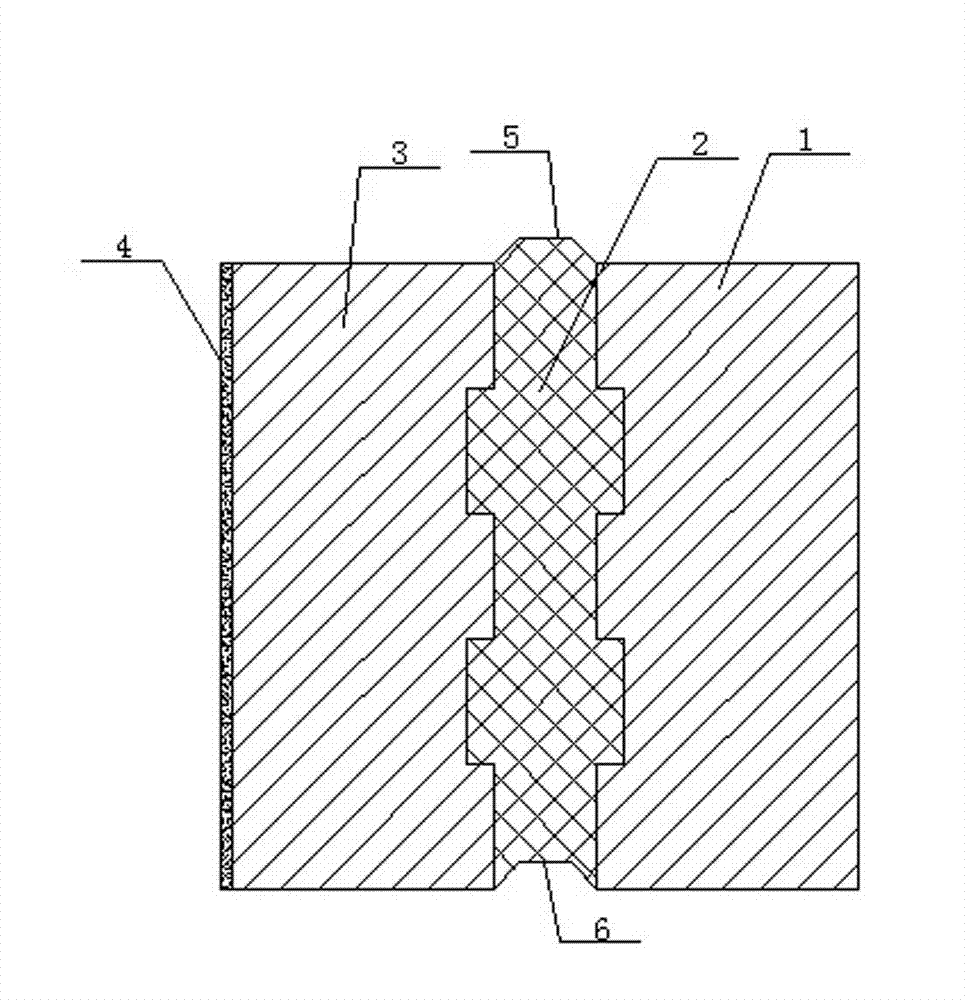

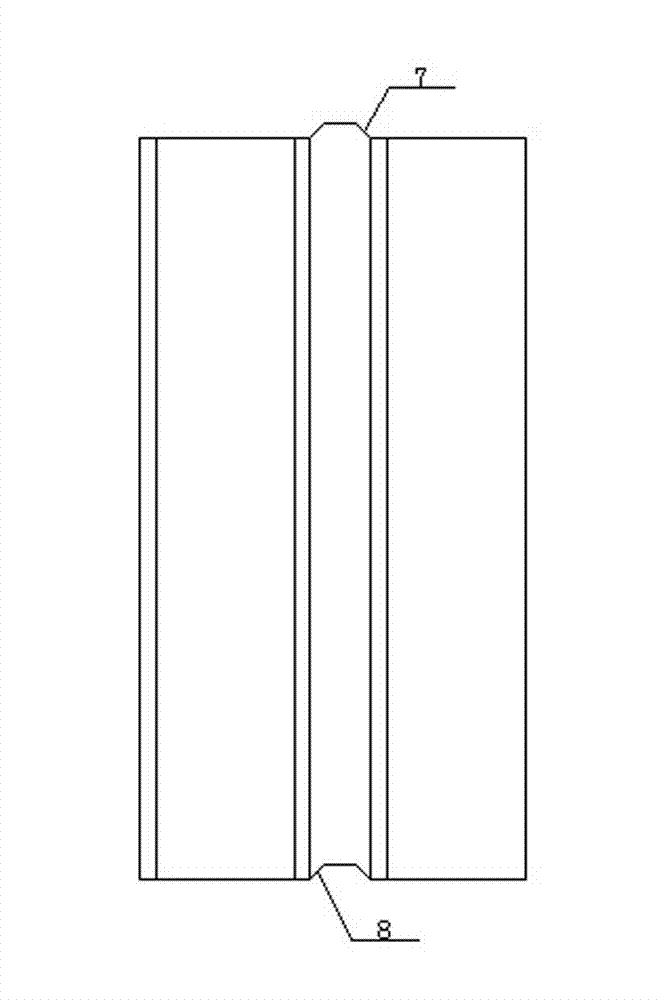

[0012] like figure 1 As shown, the novel composite wall brick of the present invention comprises a first foamed concrete layer 1, a foamed polyurethane layer 2, a second foamed concrete layer 3 and a surface sprayed plastic layer 4, the first foamed concrete layer The foamed concrete layer 1, the foamed polyurethane layer 2, the second foamed concrete layer 3, and the surface spray layer 4 are closely arranged from the inside to the outside. In this embodiment, the first foamed concrete layer 1 and the second foamed concrete layer The foam concrete layer 3 plays the role of load-bearing and waterproof, the foamed polyurethane layer 2 plays the role of heat preservation, and the surface spray layer 4 can pre-set the color and pattern according to the construction requirements, and the one-time construction is in place. The first foamed concrete layer 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com