Prefabricated reinforced concrete cinema stand structure

A reinforced concrete, prefabricated assembly technology, applied in theaters, building structures, buildings, etc., can solve the problems of insufficient structural safety, large on-site workload, and difficult construction of assembled and shelved stands, and achieve overall project cost reduction and use. The effect of saving steel and simplifying on-site construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

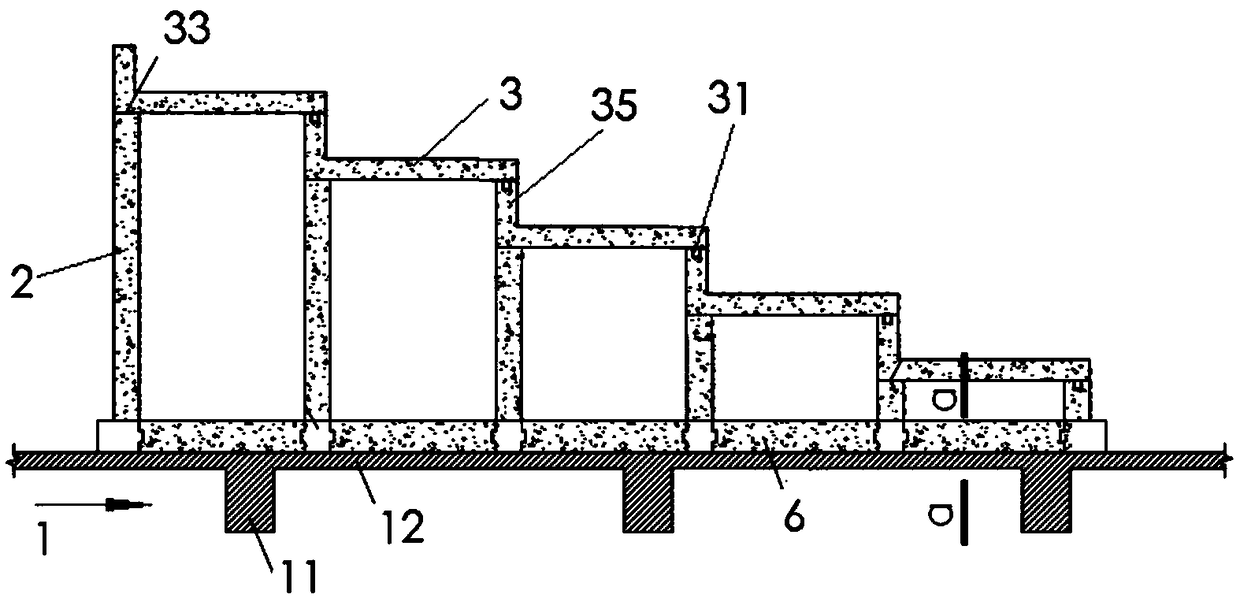

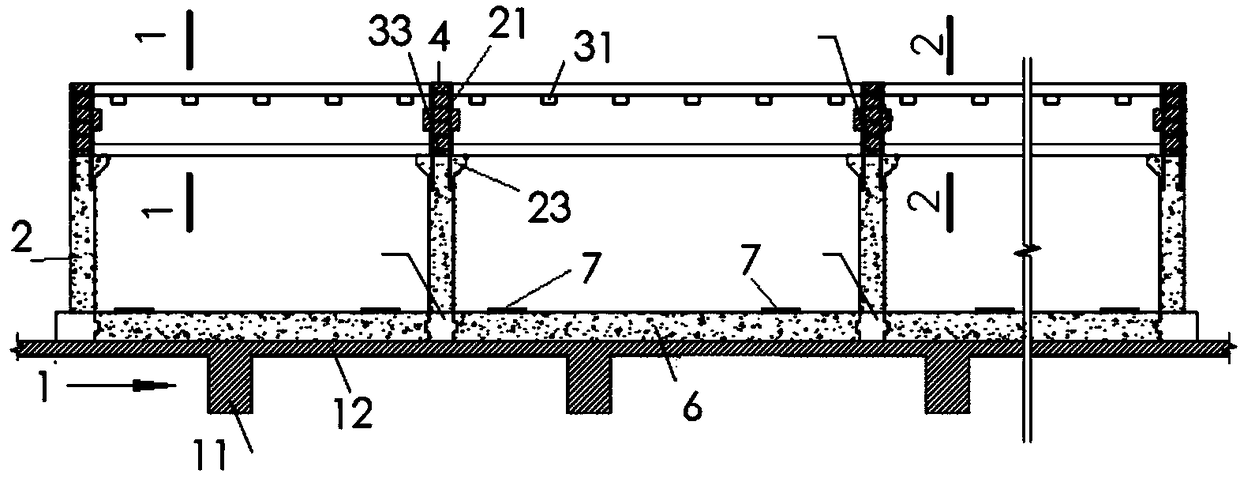

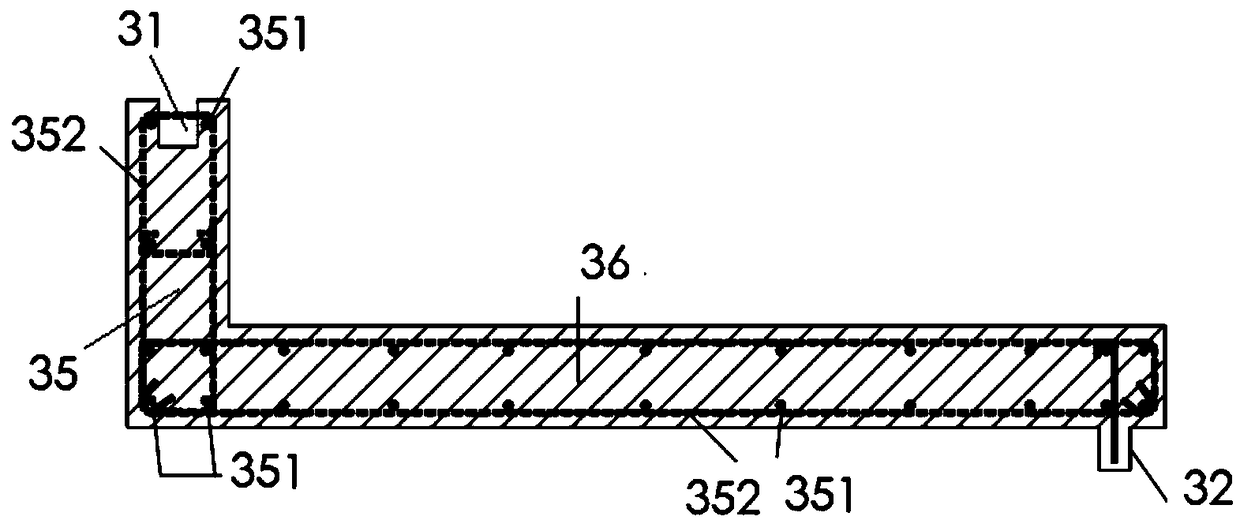

[0049] Embodiment 1: as figure 1 As shown, a reinforced concrete prefabricated theater stand structure includes a main structure 1 composed of a main structural beam 11 and a main structural plate 12 connected to the main structural beam 11, and a stand column 2 is connected to the main structure 1, and the stand The stand 3 is connected to the column 2; both the stand column 2 and the stand 3 are prefabricated reinforced concrete parts; between the adjacent stand 3 and the stand, between the stand 3 and the stand 2, the stand 2 It is connected with the main structure 1 through a preset connection structure with steel bars or / and steel plates and high-strength non-shrinkage adhesive grout 4, so that the main structure 1, all the stand columns 2 and all the stand boards 3 are all connected together to form a strong monolithic structure. High-strength non-shrinkage grouting material has high-strength and high-binding properties, and has the advantages of high fluidity without v...

Embodiment 2

[0056] Embodiment 2: The connection structure between the stand column 2 and the main structure 1 is that the lower end of the stand column 2 is provided with a prefabricated steel concrete column 22, and the anchor bar 27 is connected to the prefabricated steel concrete column 22, and the lower end of the anchor bar is implanted in the main structural beam, and finally Water the high-strength non-shrinkage adhesive grout 4 slurry, and the rest of the structure is the same as in Example 1, see Figure 10 .

Embodiment 3

[0057] Embodiment 3: The connection structure between the stand column 2 and the main structure 1 is that the lower end of the stand column 2 is inserted into the prefabricated steel concrete beam 6 and poured with high-strength non-shrinkage adhesive grouting material 4, and the outside of the prefabricated steel concrete beam 6 is spaced apart. Covered with a number of outer jacket square steel sleeves 7, the lower end of each outer jacket square steel sleeve 7 is welded with a connecting steel plate as a flange and welded with 2-4 evenly distributed stiffeners 26. The prefabricated steel concrete beam 6 is connected to the main structural plate 12, and the rest of the structure is the same as that of Embodiment 1 or Embodiment 2. see figure 1 , figure 2 , Figure 11 , Figure 12 , Figure 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com