Novel composite wall brick

A composite wall and a new type of technology, applied in the direction of building materials, etc., can solve the problems of high safety risks, high construction costs, and heavy construction workload of personnel, so as to save manpower and material resources, simplify construction workload, and leave work quickly and safely. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

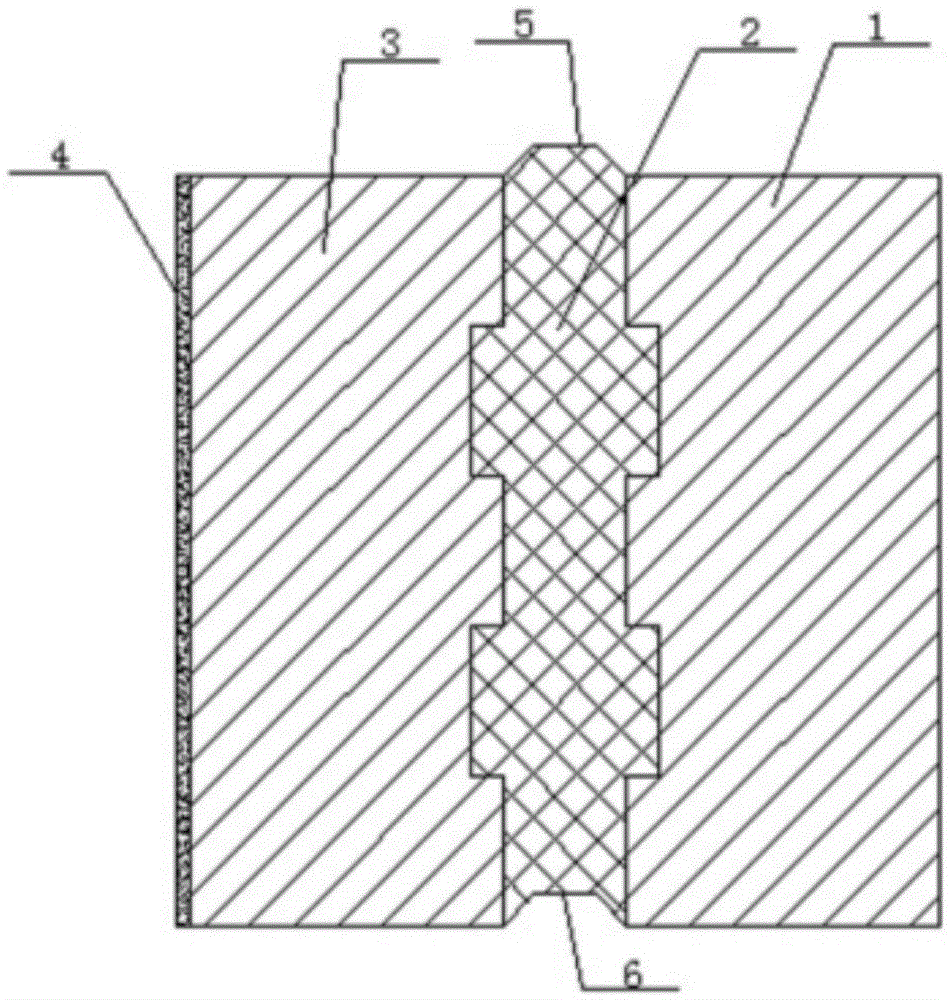

[0011] A new type of composite wall brick, including a 2cm first foamed concrete layer (1), a 0.5cm foamed polyurethane layer (2), a 2cm second foamed concrete layer (3) and a 1cm surface spray layer (4) , the first foamed concrete layer (1), the foamed polyurethane layer (2), the second foamed concrete layer (3) and the surface sprayed plastic layer (4) are closely arranged sequentially from the inside to the outside, and the The inner surfaces of the contact surfaces of the first foamed concrete layer (1) and the second foamed concrete layer (3) with the foamed polyurethane layer (2) are tooth-shaped grooves.

[0012] The upper top surface of the composite wall brick is provided with a first trapezoidal boss (5).

[0013] The lower bottom surface of the composite wall brick is provided with a first trapezoidal groove (6) matched with the first trapezoidal boss (5) on the upper top surface.

[0014] One side of the composite wall brick is provided with a second trapezoidal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com