Thermal insulation system with long service life for silicon carbide crystal growth furnace

A technology of crystal growth furnace and heat preservation system, which is applied in crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of large thermal corrosion, enhanced thermal conductivity, large thermal shock, etc., and achieves the reduction of chemical corrosion rate and the overall lifespan The effect of prolonging and improving the overall lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

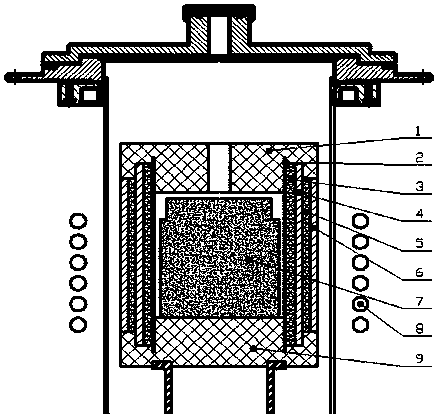

[0009] Such as figure 1 , 2 Shown: Silicon carbide crystal growth furnace high-life insulation system, including top insulation plate 1, inner layer insulation soft felt 3, inner layer hard insulation felt 4, outer layer insulation soft felt 5, outer layer hard insulation felt 6, bottom insulation plate 9. It is characterized in that it also includes a C / C composite sleeve 2, the C / C composite sleeve 2 is a cylinder made of C / C composite material with a thickness of 0.5mm, and the inner diameter is 5-10mm larger than the outer diameter of the growth crucible 7, The height is 5-10mm higher than that of the growth crucible 7, and the upper and lower ends of the cylinder are cut off. Two fractures per week, the fracture width is 1-1.5mm, and the length is 2 / 3 of the cylinder height, avoiding the formation of a closed loop. The growth crucible 7 Place the C / C composite sleeve 2 concentrically on the outside, and the C / C composite sleeve 2 wraps the inner layer of soft insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com